Method for preparing anatase type nano titanium dioxide photocatalyst

A nano-titanium dioxide, anatase type technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of cumbersome, unfavorable to obtain high photocatalytic activity nano-titanium dioxide, increase equipment investment and other problems , to achieve the effect of improving the yield and shortening the complete hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare the anatase type nano-titanium dioxide photocatalyst according to the following steps:

[0036] (1) preparation concentration is the titanium sulfate aqueous solution of 0.5mol / L, preparation concentration is the ammonia solution of 2.0mol / L,

[0037] (2) Under stirring, the prepared titanium sulfate aqueous solution is heated to boiling, and kept under reflux, so that the titanium sulfate is hydrolyzed rapidly, and the hydrated titanium dioxide crystal nuclei are uniformly produced,

[0038] (3) After the above-mentioned titanium sulfate aqueous solution that has begun to be hydrolyzed boils and refluxes for 40min, stop heating, and cool down naturally,

[0039] (4) When the temperature of the above aqueous solution drops to 80°C, under stirring, add the prepared ammonia solution dropwise, and gradually increase the pH value of the solution to 8.5, so that the titanium sulfate is completely hydrolyzed to form a hydrated titanium dioxide precipitate,

[0040] (5)...

Embodiment 2~ Embodiment 9

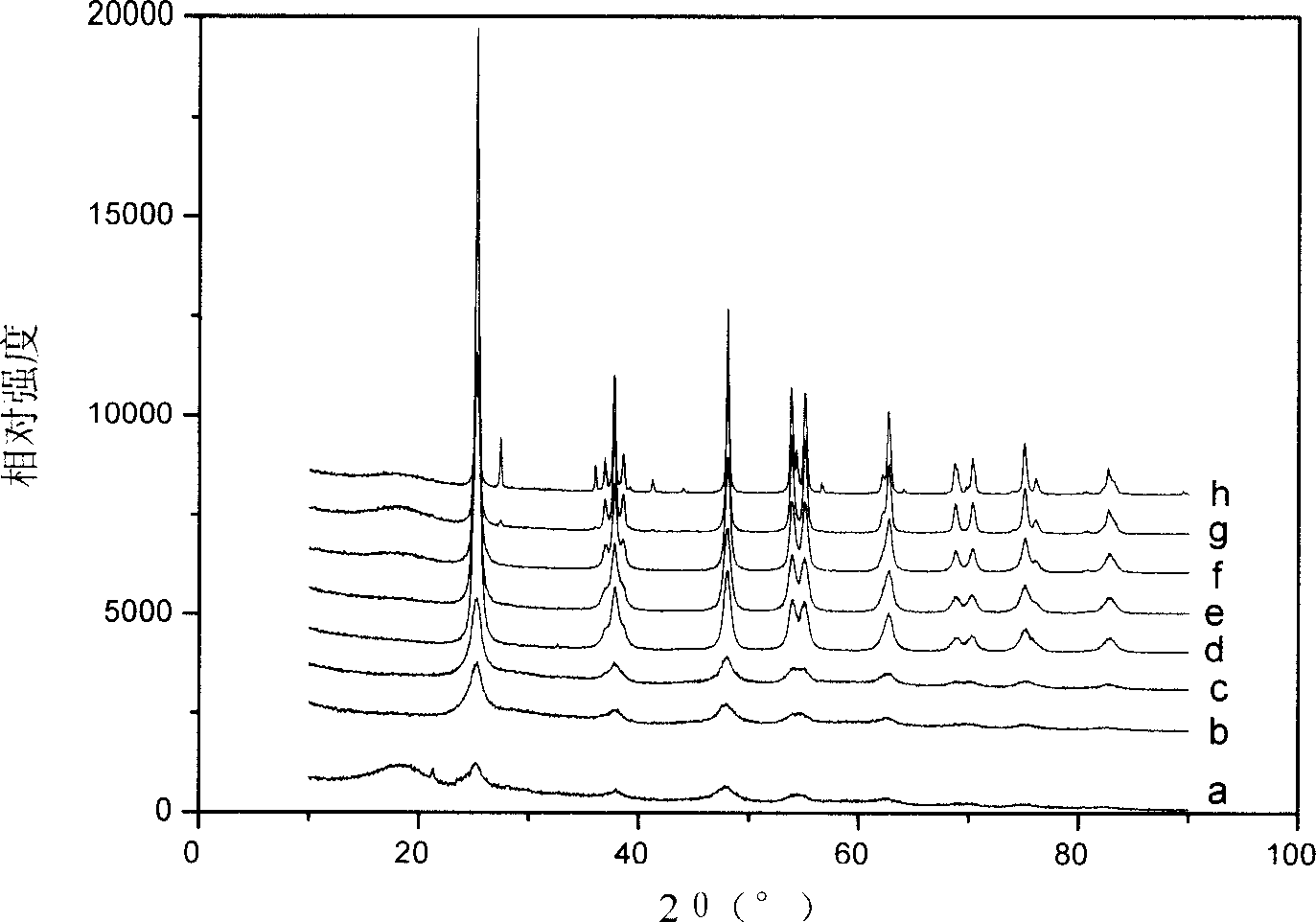

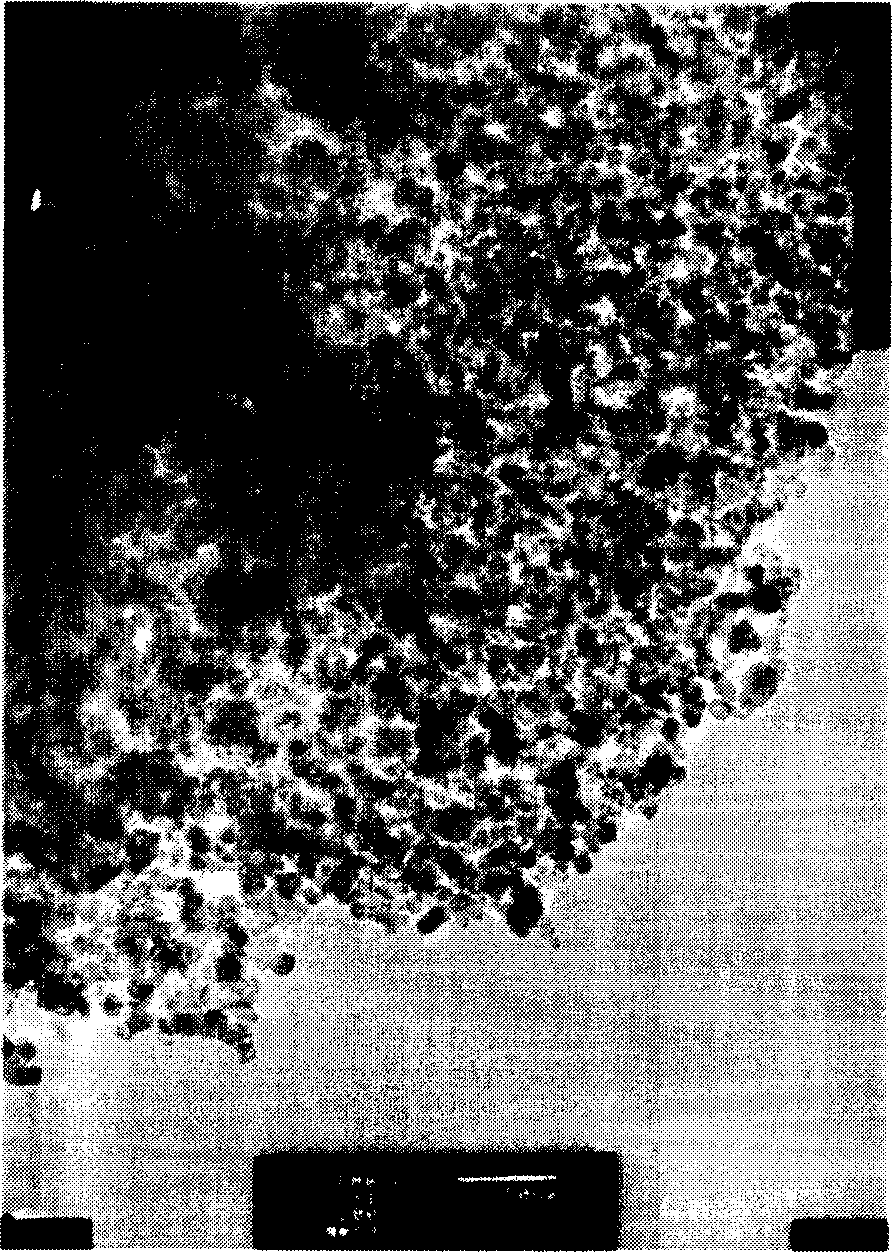

[0047] The preparation methods of Examples 2 to 9 are the same as those of Example 1 except that certain preparation conditions are changed. The preparation conditions of Examples 2 to 9 and the characterization of the corresponding products obtained are listed in Table 1.

[0048] The products obtained in Examples 2 to 9 were respectively used as photocatalysts, and methyl orange was used as the degradation target compound. The dosage of the products obtained in Examples 2 to 9 is 0.1g, and 25ml of 20ppm methyl orange solution is processed, and irradiated with a 10W-254nm ultraviolet lamp for 20min. The experimental results are also listed in Table 1.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com