Honeycombed SCR (selective catalytic reduction) denitrification catalyst for low-temperature flue gas denitrification and preparation method thereof

A denitrification catalyst and low-temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low NO conversion rate and easy falling off of active substances, etc. problems, to achieve the effect of increasing acidic adsorption sites, good flexibility and plasticity, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

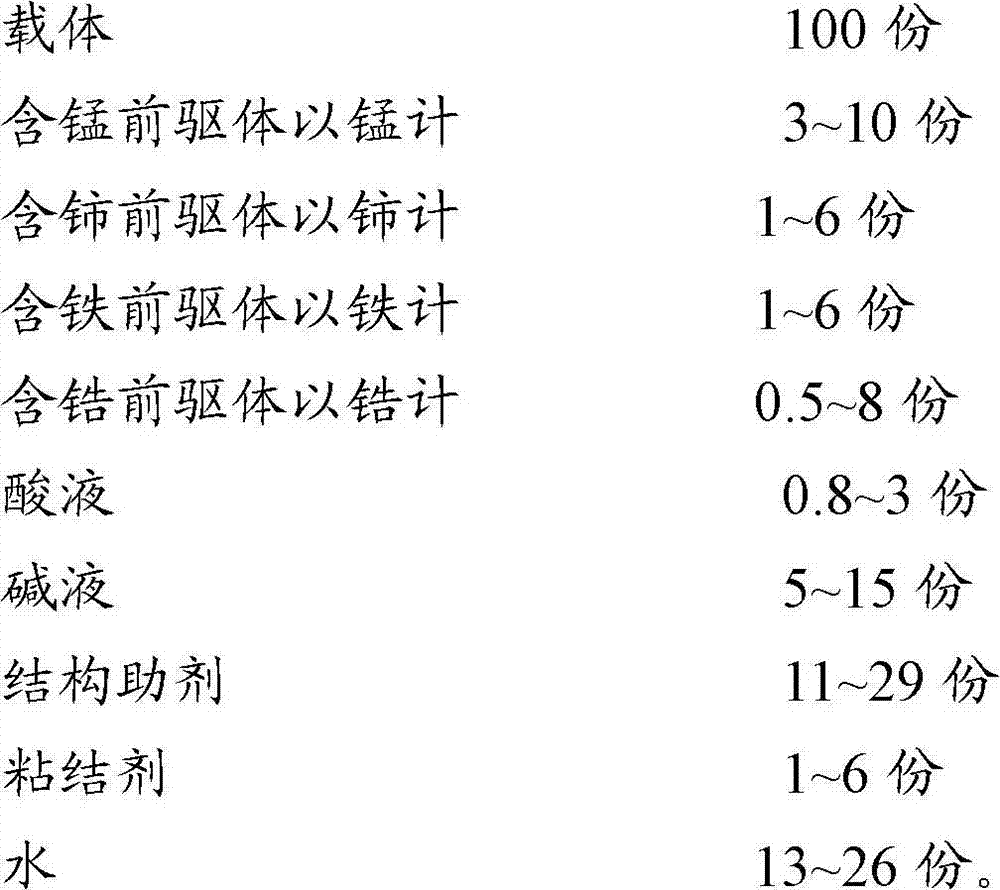

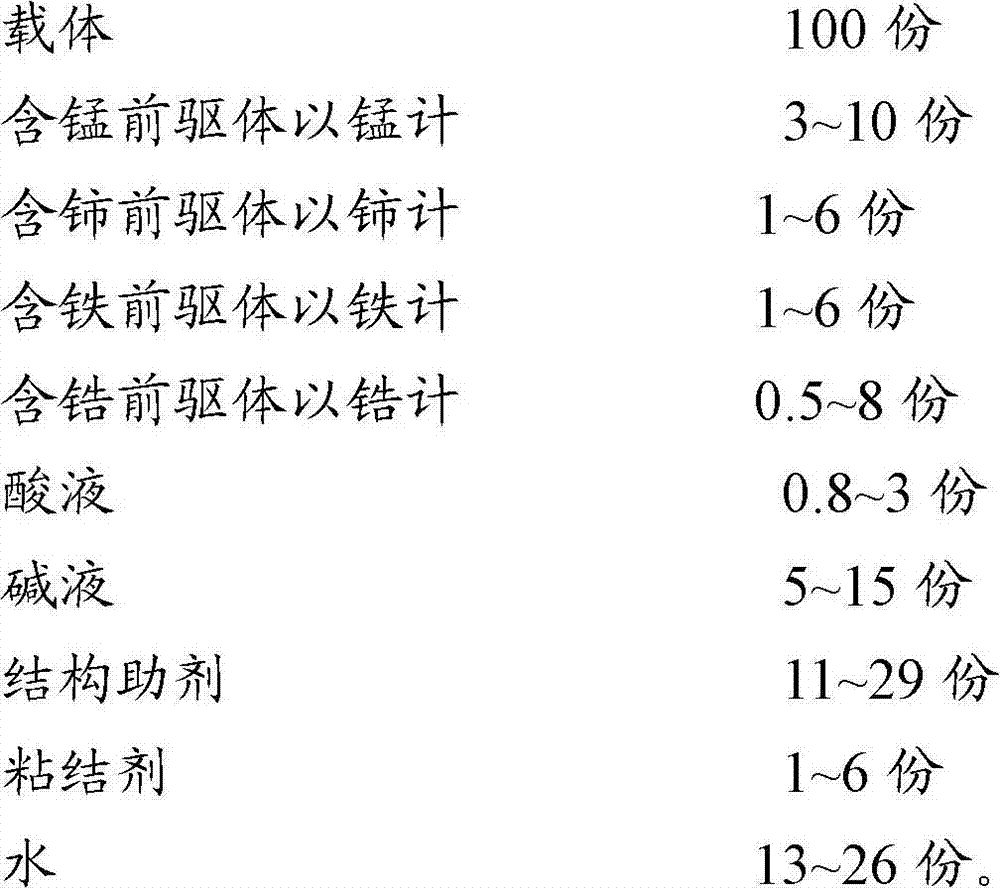

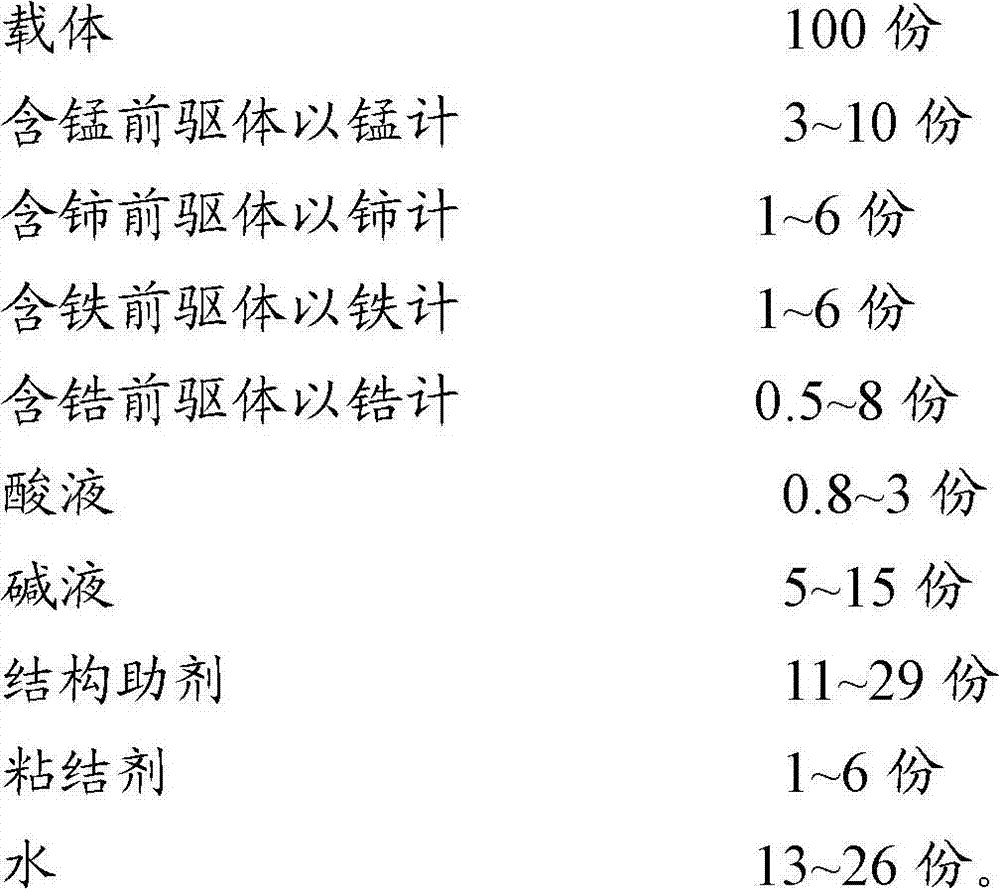

[0031] 1) Dry mixing of carrier and solid powder. Weigh titanium tungsten powder 480.00g, titanium silicon powder 120.00g, manganese acetate 209.80g, cerium nitrate 41.96g, ferrous oxalate 20.98g, zirconium nitrate 20.98g, stearic acid 1.80g, zirconium nitrate and nitric acid after drying Cerium and manganese acetate were ground into powder, and put into a mixer for dry mixing for 20 minutes.

[0032] 2) Add acid, lye and water for conditioning. Measure 5.97g of lactic acid with a concentration of 85%, dilute it to 20g with water, add it to the uniformly mixed solid powder, stir for 10 minutes, and then add 51.47g of ammonia water with a concentration of 25%. 3) Add structural aids and water to adjust strength and structure. Add 48.70g of glass fiber and 4.40g of pulp cotton, after stirring for 15min, slowly add 7.34g of monoethanolamine and 63g of glycerin, continue stirring for 20min, then add 70g of distilled water step by step according to the principle of small amounts ...

Embodiment 2

[0038] 209.80g manganese acetate in embodiment 1 is replaced by 104.90g, 41.96g cerium nitrate is replaced by 20.98g, 5.97g lactic acid is replaced by 11.94g under the same concentration, 51.47g ammoniacal liquor is replaced by 64.34g under the same concentration, 70g distilled water Replaced with 96g, other steps are identical to make catalyst finished product. Under the same conditions, the measured NO conversion rate was 90.53%, and the axial and transverse mechanical strengths were 527.1N / cm and 135.2N / cm, respectively.

Embodiment 3

[0040] The 41.96g cerium nitrate in embodiment 1 is replaced by 33.25g cerium oxide, 5.97g lactic acid is replaced by 17.91g under the same concentration, diluted to 30g, 51.47g ammonia water is replaced by 77.20g under the same concentration, and 70g distilled water is replaced by 66g, other steps are identically made catalyst finished product. Under the same conditions, the measured NO conversion rate was 95.02%, and the axial and transverse mechanical strengths were 542.9N / cm and 144.2N / cm, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com