Preparation method for photocatalyst TiO2 supporter and manufacturing method for photocatalyst air cleaner

A photocatalyst and photocatalytic technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using the method of spraying, the aluminum silicate ceramic hollow body (Al 2 o 3 =76%, SiO 2 = 19%, porosity 85%), double-sided spray-coated metal alkyl titanium dioxide (TiO 2 ) coating liquid, after drying at about 100°C for one hour, then firing at 450°C for one hour in a firing furnace to form a film. Then use the same method to form a film again to make a photocatalyst ceramic filter A-1, TiO 2 The amount of spraying is about 60g / m 2 . After making A-1, dip A-1 in the metal alkyl titanium dioxide coating solution, dry it at about 100°C for one hour as described above, and then dry it in a firing furnace at 450°C for one hour Firing to form a film to make a multi-layer photocatalytic photocatalyst ceramic filter A-2.

Embodiment 2

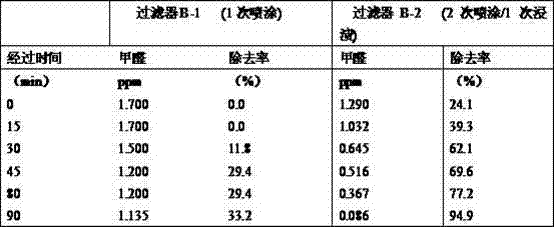

[0020] Using the method of spraying, the aluminum silicate ceramic hollow body (Al 2 o 3 =76%, SiO 2 =19%, porosity 85%) spraying on both sides of 0.85% (solid content) nano-titanium dioxide (TiO 2 ) Neutral aqueous solution sol coating solution, after drying at about 100°C for one hour, it is fired in a firing furnace at 450°C for one hour to form a film. Then, the same method was used to form a film again to make a photocatalyst ceramic filter B-1. TiO 2 The amount of spraying is about 60g / m 2 . After making B-1, mix B-1 with 0.85% (solid content) nano-titanium dioxide (TiO 2 ) Dip coating in a neutral aqueous solution sol coating liquid, after drying at about 100°C for one hour as described above, then firing in a firing furnace at 450°C for one hour to form a film to form a multi-layer photocatalytic Photocatalyst ceramic filter B-2.

Embodiment 3

[0027] Using the method of spraying, in silicon carbide porous ceramics (SiC=67%, Al 2 o 3 =12%, SiO 2 =19%, porosity 85%), the two sides are sprayed with metal alkyl titanium dioxide coating solution, dried at about 100°C for one hour, and fired in a firing furnace at 450°C for one hour to form a film. After that, dip coating is carried out in the metal alkyl titanium dioxide coating solution, and after drying at about 100°C for one hour as described above, it is fired in a firing furnace at 450°C for one hour to form a film to form a photocatalytic Photocatalyst ceramic filter C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com