Organic clay loaded with nanometer anatase type titanium dioxide and its preparation method and use

A technology of titanium dioxide and nano-anatase, which is applied in chemical instruments and methods, catalyst activation/preparation, catalyst carrier and other directions, can solve the problems of inability to disperse titanium dioxide, reduce surface area, increase particle size, etc., and achieves low price and adsorption. Strong, highly dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Organic modification of clay: 5g montmorillonite was dispersed in 500ml deionized water to form a stable suspension. Weigh 1.64g of cetyltrimethylammonium bromide and add it to the montmorillonite suspension and stir to dissolve at 80°C.

[0037] Titanium precursor alcohol solution was hydrolyzed under acidic conditions: 17ml of tetra-n-butyl titanate was dissolved in 34ml of ethanol, slowly added to 250ml of HCl solution with a molar concentration of 1mol / L, and vigorously stirred at 25°C until a transparent solution was formed.

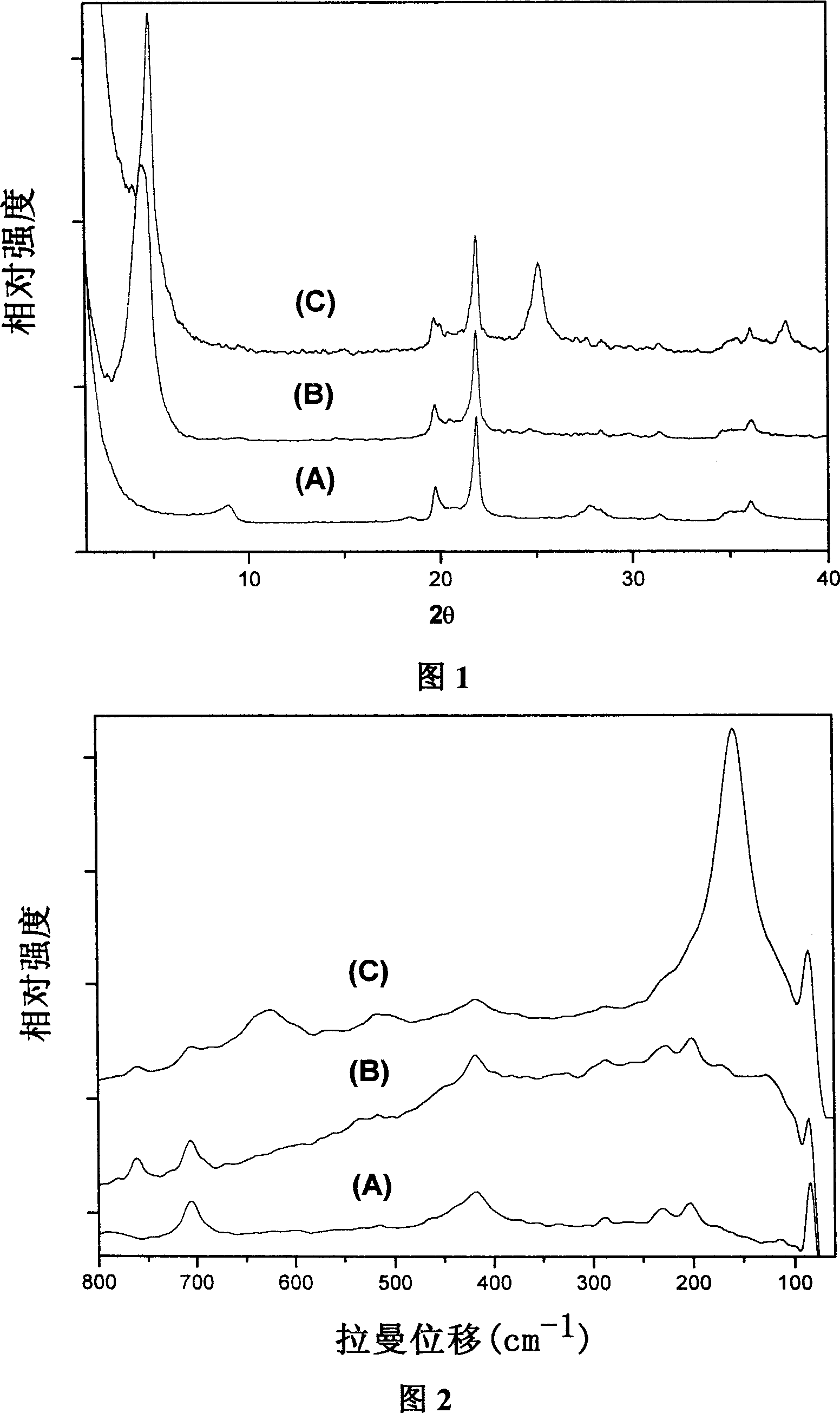

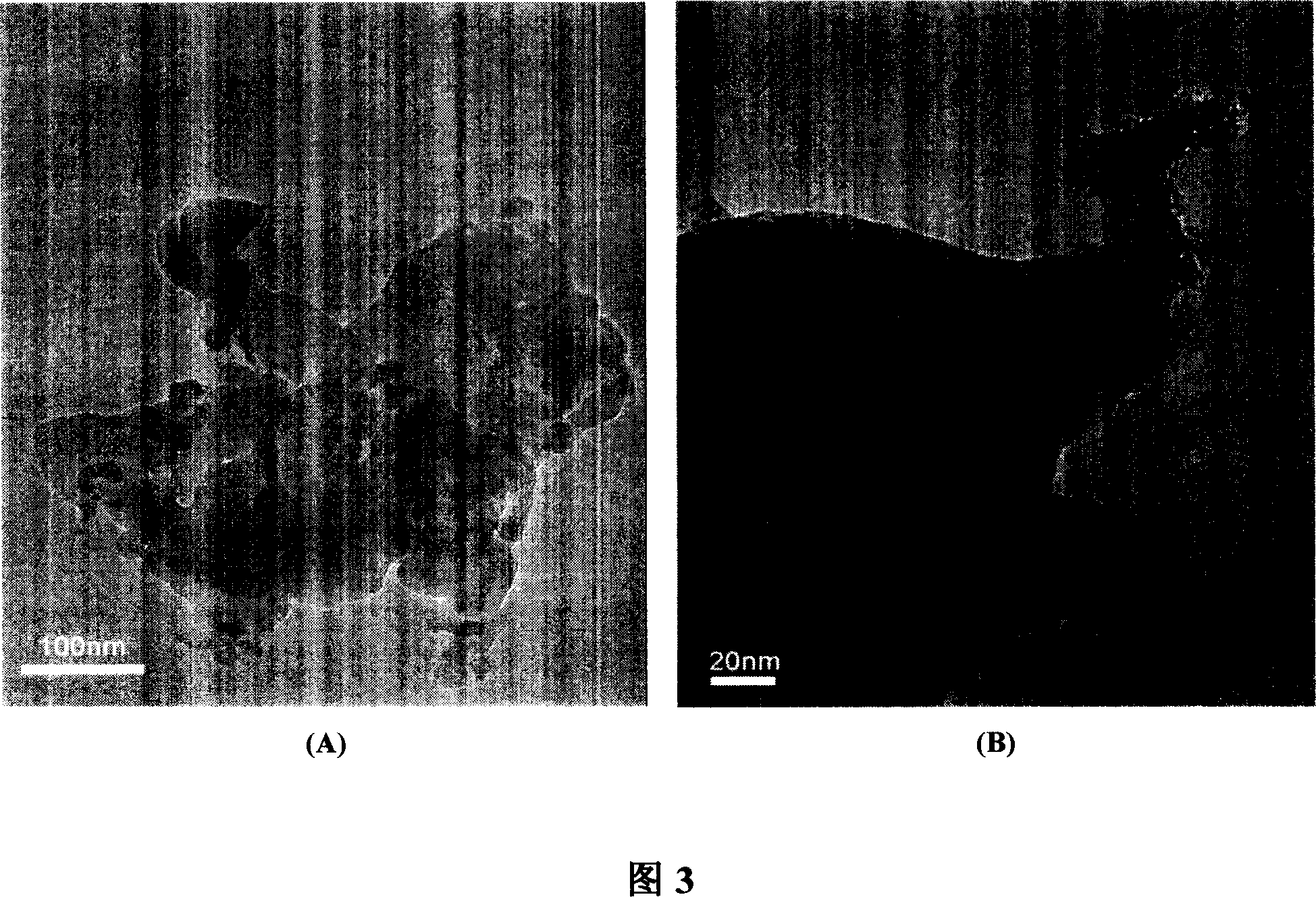

[0038] Loading of nano-titanium dioxide on organoclay: add the prepared transparent solution dropwise to the suspension of montmorillonite, and stir at 80° C. for 10 h. Filter with suction and wash with water until the pH of the filtrate is 6-7. The solid is separated, vacuum-dried at 100° C., and ground into powder to obtain an organic montmorillonite loaded with nano-anatase titanium dioxide particles distributed in the middle of the organ...

Embodiment 2

[0040] Organic modification of clay: 5g montmorillonite was dispersed in 500ml deionized water to form a stable suspension. Weigh 2.64 g of dioctadecyl dimethyl ammonium chloride and add to the montmorillonite suspension at 80° C. and stir to dissolve.

[0041] The titanium precursor alcohol solution is hydrolyzed under acidic conditions: 17ml of tetra-n-butyl titanate is dissolved in 34ml of ethanol, and slowly added to 250ml of H with a molar concentration of 1mol / L 3 PO 4 In the solution, stir vigorously at 25°C until a transparent solution is formed.

[0042] Loading of nano-titanium dioxide on organoclay: add the prepared transparent solution dropwise to the suspension of montmorillonite, and stir at 80° C. for 10 h. Suction filter and wash with water until the pH of the filtrate is 6-7. The solid is separated, vacuum-dried at 100° C., and ground into powder to obtain an organic montmorillonite loaded with nano-anatase titanium dioxide particles distributed in the midd...

Embodiment 3

[0044] Organic modification of clay: 5 g of vermiculite was dispersed in 500 ml of deionized water to form a stable suspension. Weigh 1.70 g of cetyltrimethylammonium chloride and add it to the vermiculite suspension and stir to dissolve at 80°C.

[0045] Titanium precursor alcohol solution is hydrolyzed under acidic conditions: 14.2ml of tetraisopropyl titanate is dissolved in 28.4ml of ethanol, slowly added to 250ml of HCl solution with a molar concentration of 1mol / L, and stirred vigorously at 25°C until a transparent solution is formed .

[0046] Loading of nano-titanium dioxide on organoclay: add the prepared transparent solution dropwise to the vermiculite suspension, and stir at 80° C. for 10 h. Filter with suction and wash with water until the pH of the filtrate is 6-7. The solid is separated, vacuum-dried at 100° C., and ground into powder to obtain organic vermiculite loaded with nano-anatase titanium dioxide particles distributed in the middle of the organoclay sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com