Method for producing nano-anatase mine-titanium oxide water sol

A technology of titanium dioxide and nano-anatase, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to avoid particle growth, good uniformity and dispersion, and simple preparation method

Inactive Publication Date: 2007-09-05

YUNNAN UNIV

View PDF2 Cites 60 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In summary, although the preparation methods of the nano-anatase titanium dioxide aqueous sol reported at present are various, from the perspective of industrial production and considering environmental factors, there are deficiencies in varying degrees.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

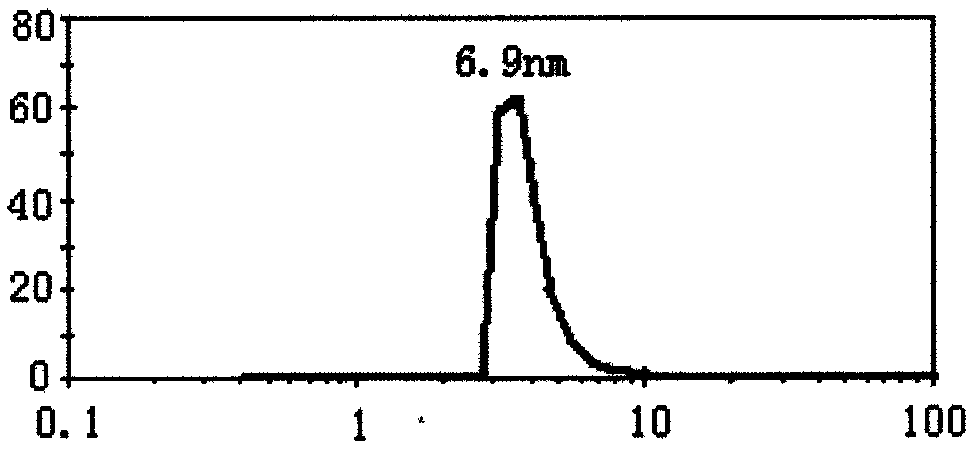

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

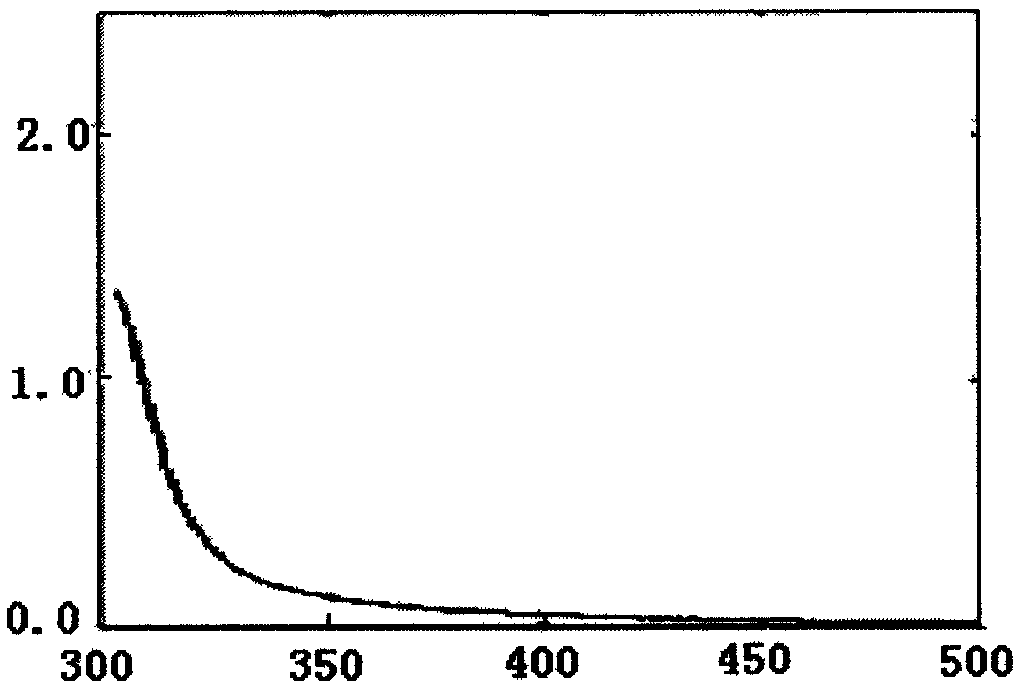

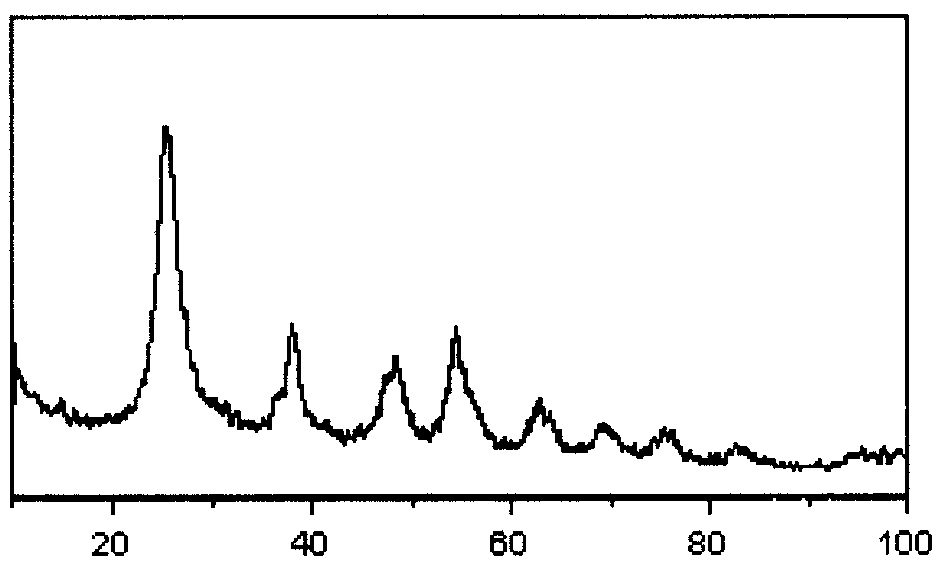

A process for preparing the hydrosol of nano-class anatase-type TiO2 features that reaction between Ti-contained organic substance, distilled water or deionized water, chelating agent and hydrodecomposing inhibitor at 30-120 deg.C for 3-12 hr while stirring and controlling pH=1-5.

Description

technical field The invention belongs to the preparation method of nano titanium dioxide photocatalytic material, in particular to the preparation method of anatase type titanium dioxide aqueous sol responsive to visible light. Background technique Due to its excellent physical and chemical properties, nano-titanium dioxide has broad application prospects in solar energy conversion and utilization, environmental purification, etc., so it has become a research and development hotspot in domestic and foreign academic circles and enterprises in recent years. At present, the methods for preparing nano titanium dioxide mainly include hydrolysis method, chemical precipitation method, sol-gel method, microemulsion method and gas phase reaction method, etc. Among them, the sol-gel method is favored because of its simple operation, high purity and small particle size of the synthesized titanium dioxide. Favored, that is to use titanium salt as raw material ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01G23/053

Inventor 柳清菊张瑾朱忠其周密

Owner YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com