Nontoxic rare-earth denitration catalyst and preparation method and application thereof

A denitration catalyst and catalyst technology, which are applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems that the catalyst cannot have a stepped pore structure system, rarely reported solutions, and reduce catalytic activity. Achieve protection and catalytic performance, overcome insufficient conversion activity, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

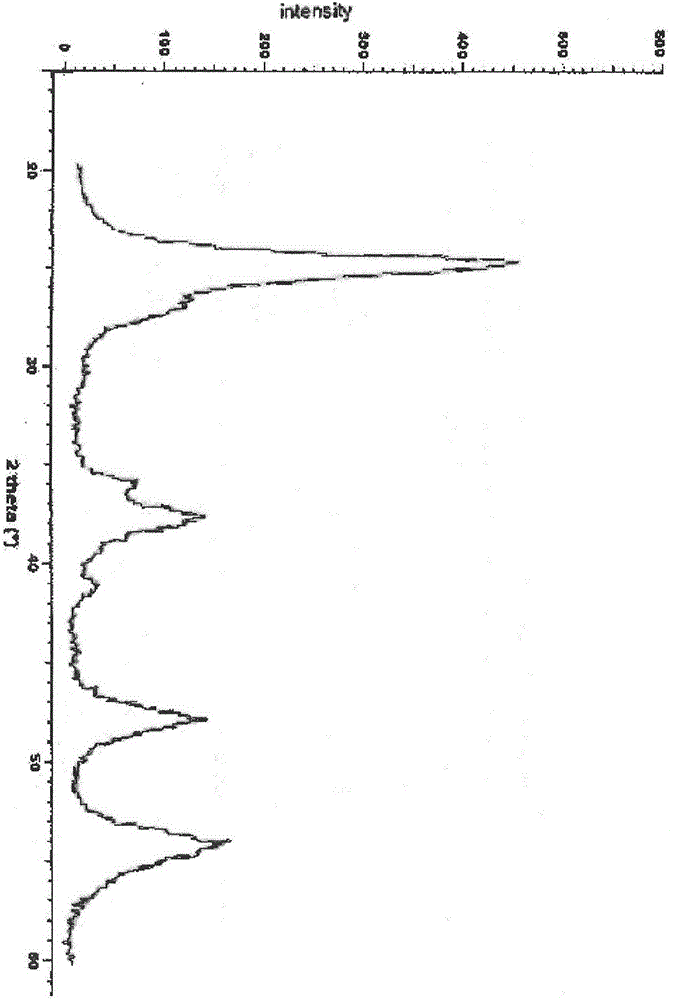

Image

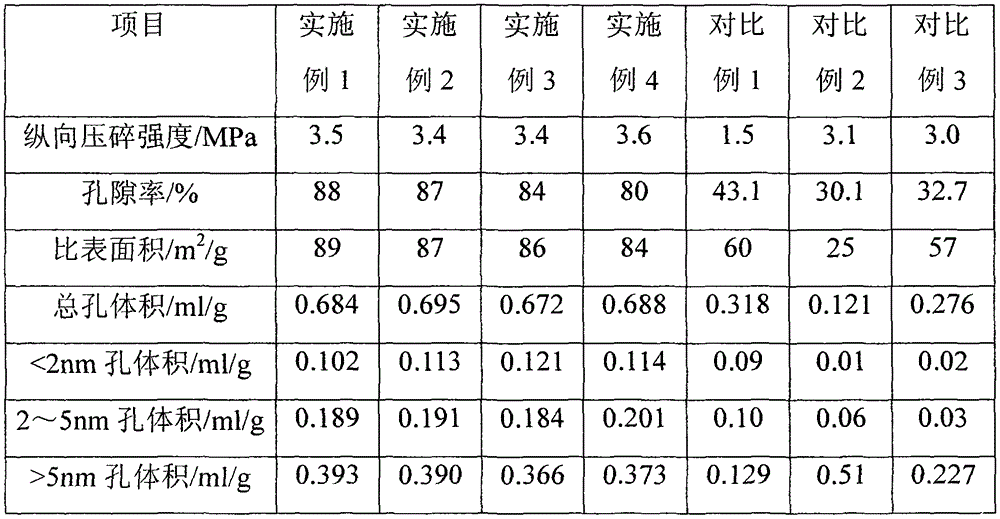

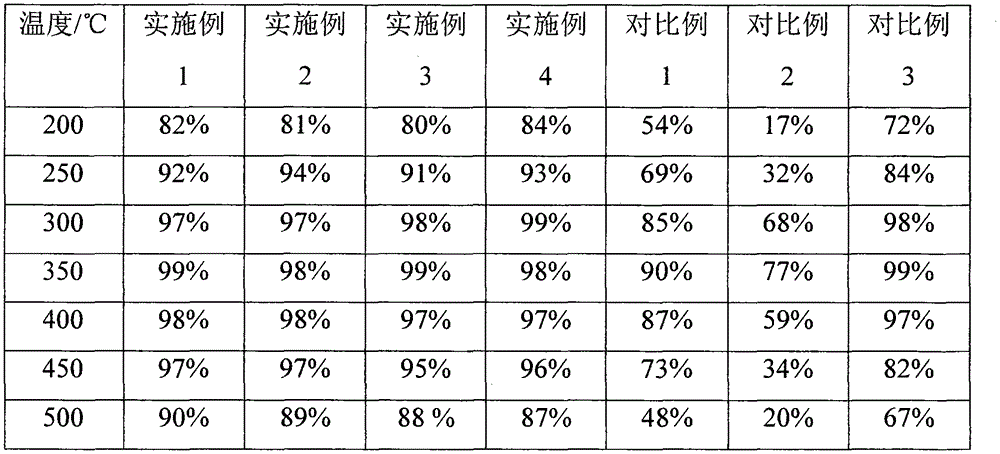

Examples

Embodiment 1

[0040] Will be taken from the deactivation of a local oil refinery in Shandong and unload the spent oil refinery catalyst (deoiled), and 250 grams of rare earth type catalytic cracking spent catalyst (FCC cerium-rich type anti-vanadium agent, CeO 2 4%, alumina ≥ 45%) and 250 grams of tungsten-containing hydrodenitrogenation refined waste catalyst (WO 3 22%, macroporous alumina ≥ 70%), crushed, ball milled, and passed through a 60-mesh sieve, mixed with 100 grams of high-alumina cement (industrial products, alumina ≥ 50%, Beijing Aoming Technology Co., Ltd.), 20 grams Corn starch (industrial product, moisture ≤ 11%, Nanjing Hanying Chemical Co., Ltd.), add deionized water and knead in a kneader. The water / powder weight ratio of the material is about 0.3:1. After kneading, it is extruded into a honeycomb shape The green body is cured at room temperature of 25° C. for 24 hours to become a silicon and aluminum oxide honeycomb green body containing rare earth and tungsten.

[00...

Embodiment 2

[0052] The molybdenum-containing hydrodesulfurization spent catalyst (MoO 3 13%, macroporous alumina ≥ 70%) 250 grams, replace the hydrodenitrogenation refining waste catalyst containing tungsten in embodiment 1, other preparation contents and steps are identical with embodiment 1, obtain the catalyzer of embodiment 2.

Embodiment 3

[0054] Get 200 grams of manganese acetate (chemically pure, ≥95%, Beijing Chemical Reagent Company), replace 140 grams of zirconium oxychloride in embodiment 1, other preparation content and steps are identical with embodiment 1, obtain the catalyst of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com