Method for preparing stable nano anatase titanium dioxide alcohol phase sol at low temperature

A technology of titanium dioxide and nano-anatase, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as agglomeration, and achieve good sol stability, easy mass production, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

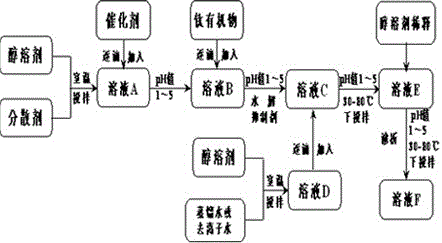

Method used

Image

Examples

Embodiment 1

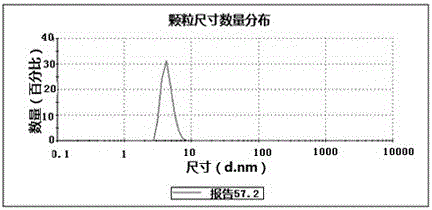

[0035] In the 2-methoxyethanol solution mixed with ethyl acetate and hydrochloric acid, add tetraethyl titanate dropwise, then add an appropriate amount of acrylic acid, and finally add water-containing 2-methoxyethanol solution. After stirring for 20 hours, the pH value of the reactant was controlled to be 5, and a transparent and stable anatase titanium dioxide alcohol phase sol was obtained. Finally, a semi-permeable membrane with a pore size of 1nm is used as the sol-wrapped sol in the dialysis process, and placed in isopropanol solvent to remove Cl - ion. The molar ratio of tetraethyl titanate, ethanol, distilled water or deionized water, ethyl acetate, acrylic acid, and hydrochloric acid is 1:40:1:2:1:1.5;

Embodiment 2

[0037] Add tetrapropyl titanate dropwise to the n-butanol solution mixed with glycerol, nitric acid and hydrochloric acid, then add an appropriate amount of acetic acid, and finally add water-containing n-butanol solution, and stir at normal pressure and 40°C for 24 hours. The pH value of the reactant is controlled to be 3 to obtain a transparent and stable anatase titanium dioxide alcohol phase sol. Finally, a semi-permeable membrane with a pore size of 1nm is used as the sol-wrapped sol in the dialysis process, and placed in isopropanol solvent to remove Cl - ion. The molar ratio of the mixed solution of tetrapropyl titanate, n-butanol, distilled water or deionized water, glycerin, acetic acid, nitric acid and hydrochloric acid is 1:30:1.5:2:1.5:1;

Embodiment 3

[0039] Add tetrabutyl titanate dropwise to the isopropanol solution mixed with acetic acid and hydrochloric acid, then add an appropriate amount of MAP, and finally add aqueous isopropanol solution, stir at normal pressure and 80°C for 48 hours, and control the pH of the reactant When the value is 3, a transparent and stable anatase titanium dioxide alcohol phase sol is obtained. Finally, a semi-permeable membrane with a pore size of 1nm is used as the sol-wrapped sol in the dialysis process, and placed in isopropanol solvent to remove Cl - ion. The molar ratio of tetrabutyl titanate, isopropanol, distilled water or deionized water, acetic acid, MAP, hydrochloric acid mixed solution is 1:25:2:3:2:0.8;

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com