Preparation method of novel diatom ooze coating

A diatom mud coating, a new type of technology, applied in the field of building material coatings, can solve the problems of cumbersome implementation, high cost of materials, and lack of low-carbon energy saving and environmental protection economy, and achieve shortened drying time, low material cost, and good indoor humidity adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

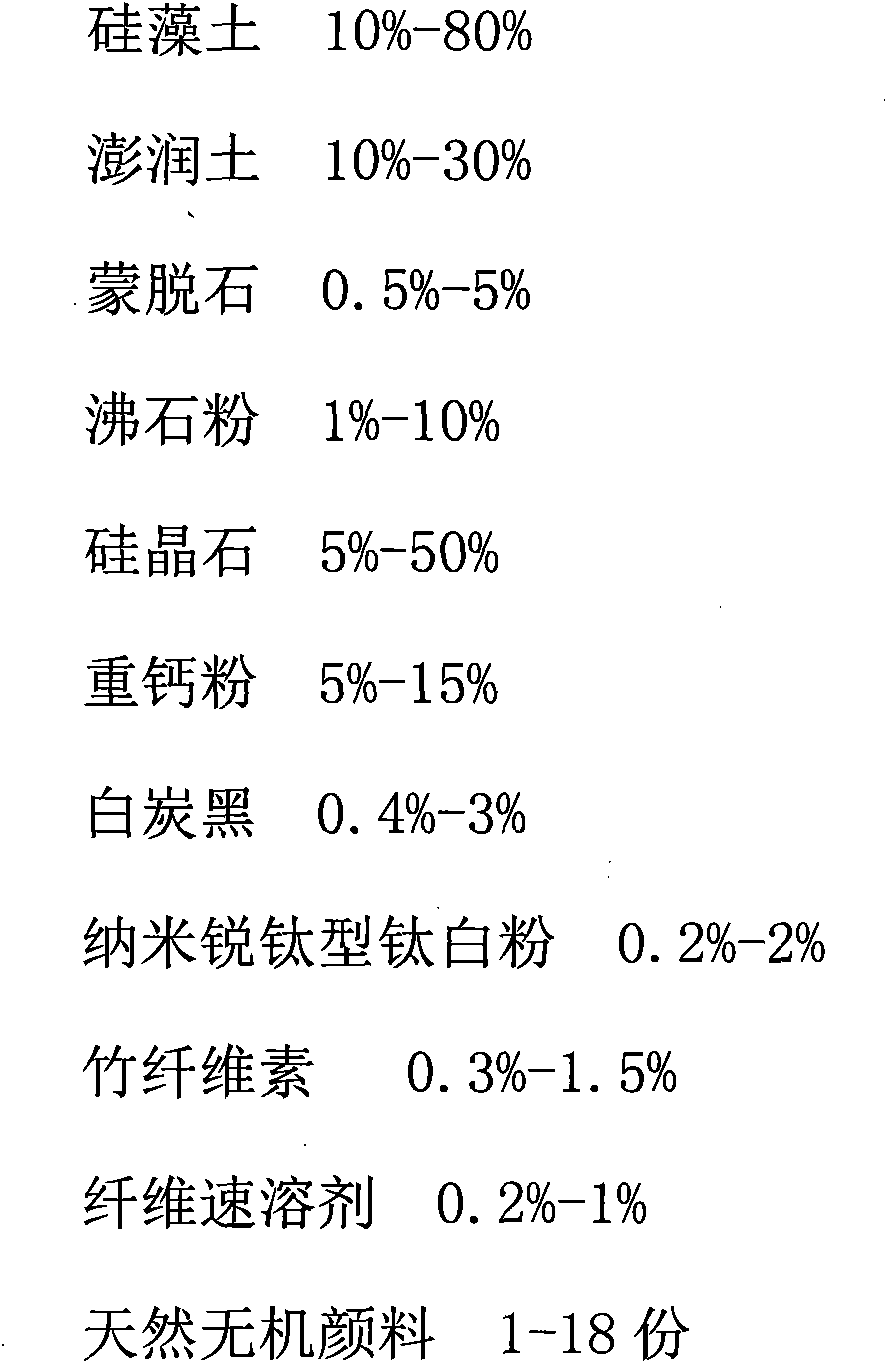

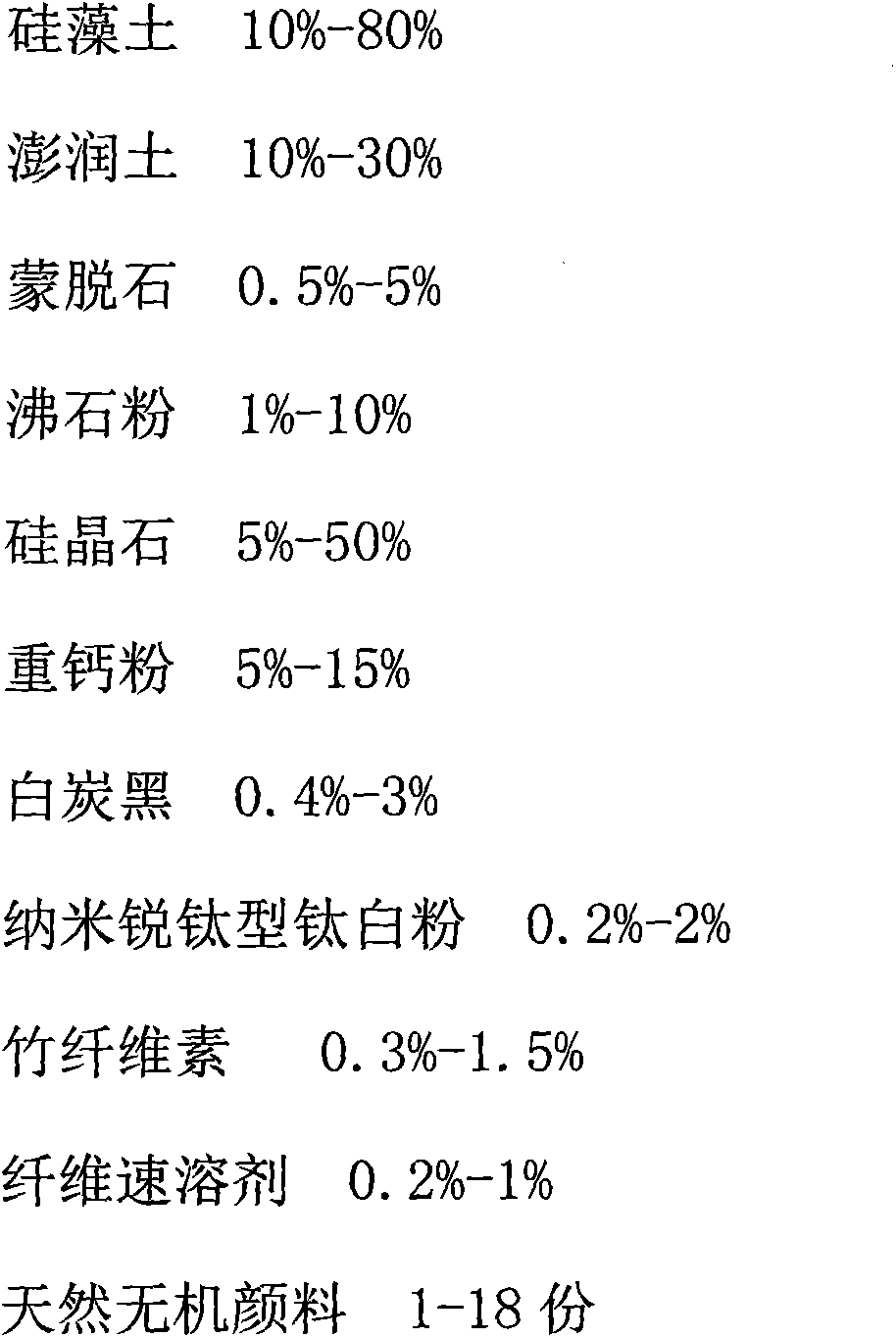

[0024] A method for preparing a novel diatom mud coating, characterized in that: it is composed of the following components in proportion by mass percentage;

[0025]

[0026] The diatomite is 200-600 mesh diatomite, the bentonite is 200-600 mesh bentonite, the montmorillonite is 325-600 mesh montmorillonite, and the zeolite powder is 325-400 mesh Mesh zeolite powder, the silica spar is 325-400 mesh silica spar, the heavy calcium powder is 325-600 mesh heavy calcium powder, the white carbon black is 325-400 mesh white carbon black, and the nano anatase The anatase-type titanium dioxide is 352-400 mesh nano anatase titanium dioxide, the bamboo cellulose is 80-400 mesh bamboo cellulose, and the fiber instant solvent is 325-400 mesh fiber instant solvent.

Embodiment 2

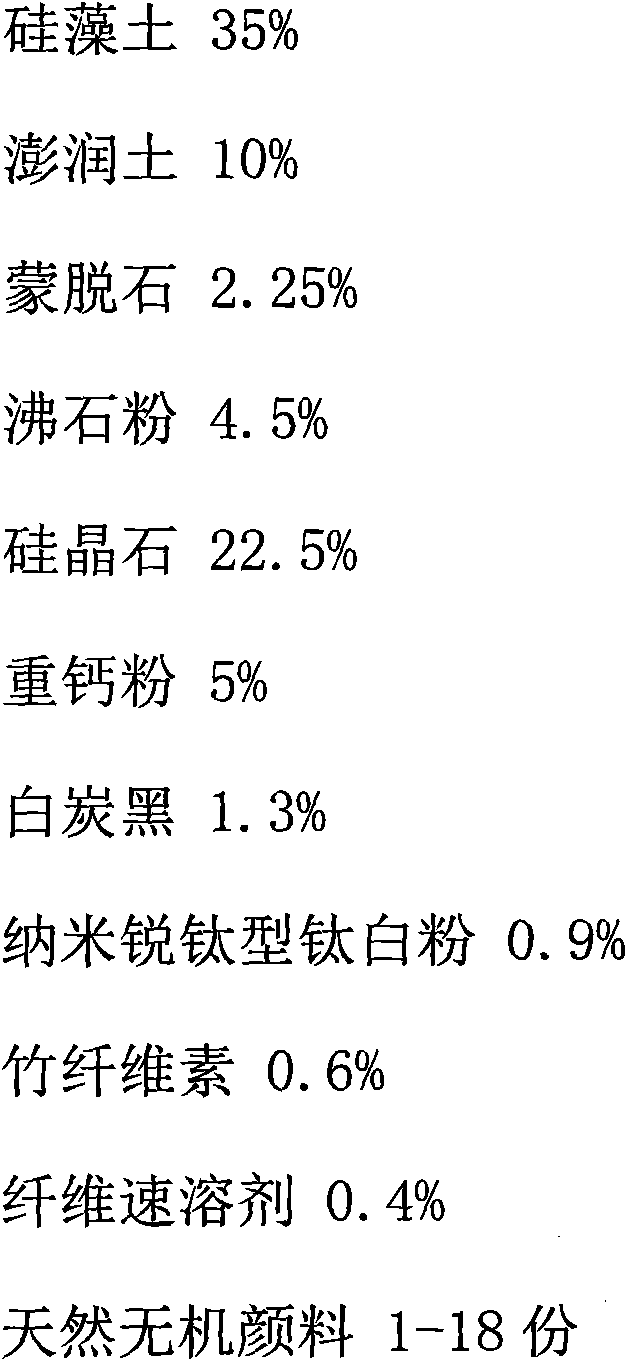

[0028] The preparation method of described a kind of novel diatom mud coating is characterized in that each component mass ratio of described novel diatom mud coating is as follows:

[0029]

[0030] The preparation method of a novel diatom mud coating is characterized in that the above-mentioned materials selected for the diatom mud coating are porous and have adsorption capacity.

[0031] The preparation method of described a kind of novel diatom mud coating is characterized in that described preparation method comprises the following steps:

[0032] Mix the ingredients according to the ratio described in any one of claims 1-2, and fully stir them evenly with a horizontal high-speed stirring device;

[0033] Add water to the above mixture, the mass ratio of the added water to the above mixture is 0.9:1, artificially stir to form a viscous shape, and after 15 minutes, use a mixer to make a paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com