Method for controlling nano-anatase TiO* feature with NaAc as additive agent

An anatase and additive technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effect of simple preparation process, uniform particle size, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

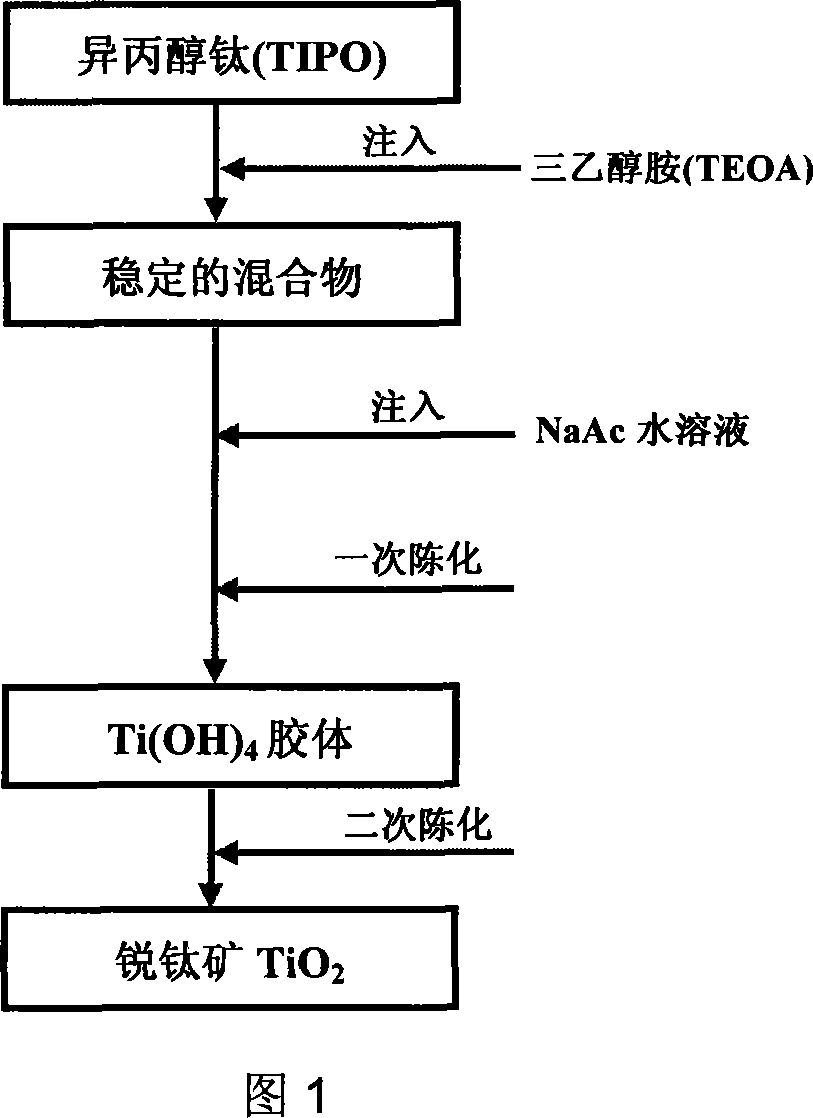

Method used

Image

Examples

Embodiment 1

[0022] a) Weigh 0.02mol of titanium isopropoxide, add 0.01mol of triethanolamine, add deionized water to prepare 0.5mol / l Ti 4+ solution;

[0023] b) Mix 10ml of the solution in step a) with the same volume of deionized water;

[0024] c) The solution obtained in b) is adjusted to a pH value of 9.5 with NaOH solution, and then aged in a hydrothermal reactor at 100° C. for 24 hours;

[0025] d) Aging the viscous colloid in step c) for 72 hours in a hydrothermal reactor at 140°C.

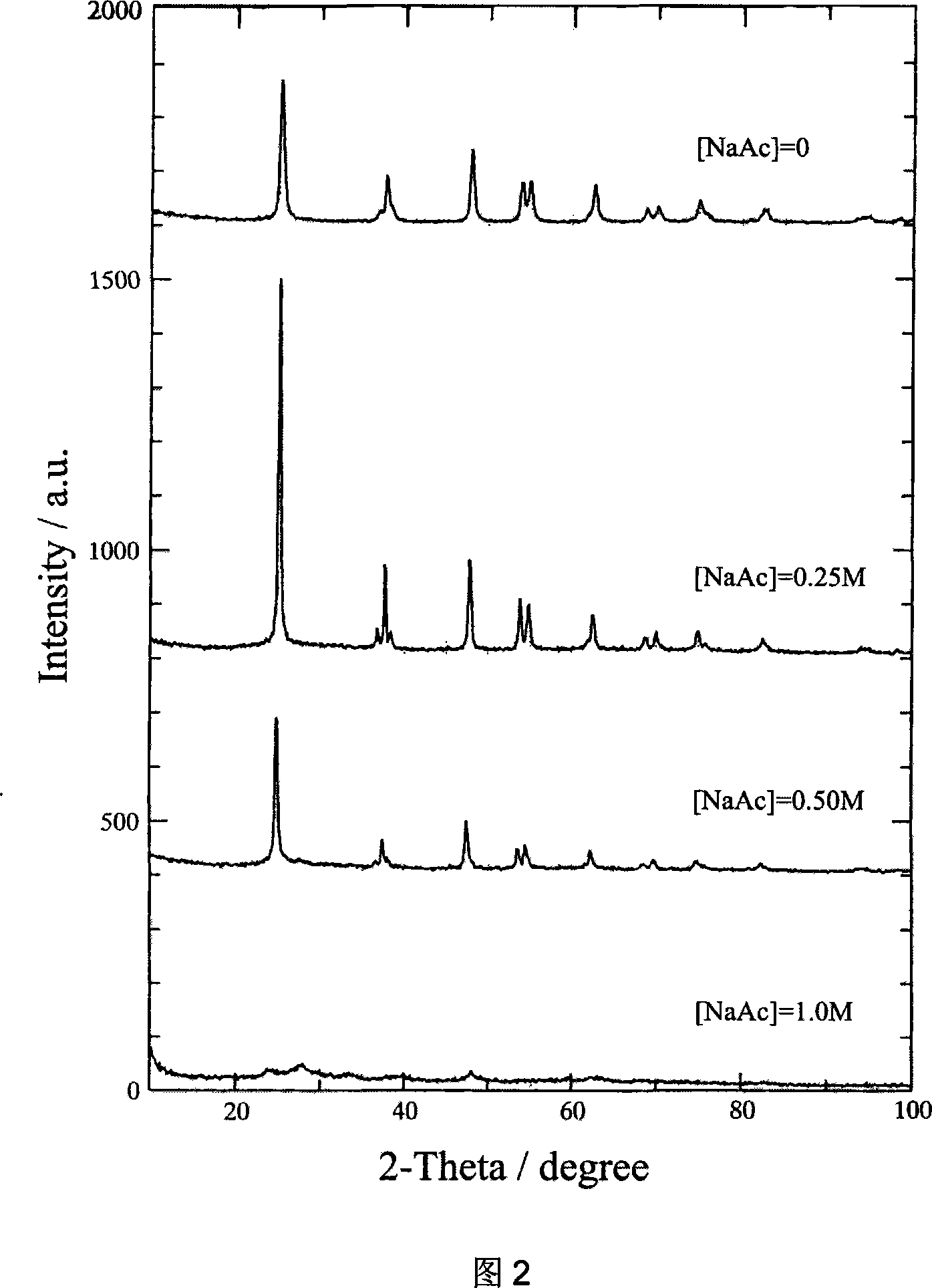

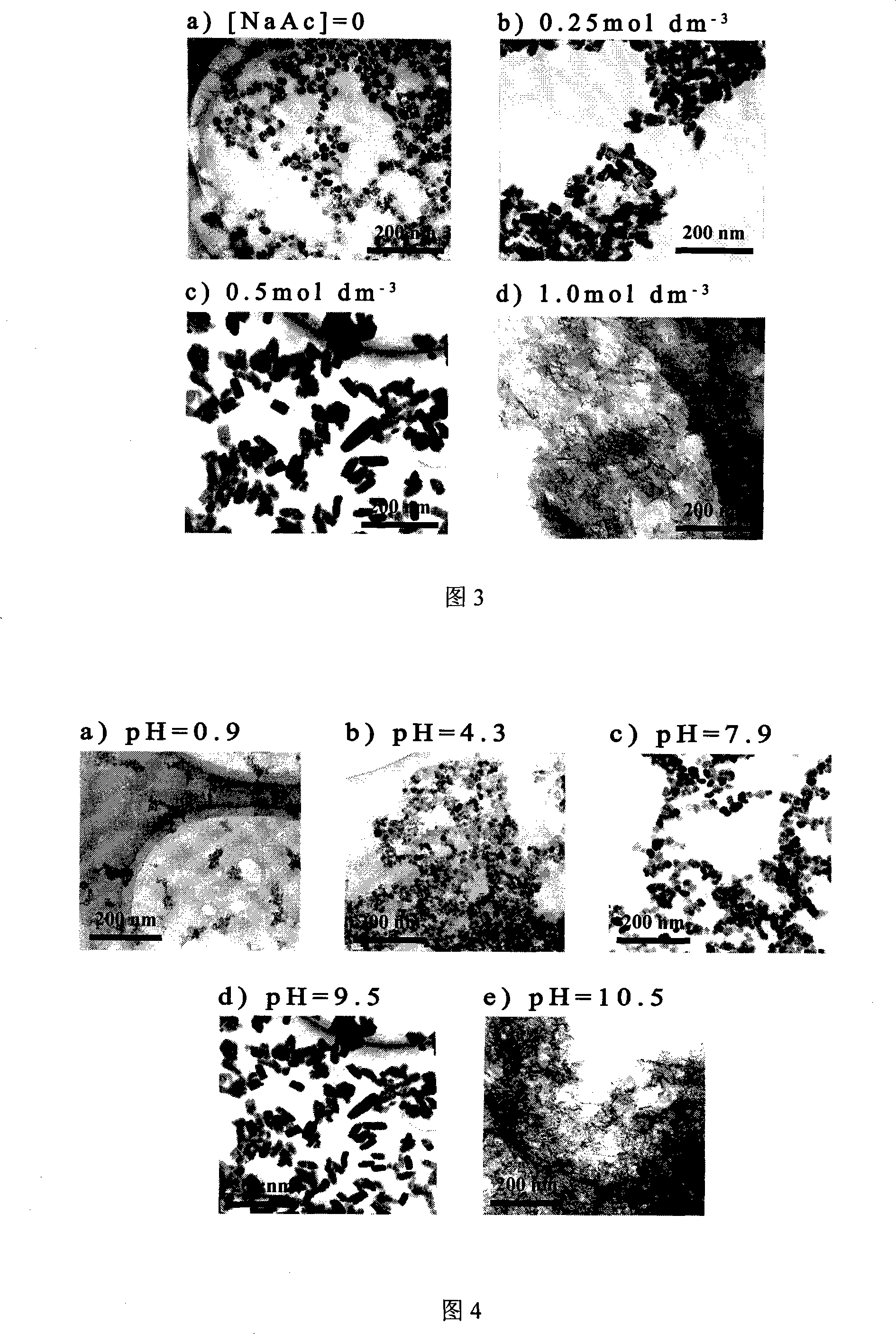

[0026] Nano anatase TiO prepared by this method 2 The XRD (X-ray diffraction, X-ray diffraction) analysis is shown in accompanying drawing 2, and its transmission electron microscope picture is shown in accompanying drawing 3 (a), and particle diameter is 21 nanometers.

Embodiment 2

[0028] a) Weigh 0.02moL titanium isopropoxide, add 0.01moL triethanolamine, add deionized water to prepare 0.5moL / L Ti 4+ solution;

[0029] b) prepare the sodium acetate solution of 0.5moL / L;

[0030] c) Mix 10mL of the solution in step a) with the same volume of deionized water, and take 10mL of the solution in b) and mix evenly;

[0031] d) The solution obtained in c) is adjusted to a pH value of 9.5 with NaOH solution, and aged in a hydrothermal reactor at 100° C. for 24 hours;

[0032] e) Aging the viscous colloid in step d) for 96 hours in a hydrothermal reaction kettle at 130°C.

[0033] Nano anatase TiO prepared by this method 2 See accompanying drawing 2 for its XRD analysis, and its transmission electron micrograph is shown in accompanying drawing 3 (c), and the particle diameter is 20.2×38.0 nanometers.

Embodiment 3

[0035] a) Weigh 0.02moL titanium isopropoxide, add 0.01moL triethanolamine, add deionized water to prepare 0.5moL / L Ti 4+ solution;

[0036] b) prepare the sodium acetate solution of 1.0moL / L;

[0037] c) Mix 10mL of the solution in step a) with the same volume of deionized water, and take 10mL of the solution in b) and mix evenly;

[0038] d) adjust the solution obtained in c) to pH 9.5 with NaOH solution, and age at 110° C. for 36 hours;

[0039] e) Aging the viscous colloid in step d) at 120° C. for 96 hours.

[0040] Nano anatase TiO prepared by this method 2 See accompanying drawing 2 for its XRD analysis, and its transmission electron micrograph is shown in accompanying drawing 3 (d), and the particle size is 23.1×48.4 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com