Dielectric ceramic for high-frequency section and preparation method thereof

A technology of dielectric ceramics and high-frequency bands, applied in the field of dielectric ceramics and its preparation, can solve the problems of complex material composition, unstable amplification process, and dielectric constant value lower than 25, and achieve easy process amplification, good chemical stability, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

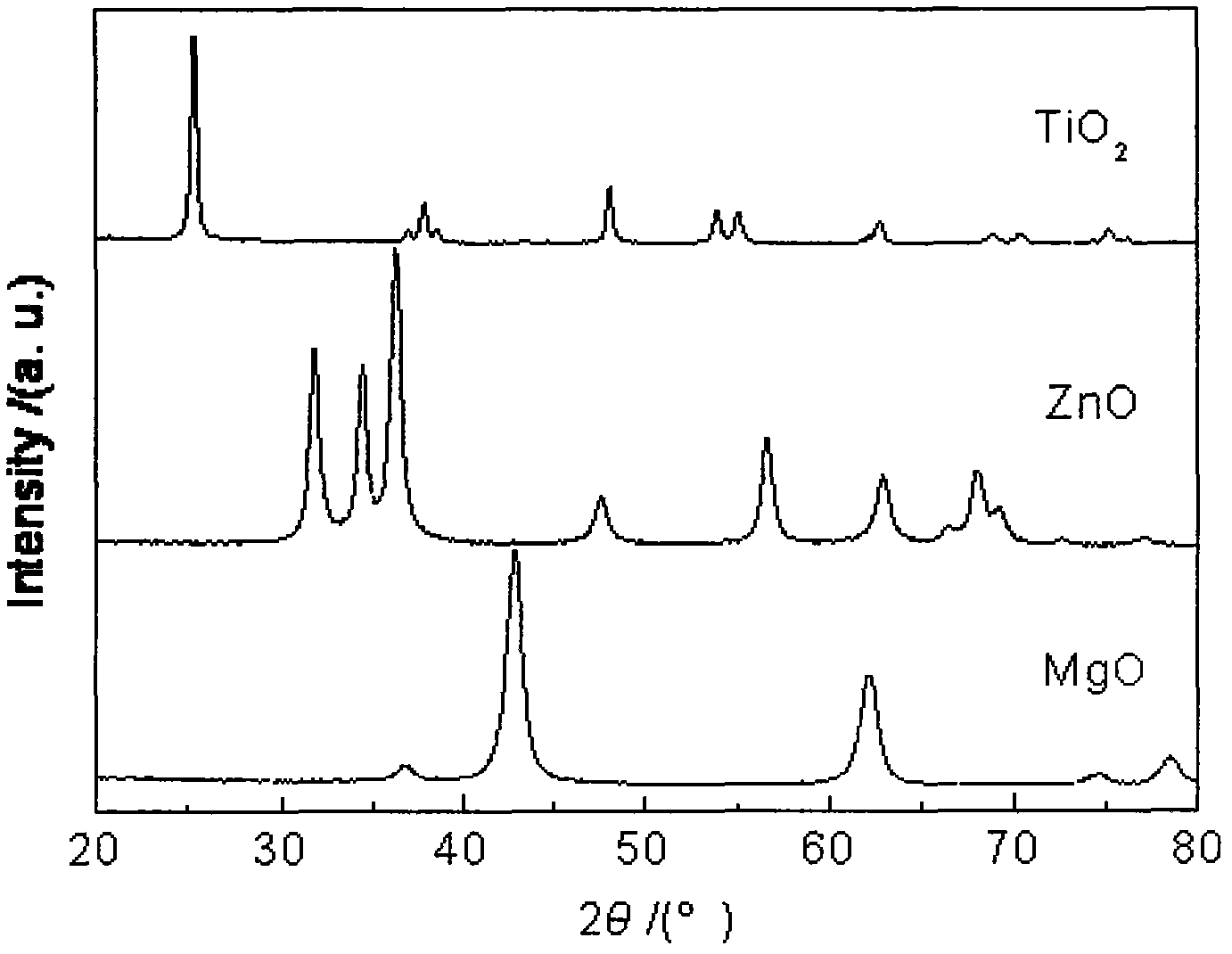

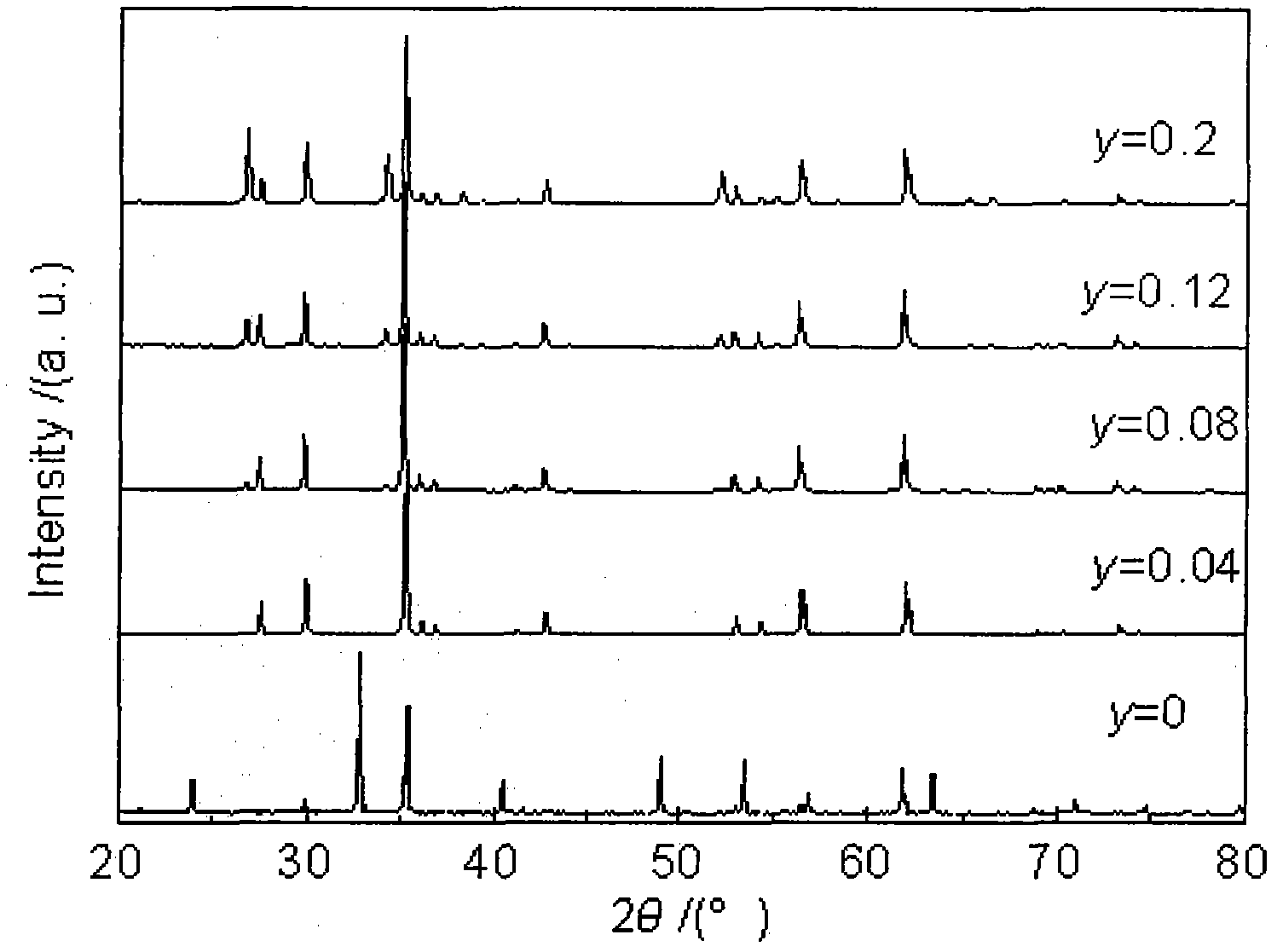

[0019] In this example, a chemical method is used to obtain nano-zinc oxide and nano-magnesium oxide as starting materials for preparing a ceramic composition. The ratio of raw materials in this embodiment is: 1 part of zinc oxide, 0.92 part of nano anatase titanium dioxide, 0.08 part of tin dioxide, and 1.00 wt % of additives. Zinc oxide is produced by the decomposition of basic zinc carbonate. The additive is based on the total weight of the base material as 100.

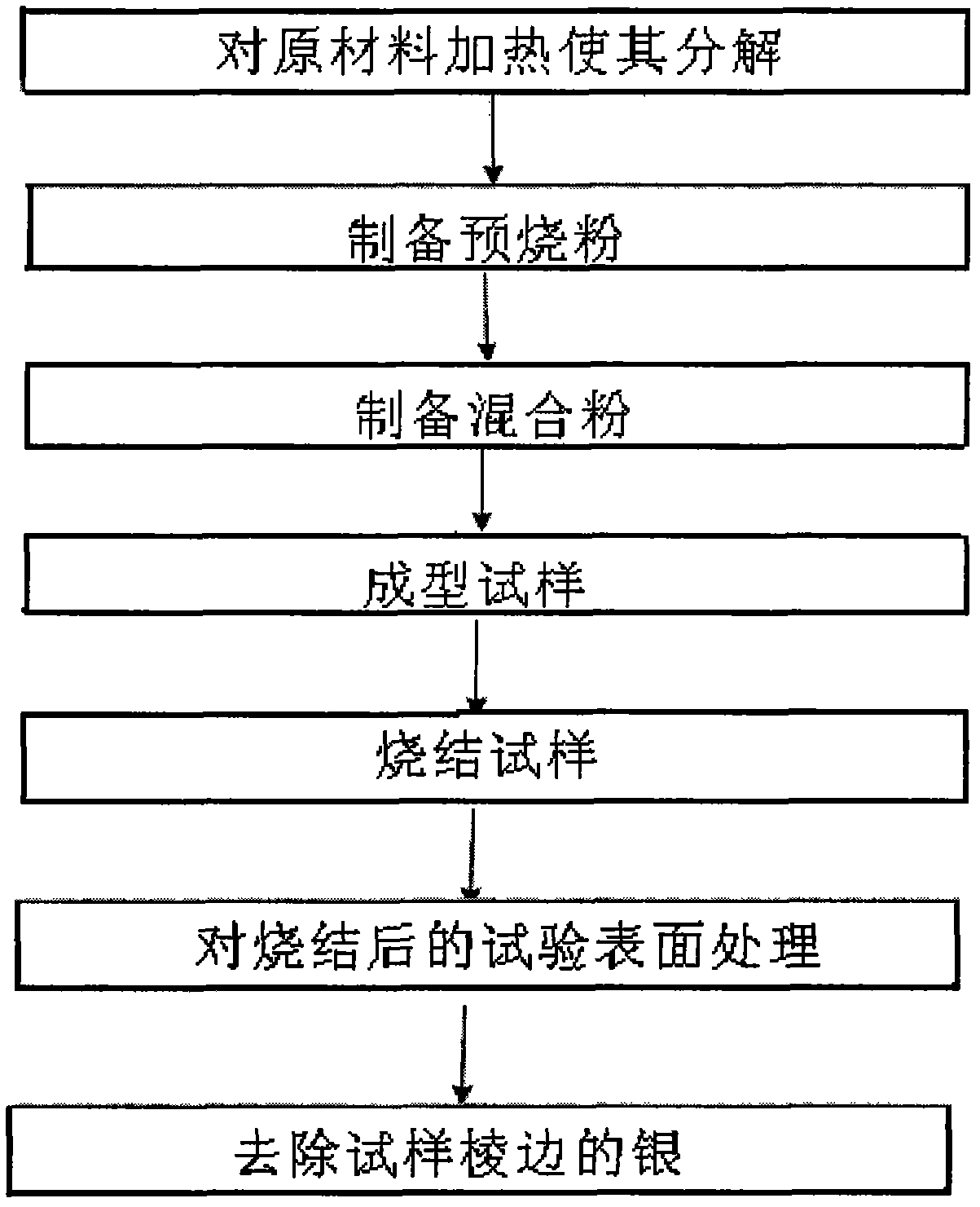

[0020] The preparation process of this embodiment is:

[0021] In the first step, the raw material is heated to decompose it. Analytical pure basic zinc carbonate is heated to decompose it into zinc oxide. The heating temperature is 350° C., the holding time is 3 hours, and the heating rate is 5° C. / min. The particle diameter of the obtained zinc oxide is 50-80 nm.

[0022] The second step is to prepare calcined powder. Mix zinc oxide, nano-anatase titanium dioxide and tin dioxide in a ratio of 1 part zinc o...

Embodiment 2

[0030] In this example, a chemical method is used to obtain nano-zinc oxide and nano-magnesium oxide as starting materials for preparing a ceramic composition. The ratio of raw materials in this embodiment is: 0.7 parts of zinc oxide, 0.3 parts of magnesium oxide, 0.88 parts of nano-anatase titanium dioxide, 0.12 parts of tin dioxide, plus 1.10 weight percent additives. Among them, zinc oxide is generated by the decomposition of basic zinc carbonate, and magnesium oxide is generated by the decomposition of basic magnesium carbonate. The additive is based on the total weight of the base material as 100.

[0031] The preparation process of this embodiment is:

[0032] In the first step, the raw material is heated to decompose it. Heat analytically pure basic zinc carbonate and basic magnesium carbonate to decompose them into zinc oxide and magnesium oxide. The heating temperature is 350°C, the holding time is 3 hours, and the heating rate is 5°C / min. The diameter is 50-80nm; ...

Embodiment 3

[0041] In this example, a chemical method is used to obtain nano-zinc oxide and nano-magnesium oxide as starting materials for preparing a ceramic composition. The ratio of raw materials in this embodiment is: 0.2 part of zinc oxide, 0.8 part of magnesium oxide, 0.8 part of nano-anatase titanium dioxide, 0.2 part of tin dioxide, plus 1.20% by weight of additives. Among them, zinc oxide is generated by the decomposition of basic zinc carbonate, and magnesium oxide is generated by the decomposition of basic magnesium carbonate. The additive is based on the total weight of the base material as 100.

[0042] The preparation steps are:

[0043] In the first step, the raw material is heated to decompose it. The analytically pure basic zinc carbonate is heated to decompose it into zinc oxide, the heating temperature is 350°C, the holding time is 3 hours, the heating rate is 5°C / min, the particle size of the obtained zinc oxide is 50-80nm; the analytically pure The basic magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com