Anti-impulse tensile high frequency enamelled winding wire

An enamelled winding wire, anti-pulse technology, applied in the direction of conductors, insulated cables, electrical components, etc., can solve the problems of inability to guarantee product diameter consistency, waste of human and material resources, etc., achieve good flexibility, reduce production costs, simplify The effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

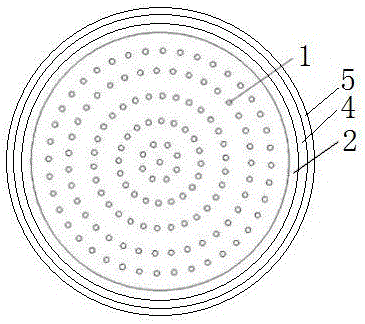

[0017] Embodiment 1, forty-one metal wire cores 1 with a diameter of Φ0.25 mm are twisted into a bundle, and the outer surface is coated with a polyester protective layer 2, a polyamide-imide layer 4, and a polyurethane layer 5 sequentially from the inside to the outside. It constitutes an anti-pulse and tensile high-frequency enamelled winding wire. The overall cross-sectional area of the winding wire is 2 mm 2 , withstand voltage ≥ 5000V, heat shock resistance 155 ℃.

Embodiment 2

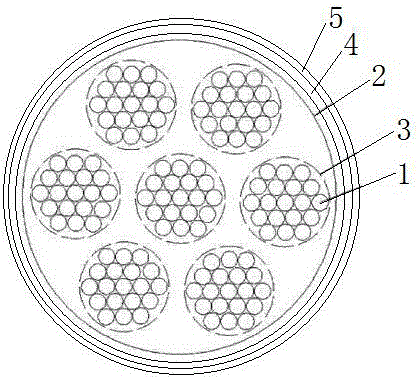

[0018] Embodiment 2, thirteen metal wire cores 1 with a diameter of Φ0.25mm are twisted into a group to form a primary group 3 of enameled wires, and seven groups of primary groups 3 of enameled wires are twisted into bundles, and the outer surfaces are coated with polycarbonate in sequence from the inside to the outside. The ester protective layer 2, the polyamide-imide layer 4, and the polyurethane layer 5 constitute an anti-pulse and tensile high-frequency enamelled winding wire. There are ninety-one metal wire cores 1 of the winding wire, and the overall cross-sectional area of the winding wire is 4.5 mm 2 , withstand voltage ≥ 5000V, heat shock resistance 155 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Withstand voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com