Patents

Literature

76 results about "Titanium peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium Oxalate (Spectrophotometric) Principle. The sample is clarified by treatment with aluminum chloride and sodium hydroxide solution and the hydrogen peroxide reacted with potassium titanium oxalate in acid solution to form the yellow pertitanic acid complex.

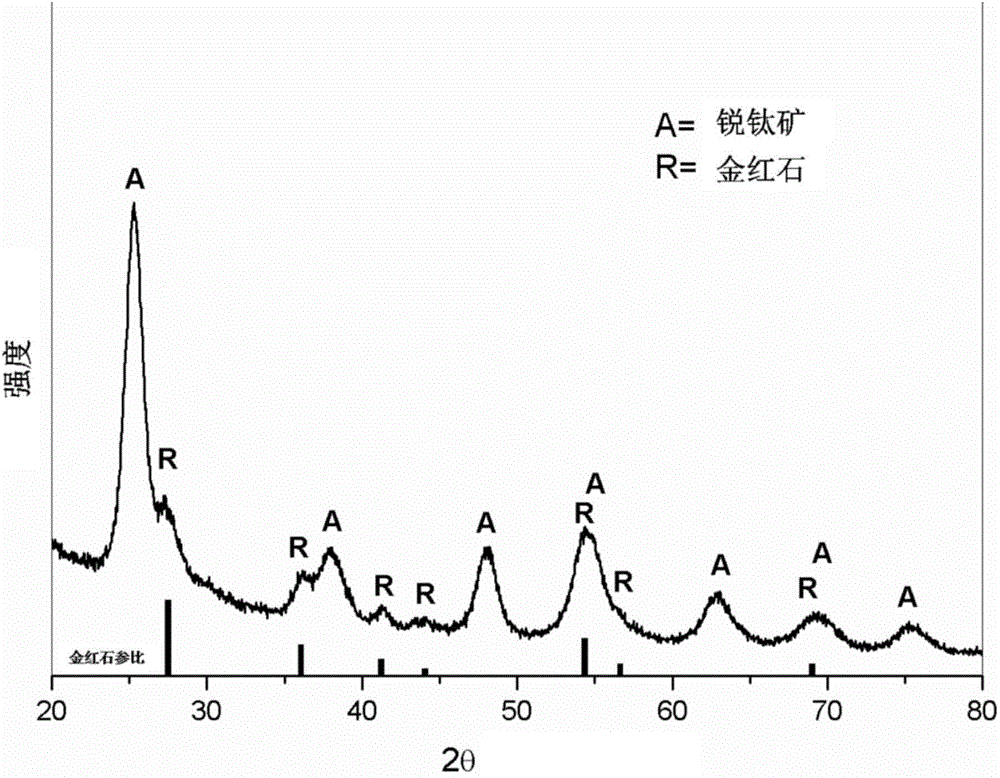

Photocatalytic body and method for making same

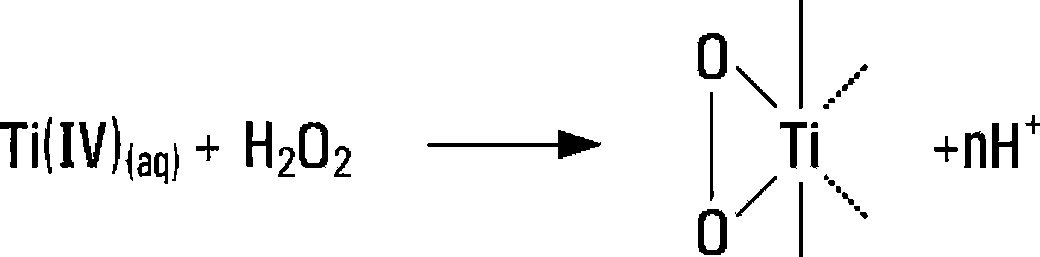

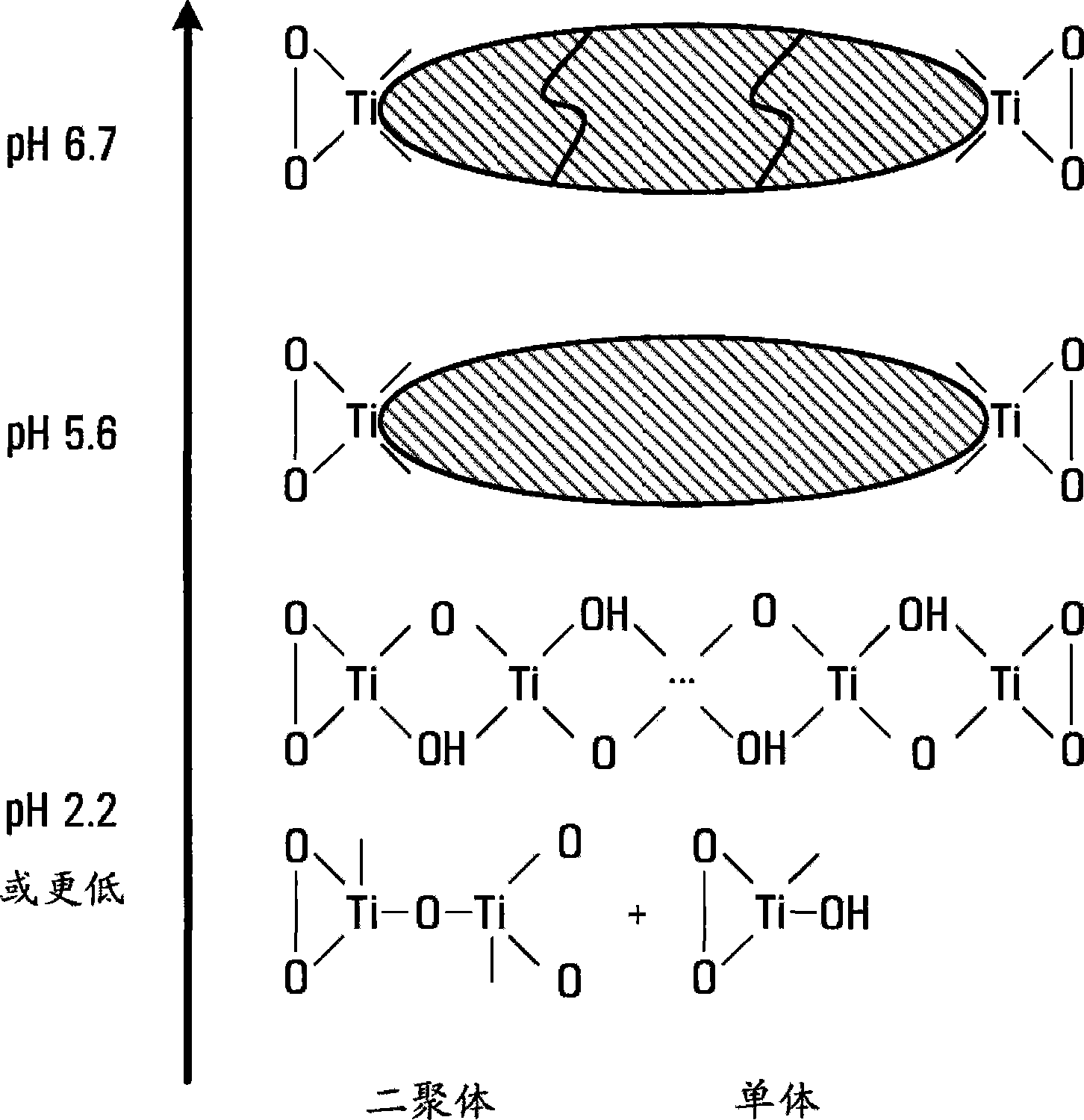

An amorphous titanium peroxide sol made by a process which includes adding an alkali hydroxide to an aqueous titanium salt solution and reacting the resulting amorphous titanium hydroxide with an aqueous hydrogen peroxide solution to obtain an amorphous titanium peroxide sol. The amorphous titanium peroxide sol is afterward raised to a temperature sufficient to obtain an anatase titanium oxide sol. The resulting anatase titanium oxide sol can thereafter be heated to a temperature sufficient to obtain anatase titanium oxide. The claimed compositions are useful as binders to support the particles of a photocatalyst on a variety of substrates.

Owner:SAGA KEN

Method for synthesizing anatase type crystallizing titanium dioxide nano nuclear-shell or shell structure material by water phase one-step method

InactiveCN101077792AThe method flow is simpleEasy to operateTitanium dioxidePhotonic crystalPolystyrene

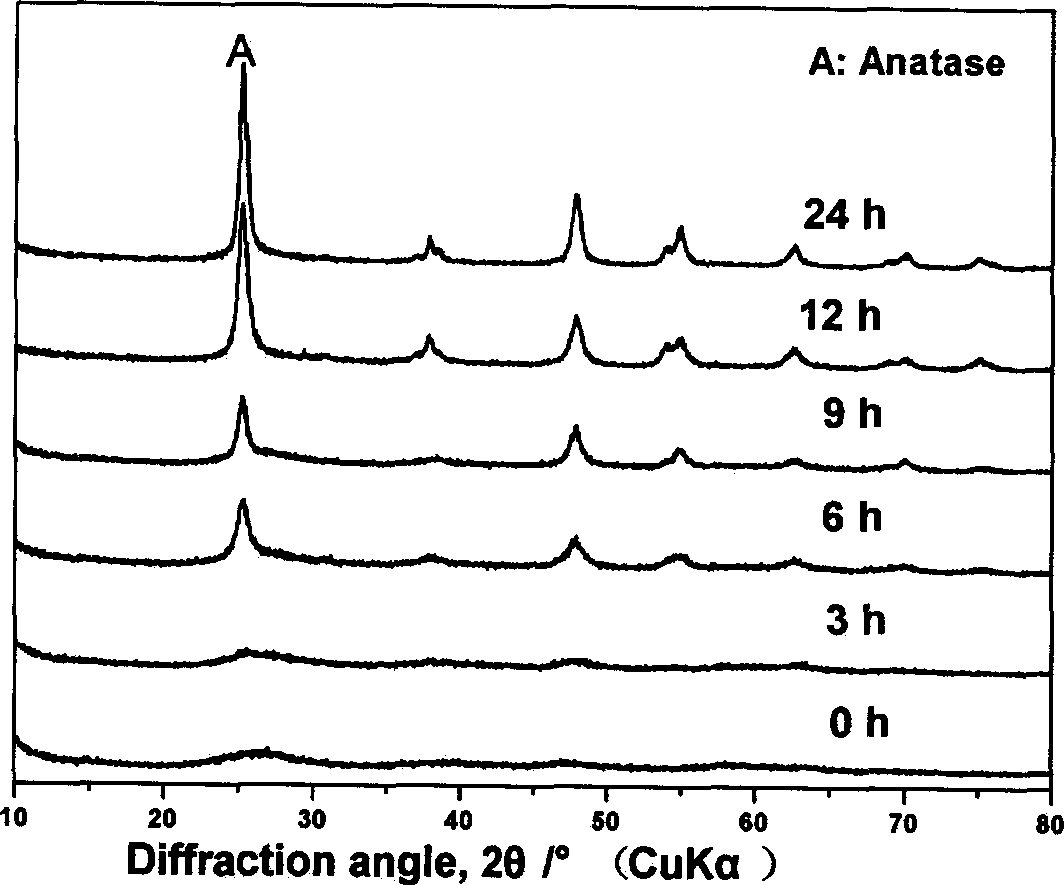

The present invention relates to preparation process of core-shell material and hollow material, and is especially water phase one-step synthesis process for preparing nanometer crystallized anatase type titania material in core-shell and hollow structure. Water soluble titanium peroxide precursor is treated through a sol-gel process so as to coat a nanometer titania layer onto the surface of polystyrene, and the nanometer titania layer in the shell is crystallized directly at relatively low temperature to form nanometer anatase type titania without needing sintering. Furthermore, the precursor may be controlled properly, so that the polystyrene core serving as the template may be dissolved spontaneously after the shell is formed and crystallized and nanometer hollow titania may be obtained directly in water phase. The present invention is simple, easy to operate, low in cost and suitable for batch production, and may find wide application in different aspects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

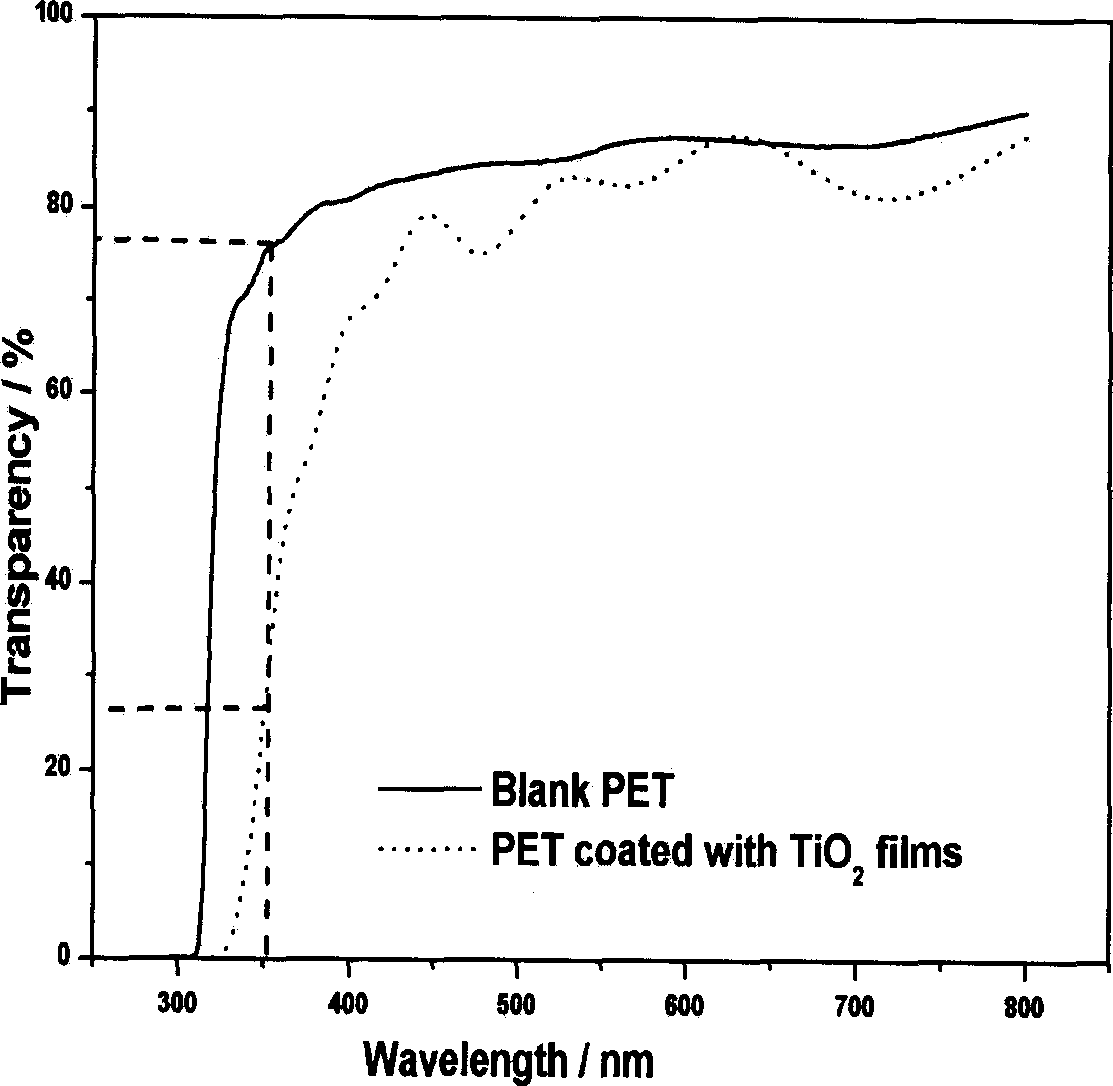

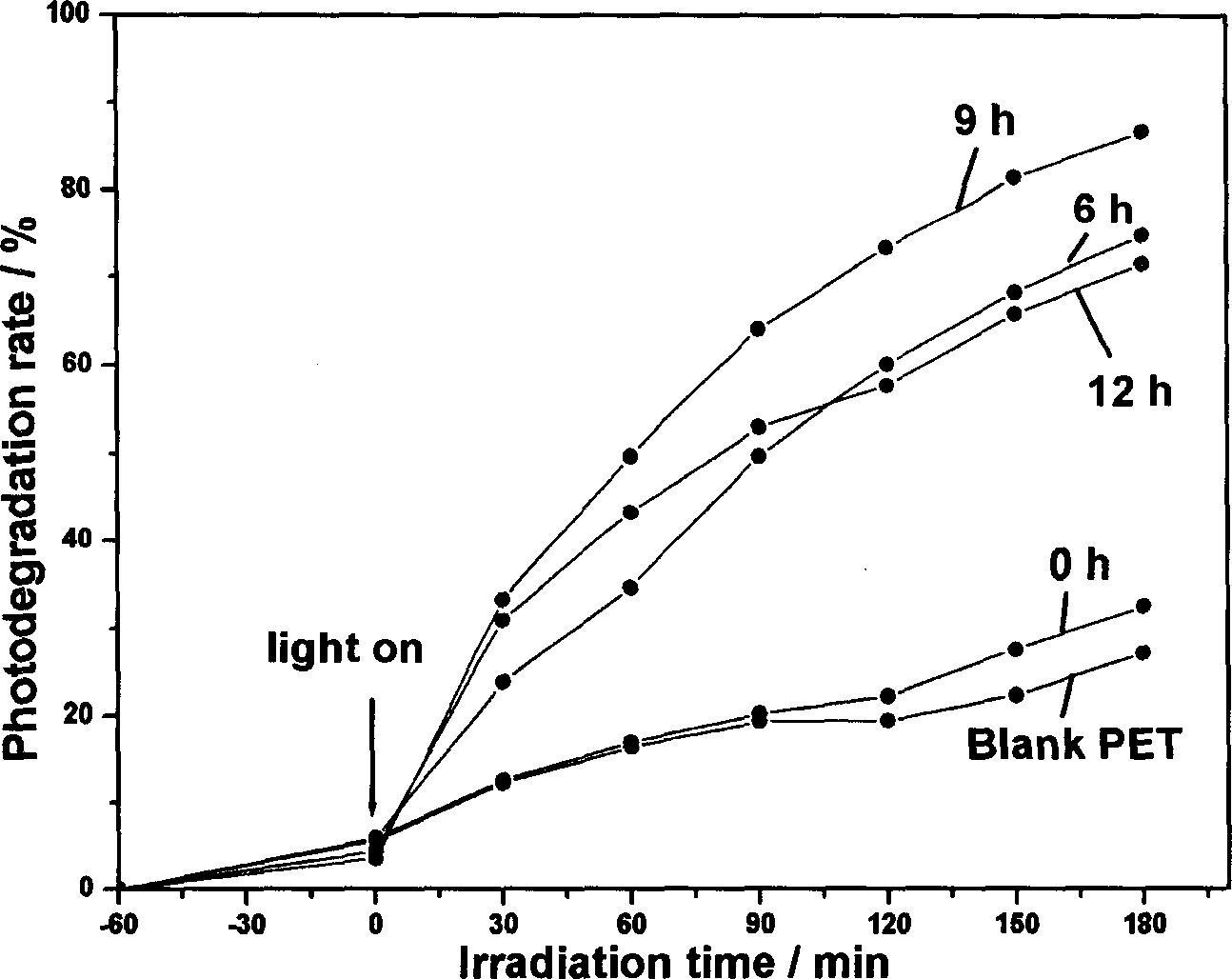

Method for preparing titanium dioxide functional film from poly ethylene glycol terephthalate substrate surface

The invention discloses a method to make nm titanium dioxide light catalyzing film on PET base material the feature includes aging titanium peroxide acid sol to make aqueous phase nm titanium dioxide sol, adding film forming agent to gain film coating liquid, finally, making titanium dioxide film on the pre-treated PET base material. It could be used for aseptic package, antibiotic fabric, antifogging dripping and self-cleaning film. It is low cost, easy to operate and is suited for manufacturing.

Owner:EAST CHINA UNIV OF SCI & TECH

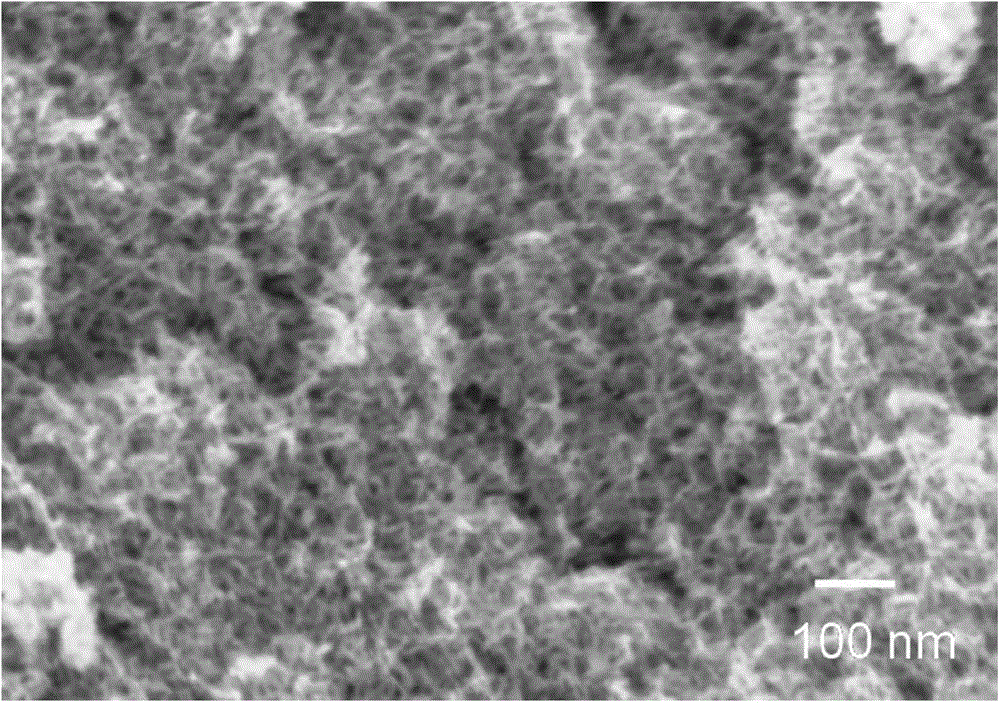

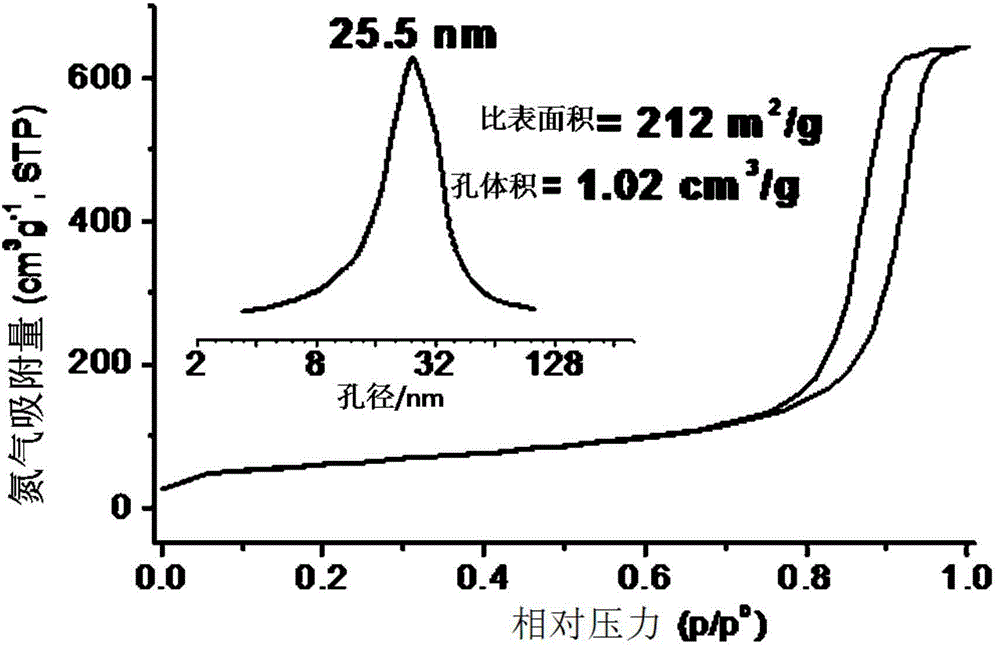

Mesoporous titanium dioxide material and preparation method thereof

InactiveCN103979605AHigh specific surface areaIncrease the apertureTitanium dioxideRoom temperatureMesoporous material

The invention relates to the field of a mesoporous material, and in particular relates to a mesoporous titanium dioxide material and a preparation method thereof. According to the mesoporous titanium dioxide material disclosed by the invention, an aperture is 10-30nm, a specific surface area is 63-235m<2> / g and a pore volume is 0.55-1.02cm<3> / g. Compared to a current mesoporous titanium dioxide material, the mesoporous titanium dioxide material disclosed by the invention greatly improves specific surface area, aperture and pore volume; the preparation method comprises the following steps: preparing titanium peroxide acid sol through titanic acid and hydrogen peroxide, forming an self-assembling system through titanium oxide acid sol and a surfactant, and drying and baking the self-assembling system to obtain the mesoporous titanium dioxide material; the method is simple and easy to implement; moreover, the entire preparation process is free from other organic chelating agents or inorganic additives and mineral acids; the preparation system is a pure water system which is independent from any other non-polar or weak-polar solvents; and in addition, the titanium peroxide acid sol prepared is relatively stable at room temperature, and control process is relatively simple.

Owner:NORTHEASTERN UNIV

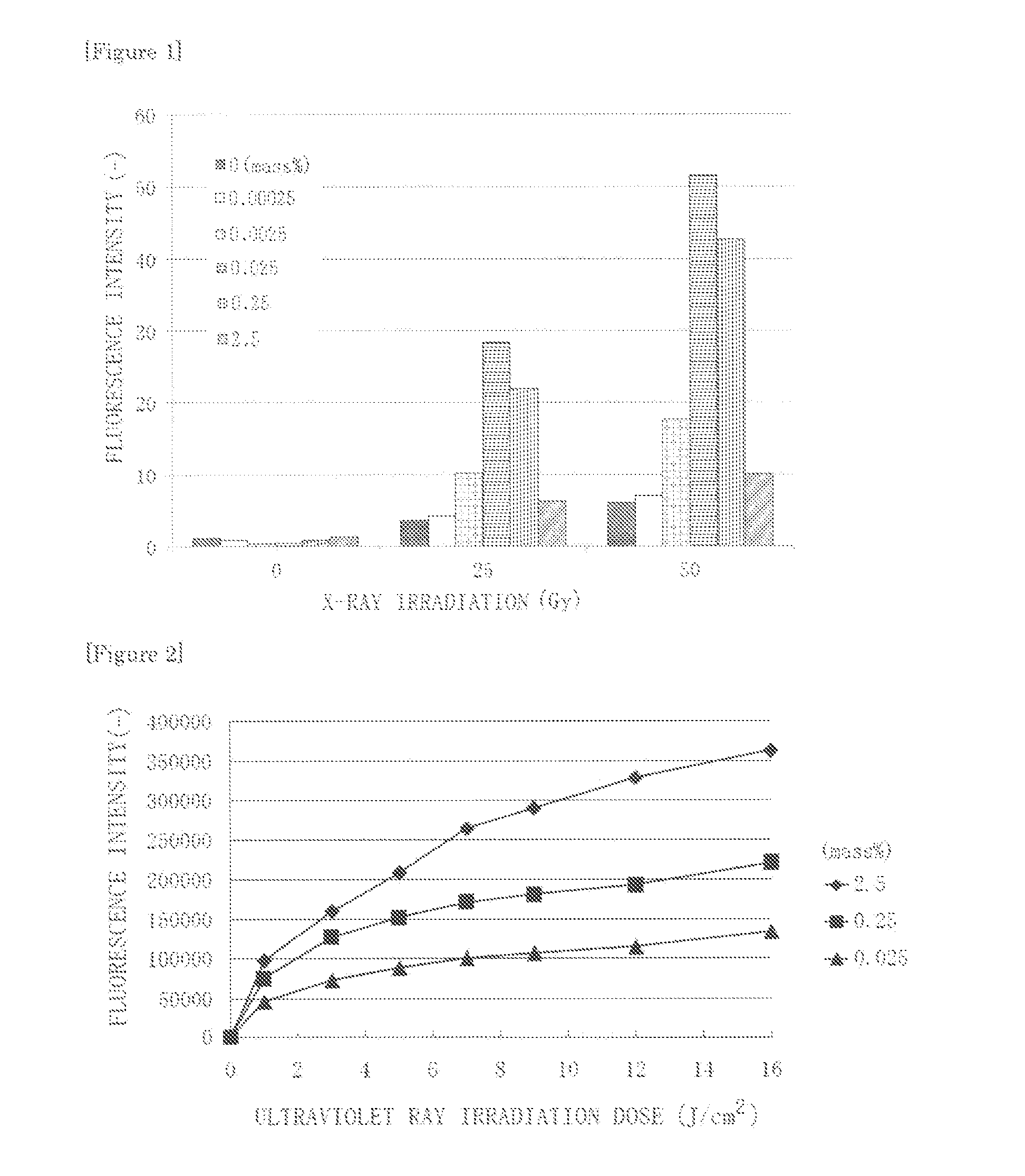

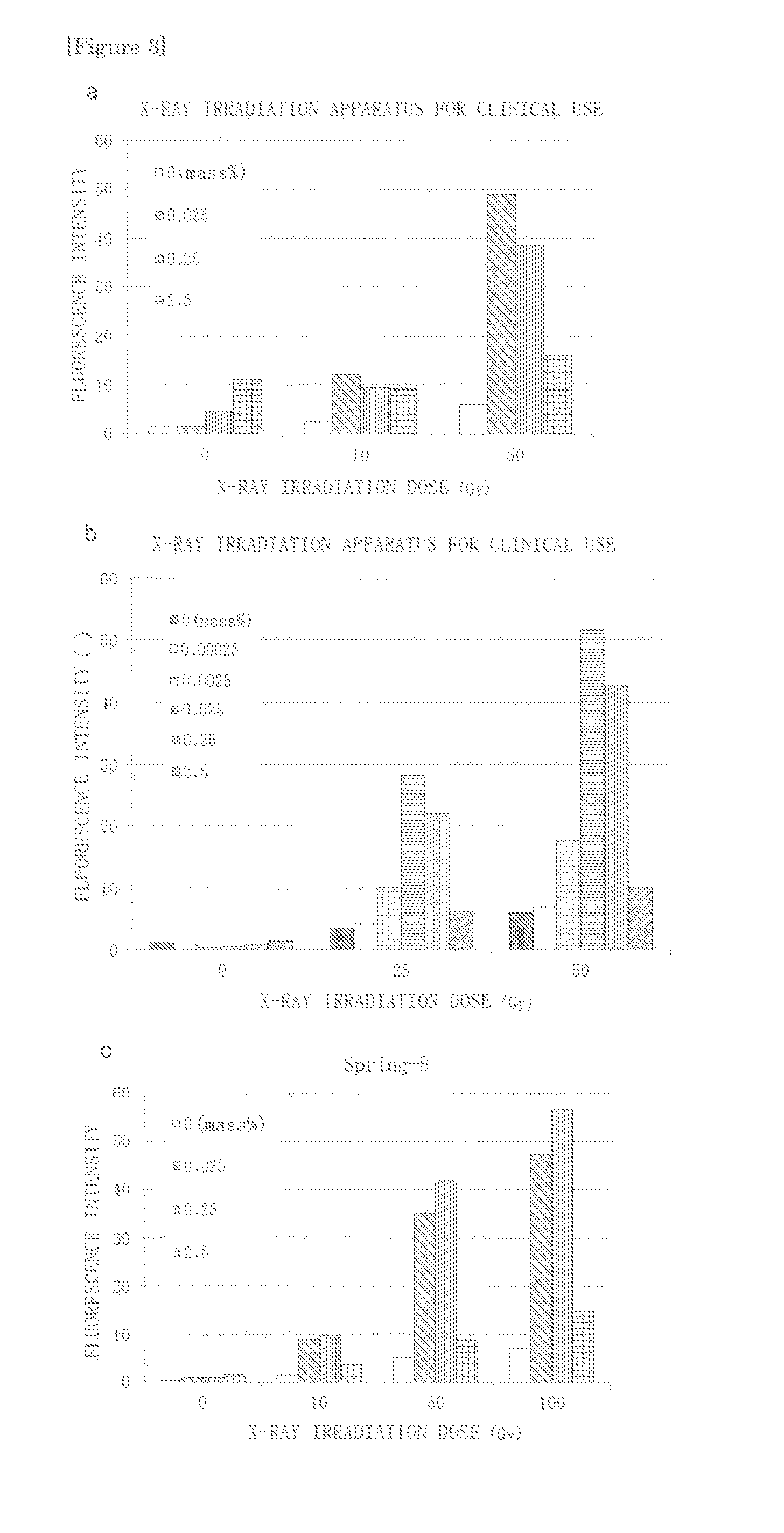

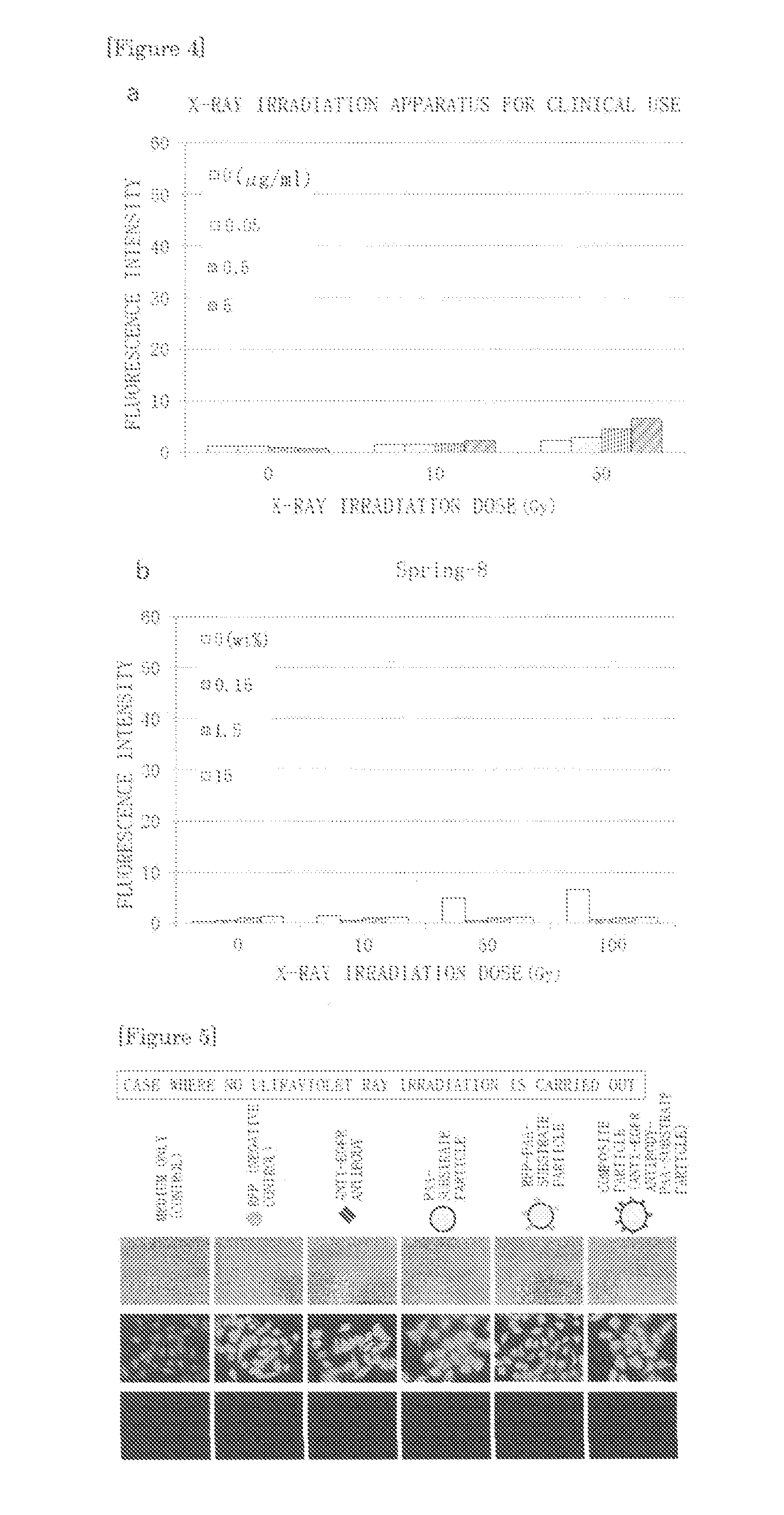

Radiation Therapy Agent

ActiveUS20130017266A1Efficient damageSufficient therapeutic effectPowder deliveryAntipyreticSide effectCombinatorial chemistry

Provided is a radiotherapeutic agent, including a composite particle, which is obtained by binding a molecule that specifically recognizes a target to a substrate particle including titanium peroxide, and which generates reactive oxygen through irradiation with a radiation. Further, because the radiotherapeutic agent contains the molecule that specifically recognizes a target, the radiotherapeutic agent has a function of accumulating in the target. The radiotherapeutic agent is capable of enhancing effects of radiotherapy, and is capable of reducing side effects on a living body to efficiently attack the target.

Owner:KOBE UNIV

Wall material with zeolite layer at surface and wall material adhered with porous substance layer on surface

The present invention utilizes the combination of zeolites in photocatalyst to raise the capability for decomposing and removing harmful chemical substances in the air, in the place having faint UV ray said invention utilizes titanium oxide to raise the capability for decomposing harmful chemical substances. Its solution method includes the following steps: on the surface of base material fixing powdered or granular zeolites to form zeolite layer; on the surface of powdered or granular zeolites formed into said zeolile layer fixing photocatalyst to form photocatalyst layer. The constitution of said photocatalyst forming said photocatalyst layer and the powdered or granular zeolites forming said zeolite layer can be freely contacted with air, and the photocatalyst forming said photocatalyst layer uses titanium oxide as main component.

Owner:MIYA TECH

Process for preparing microporous crystalline titanium silicate

InactiveUS20040024075A1Highly cost-effectiveHigh mechanical strengthPigmenting treatmentAluminium compoundsAlcoholTitanium

A process for the preparation of crystalline microporous titanium silicates using ethylsilicate-40 and titanium peroxide as silicon and titanium sources respectively is described. The process permits a significant decrease in the production cost of titanium silicate containing higher amount of titanium (Si / Ti=20) because of cheaper raw materials as well as reduction in the quantity of tetarpropylammonium hydroxide (TPAOH) template (SiO2:TPAOH=1:0.06-0.1) required for preparation. The material obtained by the present invention is useful as an active catalyst in the reactions such as oxidation of hydrocarbons, alcohols, sulphides, and thioethers.

Owner:COUNCIL OF SCI & IND RES

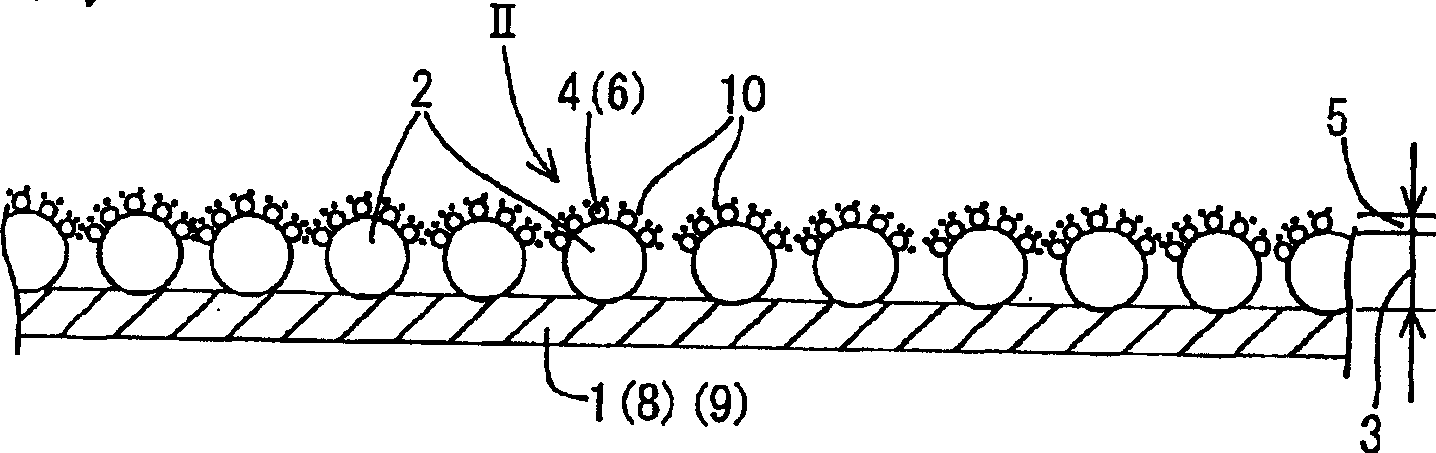

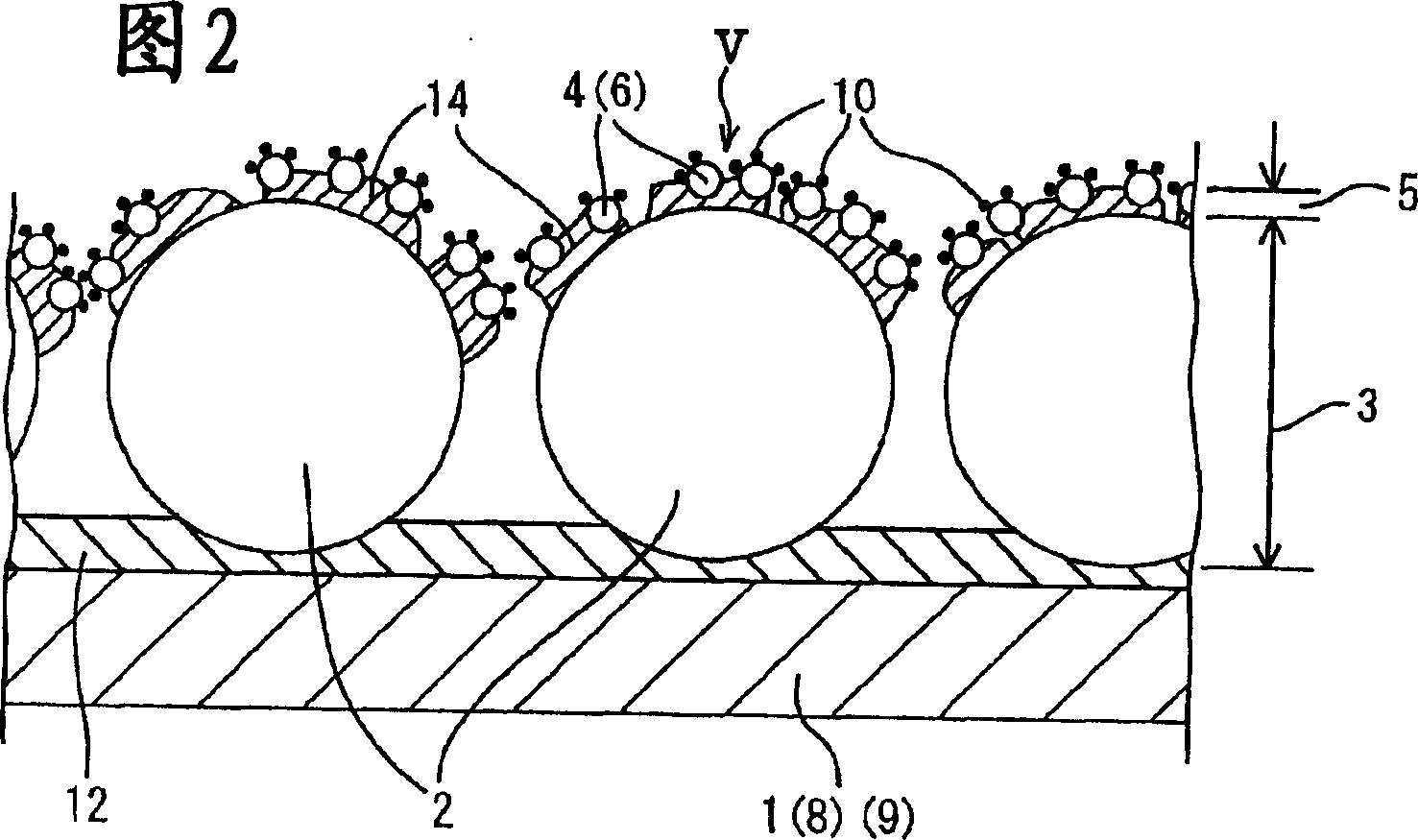

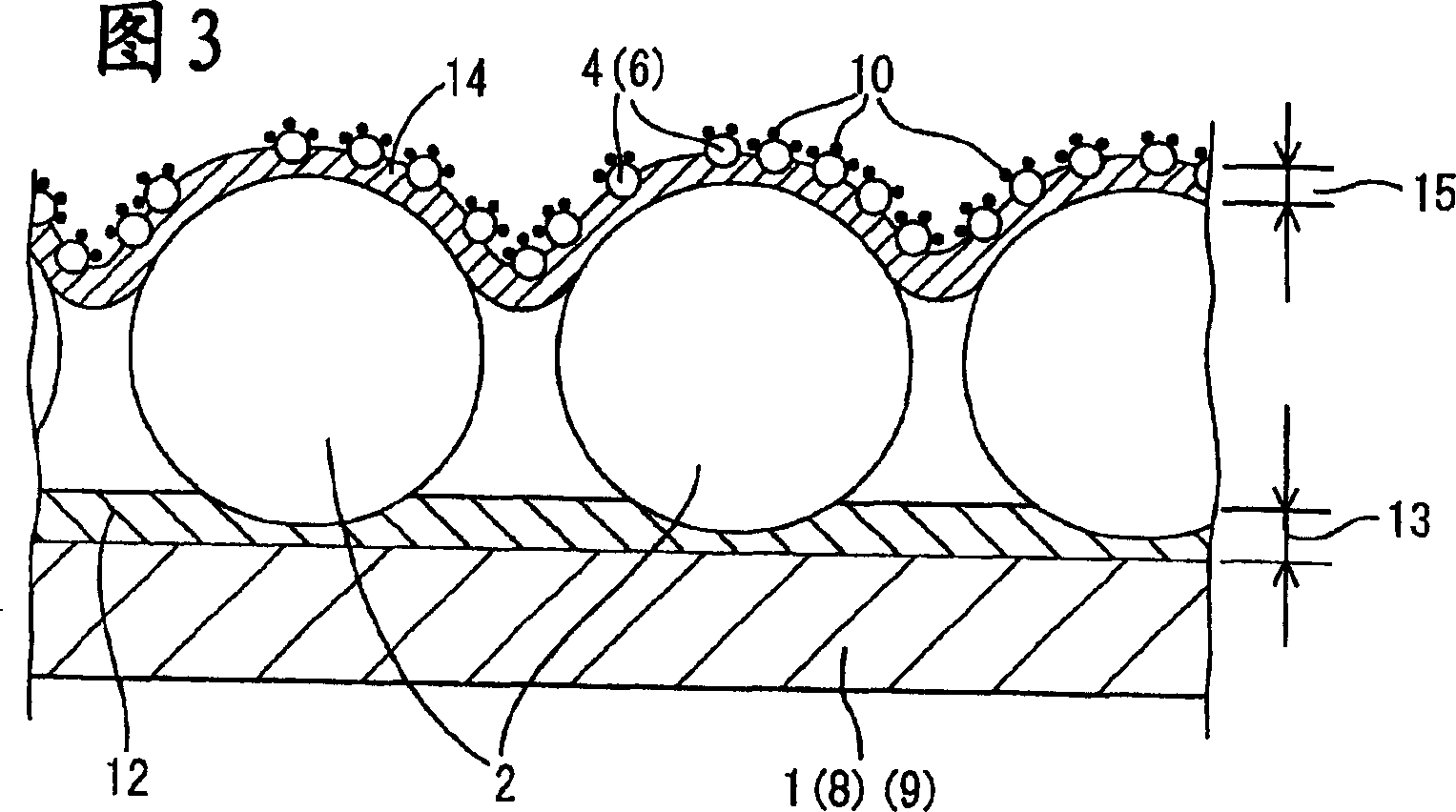

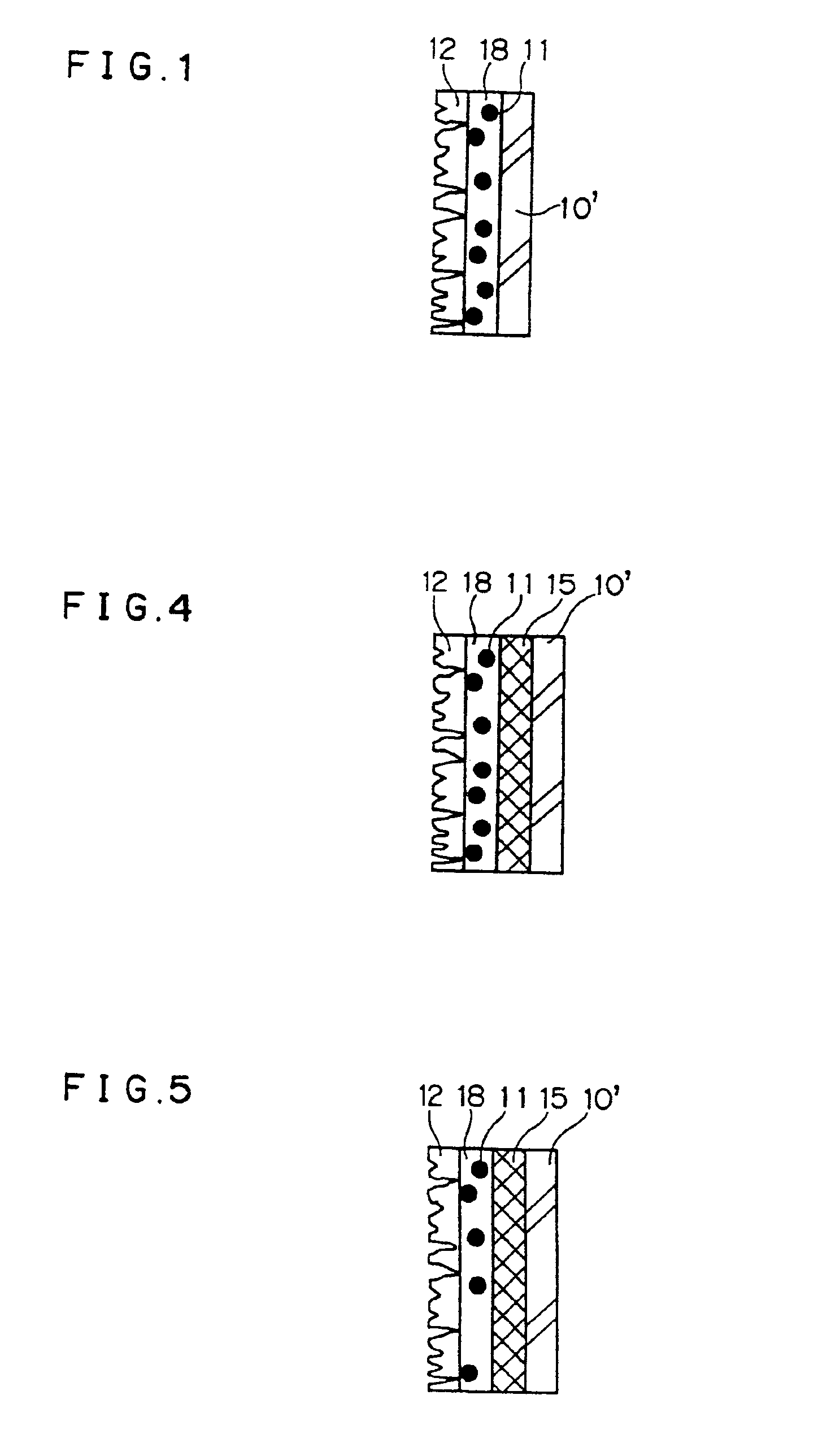

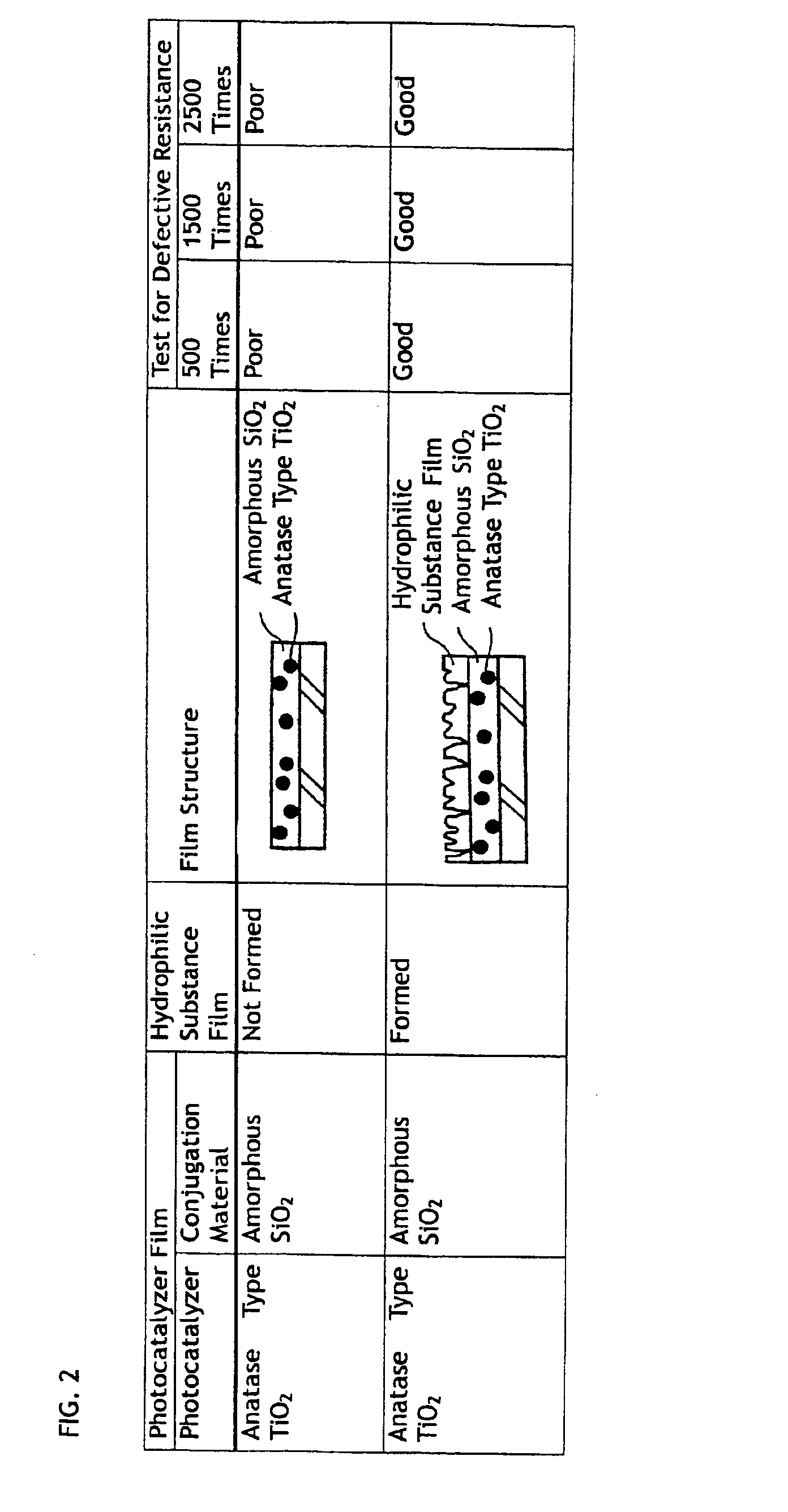

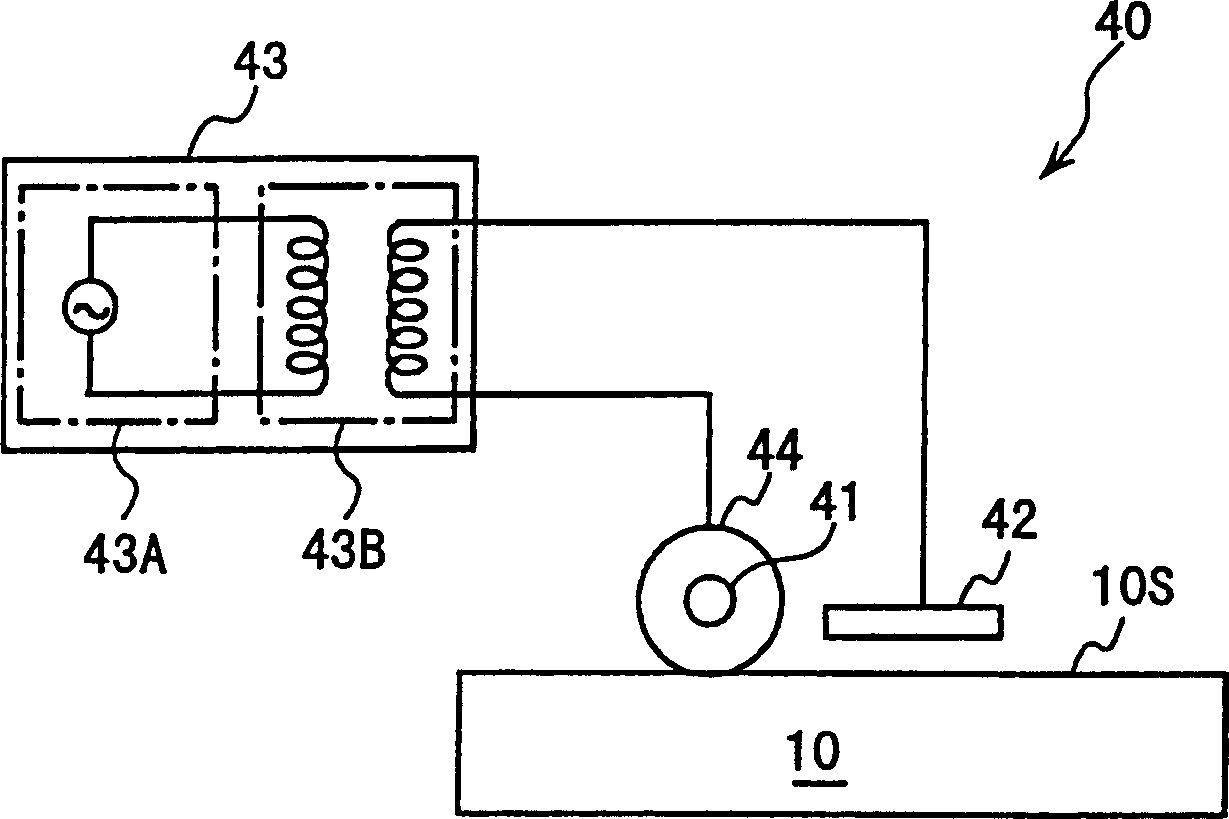

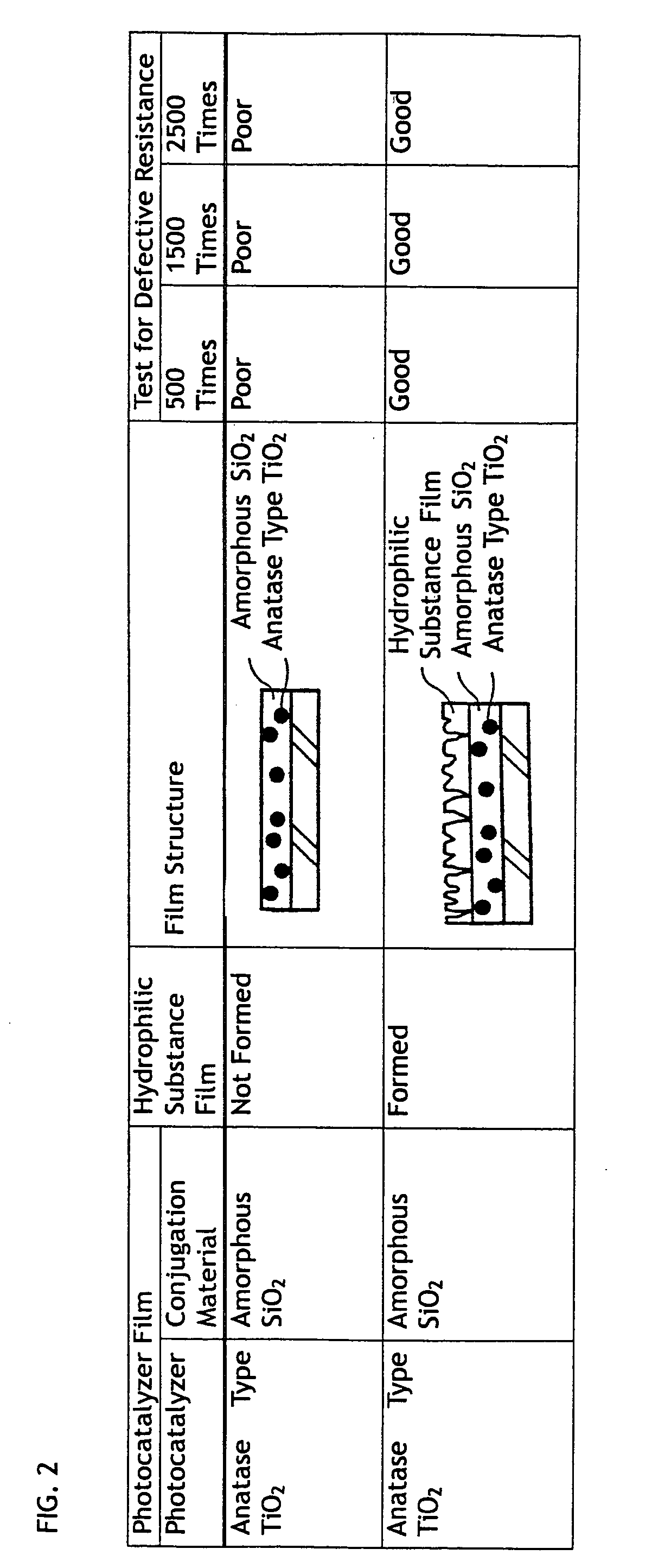

Antifogging element and method for forming the same

A coating agent including photocatalyst particles dispersed in a titanium peroxide solution obtainable by causing titanium hydroxide (orthotitanic acid) gel to act with hydrogen peroxide being used as a material for the photocatalyzer film is used to a photocatalyzer film having photocatalyst particles supported therein. By forming a porous hydrophilic substance film on the photocatalyzer film, the defects of the film caused by the wiping can be prevented. Also, a film formed by using the coating agent including photocatalyst particles dispersed in a titanium peroxide solution at a temperature of from normal room temperature to 200° C. is of high porosity in comparison with a film formed at a higher temperature and with a film not having a photocatalyst particles dispersed therein. Consequently, the photocatalyzer film and the hydrophilic substance film have good adhesion property when use with each other.

Owner:MURAKAMI CORP

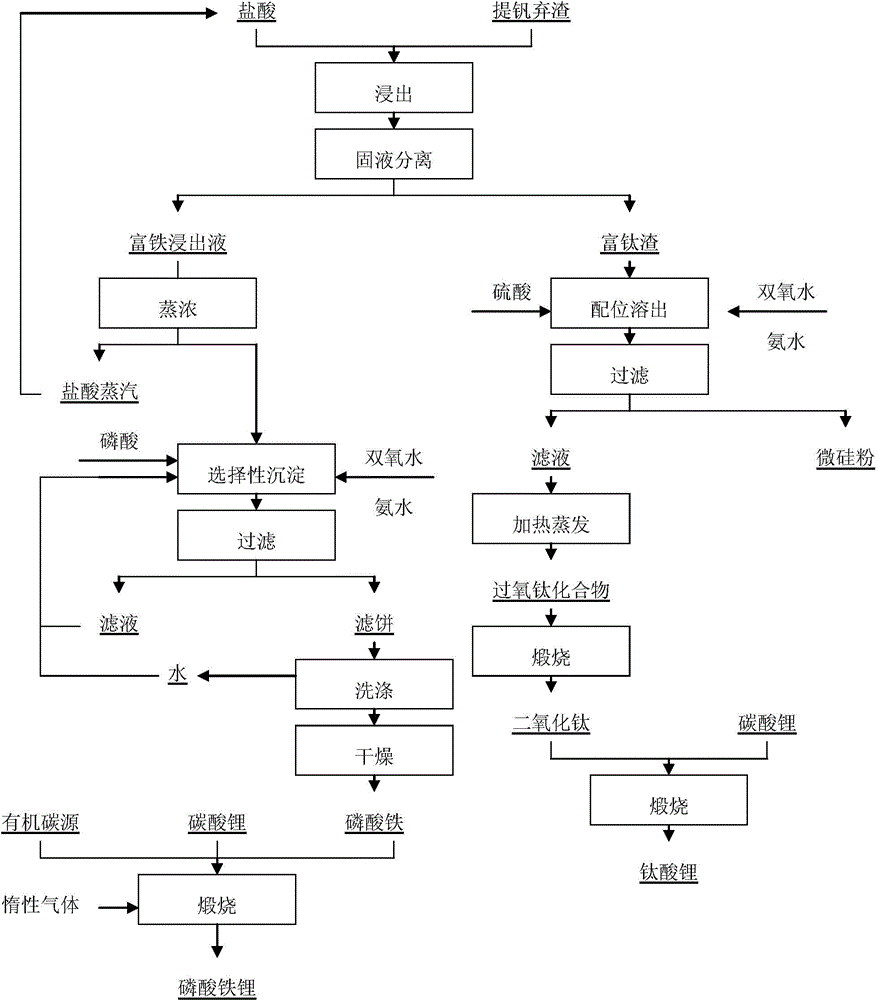

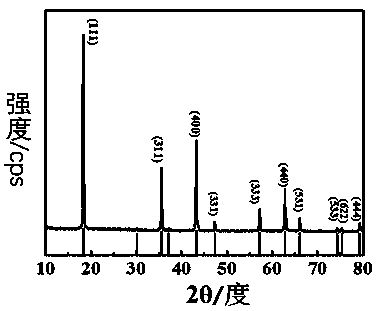

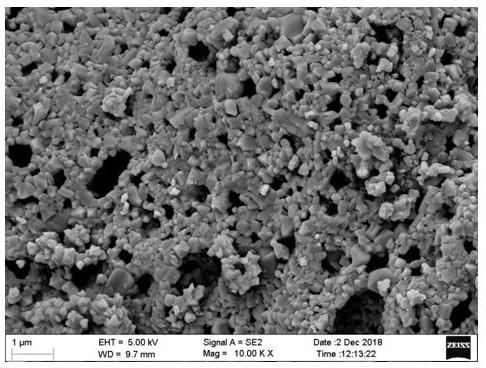

Method for preparing lithium battery electrode materials LiFePO4 and Li4Ti5O12 from vanadium extraction slag

ActiveCN104805299AImprove electrochemical performanceAvoid pollutionTitanium compoundsProcess efficiency improvementSlagPhosphoric acid

The invention discloses a method for preparing lithium battery electrode materials LiFePO4 and Li4Ti5O12 from vanadium extraction slag. The method comprises the following steps: (1), iron and titanium separation: the vanadium extraction slag is leached with hydrochloric acid and filtered to obtain iron-rich leached filtrate and titanium-rich leached residues; (2), preparation of a LiFePO4 precursor: phosphoric acid is added to the iron-rich leached filtrate, H2O2 and ammonia water are added, and the mixture is precipitated, filtered and dried to obtain FePO4 powder; (3) preparation of a LiFePO4 lithium secondary battery cathode material: the FePO4 precursor, Li2CO3 and an organic carbon source are mixed and calcined to obtain LiFePO4 / C; (4) preparation of a Li4Ti5O12 precursor: NH3*H2O is added to the titanium-rich leached residues, the mixture is heated, then H2O2, ammonia water and concentrated H2SO4 are added, and filtrate is subjected to heating reaction and evaporated to dryness to obtain a titanium peroxide compound; (5), preparation of Li4Ti5O12 lithium secondary battery anode material: the titanium peroxide compound is calcined to obtain TiO2, and TiO2 and Li2CO3 are mixed and calcined to obtain Li4Ti5O12. Valuable elements of the vanadium extraction slag are wholly used to acquire a high added-value product, and efficient vanadium extraction slag utilization and environmental protection are realized.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing finishing varnish with photocatalytic activity

The invention discloses a method for preparing a finishing varnish with photocatalytic activity, and the method belongs to the field of building coating. The method comprises the following steps of: dissolving titanium tetrachloride into a cold water to form solution, and dripping excessive hydrogen peroxide into the solution to obtain a titanium peroxide compound; dripping ammonia water into the titanium peroxide compound until the pH of the titanium peroxide compound is 10, stirring to react, filtering and washing to obtain hydration titanium peroxide; and dissolving the hydration titanium peroxide in the water, adding nano silicon dioxide sol for hydrothermal reaction, and thus obtaining a product-nano titanium dioxide compound silicon dioxide gel, i.e. the finishing varnish with photocatalytic activity. When the low-temperature decomposition hydration titanium peroxide is adopted by the method to prepare the nano titanium dioxide sol, the nano silicon dioxide sol is added, so that the photocatalytic activity of nano anatase obtained after the reaction is higher, and a film can be formed later due to hydroxyl on a silicon dioxide surface; and the nano titanium dioxide is an inorganic substance and cannot be easily decomposed through the photochemical catalytic reaction of titanium dioxide.

Owner:FIRST NEW MATERIAL TECH DEV

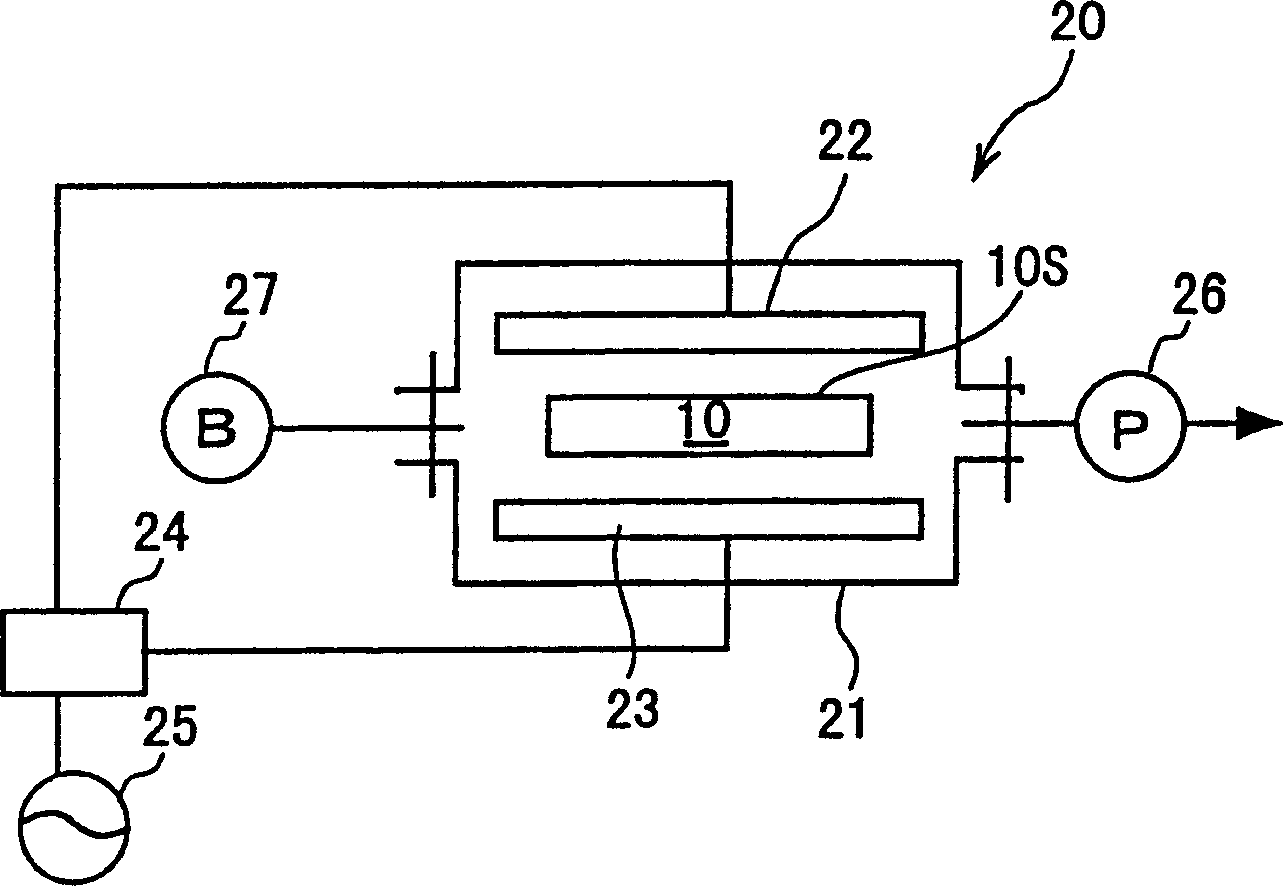

Anti-fogging element and method for forming the same

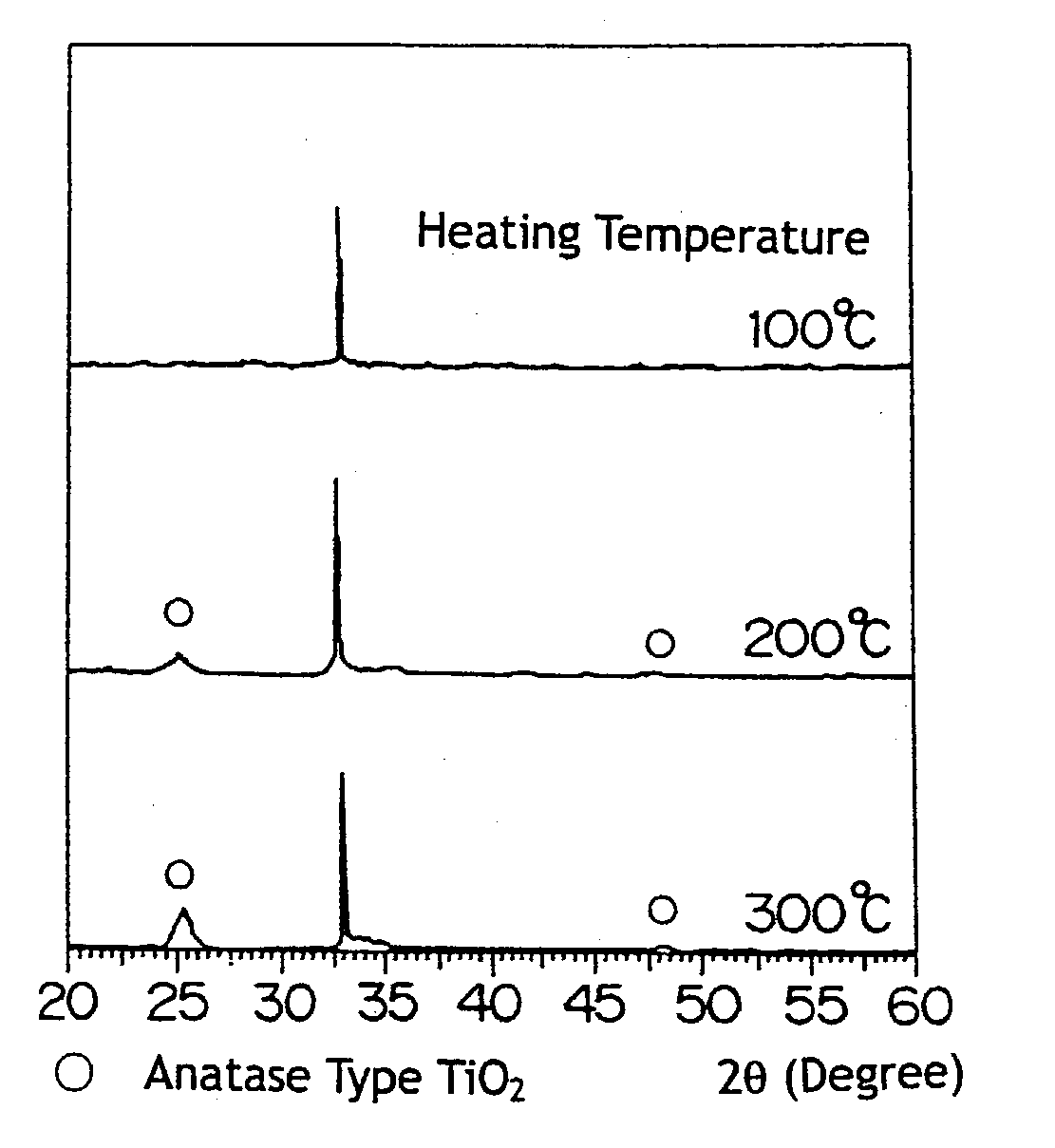

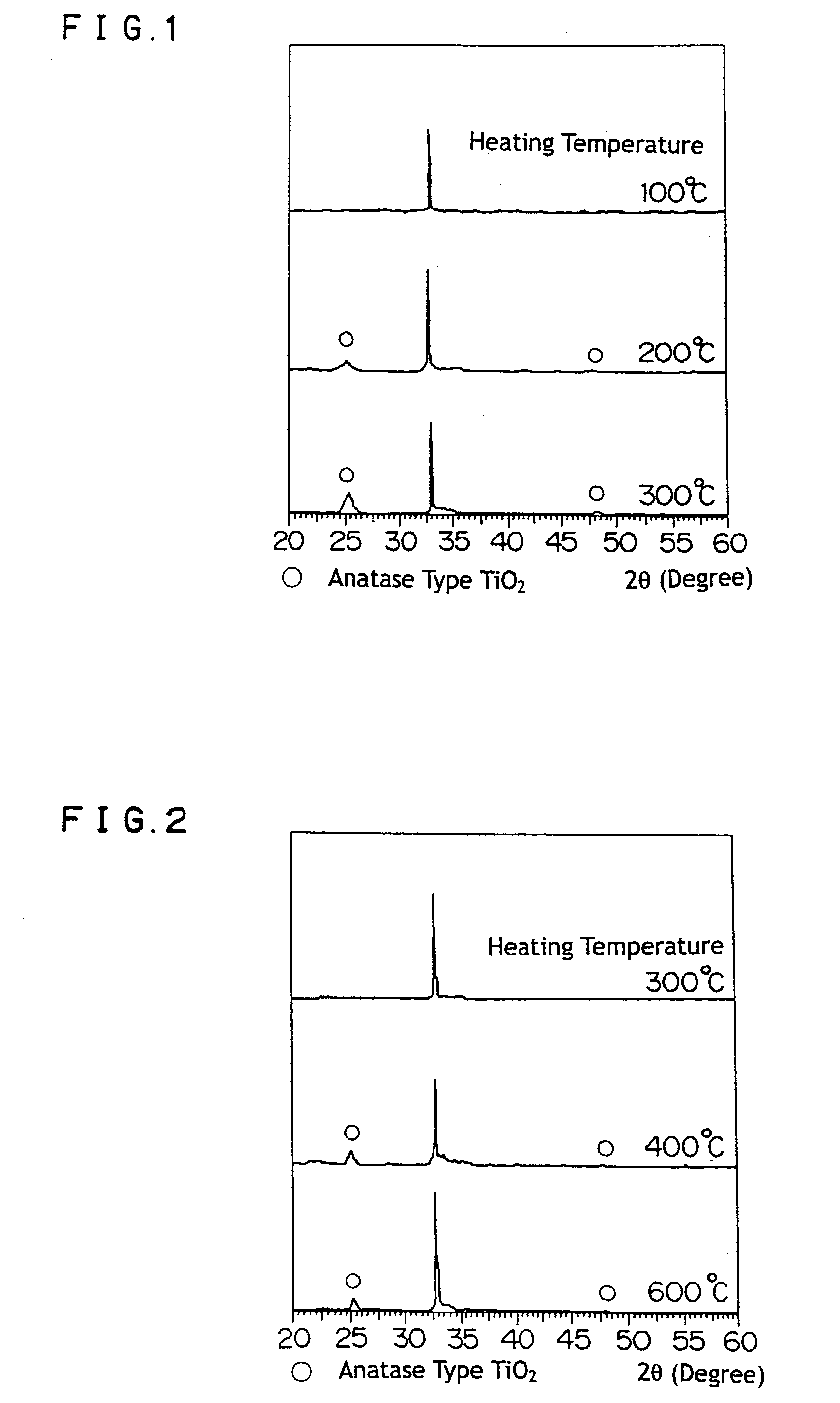

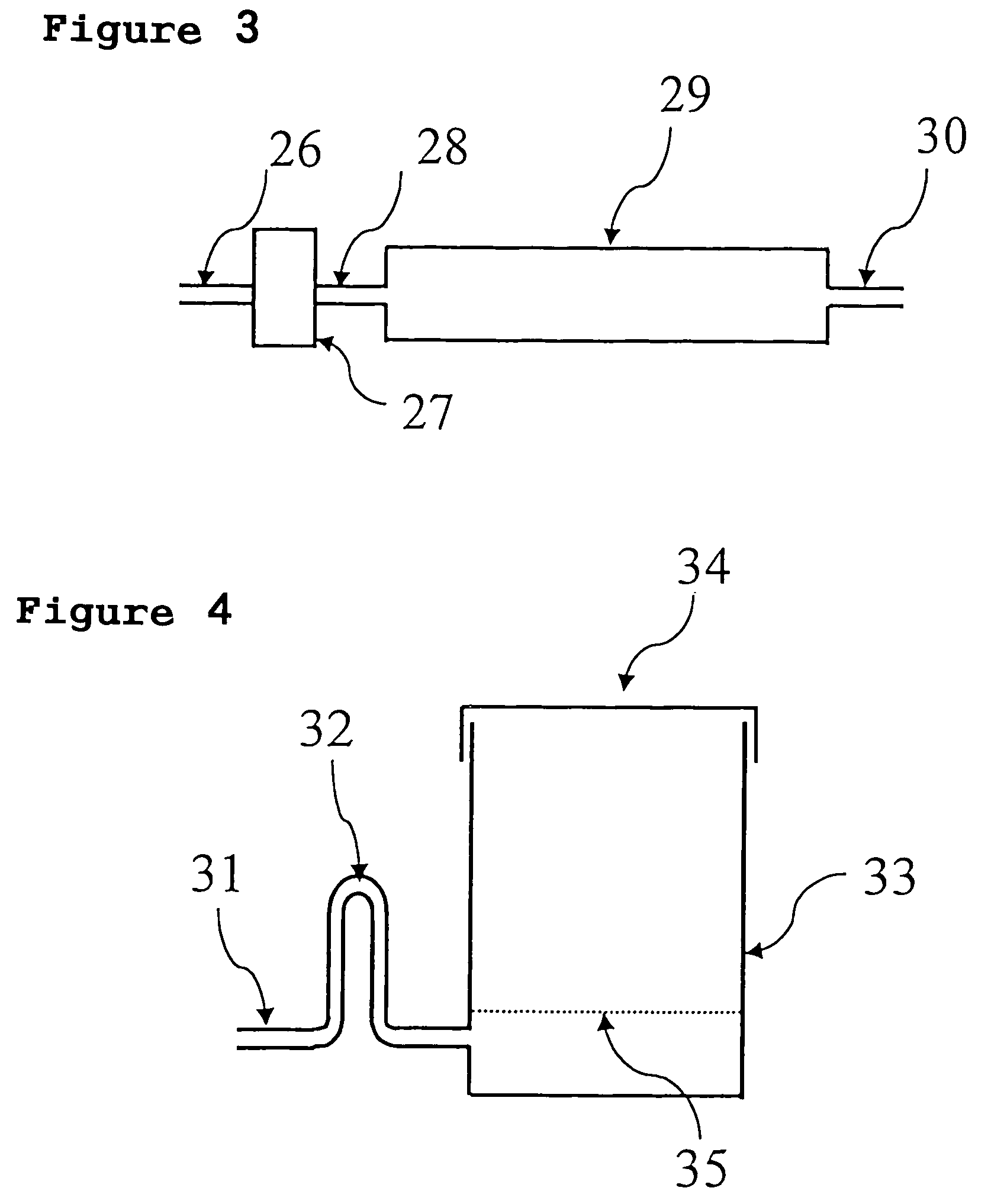

In an anti-fog element comprising a substrate, a photocatalyzer film formed on the surface of the substrate, and a porous hydrophilic film formed thereon, and a process for forming the same, a titanium peroxide solution obtainable by causing a titanium peroxide gel (orthotitanic acid) to act with hydrogen peroxide is used as a material for the photocatalyzer film. When the titanium peroxide solution is used to form a photocatalyzer film, an anatase type titanium dioxide film can be obtained at a low temperature, for example, of 200° C. Consequently, in the course of the fabrication of the anti-fog element, any alkaline substance is difficult to be dispersed into the photocatalyzer film and, thus, even if a soda lime glass is used as the substrate, no film for preventing the alkali dispersion is required. For this reason, no photocatalytic property is impaired even if no film for preventing the alkali dispersion is provided. Due to the treatment at a low temperature, it is difficult for the reflecting film to be oxidized, not impairing the reflecting ratio. What is more, the treatment at a low temperature saves energy and reduces the cost, leading decreased cost.

Owner:MURAKAMI CORP

Process for preparing microporous crystalline titanium silicate

A process for the preparation of crystalline microporous titanium silicates using ethylsilicate-40 and titanium peroxide as silicon and titanium sources respectively is described. The process permits a significant decrease in the production cost of titanium silicate containing higher amount of titanium (Si / Ti=20) because of cheaper raw materials as well as reduction in the quantity of tetarpropylammonium hydroxide (TPAOH) template (SiO2:TPAOH=1:0.06–0.1) required for preparation. The material obtained by the present invention is useful as an active catalyst in the reactions such as oxidation of hydrocarbons, alcohols, sulphides, and thioethers.

Owner:COUNCIL OF SCI & IND RES

Removal of organic dyes and organic pollutants by titanium peroxide gel

InactiveUS20120125844A1Efficient and economical processEfficient and economical for separationIon-exchange process apparatusIon-exchanger regenerationZeta potentialOrganic dye

The one step process of removal of chromophore / dye / organic pollutant from a solution comprising a polymer free titanium oxide gel i.e. high zeta potential is disclosed. The concentration of the chromophores is removed up to 95-100%.

Owner:COUNCIL OF SCI & IND RES

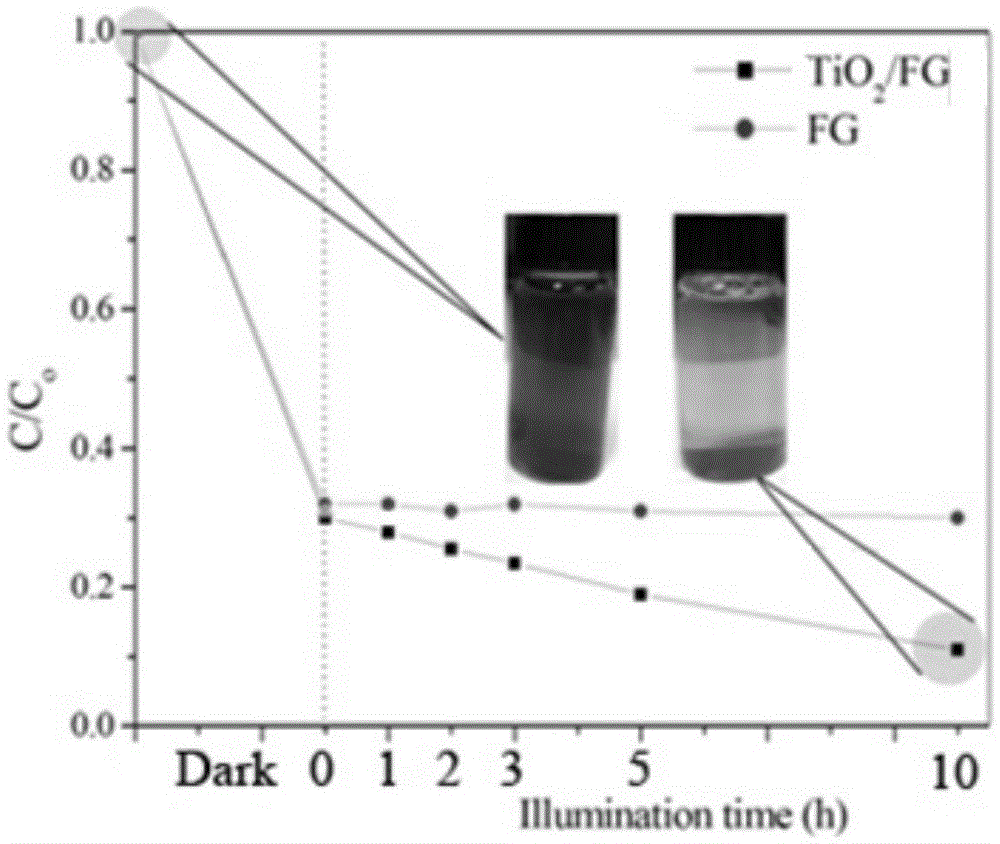

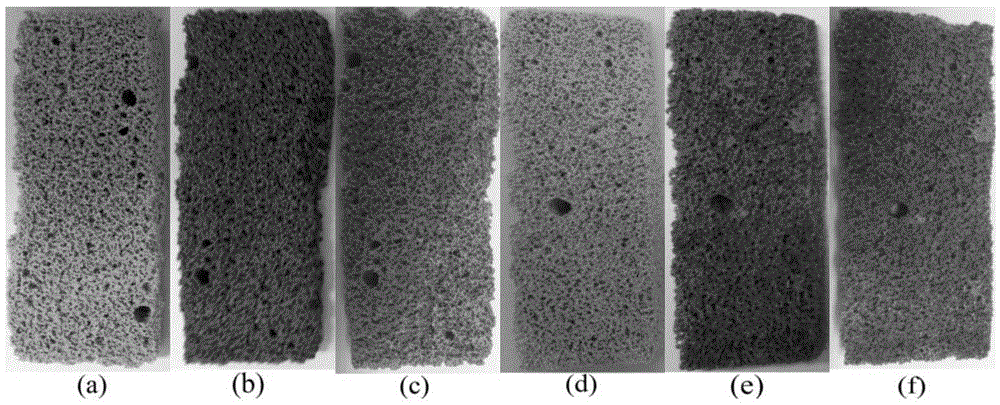

Preparation method of foam glass-loaded titanium dioxide photocatalyst

InactiveCN105618024AImprove photocatalytic efficiencyImprove stabilityPhysical/chemical process catalystsDyeing wastewaterOrganic matter

The invention discloses a preparation method of a foam glass-loaded titanium dioxide photocatalyst, and relates to a photocatalyst. The preparation method comprises the steps that 1, ball milling is performed on solid waste to obtain solid waste powder; 2, water glass is mixed with the solid waste powder obtained in the step 1 to obtain a sticky mixture; 3, pored PU foam is soaked in the sticky mixture obtained in the step 2; 4, the infiltrated PU foam is taken out to be dried and calcined to obtain pored foam glass; 5, the foam glass obtained in the step 4 is soaked in an aqueous titanium peroxide complex solution to enable a titanium peroxide complex to be adsorbed to the foam glass; 6, the foam glass adsorbed with the titanium peroxide complex is taken out to be dried and calcined, and then the foam glass-loaded titanium dioxide photocatalyst is obtained. The prepared foam glass-loaded titanium dioxide photocatalyst has the advantages of being low in density, high in dye adsorption capacity, photocatalytic efficiency and stability and the like and can effectively degrade organic matter in printing and dyeing wastewater.

Owner:XIAMEN UNIV +1

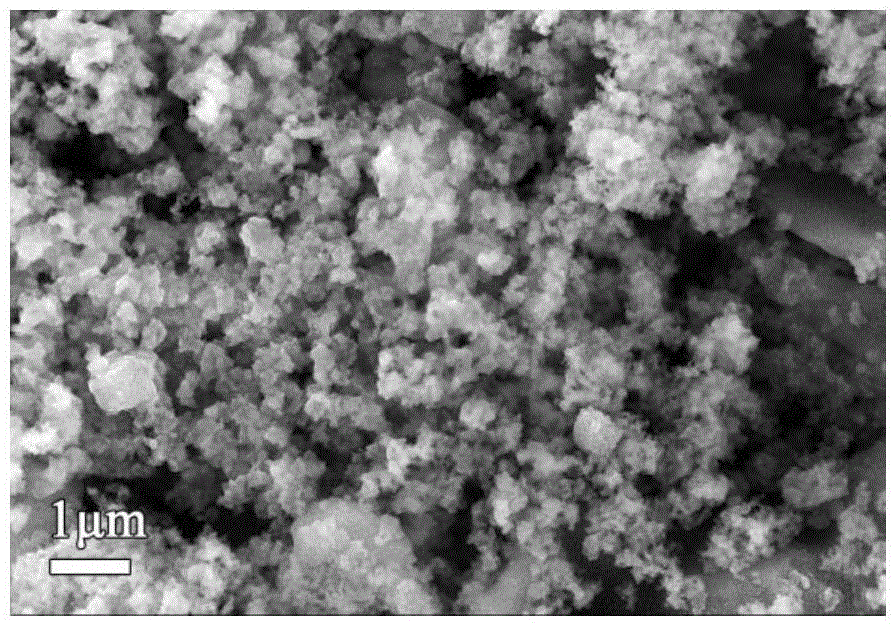

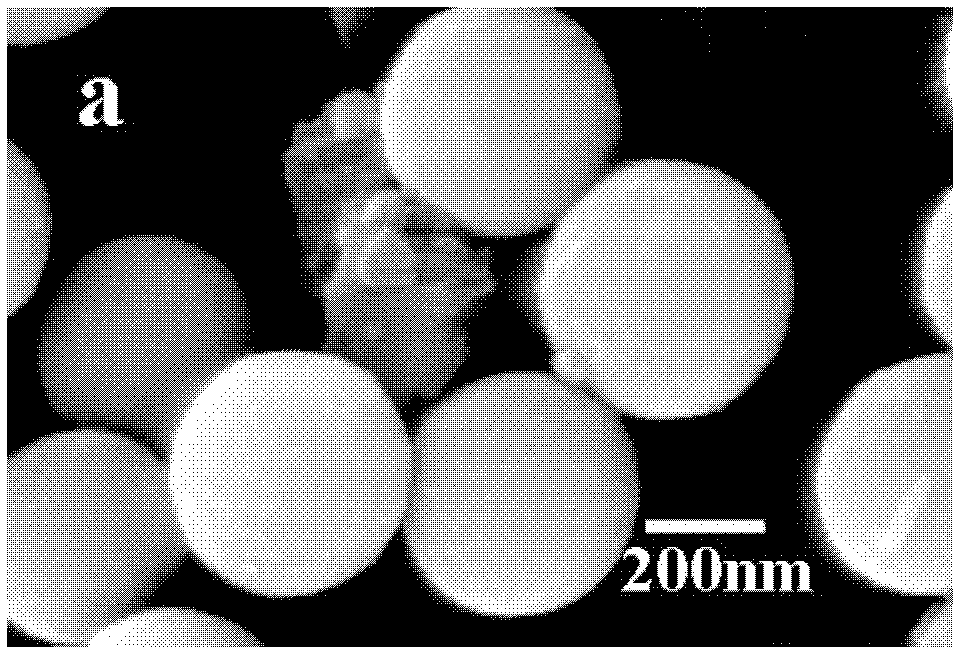

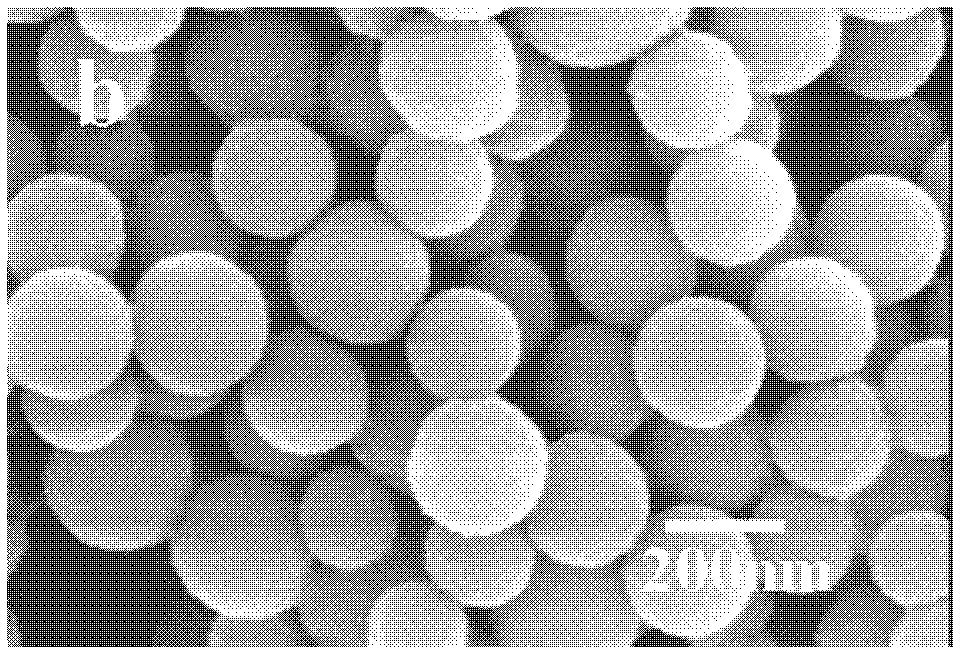

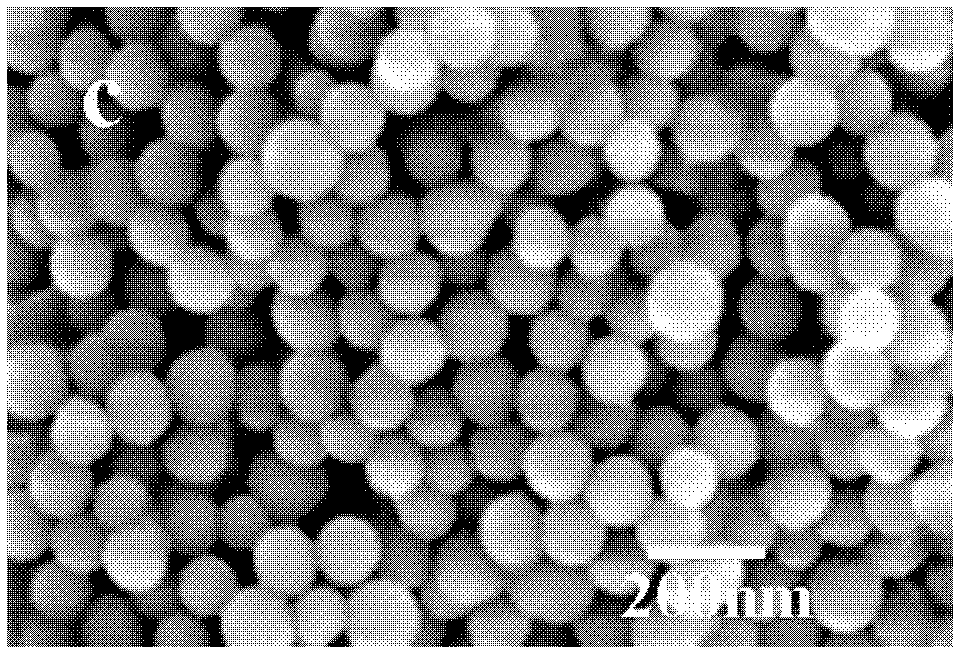

Method for preparing monodisperse submicron microsphere of titanium dioxide

The invention discloses a method for preparing monodisperse submicron microsphere of titanium dioxide, which comprises the following steps: adding a reducing agent in the aqueous solution of titanium peroxide at the temperature of 0 DEG C; aging the obtained mixed solution till the system is white emulsion; and sintering the white emulsion to obtain the monodisperse submicron microsphere of titanium dioxide. The method does not need expensive and harmful organic reagent, and is low in cost, strong in process operability and suitable for mass production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method of preparing a solution for titania film

InactiveUS6267944B1Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationUltraviolet lightsSilicon dioxide

A method of preparing a solution for titanium oxide film is provided such that said solution has the effect of a photocatalyst, by coating, or impregnating therewith a variety of substrates being positioned in a place where no ultraviolet light is emitted.Utilizing a solution for titania film provided by a mixture of a titanium peroxide solution made from a compound of a titanium hydrate gel and a peroxide solution, and a solution forming titanium peroxide particles by calcining said titanium peroxide solution at a temperature over 80° C., particles of capsicin, magnetite and tourmaline, as well as a silica solution are each compounded to said solution for titania film, such that an improved solution for titania film can be obtained having the photocatalystic effect without any exterior light source.

Owner:MORIOKI SANGYO

Method for forming antifouling coating and antifouling material having antifouling coating

InactiveCN1531465AAvoid pollutionAntifouling/underwater paintsPretreated surfacesCorona dischargeUltraviolet

A method for forming an antifouling coating disposed on the surface to be treated of a substrate having a surface comprising a plastic or a rubber, which contains a photocatalyst and an amorphous titanium peroxide having substantially no photocatalytic activity, characterized in that it comprises a step of subjecting the surface to be treated of the substrate to a dry treatment for introducing a hydrophilic group onto the surface, and a step of applying an aqueous coating material containing a photocatalyst and an amorphous titanium peroxide having substantially no photocatalytic activity on the resultant surface after the treatment; and an antifouling material having an antifouling coating formed by the method. The dry treatment is preferably a plasma discharge treatment, a corona discharge treatment or an ultraviolet irradiation treatment.

Owner:BRIDGESTONE CORP

Method for producing titanium oxide

InactiveUS7303738B2Large specific surface areaPhysical/chemical process catalystsTitanium dioxideSteam pressureMetallurgy

Owner:SUMITOMO CHEM CO LTD

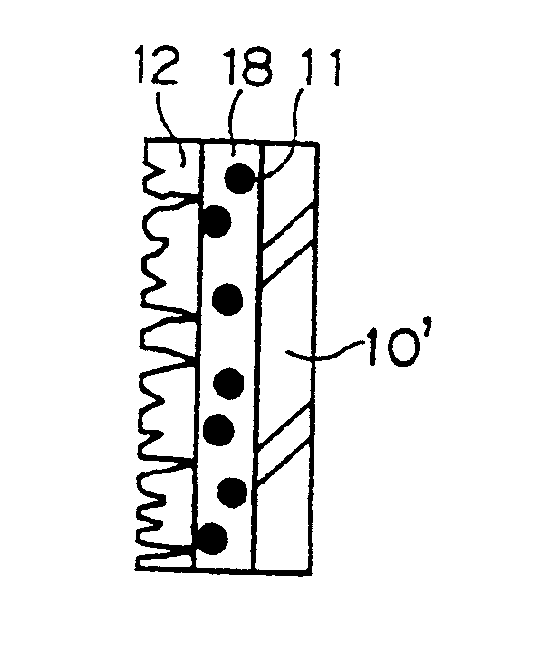

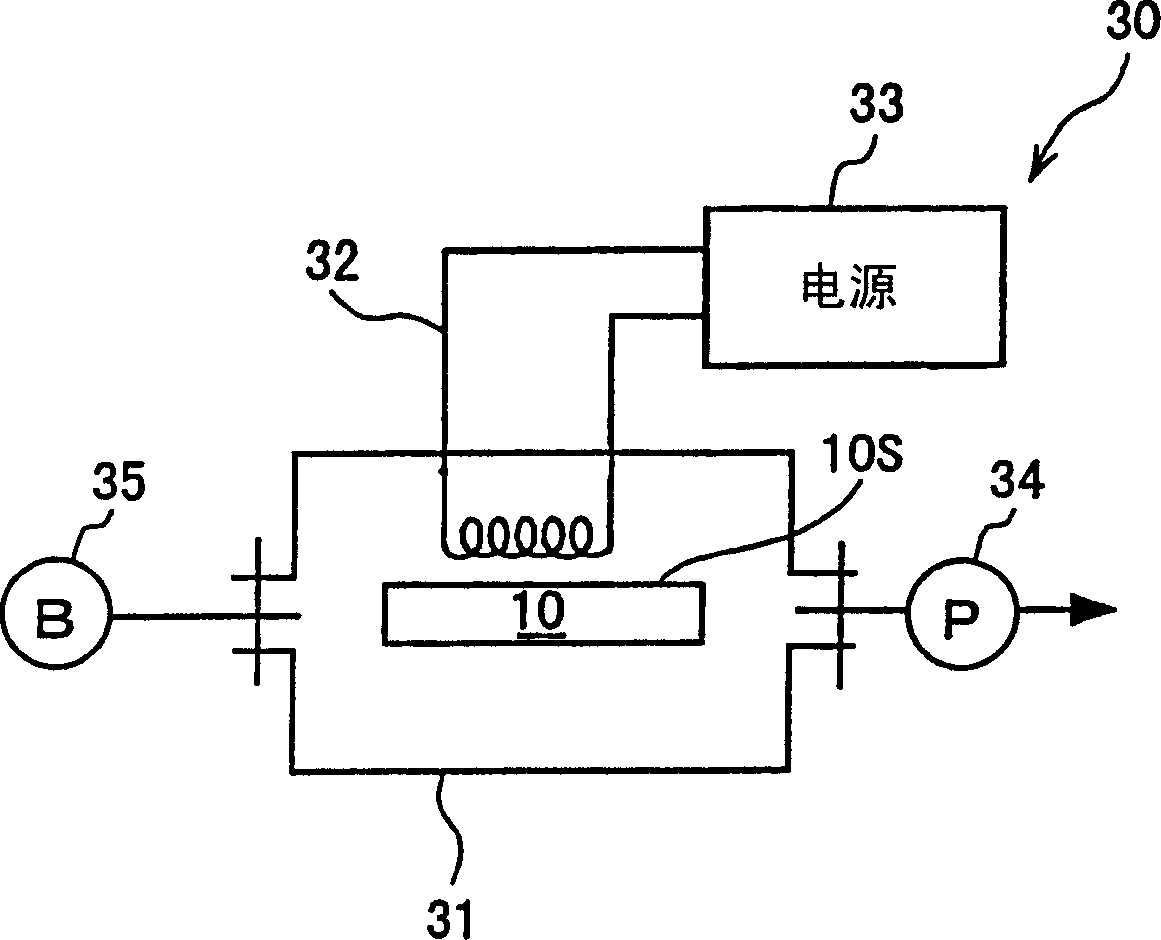

Antifogging element and method for forming the same

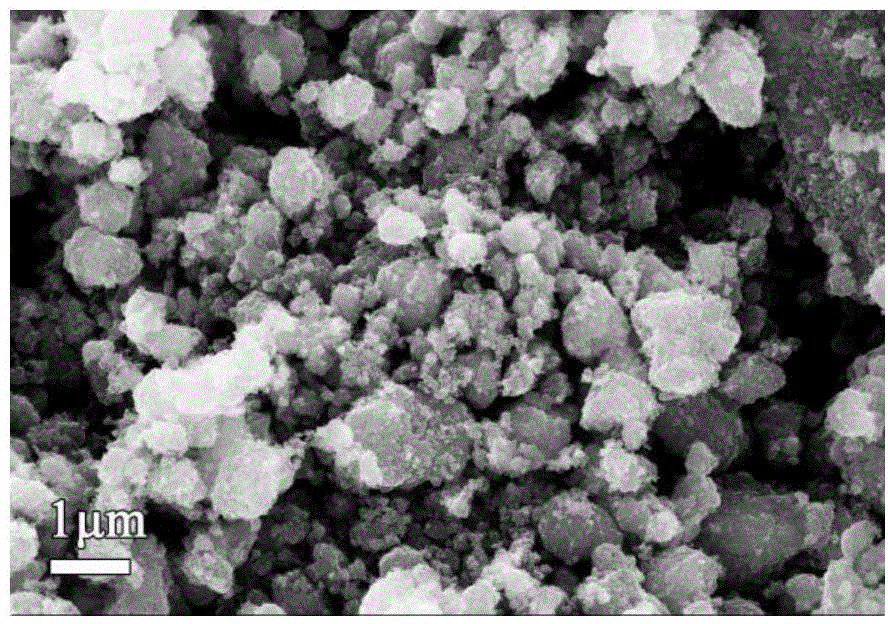

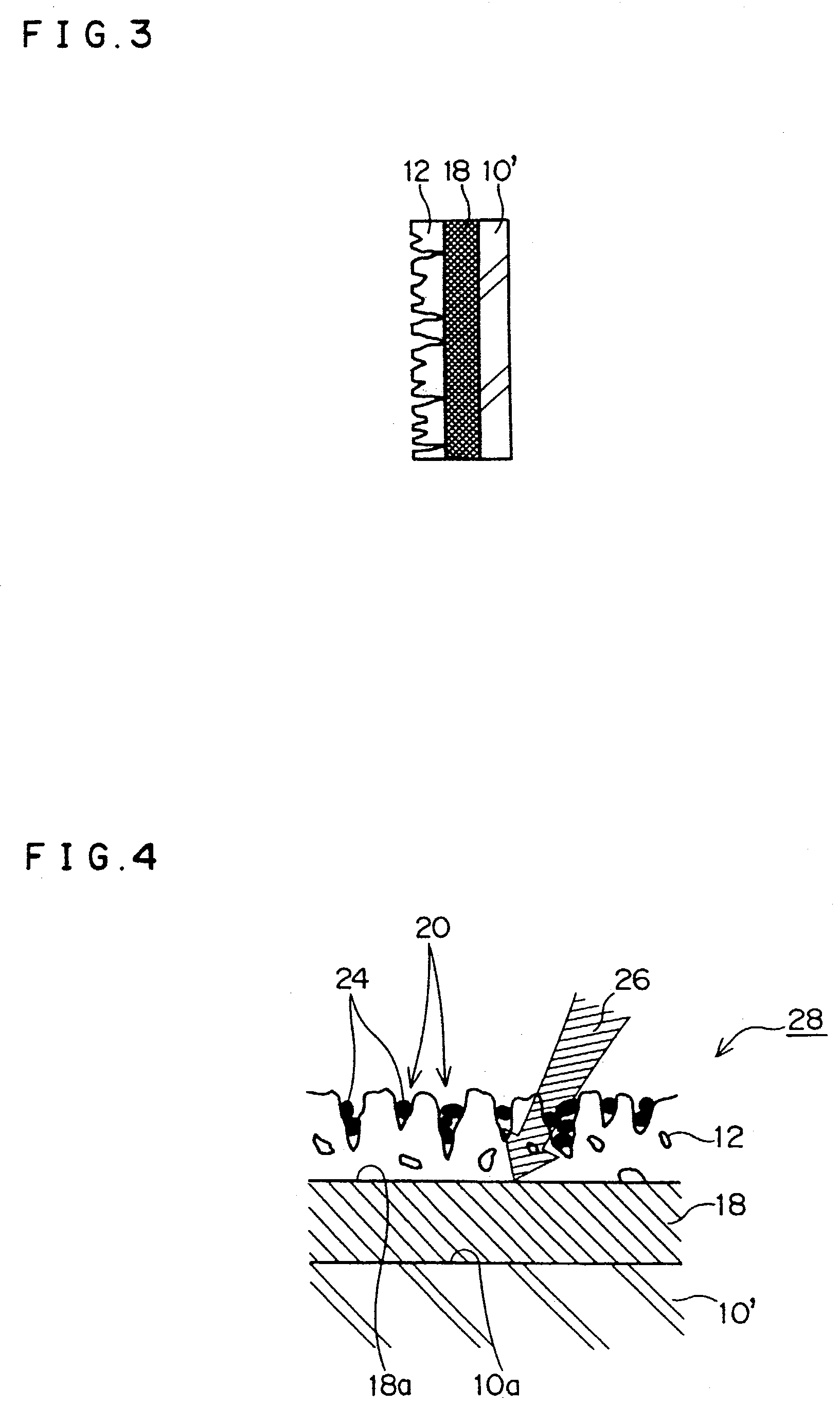

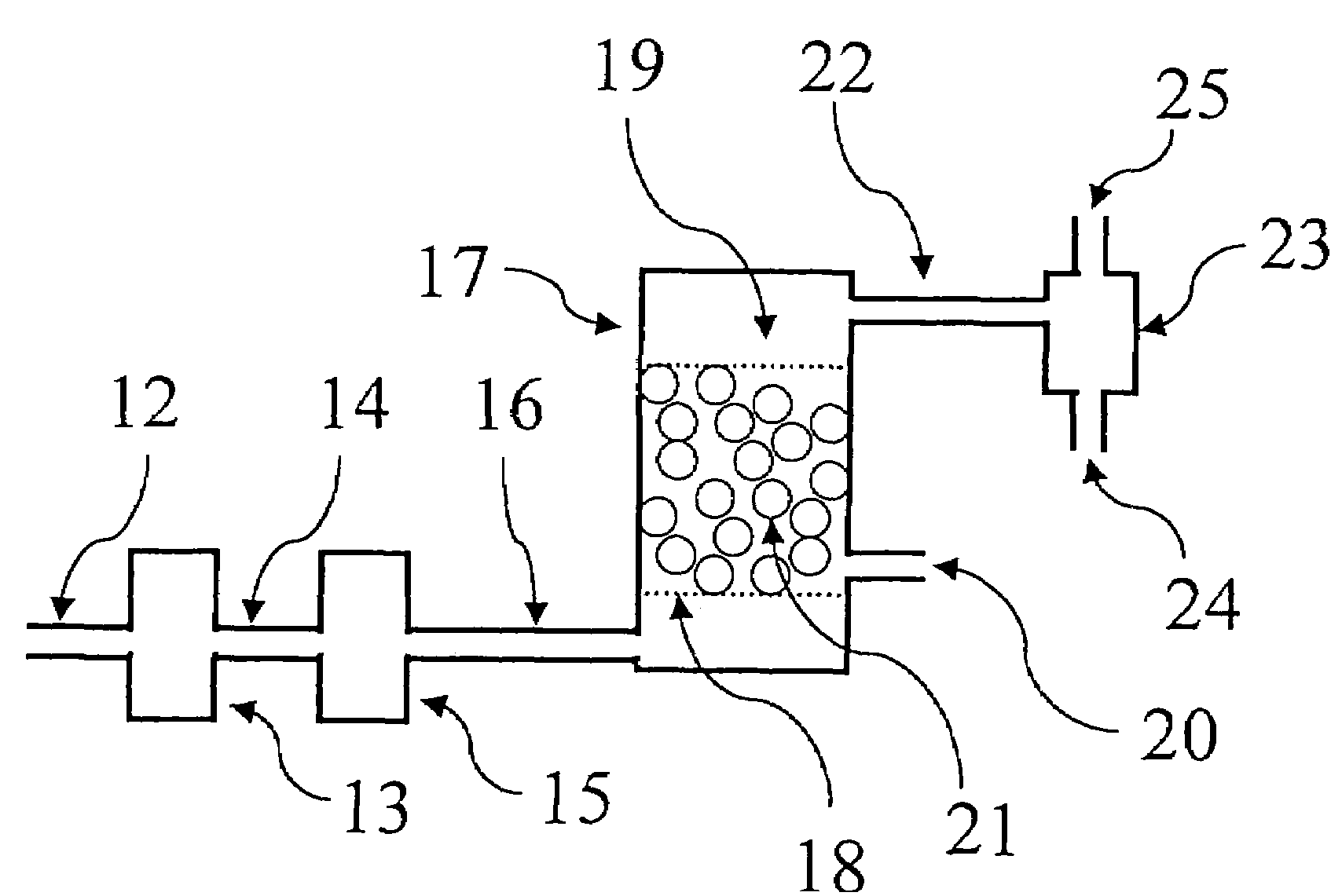

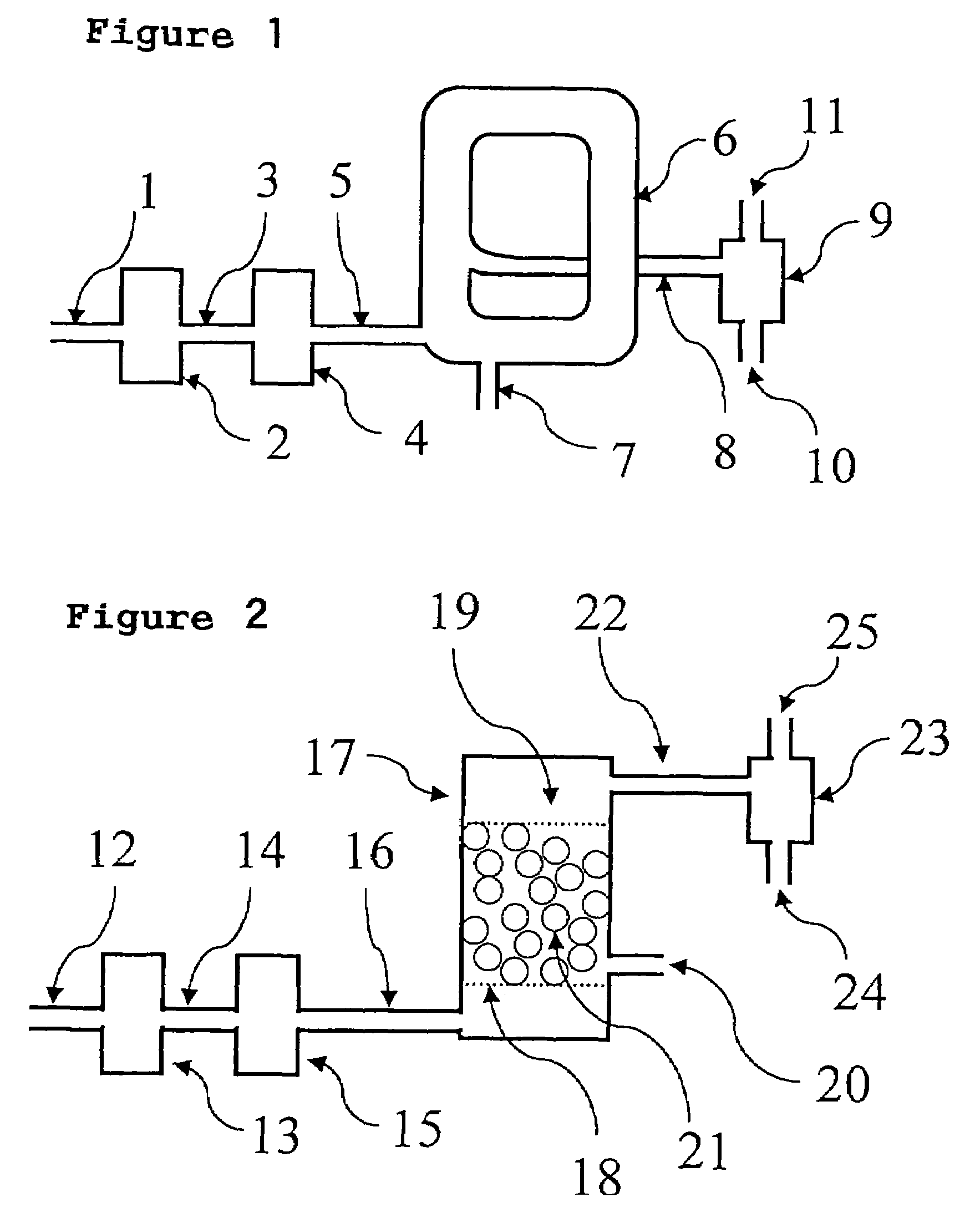

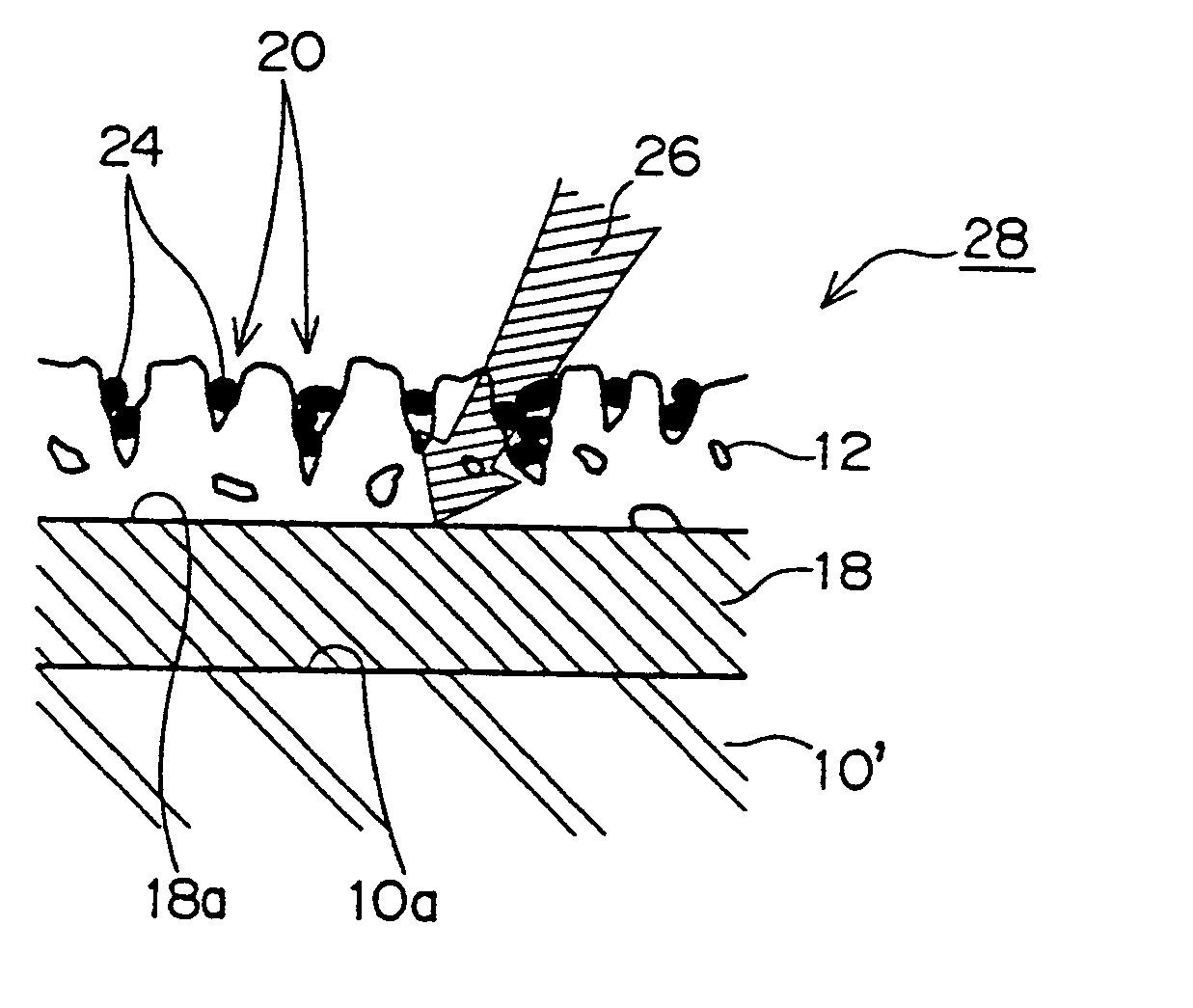

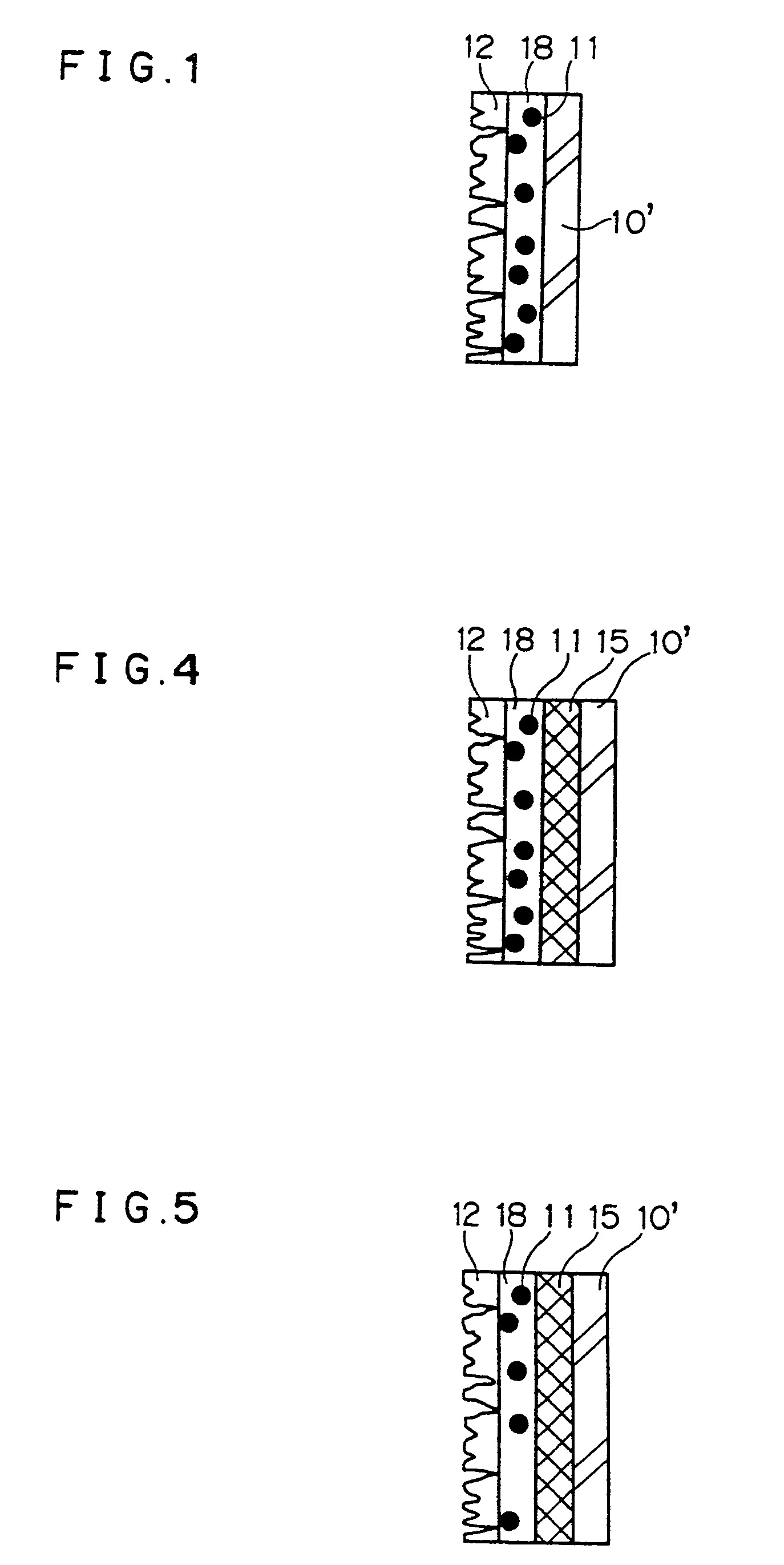

In the present invention, a coating agent comprising photocatalyst particles dispersed in a titanium peroxide solution obtainable by causing titanium hydroxide (orthotitanic acid) gel to act with hydrogen peroxide being used as a material for the photocatalyzer film is used to a photocatalyzer film (18) having photocatalyst particles (18) supported therein. By forming a porous hydrophilic substance film (12) on the photocatalyzer film (18), the defects of the film caused by the wiping can be prevented. Also, a film formed by using the coating agent comprising photocatalyst particles dispersed in a titanium peroxide solution at a temperature of from normal room temperature to 200° C. is of high porosity in comparison with a film formed at a higher temperature and with a film not having a photocatalyst particles dispersed therein. Consequently, the photocatalyzer film (18) and the hydrophilic substance film (12) have good adhesion property when use each other.

Owner:MURAKAMI CORP

Preparation method for polymerizing titanium dioxide by graphene oxide in situ

InactiveCN106698506AAchieve aggregationReduced self-agglomerationCarbon compoundsCatalyst activation/preparationIn situ polymerizationTitanium oxide

The invention discloses a preparation method for polymerizing titanium dioxide by graphene oxide in situ. The method comprises the following steps: preparing graphene oxide suspension liquid; pouring metatitanic acid into the graphene oxide suspension liquid, adding a hydrogen peroxide solution at the concentration of 30 percent slowly and dropwise, stirring, adding ammonia water dropwise to adjust the ph value to be 8.5 to 10, and stirring for 3 to 10 hours to obtain titanium peroxide and graphene oxide sol, wherein the mass ratio of the metatitanic acid to the hydrogen peroxide solution to the graphene oxide suspension liquid is (5-7):(40-60):(100-105); performing heat preservation on the obtained titanium peroxide and graphene oxide sol at 80 to 120 DEG C for 4 to 24 hours; adding the ammonia water into the heated titanium peroxide and graphene oxide sol dropwise to enable the graphene oxide to polymerize the titanium dioxide to separate out of the solution, and filtering and drying to obtain the graphene oxide polymerized doped titanium dioxide. The hydroxyl and the carboxyl on the surface of the graphene oxide and the hydroxyl of the titanium peroxide can perform hydroxyl shrinking reaction or dehydration reaction under the hydrothermal action, so the in-situ polymerization of the titanium dioxide on the surface of the graphene oxide is realized.

Owner:重庆中鼎三正科技有限公司

Manufacturing method of oxygenation type seed treatment agent containing titanium superoxide

ActiveCN102531773APromote germinationPromote rootingFertilizer mixturesTitanium chlorideTitanium citrate

The invention relates to a manufacturing method of an oxygenation type seed treatment agent containing titanium superoxide. The manufacturing method is characterized by comprising the following steps of: neutralizing titanium salt ice water solution with a base to prepare a new precipitate metatitanic acid capable of being dissolved in citric acid; replacing titanium chloride or sulfate with metatitanic acid to be used as a raw material for synthesizing titanium citrate; synthesizing titanium citrate with metatitanic acid as a titanium source and citric acid as an acid solvent and chelating agent by a microwave hot melt chelating process; neutralizing titanium citrate saturated solution with potassium carbonate powder to adjust the pH to 5.5-6.5, and salting out to prepare organic titanium-organic potassium compound salt; carrying out complex reaction on the titanium citrate-potassium citrate compound salt and hydrogen peroxide to prepare potassium citrate compound salt containing titanium superoxide; and compounding potassium citrate compound salt containing titanium superoxide with urea, and mixing with sprout polysaccharide, potassium borate and potassium phosphate to prepare the oxygenation type seed treatment agent containing titanium superoxide. According to the invention, titanium superoxide is used as an oxygenation agent, sterilizing agent and seed germination and rooting accelerant of the seed treatment agent.

Owner:FUJIAN CHAODA MODERN SEED IND

Solution of particles containing titanium dioxide and titanium peroxide complex and preparation thereof

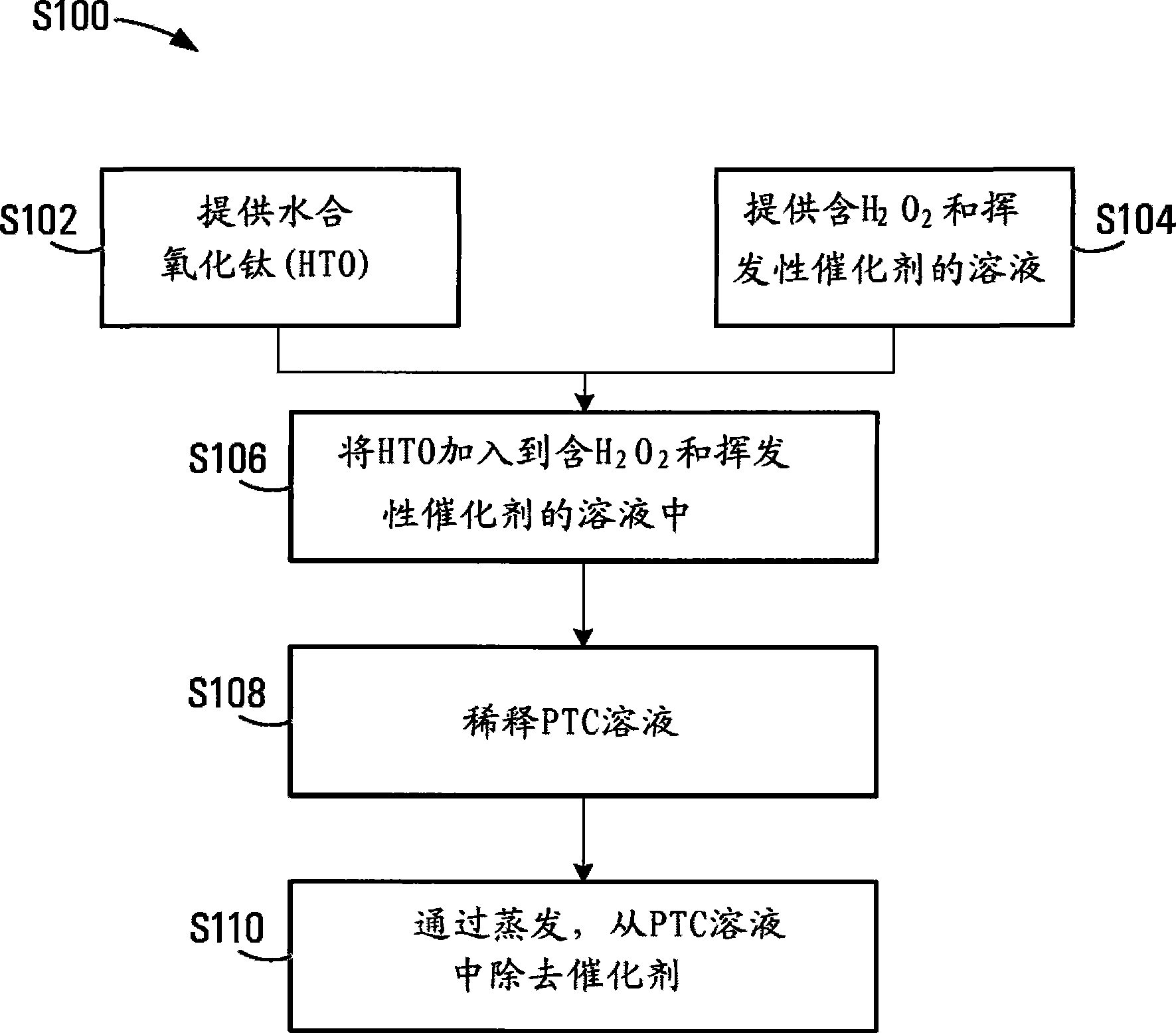

InactiveCN101448742AObvious discolorationObvious precipitationMaterial nanotechnologyTitanium dioxideEvaporationTitanium oxide

In solution, hydrous titanium oxide (HTO) reacts with hydrogen peroxide (H2O2) in the presence of a volatile base catalyst to produce a titanium peroxide complex (PTC), thus preparing solution of titanium dioxide particles. The solution is diluted by at least two folds. Then, part of the volatile catalyst is removed from the solution by evaporation to form the particles, and the particles contain the titanium dioxide and the PTC which is adsorbed on the particle, thus obtaining the transparent solution with the pH being 7. The particles in the solution can have minus 60-minus 80mV xi electric potential, 10nm-25nm particle size and more than 4wt% concentration, such as 6-8wt%.

Owner:AGENCY FOR SCI TECH & RES

Method for synthesizing citricacide-titatnium chelate by microwave chelation process by using new metatitanic acid precipitate

InactiveCN102557919AHigh purityImprove performanceCarboxylic acid salt preparationTitanium chlorideTitanium citrate

The invention relates to a method for synthesizing citricacide-titatnium chelate by a microwave chelation process by using new metatitanic acid precipitate. The method is characterized in that: the new metatitanic acid precipitate is prepared by neutralizing an iced solution of titanium salt by using alkali; the new metatitanic acid precipitate replacing titanium chloride and sulfate is used as raw materials for synthesizing the citricacide-titatnium chelate; and the citricacide-titatnium chelate is synthesized by a microwave hot melting chelation process by using the new metatitanic acid precipitate as a titanium source and citric acid as an acid solvent and chelant. The synthesized citricacide-titatnium chelate is high in purity, does not contain foreign ions such as chlorine ions or sulfur ions, is stable in performance, and can be placed for a long time; titanium gel precipitate is not separated out after the citricacide-titatnium chelate is diluted; and the citricacide-titatnium chelate can be compounded with multiple kinds to metal ions and organic matter, can be reacted with peroxide to form titanium peroxide complex, and can also be compounded into various functional materials. A process is simple and is easy to control.

Owner:福建超大现代农业集团有限公司

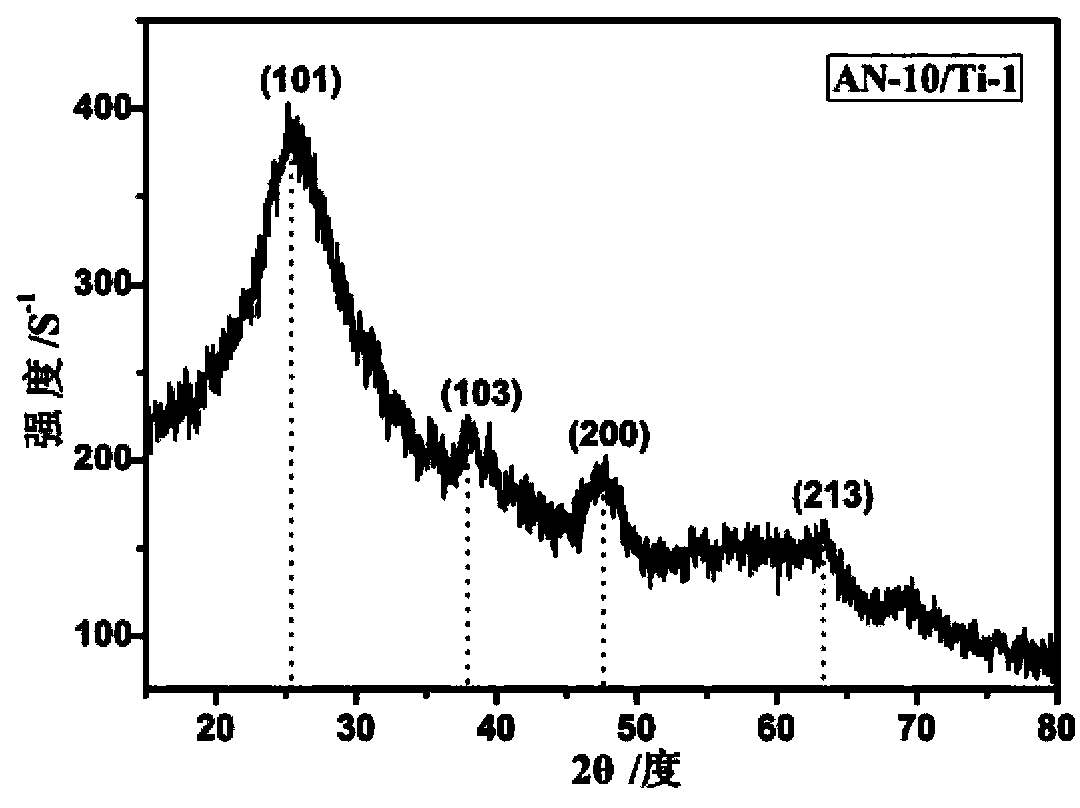

Preparation method for titanium dioxide/carbon nanotube composite nanosheets

InactiveCN109607605ARich sourcesLow priceMaterial nanotechnologyPhysical/chemical process catalystsIce waterCarbon nanotube

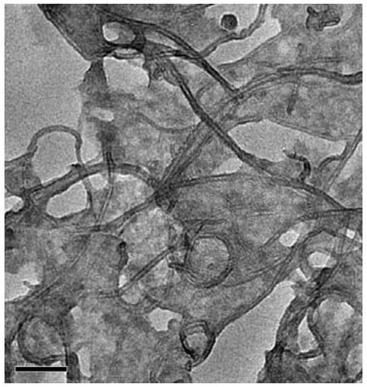

The invention provides a preparation method for titanium dioxide / carbon nanotube composite nanosheets, and relates to the composite nanosheets. The preparation method comprises the following steps: adding a titanium source into deionized water, performing stirring in an ice water bath, adding an alkaline solution, performing a reaction to generate a white precipitate, performing centrifugation toremove a supernatant liquid, performing washing by using water, dispersing the white precipitate into water, adding hydrogen peroxide until the solution is yellow and transparent, adding deionized water for dilution to obtain a titanium peroxide complex aqueous solution, and storing the aqueous solution in a refrigerator for standby application; dispersing the carbon nanotubes into a nitric acid solution, performing reflux treatment, performing centrifugal washing, and dispersing the carbon nanotubes into deionized water; mixing the titanium peroxide complex aqueous solution and the carbon nanotube dispersion liquid, performing stirring, and allowing the stirred material to stand for aging; and freezing the mixed solution obtained after stand aging, performing drying to remove water to obtain a precursor of bulk-shaped dried titanium dioxide / carbon nanotube composite nanosheets, and performing calcination to obtain the titanium dioxide / carbon nanotube composite nanosheets. The titaniumdioxide / carbon nanotube composite nanosheets provided by the invention have a porous two-dimensional laminated structure.

Owner:XIAMEN UNIV

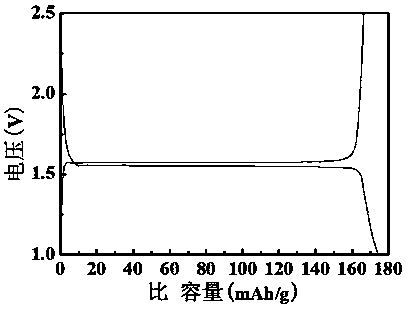

Preparation method of low-cost lithium titanate material

InactiveCN109888272ALow costReduce energy consumptionCell electrodesSecondary cellsLithiumCharge discharge

The invention provides a preparation method of a low-cost lithium titanate material. The preparation method comprises the following steps of (1) allowing metatitanic acid to react with hydrogen peroxide, adding an appropriate amount of ammonia water to form a stable titanium peroxide complex solution; and (2) weighting a lithium source according to a proportion, adding the lithium source into thetitanium peroxide complex solution prepared in the step (1), adding a dispersing agent, stirring to form a uniform solution, and drying and roasting to prepare the lithium titanate material. The low-cost metatitanic acid (the cost is about one third of titanium dioxide) is a titanium source, the cost is reduced, the appropriate amount of hydrogen peroxide and the ammonia water to prepare the stable titanium peroxide complex compound, the titanium peroxide complex compound more fully reacts with a lithium salt, the prepared lithium titanate material is excellent in performance, the half-batteryinitial capacity is 174mAh / g, and the initial charge-discharge efficiency is larger than 95%.

Owner:郑州中科新兴产业技术研究院 +1

Method for preparing TiO2 film on flexible substrate

ActiveCN103898492AEfficient depositionNo heat treatmentSolid/suspension decomposition chemical coatingRoom temperatureTitanium

The invention discloses a method for preparing a TiO2 film on a flexible substrate. According to the method, based on a titanium peroxide technology, by using phenylamine a reducing agent, through a reducing function of phenylamine to titanium peroxide, an anatase type TiO2 functional film is deposited on the surface of the flexible substrate at a normal temperature; and the generated TiO2 particles uniformly cover the surface of the substrate and are firmly combined with the substrate, and the obtained TiO2 flexible film is better in photocatalytic performance. The method is performed at a normal temperature, and no heat treatment is needed in a preparation process, and the method is simple and easy to operate.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Photocatalytically-active, self-cleaning aqueous coating compositions and methods

Method for producing novel photochemically-active metal oxide-containing aqueous compositions such as TiO2 compositions coated or sprayed and dried under ambient conditions to form novel photochemically-active, colorless coatings having strong wetability and adhesion to clear substrates such as window glass. Preferably the present compositions include a suitable wetting agent or combination of agents to improve the wetability of the Titanium peroxide-containing amorphous film, allowing thinner films to be readily applied. Also the inclusion of an acrylic aliphatic urethane polymer can replace wholly or partially the titanium peroxide sol and provide additional film forming and wetability properties. The acrylic urethane polymer reduces or eliminates the amount of titanyl peroxide that is required and thereby reduces or eliminates the yellow color.

Owner:PRIZMALITE IND

Preparation method of polymer foam material with purifying function

The invention discloses a preparation method of a polymer material with a purifying function. The method comprises the following steps: (1) synthesizing an acidic titanium peroxide precursor; (2) preparing a water-soluble low-molecular-weight chitosan titanium oxide composite; and (3) preparing the polyurethane foam with the purifying function. According to the preparation method disclosed by theinvention, by adopting the chitosan - the exclusive natural alkaline polysaccharide, the polymer foam material prepared by the preparation method has a good antibacterial effect. After being degradedby acidic titanium peroxide, the low-molecular-weight chitosan is formed, so that the water solubility is good, and the antibacterial effect under a light-free dark field condition is provided; and secondly, the water-soluble titanium peroxide is used as a foam generation source in the forming process of the foam, the embedding effect of a polymer can be avoided, and the foam is automatically exposed, so that the foam with a good photocatalytic purification effect can be formed. By combining the chitosan and the water-soluble titanium peroxide, the polymer foam material which is antibacterialin a dark field and is automatically deodorized, purified and regenerated after the lighting can be formed.

Owner:NATURE ENVIRONMENTAL PROTECTION TECH

Preparation method of transparent, self-cleaning, antibacterial, and wear-resistant coating on polymer surface

The invention discloses a processing method of a transparent, self-cleaning, antibacterial, and wear-resistant coating on the polymer surface. The preparation method comprises the following steps: preparing a titanium peroxide solution; preparing a titanium peroxide compounded complex solution; preprocessing a substrate; impregnating the substrate into the titanium peroxide compounded complex solution, and carrying out a heat treatment to obtaina transparent, self-cleaning, antibacterial, and wear-resistant coating on the substrate. The provided method can produce a transition metal oxide coating on the surface of a substrate, the coating has a large surface and photoelectrical function, the production cost is low, no pricy equipment is needed, and the procedure is simple. Through the redox reactions between polymer monomers with a conjugate structure and a transition metal peroxide compounded complex, the destruction to adhesive and substrate due to optical corrosion of optical active oxides is avoided, and moreover, the optical activity is enhanced through the heterojunction effect. Besides, through the design and synthesis of a peroxide compounded complex system, the application range of painting by utilizing the redox reactions between polymer monomers with a conjugate structure and a transition metal peroxide compounded complex is enlarged.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of titanium dioxide-metal water-based nanometer composite sol

ActiveCN104226210AEffective Composite StructureAvoid heterogeneous nucleationNanotechnologyColloidal chemistry detailsWater basedSuperoxide

The invention discloses a preparation method of titanium dioxide-metal water-based nanometer composite sol. The preparation method comprises the following steps: 1, dissolving metal salt in water to obtain a metal salt water solution, and reflowing the metal salt water solution by heating while adding a reducing agent water solution until a reflowing water solution system discolors for later use, wherein a mol ratio of the added reducing agent to metal ions is 1-50; 2, dissolving titanate in an aqueous solution of hydrogen peroxide to obtain an aqueous solution of titanium superoxide, regulating the pH value of the aqueous solution of titanium superoxide by virtue of an inorganic aqueous alkali solution; and 3, adding the aqueous solution of titanium superoxide prepared in the step 2 into the discolored metal salt water solution prepared in the step 1 to obtain a composite solution, and reflowing the composite solution by heating to obtain the final product. According to the preparation method disclosed by the invention, a metal-oxide composite structure can be effectively formed, and the process operability is high; the preparation method is suitable for batch preparation, and has a possibility of industrialized production and wide practicability.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com