Preparation method of polymer foam material with purifying function

A technology of polymer materials and manufacturing methods, applied in the field of functional polymer polymer materials, can solve the problems that photocatalytic materials cannot produce effects, photocatalytic materials cannot produce catalytic effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

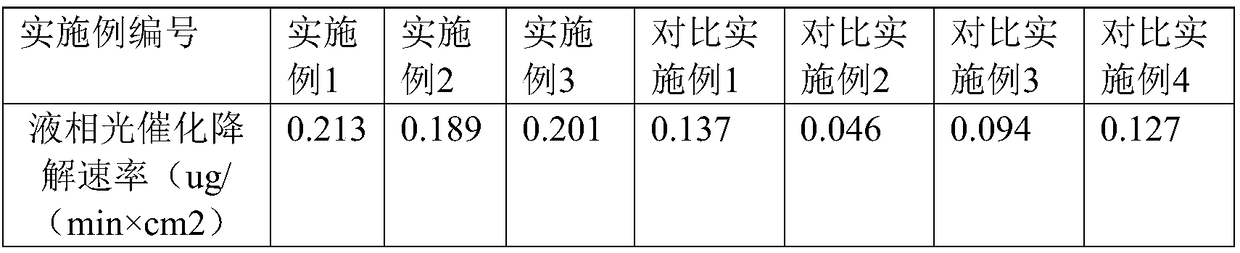

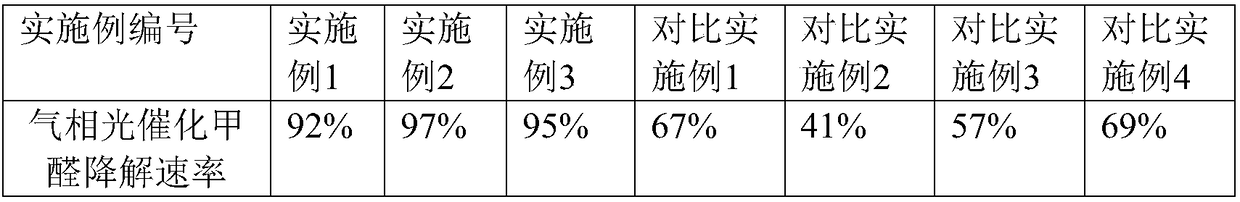

Examples

Embodiment 1

[0035] First, dissolve 100 g of titanyl sulfate with 500 ml of deionized water to obtain a titanyl sulfate aqueous solution; titrate the titanyl sulfate solution with 36% ammonia water to a pH of 9 to obtain a precipitate, wash with deionized water 3 times, and obtain the original titanium acid. Dissolve 5g of orthotitanic acid in 30% aqueous hydrogen peroxide solution to obtain titanium peroxide aqueous solution (H 2 o 2 The molecular molar ratio with Ti is 4:1), and the pH of the titanium peroxide aqueous solution is adjusted to be about 3 to obtain an acidic titanium peroxide solution with a mass percent concentration of 2.5% acetic acid;

[0036] Take 20mL of the acidic titanium peroxide with the above-mentioned pH=3 and a Ti concentration of 0.11mol / L, slowly add a chitosan solution with a mass concentration of 20%, wherein the mass percentage of titanium peroxide and chitosan is 0.2:1, and stir Evenly, pour condensed water, control the water temperature not to exceed 5...

Embodiment 2

[0040] First dissolve 10g of titanium tetrachloride with 500ml of deionized water to obtain an aqueous solution of titanium chloride; titrate the titanium chloride solution to a pH of 9 with a mass concentration of 36% ammonia water to obtain a precipitate, wash 3 times with deionized water to obtain the original titanic acid. Dissolve 5g of orthotitanic acid in 30% aqueous hydrogen peroxide solution to obtain titanium peroxide aqueous solution (H 2 o 2 The molecular molar ratio to Ti is 6:1), and the pH of the titanium peroxide aqueous solution is adjusted to be about 4 to obtain an acidic titanium peroxide solution with a mass percent concentration of 5% citric acid;

[0041] Take 20mL of the acidic titanium peroxide with the above-mentioned pH=3 and a Ti concentration of 0.11mol / L, slowly add a chitosan solution with a mass concentration of 20%, wherein the mass percentage of titanium peroxide and chitosan is 2:1, and stir Evenly, pour condensed water, control the water t...

Embodiment 3

[0045] First dissolve 100g of titanium tetrafluoride with 500ml of deionized water to obtain an aqueous solution of titanium fluoride; titrate the titanyl sulfate solution to a pH of 9 with ammonia water with a mass concentration of 36% to obtain a precipitate, wash 3 times with deionized water to obtain the original titanic acid. Dissolve 5g of orthotitanic acid in 30% aqueous hydrogen peroxide solution to obtain titanium peroxide aqueous solution (H 2 o 2 The molecular molar ratio to Ti is 25:1), and the pH of the titanium peroxide aqueous solution is adjusted to be about 1 to obtain an acidic titanium peroxide solution with a mass percent concentration of 10% oxalic acid;

[0046] Take 20mL of the acidic titanium peroxide with the above-mentioned pH=3 and a Ti concentration of 0.11mol / L, and slowly add chitosan solids with a mass concentration of 20%, wherein the mass percentage of titanium peroxide and chitosan is 0.6:1, and stir Evenly, pour condensed water, control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com