Method for preparing monodisperse submicron microsphere of titanium dioxide

A titanium dioxide, sub-micron technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of expensive precursors and solvents, difficulty in scale-up production, environmental pollution, etc., and achieve strong process operability and wide application prospects , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of monodisperse submicron titanium dioxide microspheres, comprising the following steps:

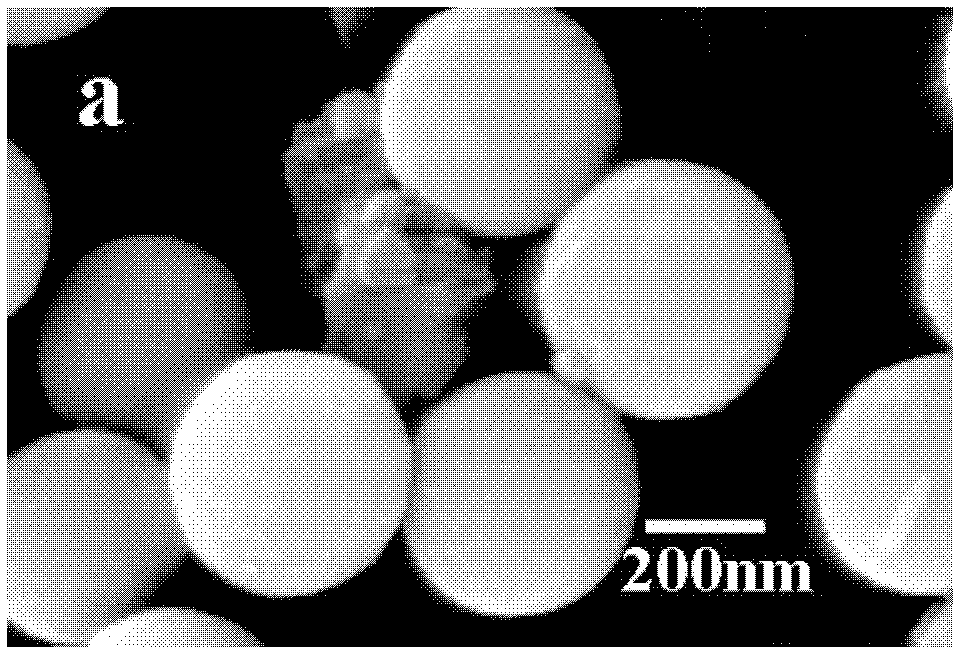

[0031] Heat and dissolve ilmenite with a concentration of 80% sulfuric acid (mass ratio ilmenite: sulfuric acid = 1: 2) to obtain a solid phase deposit, leaching with water, filtering to remove insoluble slag, freezing and recrystallizing, and filtering to remove ferrous sulfate , to obtain titanium liquid; adjust the pH value of titanium liquid to 7 with ammonia water to obtain orthotitanic acid precipitation; get 100 g of the washed and filtered precipitate and disperse it in 55 ml of hydrogen peroxide solution with a mass concentration of 30% to obtain peroxide Titanium aqueous solution; under 0 ℃ of ice-water bath conditions, add 19.2ml, the mass percent concentration is the hydrazine hydrate aqueous solution of 80% to the obtained titanium peroxide aqueous solution, and the obtained mixed solution is aged at 0 ℃ for 72 hours, and the The obtained white em...

Embodiment 2

[0034] A preparation method of monodisperse submicron titanium dioxide microspheres, comprising the following steps:

[0035] Orthotitanic acid precipitate was obtained in the same manner as in Example 1.

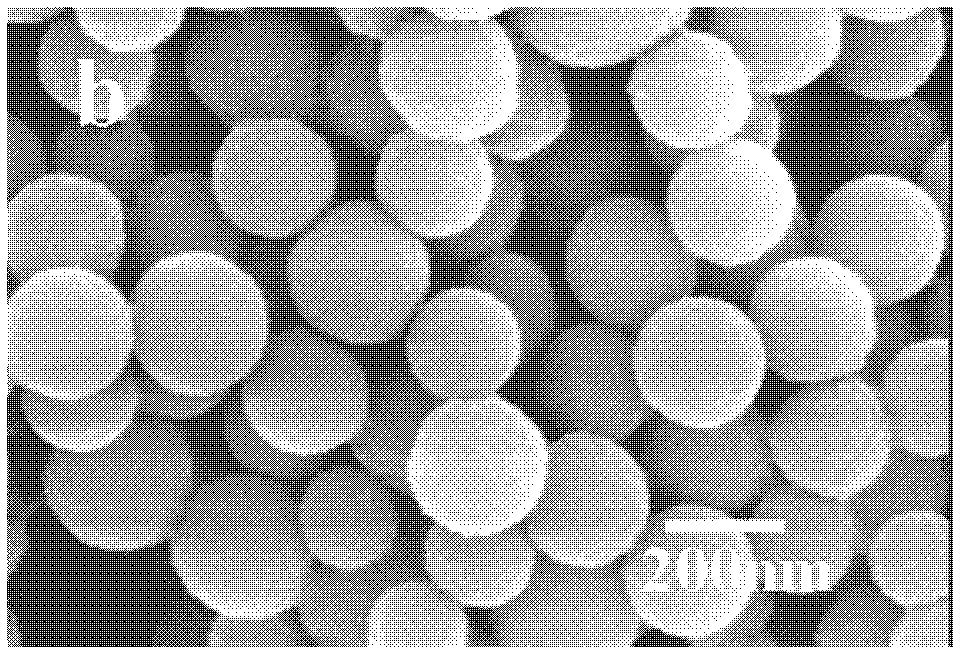

[0036] Take 20g of orthotitanic acid precipitate and add 10ml, 30% hydrogen peroxide solution to dissolve; under the condition of ice-water bath at 0°C, add 10ml, 80% mass percent concentration of hydrazine hydrate aqueous solution to the obtained titanium peroxide solution to obtain The mixed solution was aged at 10°C for 24 hours to obtain a white emulsion; the obtained white emulsion was centrifuged at 2500rpm, and the obtained precipitate was sintered at 500°C for 2 hours to obtain monodisperse submicron titanium dioxide particles with a particle size of 200nm. ball.

[0037] Morphological characterization of the titanium dioxide submicron oxide microspheres obtained, the results are shown in figure 2 , it can be seen that titanium dioxide is well dispersed.

Embodiment 3

[0039] A preparation method of monodisperse submicron titanium dioxide microspheres, comprising the following steps:

[0040] Orthotitanic acid precipitate was obtained in the same manner as in Example 1.

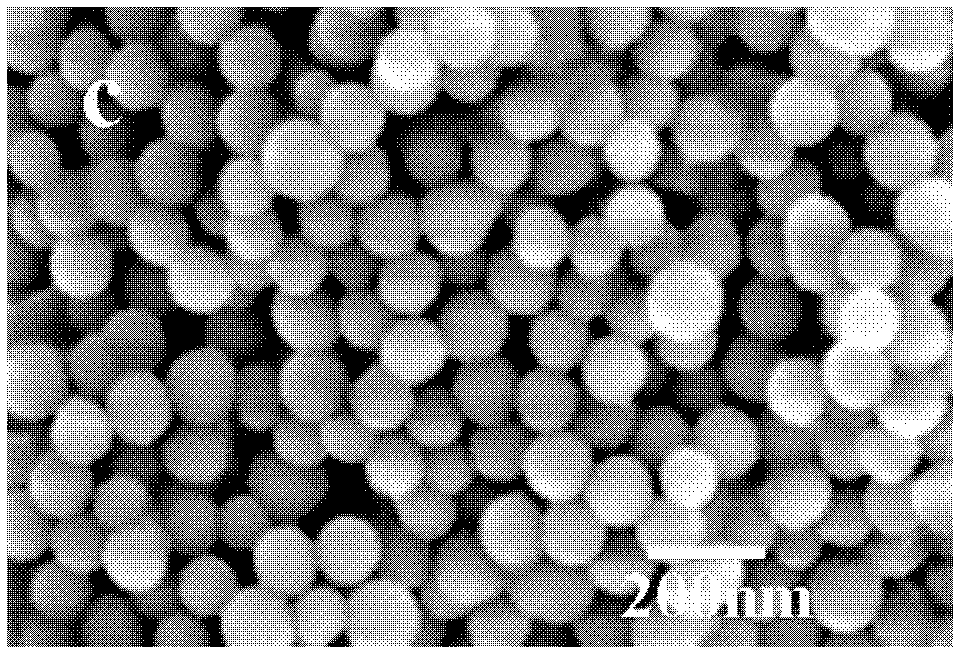

[0041] Take 20g of orthotitanic acid precipitate and add 10ml, 30% hydrogen peroxide solution to dissolve; under the condition of ice-water bath at 0°C, add 10ml, 80% mass percent concentration of hydrazine hydrate aqueous solution to the obtained titanium peroxide solution to obtain The mixed solution was aged at 20°C for 12 hours to obtain a white emulsion; the obtained white emulsion was centrifuged at 2500rpm, and the obtained precipitate was sintered at 500°C for 2 hours to obtain monodisperse submicron titanium dioxide particles with a particle size of 100nm. ball.

[0042] Morphological characterization of the titanium dioxide submicron oxide microspheres obtained, the results are shown in image 3 , it can be seen that titanium dioxide is well dispersed; carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com