Method for preparing TiO2 film on flexible substrate

A flexible substrate and coating solution technology, applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems that cannot be widely used, harsh, and restrict the development of membrane materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

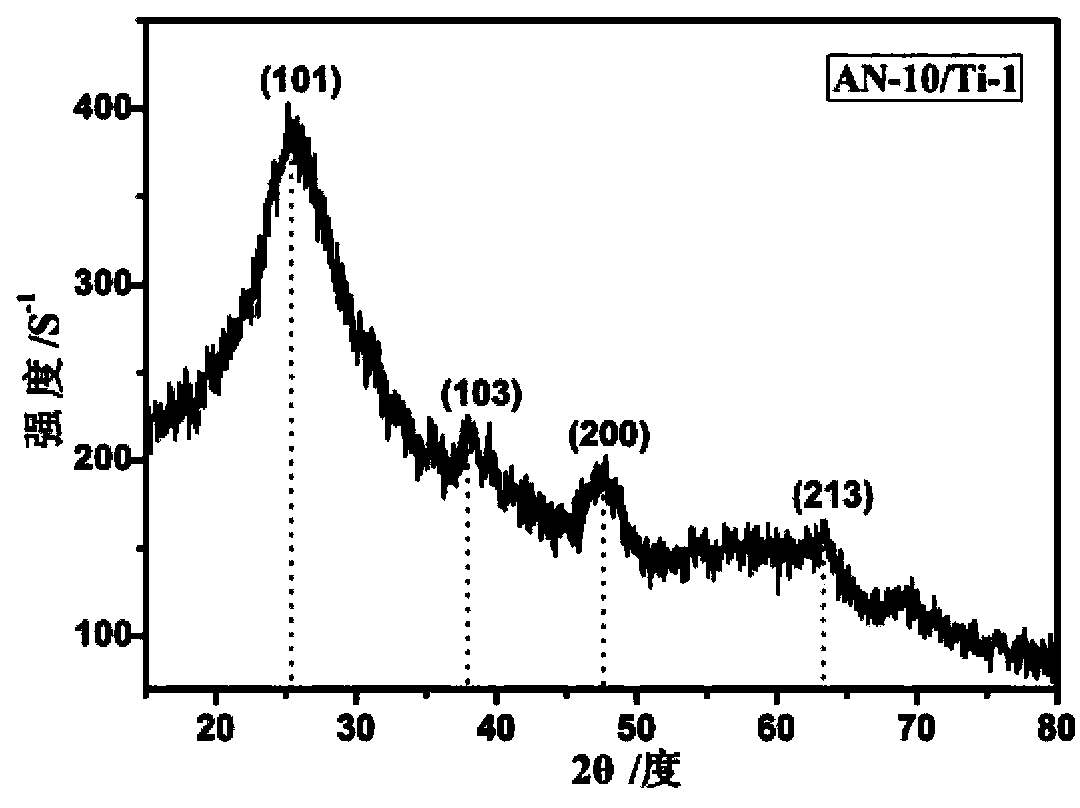

[0044] Fabrication of TiO on Flexible Substrates 2 A membrane method comprising the steps of:

[0045] 1) Preparation of titanium peroxide aqueous solution

[0046] Take 100ml of TiCl with a concentration of 0.2mol / L 4 Aqueous solution, adjust TiCl with a mass concentration of 5% ammonia water 4 The pH of the aqueous solution is 9, and white ortho-titanic acid precipitates are obtained; wash with deionized water until there is no chloride ion in the system;

[0047] Disperse the orthotitanic acid precipitate in 100ml of hydrogen peroxide solution with a volume fraction of 30%. After the precipitate is completely dissolved, add 0.01g of ferric oxide as a catalyst and heat at 50°C for 2 hours to remove free oxygen in the system. After centrifugation, a yellow-brown transparent titanium peroxide aqueous solution is obtained;

[0048] 2) Preparation of coating solution

[0049] The aniline monomer is used as a reducing agent and a binding agent, and is added to an aqueous sol...

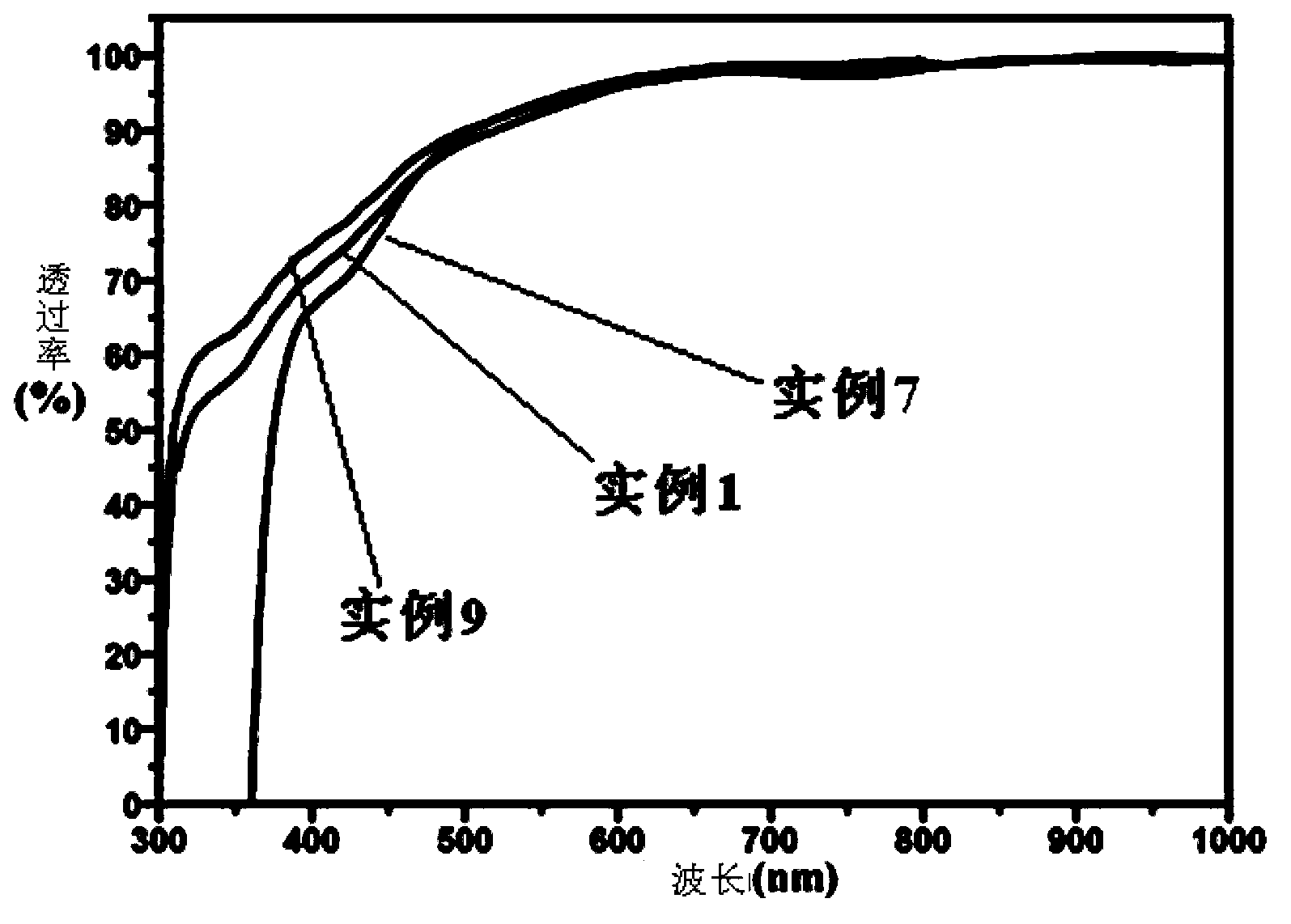

Embodiment 2

[0053] Repeat Example 1, except that the molar ratio of aniline monomer to Ti in the coating solution is 0.5 / 1 [n(AN) / n(Ti)=0.5].

Embodiment 3

[0055] Repeat Example 1, except that the molar ratio of aniline monomer to Ti in the coating solution is 1 / 1 [n(AN) / n(Ti)=1].

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com