Wall material with zeolite layer at surface and wall material adhered with porous substance layer on surface

A porous and zeolite technology, which is applied in coatings, paper coatings, decorative arts, etc., can solve the problems of long-term full removal of harmful chemicals and limited adsorption capacity of harmful chemicals, so as to improve ventilation performance, adsorption performance, and increase The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

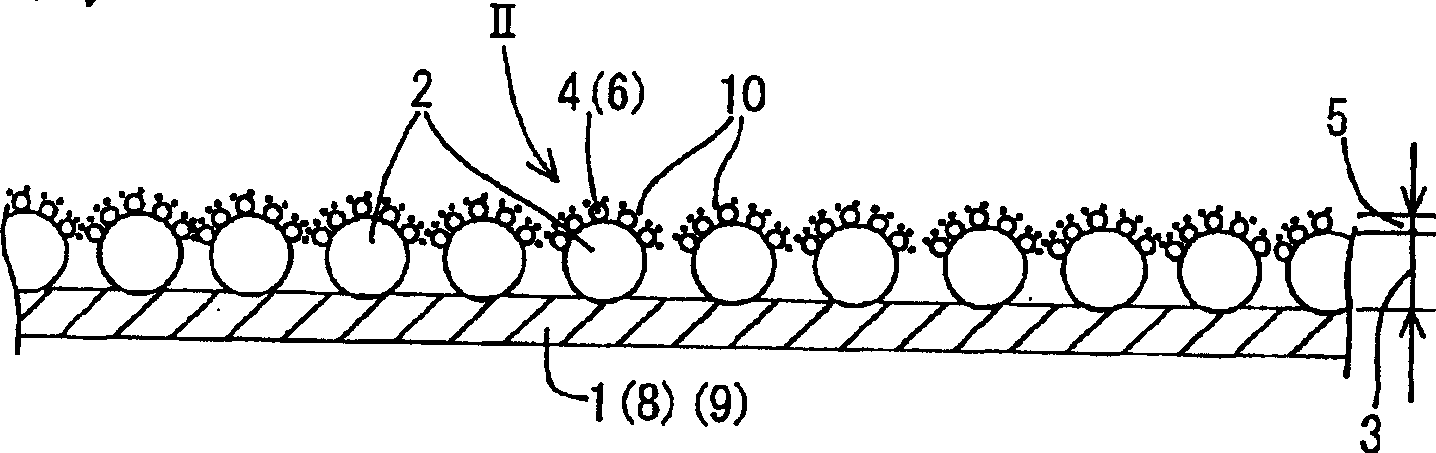

[0231] Embodiment 1: the invention of claims 1-3, 5-11, refer to Figure 1-Figure 4

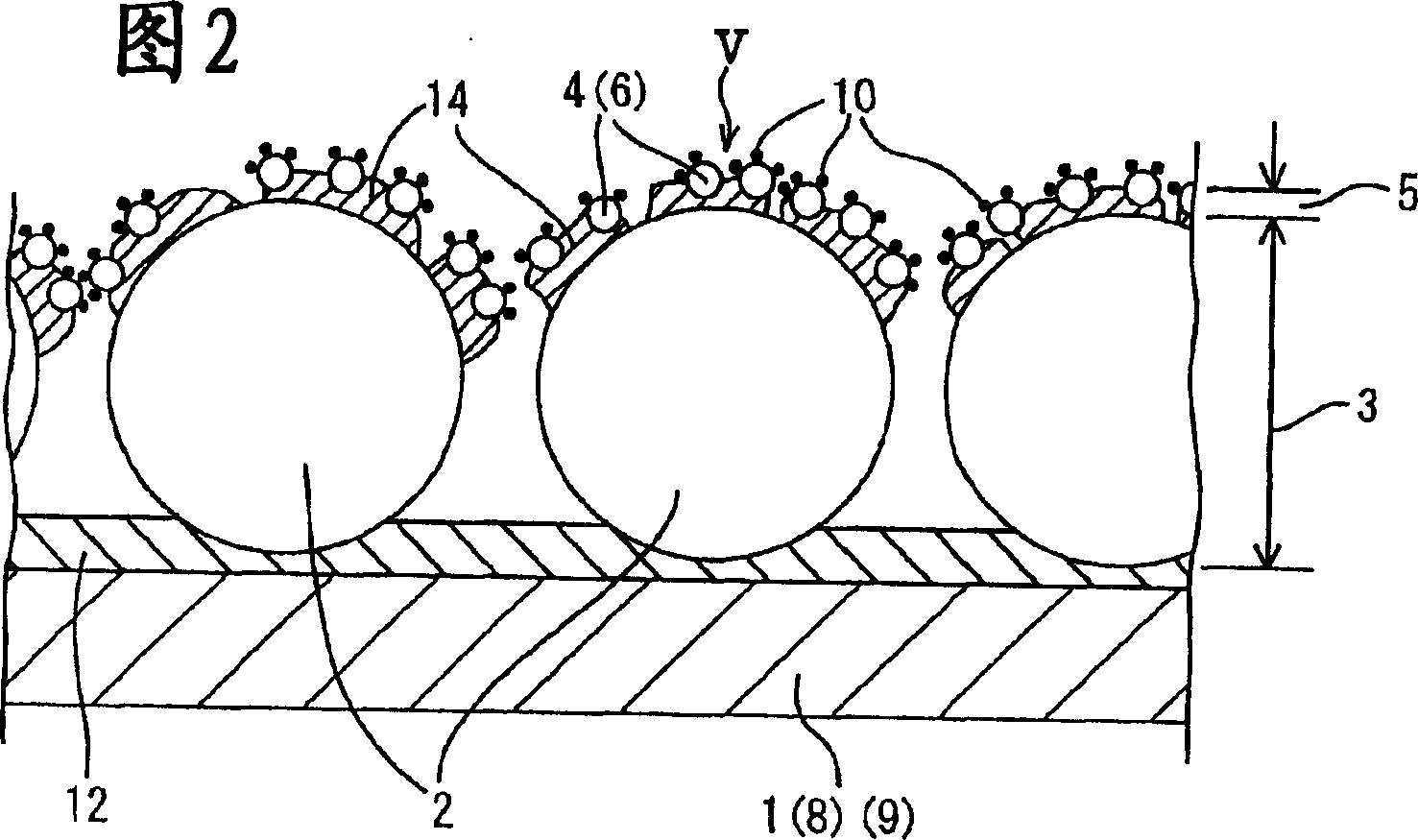

[0232] figure 1 Embodiment 1 showing the wall covering material with a zeolite layer on the surface of the present invention is a longitudinal sectional front view of a part of the wall covering material with a zeolite layer on its surface. Figure 2 is figure 1 Enlarged view of Part II.

[0233] Such as figure 1 , as shown in Figure 2, the powdery or granular zeolite (2) is fixed on the surface of the substrate (1) to form a zeolite layer (3). A photocatalyst (4) is fixed on the surface of the powdery zeolite (2) forming the zeolite layer (3) to form a photocatalyst layer (5). Both the photocatalyst (4) forming the photocatalyst layer (5) and the powdery zeolite (2) forming the above-mentioned zeolite layer (3) can freely contact the air in the atmosphere.

[0234] The photocatalyst (4) forming the photocatalyst layer (5) contains titanium oxide (6) as a main component. At least one of...

Embodiment approach 2

[0243] Embodiment 2: the invention of claim 4, refer to FIG. 5

[0244] Fig. 5 shows Embodiment 2 of the wall covering material with a zeolite layer on the surface of the present invention, and is an enlarged view of the V portion in Fig. 2 .

[0245] In this second embodiment, the configuration of the above-mentioned first embodiment is changed as follows.

[0246] Before the photocatalyst (4) forming the photocatalyst layer (5) is fixed on the surface of the powdery zeolite (2) forming the above-mentioned zeolite layer (3), the surface is covered with a fibrous insulating material made of an inorganic material in advance. (7).

[0247] Through this spacer (7), each photocatalyst (4) is fixed in a non-direct contact state with the adhesive (14) for the surface layer coated with the surface of the zeolite (2).

Embodiment approach 3

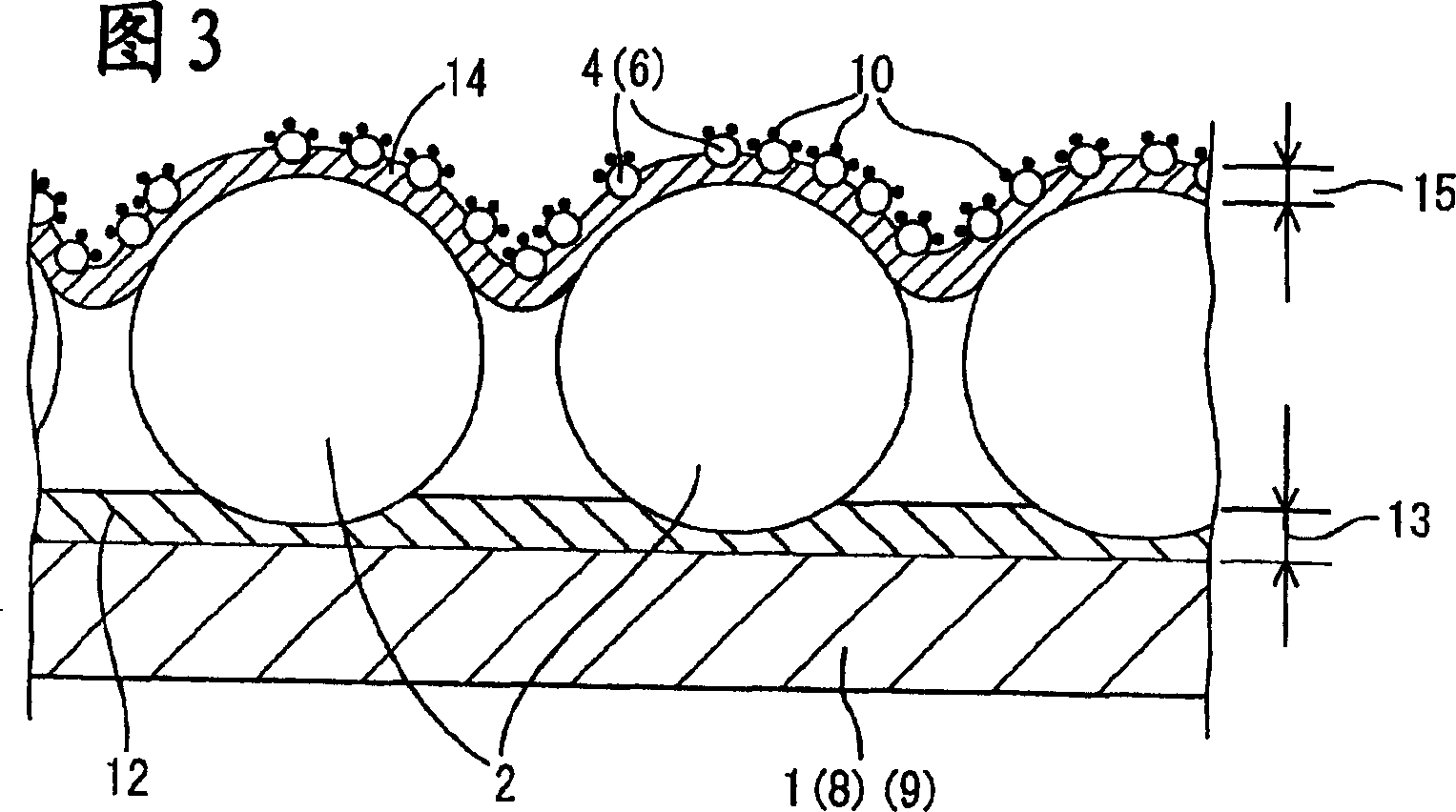

[0248] Embodiment 3: the invention of claims 1-3, 5-11, refer to FIG. 6

[0249] Fig. 6 shows Embodiment 3 of the wall covering material with a zeolite layer on the surface of the present invention, and is an enlarged view of the V portion in Fig. 2 .

[0250] In this third embodiment, the configuration of the above-mentioned first embodiment is changed as follows.

[0251] The surface coating of the powdery zeolite (2) of the zeolite layer (3) on the base layer binder layer (13) on the surface of the above-mentioned base material (1) is mixed with titanium oxide (6) in the surface layer binder (14). ) to form a surface adhesive layer (15) and a photocatalyst layer (5) simultaneously. As a result, a part of the titanium oxide (6) is exposed on the surface of the surface layer adhesive (12), and the remaining part is buried inside the surface layer adhesive (12).

[0252] In this case, there is an advantage that the surface adhesive layer (15) and the photocatalyst layer (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com