Method for preparing titanium dioxide functional film from poly ethylene glycol terephthalate substrate surface

A polyethylene terephthalate and substrate surface technology, which is applied in the field of transparent titanium dioxide functional films, can solve the problems of high cost, low degree of film crystallinity, and the substrate needs to be conductive, and achieves strong photoactive properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

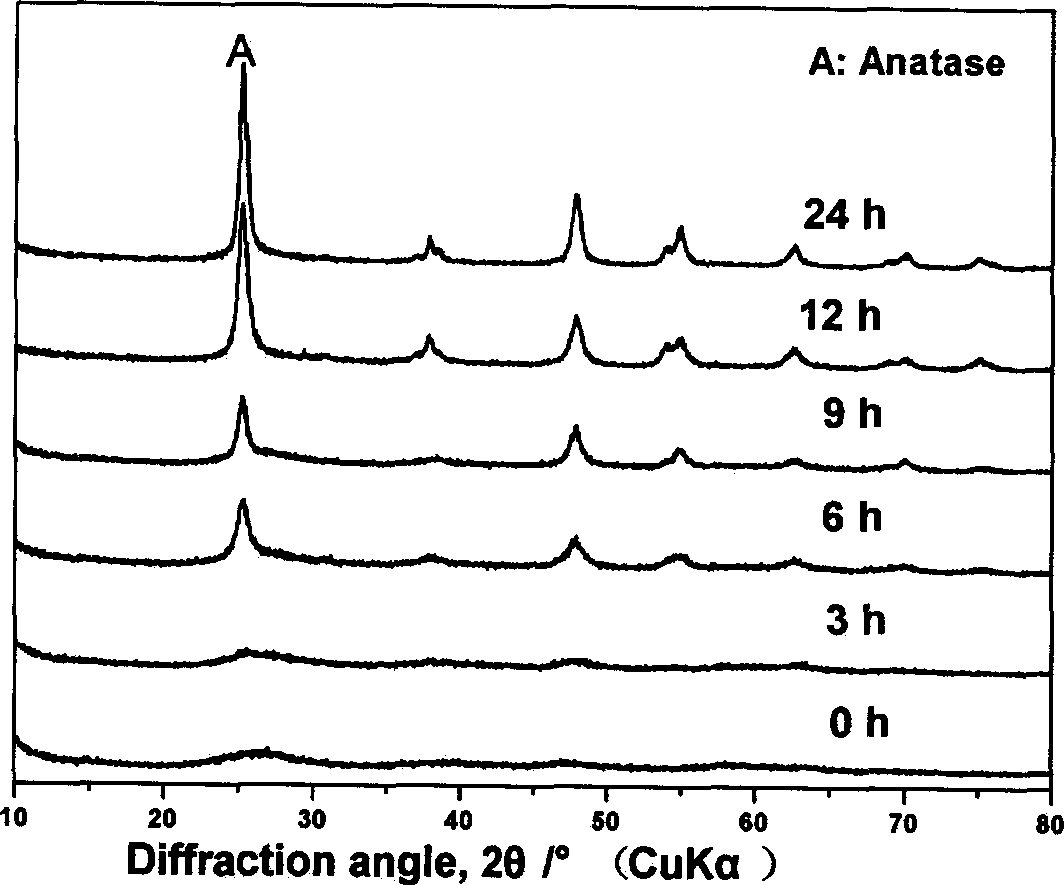

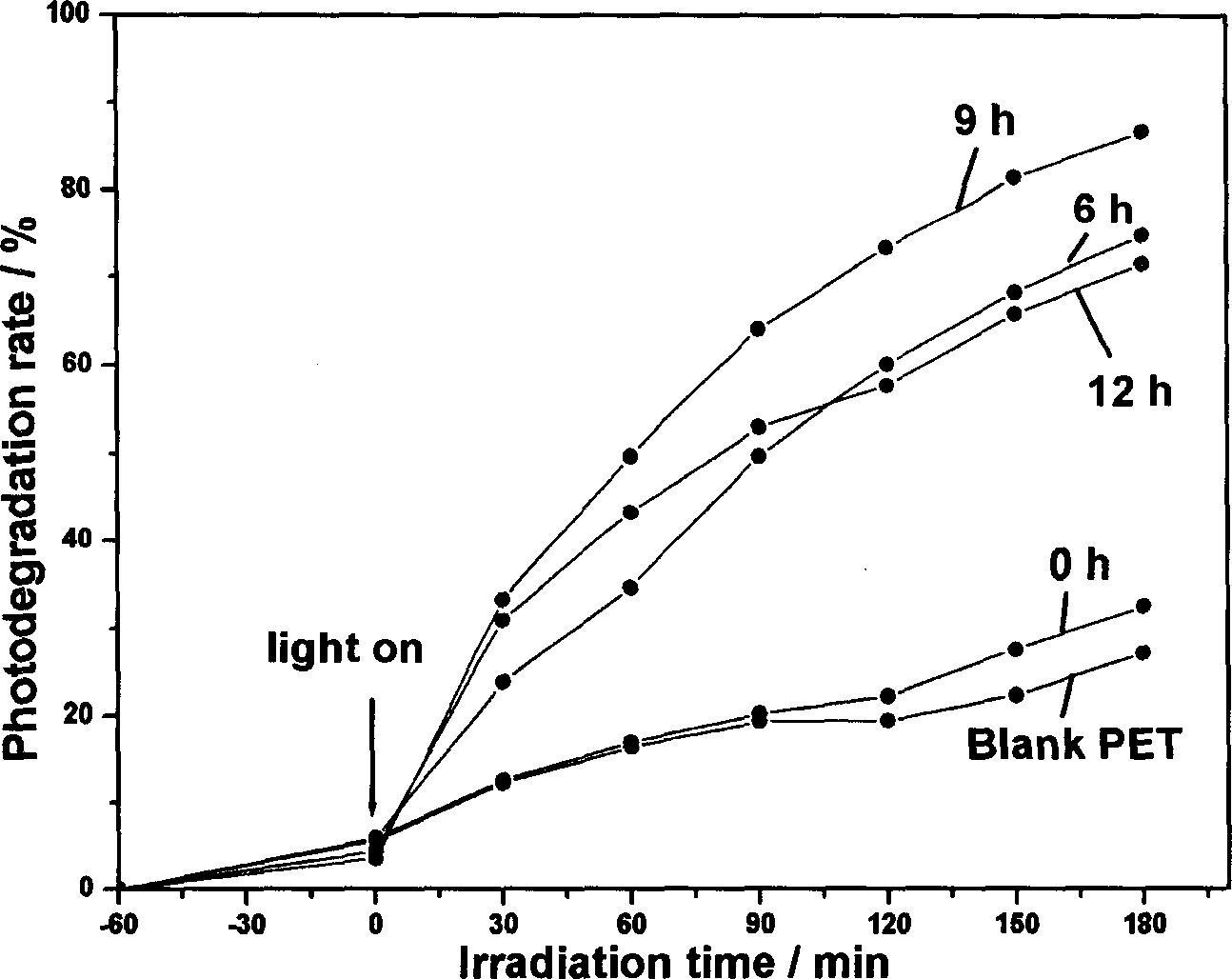

[0032] Transparent TiO on PET substrate surface 2 Film preparation

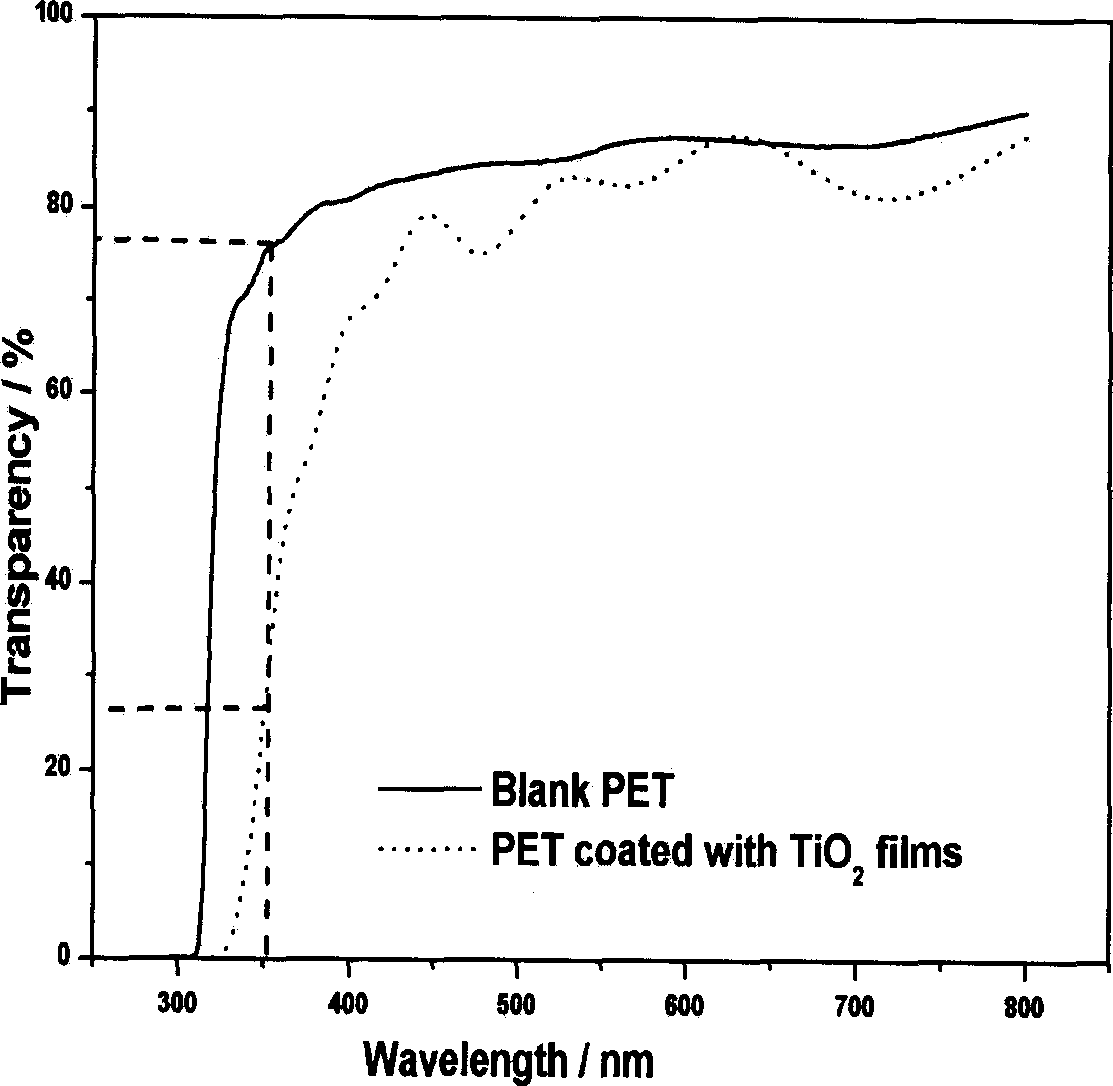

[0033] Use deionized water to ultrasonically clean the PET substrate, and then wash it with ethanol and acetone in turn. After the cleaning is completed and the surface is dry, put the PET in an acetone solution with a volume concentration of 1% silane coupling agent for surface treatment. 5- Take it out after 30 minutes and dry it under the air atmosphere of 100-150℃ for 5-60 minutes, after cooling, insert it vertically into TiO with anatase crystal form 2 In the sol-film solution, a wet film is formed on the surface of the PET substrate by the pulling method, and the pulling speed is 2.5 mm / s. Finally, the wet film is dried at 120 ° C, and the surface is coated with transparent TiO. 2 Film PET material. The blank PET substrate, the surface-treated PET material and the surface coated with TiO were tested by UV absorption spectrometer 2 The visible light transmittance of the PET material of the film. see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com