Solution of particles containing titanium dioxide and titanium peroxide complex and preparation thereof

A technology of titanium dioxide and titanium peroxide, applied in the directions of titanium oxide/hydroxide, titanium dioxide, titanium compound, etc., can solve problems such as inconvenience and achieve the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

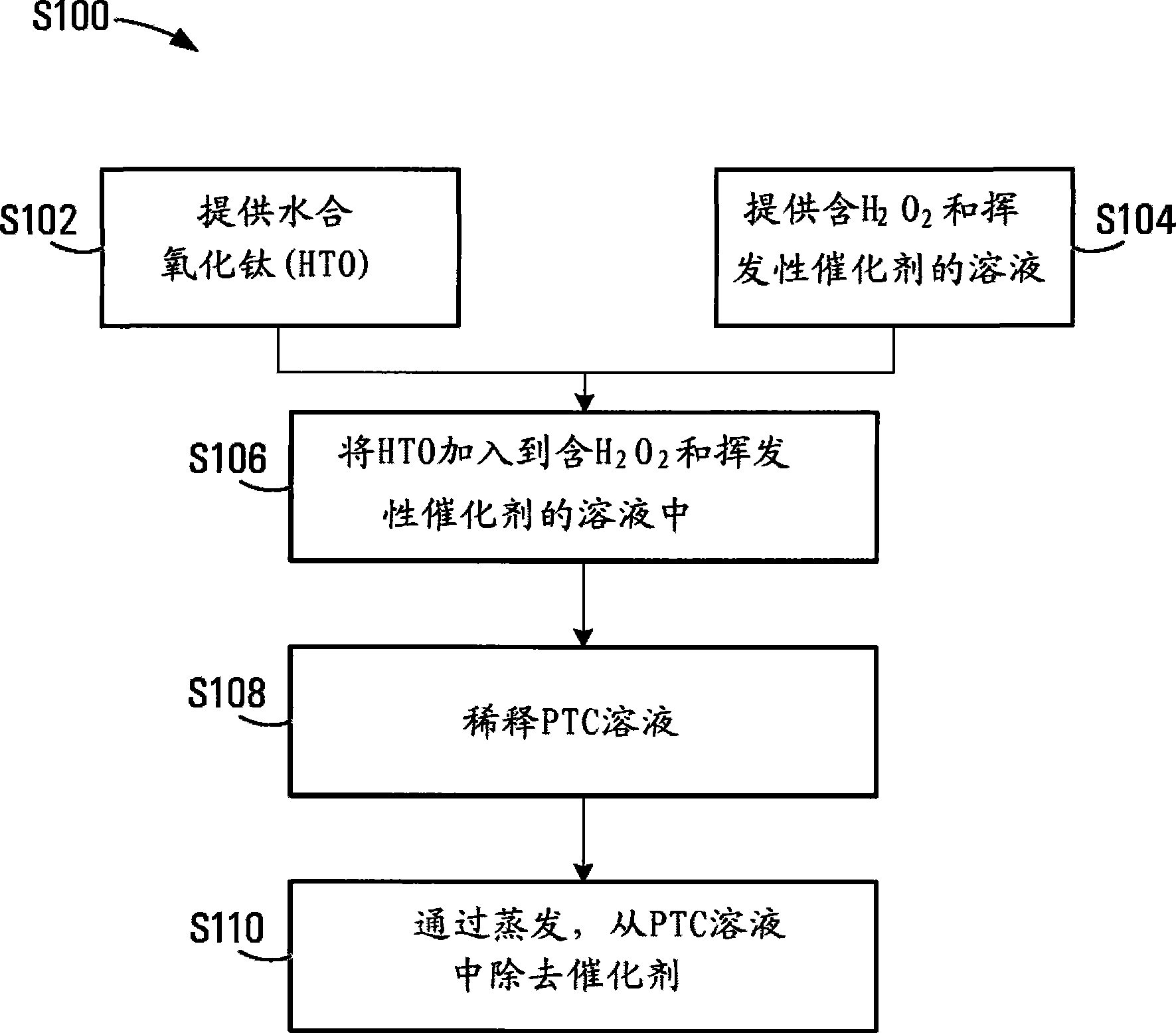

[0056] Hydrated titanium oxide was prepared as follows. First, add 5 liters of deionized water to the container. The water is ice-cooled at a temperature of 5-7°C. Add 33ml of 36.6wt% TiCl to the container 4 The solution. TiCl 4 The solution is from Sumitomo TM Co. acquired. Add 200ml of 3.0% NH to the container 4 OH NH 4 OH dilute solution. Mix the contents of the container by stirring. Then add to the vessel containing 30% NH 4 concentrated solution of OH until the pH of the mixed solution in the container is about 7. The mixed solution in the container was allowed to stand at room temperature until the hydrated titanium oxide precipitated. Then the contents in the container are washed with water until the conductivity of the liquid contents measured by a conductivity meter reaches 6˜20 μS / m. The precipitate in the vessel was separated from the liquid material to form a hydrated titania mass weighing 94 g and containing about 9.3% solid TiO 2 particles.

[005...

Embodiment II

[0059] Different PTC solutions were prepared in a similar manner to that described in Example 1, except that the concentration of ammonium hydroxide in the mixed solution was changed to 0, 100, 200, 400, 600, 800, 1,000, 1,200, 1,400, or 1,500 ppm, respectively outside. Moreover, two PTC solutions were prepared in a similar manner except that amines, ethanolamine (H 2 NCH 2 CH 2 OH), replacing the ammonium hydroxide at concentrations of 500 and 1,000 ppm, respectively.

[0060] It was found that the ammonium concentration in the mixed solution had a significant effect on the final appearance of the solution as well as the time required to form a clear solution. The test results for the two series are listed in Table IA and Table IB, respectively. As can be seen from Table IA and Table IB, NH up to 600ppm can be used 4 OH concentration to obtain a transparent PTC solution. However, in one test, 500ppm of NH 4 The OH sample solution produced a precipitate, which in this c...

Embodiment III

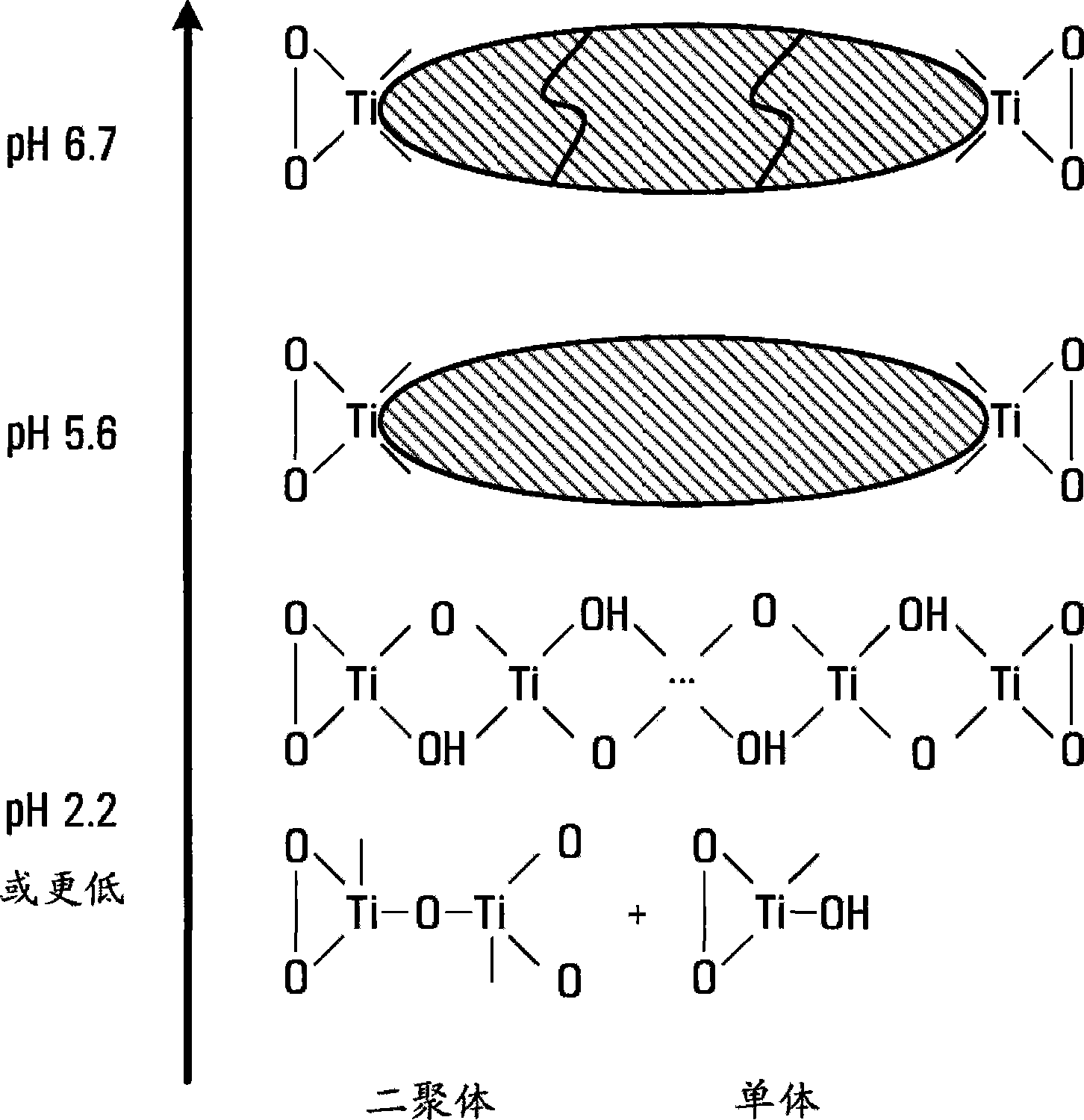

[0066] With 300ppm NH 4 OH, the PTC solution was prepared as in Example I, except that the final solution was aged without stirring. It was observed that the viscosity of the PTC solution increased with time, and the solution became translucent with time. When the pH of the solution reaches about 5, a gel develops in the solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com