Elastic nylon composite material for 3D printing and preparation method thereof

A technology of elastic nylon and composite materials, applied in the direction of additive processing, etc., can solve the problems of lack of melt flow rate, inability to meet the requirements of accuracy, reduced dimensional stability, etc., to achieve excellent anti-aging performance, reduce warpage deformation , the effect of MFR improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

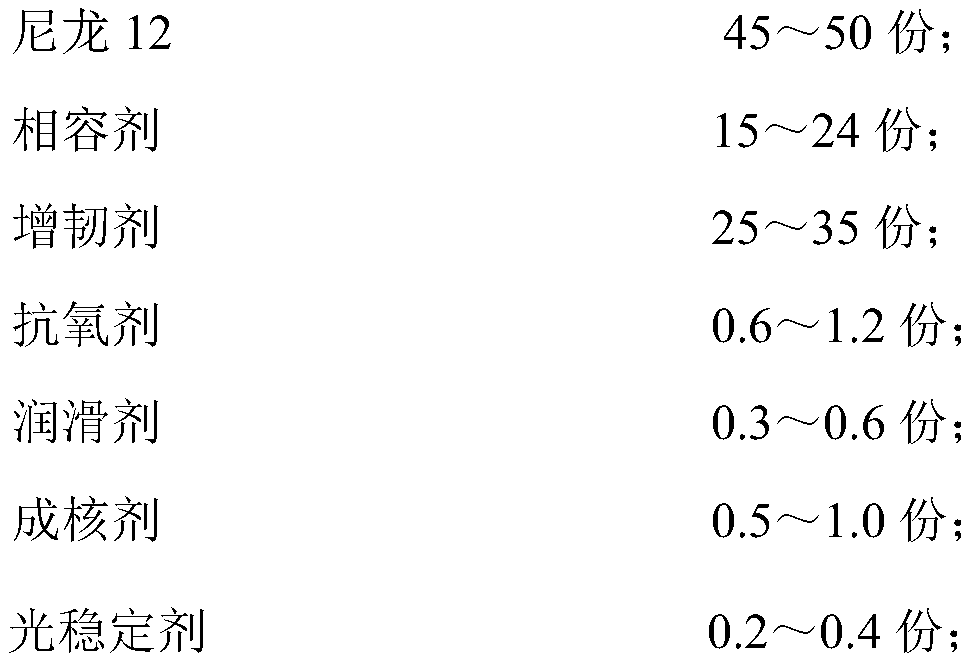

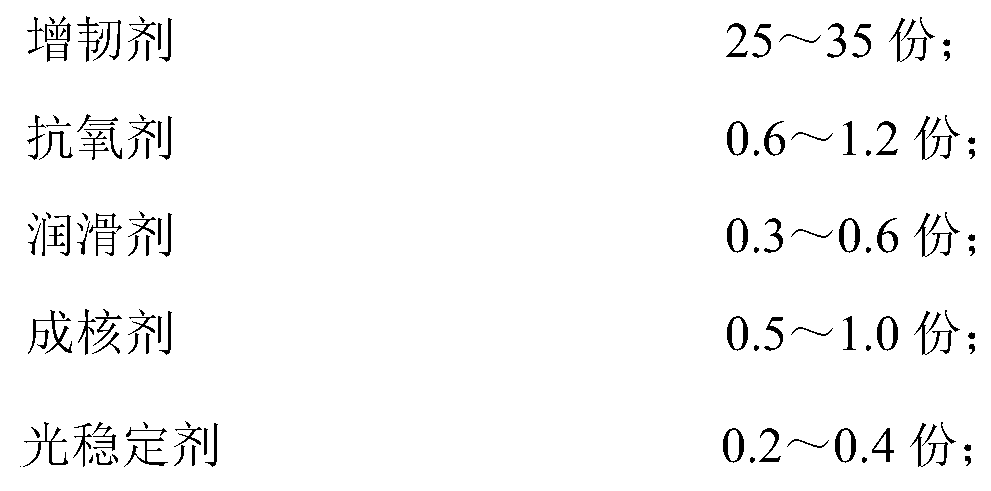

Method used

Image

Examples

Embodiment 1

[0027] Take respectively dried 50kg nylon 12, 15kg maleic anhydride grafted POE (grafting rate 1%), 5kg maleic anhydride grafted EPDM (grafting rate 1%), 30kg toughening agent SEBS, 0.5kg Antioxidant 1098, 0.5kg antioxidant 168, 0.3kg ethylene bisstearamide, 0.3kg silicone powder, 1.0kg nucleating agent nano talcum powder, 0.3kg hindered amine light stabilizer, add to the mixer and mix 8 to 10 minutes to obtain the mixture;

[0028] The mixture is extruded and granulated on a co-rotating twin-screw extruder, and then cooled, dried and pelletized after being melted and blended by a high-temperature extruder to obtain an elastic nylon composite material. The temperature settings are as follows: the temperature of the first zone is 200°C, the temperature of the second zone is 220°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 210°C, the temperature of the sixth zone is 190°C, the temperature of the ...

Embodiment 2

[0030] Take respectively dried 50kg nylon 12, 16kg maleic anhydride grafted POE (grafting rate 2%), 8kg maleic anhydride grafted EPDM (grafting rate 2%), 35kg toughening agent SEBS, 0.6kg Antioxidant 1098, 0.6kg antioxidant 168, 0.3kg ethylene bisstearamide, 0.3kg silicone powder, 0.8kg nucleating agent nano talcum powder, 0.2kg hindered amine light stabilizer, add to the mixer and mix 8 to 10 minutes to obtain the mixture;

[0031] The mixture is extruded and granulated on a co-rotating twin-screw extruder, cooled, dried, and pelletized after being melted and blended by a high-temperature extruder to obtain an elastic nylon PA12 composite material. The temperature setting of the head is: the temperature of the first zone is 200°C, the temperature of the second zone is 210°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 210°C, the temperature of the sixth zone is 190°C, the temperature of the seve...

Embodiment 3

[0033] Take respectively dried 45kg nylon 12, 12kg maleic anhydride grafted POE (grafting rate 0.5%), 3kg maleic anhydride grafted EPDM (grafting rate 0.5%), 25kg toughening agent SEBS, 0.3kg Antioxidant 1098, 0.3kg antioxidant 168, 0.2kg ethylene bisstearamide, 0.1kg silicone powder, 0.5kg nucleating agent nano talcum powder, 0.4kg hindered amine light stabilizer, add to the mixer and mix 8 to 10 minutes to obtain the mixture;

[0034] The mixture is extruded and granulated on a co-rotating twin-screw extruder, cooled, dried, and pelletized after being melted and blended by a high-temperature extruder to obtain an elastic nylon PA12 composite material. The temperature settings of the head are: the temperature of the first zone is 190°C, the temperature of the second zone is 210°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 200°C, the temperature of the sixth zone is 180°C, the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com