Metallic long-fiber reinforced polypropylene material special for automobile pedal and preparation method thereof

A technology of automobile pedals and metal texture, which is applied in the field of engineering plastic modification in polymer materials, can solve the problems of poor appearance and visual effects, achieve strong weather resistance, improve comprehensive performance, and reduce the cost of secondary processing and assembly processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention also discloses a method for preparing a special metal texture long fiber reinforced polypropylene material for automobile pedals, including:

[0032] Step 1. Weigh polypropylene, compatibilizer, metal powder, antioxidant, anti-UV agent, lubricant, glass fiber and glass fiber exposure prevention agent successively according to the formula ratio of the aforementioned mass parts, and weigh the Each component of the mixture is stirred at high speed in a high-speed mixer for 3 to 5 minutes to obtain a premix;

[0033] Step 2. Melt and extrude the polymer obtained in step 1 through a twin-screw extruder, and directly introduce it into the infiltration device, and at the same time, introduce the glass fiber into the infiltration device. After the glass fiber is soaked and coated with the polymer in the infiltration device , derived from the diameter of the round hole of the infiltration device, after water cooling, air-drying, and pelletizing, the polypropylene c...

Embodiment 1

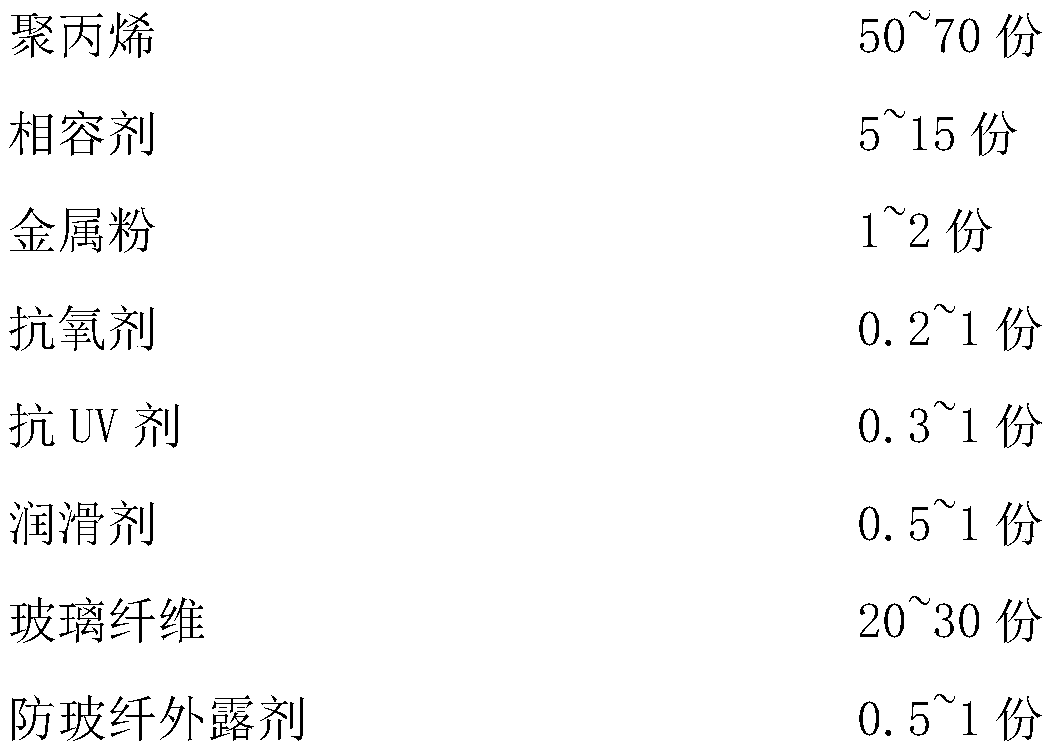

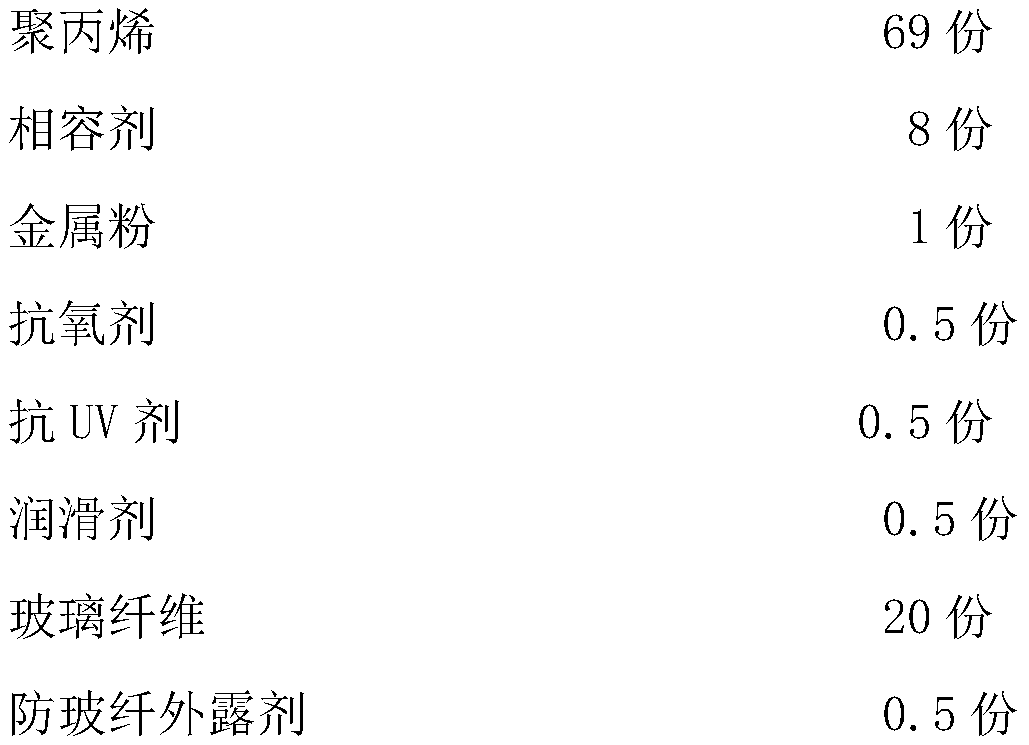

[0036] The components and parts by mass of the metal-textured long-fiber reinforced polypropylene material for automobile pedals are as follows:

[0037]

[0038] The production steps are:

[0039] Step 1. Take polypropylene, compatibilizer, metal powder, antioxidant, anti-UV agent, lubricant, glass fiber and anti-glass fiber exposure agent in sequence according to the above formula ratio, and put the weighed components in a high-speed mixer Stir at medium and high speed for 3 to 5 minutes to obtain a premix;

[0040] Step 2. Melt and extrude the polymer obtained in step 1 through a twin-screw extruder, and directly introduce it into the infiltration device, and at the same time, introduce the glass fiber into the infiltration device. After the glass fiber is soaked and coated with the polymer in the infiltration device , derived from the diameter of the round hole of the infiltration device, after water cooling, air-drying, and pelletizing, the polypropylene composite mat...

Embodiment 2

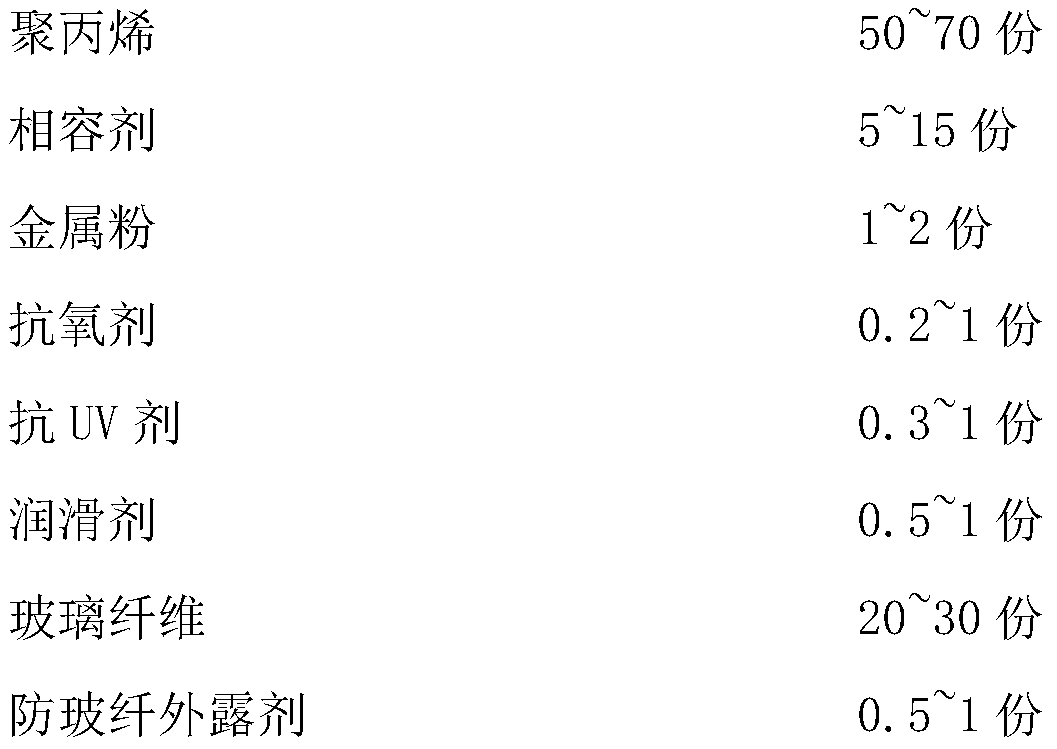

[0044] The components and parts by mass of the metal-textured long-fiber reinforced polypropylene material for automobile pedals are as follows:

[0045]

[0046] The production steps are:

[0047] Step 1. Take polypropylene, compatibilizer, metal powder, antioxidant, anti-UV agent, lubricant, glass fiber and anti-glass fiber exposure agent in sequence according to the above formula ratio, and put the weighed components in a high-speed mixer Stir at medium and high speed for 3 to 5 minutes to obtain a premix;

[0048] Step 2. Melt and extrude the polymer from the premix obtained in step 1 through a twin-screw extruder, and directly introduce it into the infiltration device, and at the same time introduce the glass fiber into the infiltration device. After the glass fiber is soaked and coated with the polymer in the infiltration device , derived from the diameter of the round hole of the infiltration device, after water cooling, air drying, and pelletizing, the polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com