A kind of universal polymer compatibilizer and preparation method thereof

A polymer, universal technology, applied in the preparation of the above-mentioned universal polymer compatibilizer, in the field of universal polymer compatibilizer, can solve the problem of poor melt fluidity, narrow scope of application, and connection of interface compatibilizers. problems such as low branch rate, to achieve the effect of easy interfacial tension, improving compatibility and reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

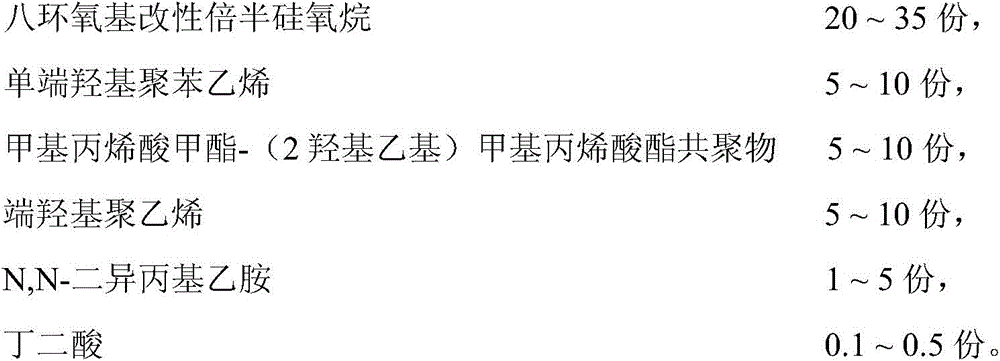

[0029]

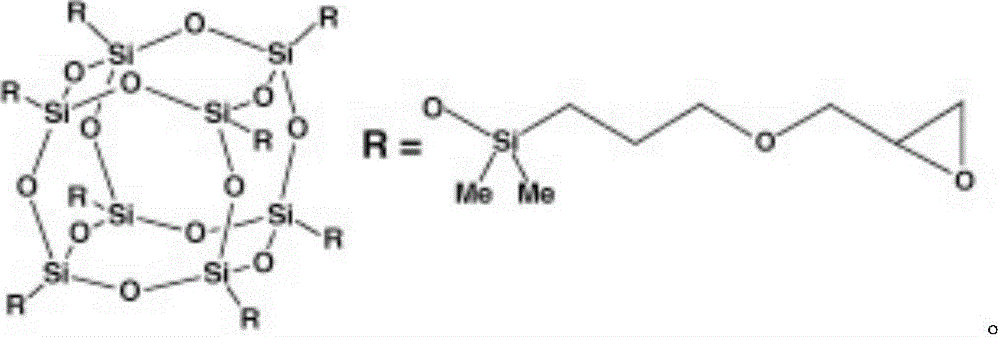

[0030] Wherein, the structural formula of octaepoxy modified silsesquioxane is as follows:

[0031]

[0032] The preparation method of above-mentioned universal polymer compatibilizer comprises the following steps:

[0033] (1) In a tank reactor, dissolve octaepoxy modified silsesquioxane in tetrahydrofuran at a ratio of 1kg / 10L, and add 2g of N,N-diisopropyl to the tank reactor base ethylamine, and then under the condition that the stirring speed is 10r / min and the temperature of the tank reactor is 30°C, the single-ended hydroxyl polystyrene is divided into five equal batches and added to the tank reactor successively, and two adjacent batches The interval time between the addition of single-ended hydroxyl polystyrene is 15 minutes, and the stirring reaction is continued for 5 hours after the addition is completed;

[0034] (2) Evaporate the mixed solution in the tank reactor after the reaction in step (1) to dryness to obtain solid A, then wash the obtained ...

Embodiment 2

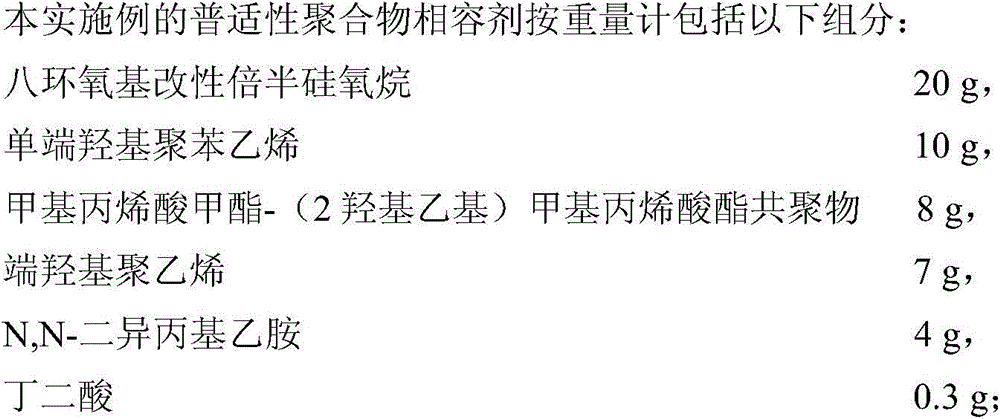

[0038] In this embodiment, the universal polymer compatibilizer comprises the following components by weight:

[0039]

[0040] Wherein, the structural formula of octaepoxy modified silsesquioxane is as follows:

[0041]

[0042] The preparation method of above-mentioned universal polymer compatibilizer comprises the following steps:

[0043] (1) In a tank reactor, dissolve octaepoxy modified silsesquioxane in tetrahydrofuran at a ratio of 1kg / 10L, and add 1.5g N, N-diiso Propylethylamine, and then under the conditions of a stirring speed of 10r / min and a tank reactor temperature of 40°C, the single-ended hydroxyl polystyrene was divided into five batches of equal amounts and added to the tank reactor in turn, and two adjacent The interval between adding batches of single-ended hydroxyl polystyrene is 15 minutes, and the stirring reaction is continued for 4.5 hours after the addition is completed;

[0044] (2) Evaporate the mixed solution in the tank reactor after the re...

Embodiment 3

[0048] In this embodiment, the universal polymer compatibilizer comprises the following components by weight:

[0049]

[0050] Wherein, the structural formula of octaepoxy modified silsesquioxane is as follows:

[0051]

[0052] The preparation method of above-mentioned universal polymer compatibilizer comprises the following steps:

[0053] (1) In a tank reactor, dissolve octaepoxy modified silsesquioxane in tetrahydrofuran at a ratio of 1kg / 10L, and add 2.5g N, N-diiso Propylethylamine, and then under the conditions of a stirring speed of 20r / min and a tank reactor temperature of 50°C, divide the single-ended hydroxyl polystyrene into five equal batches and add them to the tank reactor successively. The interval between adding batches of single-ended hydroxyl polystyrene is 15 minutes, and the stirring reaction is continued for 4 hours after the addition is completed;

[0054] (2) Evaporate the mixed solution in the tank reactor after the reaction in step (1) to dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com