A kind of anti-bonding drying equipment

A drying equipment and anti-adhesion technology, which is applied in the direction of drying chamber/container, drying solid material, drying gas arrangement, etc., can solve the problems of increasing the operation and maintenance cost of drying equipment, affecting the normal production and operation of drying equipment, and stagnant development of drying equipment, etc. , to achieve the effect of reducing operation and maintenance costs, reducing operating costs and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

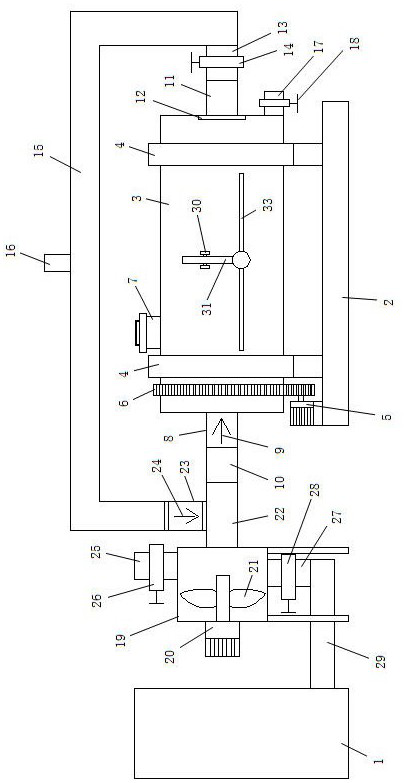

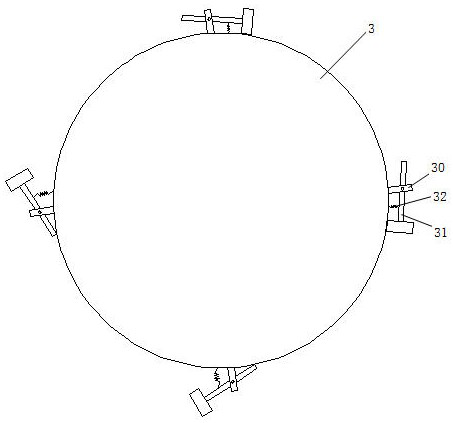

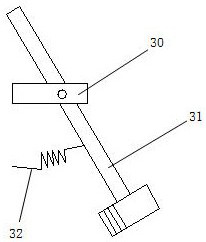

[0023] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0024] like Figure 1-Figure 4 As shown, an anti-bonding drying device includes a heat source 1, an air supply mechanism and a drying mechanism. The air supply mechanism transports the heat generated by the heat source 1 to the drying mechanism.

[0025]The drying mechanism includes a base 2 and a drying cylinder 3. Two mounting rings 4 are arranged on the base 2. The drying cylinder 3 is installed on the two mounting rings 4 in the horizontal direction through bearings. The base 2 is also provided with a driving motor 5. , the main shaft of the driving motor 5 is provided with a driving gear, the drying cylinder 3 is provided with a ring gear 6, the driving gear and the ring gear 6 are meshed for transmission, the side of the drying cylinder 3 is provided with a feed port 7, and the feed port 7 is provided with Thread sealing cover, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com