A kind of ABS toughening agent and preparation method thereof

A toughening agent and reinforcing agent technology, applied in the field of ABS toughening agent and its preparation, can solve the problems of ABS resin tensile strength, modulus, flexural strength and melt index decline, etc., to improve solubility parameters and phase dispersion ability , good compatibility, high-efficiency toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method for ABS toughening agent, comprising the following steps:

[0040] 1) Mix the ABS high rubber powder, compatibilizer, reinforcing agent, dispersant, polyhydroxy chemical coupling agent and antioxidant in the formula amount, and stir evenly to obtain the mixture;

[0041] 2) the compound is placed in the internal mixer, fully plasticized, to obtain a semi-finished product;

[0042] 3) Take the semi-finished product, cool it to room temperature, then pulverize it and sieve it.

Embodiment 1

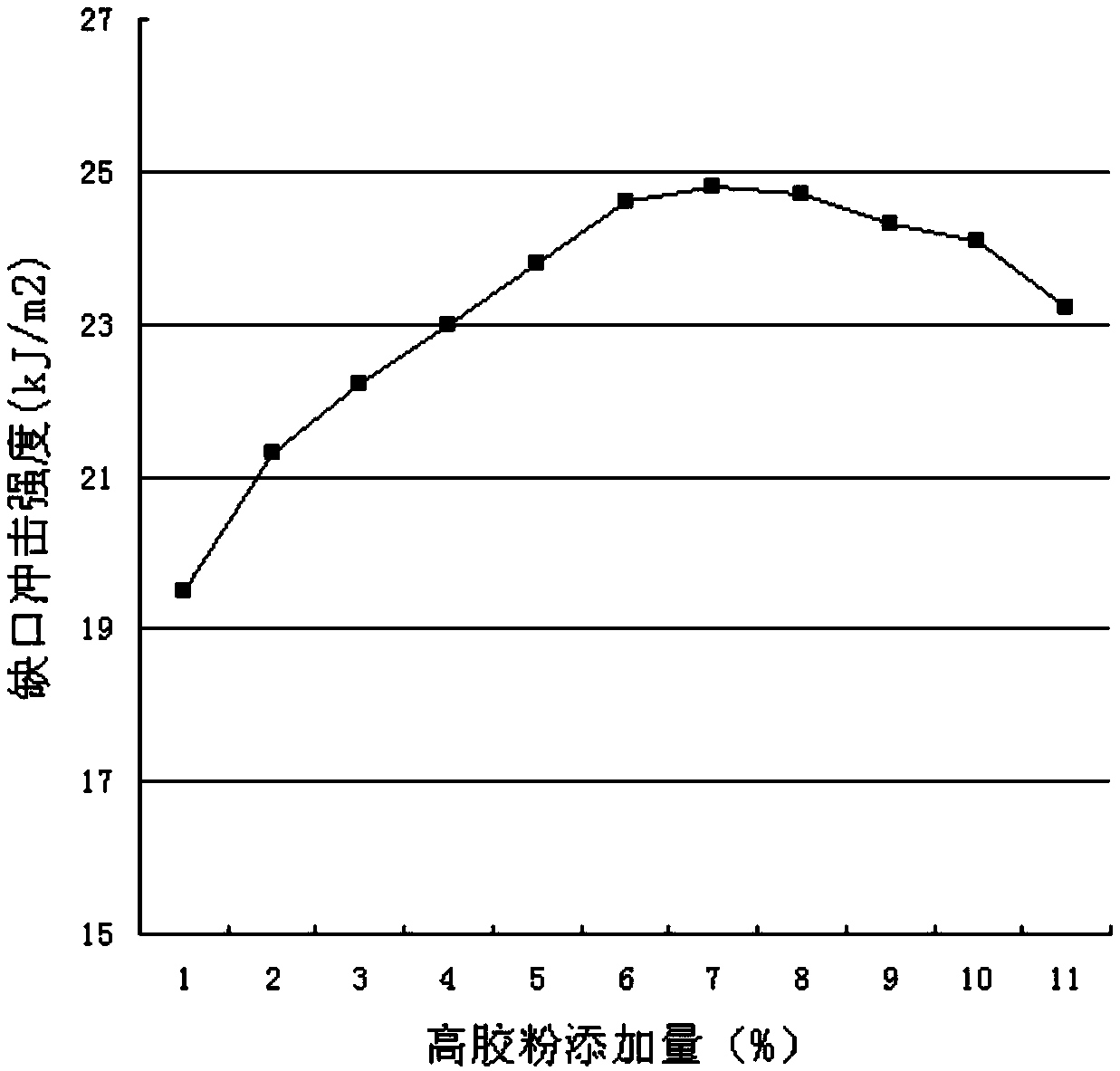

[0044] An ABS toughening agent is prepared according to the following steps: Weigh 68.5 parts of ABS high-glue powder, 20 parts of ABS-g-MAH, 5 parts of organic montmorillonite, 3 parts of barium stearate, 2 parts of zinc stearate 1 part of pentaerythritol, 0.5 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester. Put the above-mentioned ingredients into a high-speed mixer and mix them well; then put them in a double-roller internal mixer and knead them for 8 minutes, and set the kneading temperature to 230°C; Crush and screen the ABS toughening agent below 2mm for performance test.

[0045] The test method is as follows: the test indicators include notched impact strength (kJ / m 2), melt index (g / 10min), tensile strength (MPa), elongation at break (%), flexural strength (MPa) and modulus of elasticity (MPa), the test standards are strictly in accordance with ISO180, ISO 1133, ISO 1033, ISO 527, ISO 178 and other systems for verification. ...

Embodiment 2

[0051] An ABS toughening agent is prepared according to the following steps: Weigh 57.5 parts of ABS high rubber powder, 15 parts of ABS-g-MAH, 10 parts of AS-g-MAH, 10 parts of fumed nano-silica, ethylene bis 5 parts of stearamide, 2 parts of glycerin, 0.5 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester. Put the above-mentioned ingredients into a high-speed mixer, and stir well; then put them in a double-roller mixer for 10 minutes, and set the mixing temperature to 220°C; Crush and screen the ABS toughening agent below 2mm for performance test.

[0052] The test method is the same as in Example 1, and the test results are shown in Table 2 below.

[0053] The performance test record form of the ABS toughening agent of table 2 embodiment 2

[0054]

[0055]

[0056] It can be seen from Table 2 that compared with the traditional ABS high rubber powder, the ABS toughening agent provided by Example 2 of the present invention has su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com