Preparation method of foam glass-loaded titanium dioxide photocatalyst

A technology of foam glass and titanium dioxide, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex post-treatment process and degradation of photocatalytic performance, and achieve high dye adsorption capacity and low The effect of density and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

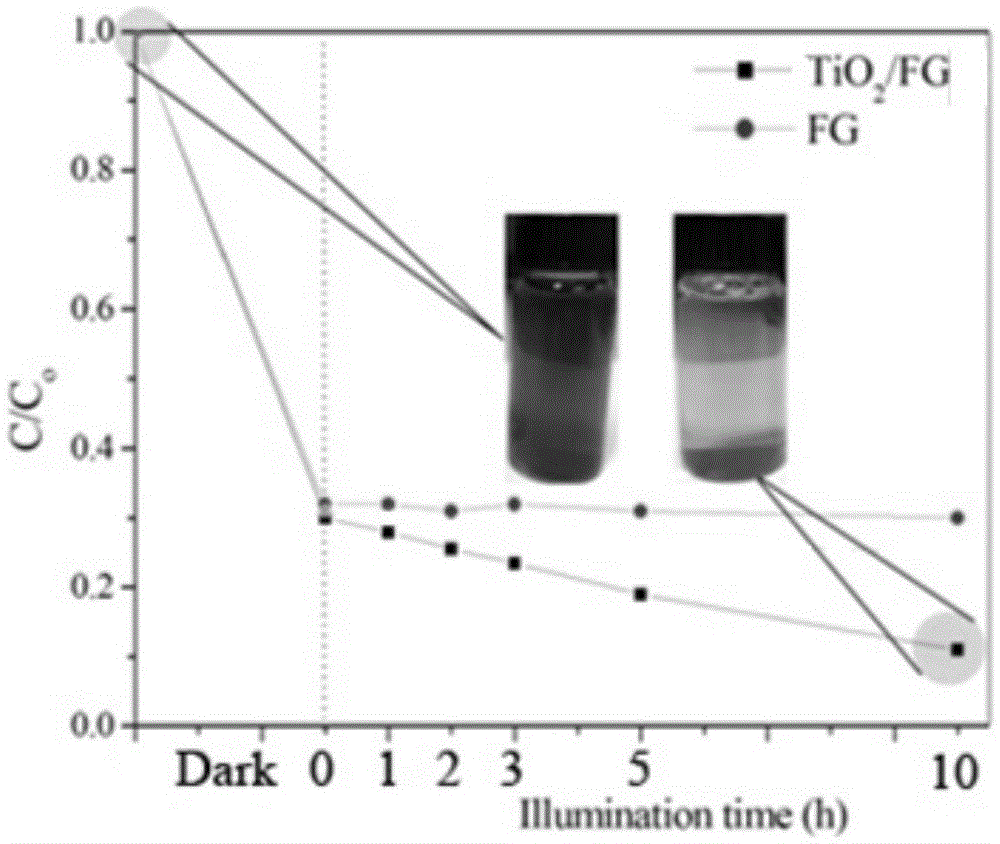

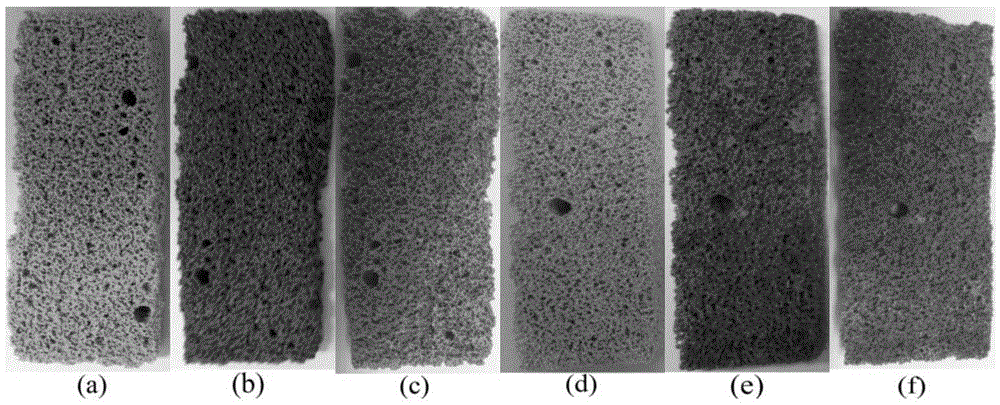

[0024] 100 g of waste glass was put into a ball mill jar, and ball milled for 10 min at a rotation speed of 300 rpm to obtain a fine powder with a particle size of less than 75 μm. Then mix 100g of fine glass powder with 100g of water glass solution and stir evenly. Take a piece of open-cell PU foam with a size of 6cm×2.5cm×0.3cm and immerse it in the viscous mixture. After soaking for 5 minutes, take it out and dry it at 100°C for 2h, then calcinate the sample at 750°C for 1h. Obtain open-cell foam glass. All the open-cell foam glass was immersed in 3% titanium peroxide complex aqueous solution for 10 min, after which the sample was removed and dried at 100°C for 1 h. Finally, the sample was calcined at 500 °C for 1 h and cooled down to room temperature naturally to obtain the photocatalyst supported by open-cell foam glass. The density of the photocatalyst supported by open-cell foam glass is about 0.98g / cm 3 ,TiO 2 The loading is 6mgTiO 2 per gram of foam glass. The p...

Embodiment 2

[0026] After the organic dyes in the waste water of the foam glass-supported photocatalyst in Example 1 are fully degraded, the photocatalyst supported by the foam glass can be easily separated and the nano-titanium dioxide therein will not agglomerate. The photocatalyst supported on foam glass can recover its photocatalytic activity. After 10 repeated experiments, the concentration of methylene blue in the solution can still be reduced to 1.2 ppm after 10 h of ultraviolet light irradiation, which shows that the photocatalyst supported by foam glass has good stability.

Embodiment 3

[0028] Put 80g of waste glass and 20g of waste incineration bottom ash into a ball mill jar, and ball mill at a rotation speed of 300rpm for 15 minutes to obtain a fine powder with a particle size of less than 50 μm, then mix the fine powder with 100g of water glass solution and stir evenly. Take a piece of open-cell PU foam with a size of 6cm×2.5cm×0.3cm and immerse it in the viscous mixture. After soaking for 5 minutes, take it out and dry it at 100°C for 2 hours, then calcinate the sample at 750°C for 2 hours. Obtain open-cell foam glass. All the open-cell foam glass was immersed in 2% titanium peroxide complex aqueous solution for 10 min, and then the sample was removed and dried at 100°C for 1 h. Finally, the sample was calcined at 500 °C for 1 h and cooled down to room temperature naturally to obtain the photocatalyst supported by open-cell foam glass. The density of the photocatalyst supported by open-cell foam glass is about 0.95g / cm 3 ,TiO 2 The loading is 5mgTiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com