Method for treating refractory organic wastewater by TiO2 film electrode photoelectric turnplate

An organic wastewater and thin-film electrode technology, which is applied in the field of environmental catalysis and electrochemistry, can solve the problems such as the decrease in the yield of photogenerated electrons and holes, the decrease in the light intensity of the electrode surface, and the decrease in the degradation efficiency of pollutants, so as to improve the utilization rate of light. , avoid light loss, improve the effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

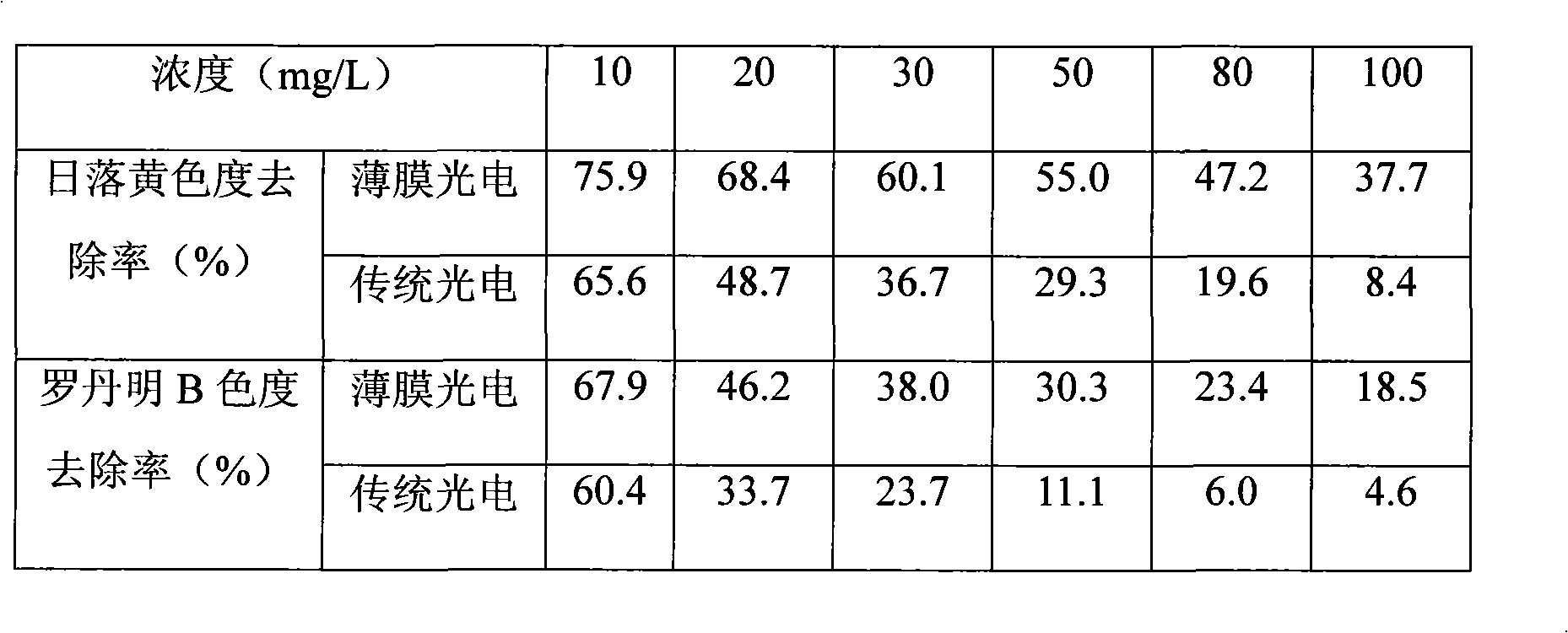

[0020] Example 1 Direct Thermal Oxidation of Monolithic TiO 2 / Ti thin film electrode photoelectric turntable method for dye wastewater treatment

[0021] The treatment object is different concentrations of sunset yellow (0.6V, pH6.5, 0.65g / LNa 2 SO 4 ) and rhodamine B (0.8V, pH5.6, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume was 55 ml each.

[0022] Adding the electrolyte anhydrous sodium sulfate to the wastewater can improve the conductivity of the solution, and the addition amount is 0.5-2g per liter.

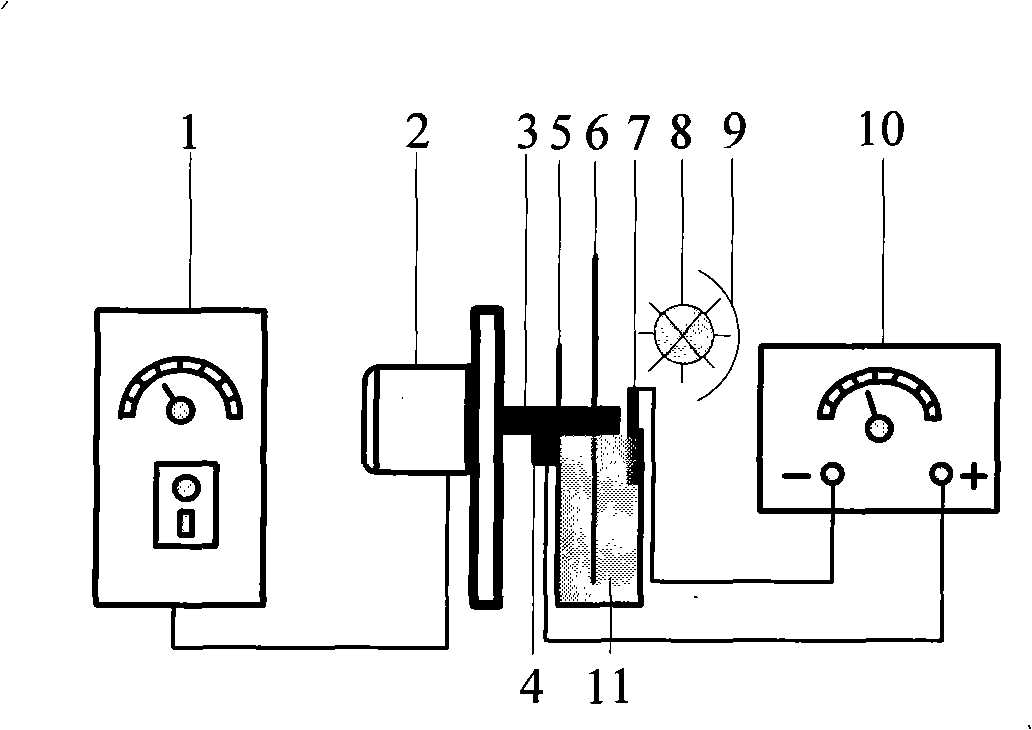

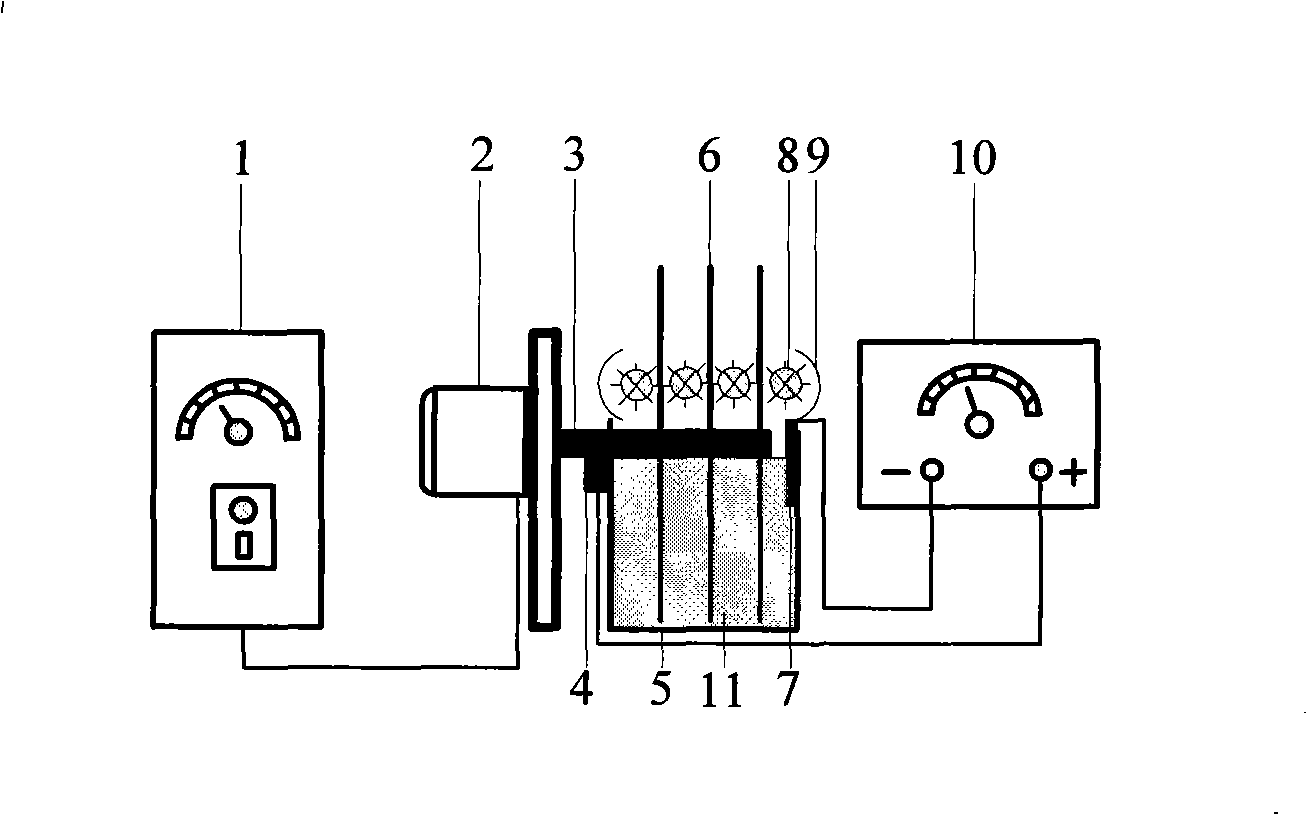

[0023] Process such as figure 1 Shown:

[0024] 1) Using a titanium disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate and fixed on the rotating shaft 3 in a monolithic manner to form a photoelectric turntable, which is used as a photoanode 6 , and the rotating shaft 3 of the photoanode is connected to the motor 2 .

[0025] 2) Place the photoanode 6 in the semi-arc reaction tank 5, the rotating shaft 3 of the photo...

Embodiment 2

[0031] Embodiment 2 sol-gel (sol-gel) monolithic TiO 2 / Ti film electrode photoelectric turntable to treat dye wastewater

[0032] The treatment object is Rhodamine B of different concentrations (pH2.5, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume was 55ml.

[0033] Process such as figure 1 Shown:

[0034] 1) Using a titanium disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate and fixed on the rotating shaft 3 in a monolithic manner to form a photoelectric turntable, which is used as a photoanode 6 , and the rotating shaft 3 of the photoanode is connected to the motor 2 .

[0035]2) Place the photoanode 6 in the semi-arc reaction tank 5, the rotating shaft 3 of the photoanode is at the water surface of the waste water, so that half of the photoanode is submerged in the waste water, and the photoanode is connected to the DC power supply 10 through the carbon brush 4 connected to the rotating shaft connected to the positive...

Embodiment 3

[0042] Embodiment 3 sol-gel (sol-gel) monolithic TiO 2 / Ti film electrode photoelectric turntable to treat actual printing and dyeing wastewater

[0043] The treatment objects are actual printing and dyeing wastewater raw water (pH12.4) and pretreated water (pH6.8). The wastewater was taken from a printing and dyeing factory in Changzhou. The waste water volume was 55 ml each.

[0044] Process such as figure 1 Shown:

[0045] 1) Using a titanium disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate and fixed on the rotating shaft 3 in a monolithic manner to form a photoelectric turntable, which is used as a photoanode 6 , and the rotating shaft 3 of the photoanode is connected to the motor 2 .

[0046] 2) Place the photoanode 6 in the semi-arc reaction tank 5, the rotating shaft 3 of the photoanode is at the water surface of the waste water, so that half of the photoanode is submerged in the waste water, and the photoanode is connected to the DC powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com