Manufacture method for triammonium phosphate compound fertilizer

A technology of triammonium phosphate and manufacturing method, which is applied to ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc. It can solve the problems of fast decomposition and loss of fertilizer efficiency, loose structure, fast dissolution and release of fertilizer, etc., so as to save repeated construction The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

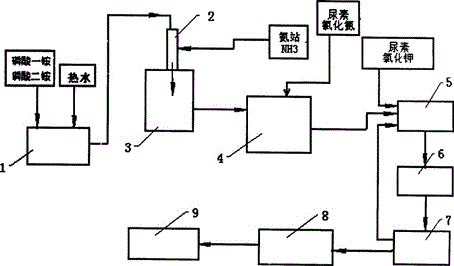

[0023] Embodiment 1: as figure 1 as shown,

[0024] Step 1: Send the mixture of monoammonium phosphate and diammonium phosphate and hot water into the dissolving tank 1, neutralize the phosphoric acid with ammonia to prepare the Anfu powder (a mixture of monoammonium phosphate and diammonium phosphate), and then pass the mixed slurry through a tubular Reactor 2 is sent to a high-pressure over-amination device, and the raw material gas ammonia (NH3) is over-ammonated, and then enters a high-pressure ammoniation device 3, the pressure of gas ammonia is 0.3Mpa, and the temperature is controlled at 60°C to prepare ammonium phosphate mixed slurry .

[0025] Step 2: After detecting that the ammonia saturation reaches process 1.4, 35 parts of ammonium phosphate mixed slurry is pressed into a buffer tank 4, and then 5 parts of ammonium chloride and 12 parts of urea are added as triammonium phosphate stabilizers.

[0026] Step 3: Then use the pump to send to the drum granulator 5, th...

Embodiment 2

[0028] Step 1: Send the mixture of monoammonium phosphate and diammonium phosphate and hot water into the dissolving tank 1, neutralize the phosphoric acid with ammonia to prepare the Anfu powder (a mixture of monoammonium phosphate and diammonium phosphate), and then pass the mixed slurry through a tubular Reactor 2 is sent to a high-pressure over-amination device, and the raw material gas ammonia (NH3) is over-ammonated, and then enters a high-pressure ammoniation device 3. The pressure of gas ammonia is 0.4Mpa, and the temperature is controlled at 70°C. Prepare ammonium phosphate mixed slurry.

[0029] Step 2: After detecting that the ammonia saturation reaches process 1.5, 28 parts of ammonium phosphate mixed slurry are automatically pressed into a buffer tank 4, and then 4 parts of ammonium chloride and 15 parts of urea are added as triammonium phosphate stabilizers .

[0030] Step 3: Then use the pump to send to the drum granulator 5, then mix with raw materials such as...

Embodiment 3

[0032] Step 1: Send the mixture of monoammonium phosphate and diammonium phosphate and hot water into the dissolving tank 1, neutralize the phosphoric acid with ammonia to prepare the Anfu powder (a mixture of monoammonium phosphate and diammonium phosphate), and then pass the mixed slurry through a tubular Reactor 2 is sent to a high-pressure over-amination device, and then over-ammonates with raw material gas ammonia (NH3), and then enters high-pressure ammoniation device 3, the pressure of gas ammonia is 0.6Mpa, and the temperature is controlled at 80°C. Prepare ammonium phosphate mixed slurry.

[0033] Step 2: After detecting that the ammonia saturation reaches process 1.3, 26 parts of ammonium phosphate mixed slurry are automatically pressed into a buffer tank 4, and then 3 parts of ammonium chloride and 10 parts of urea are added as triammonium phosphate stabilizers.

[0034] Step 3: Then use the pump to send to the drum granulator 5, then mix with raw materials such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com