Catalyst for synergistically purifying multiple pollutants and preparation method thereof

A technology of catalysts and additives, applied in the field of catalysts for synergistic purification of various pollutants and their preparation, can solve the problems of high operating costs, low operating levels, and complicated equipment, and achieves improvement of air quality, protection of health, and reduction of raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

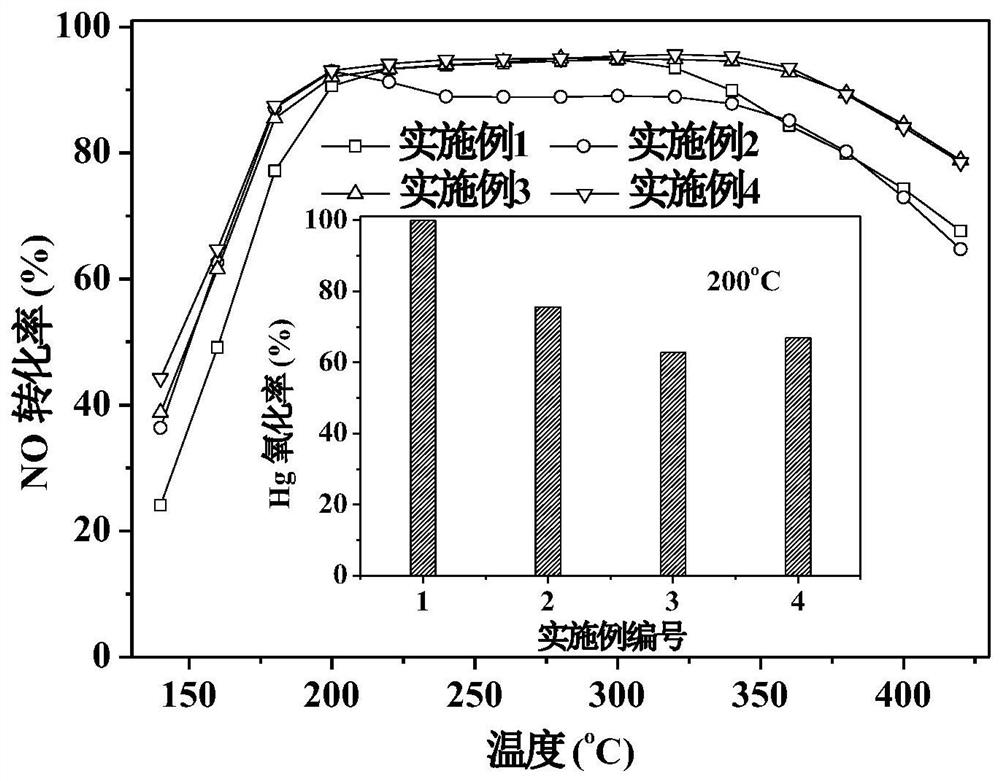

Embodiment 1

[0043] This embodiment provides a kind of catalyst, and its raw material comprises: ammonium metavanadate, ammonium molybdate, triammonium phosphate, cuprous oxide, gamma-alumina and anatase titanium dioxide; By mass ratio, ammonium metavanadate: molybdenum Ammonium acid: triammonium phosphate: cuprous oxide: γ-alumina: anatase titanium dioxide = 1:2:0.5:1:1:24.

[0044] Present embodiment provides the preparation method of above-mentioned catalyst simultaneously, comprises the steps:

[0045] (1) After mixing ammonium metavanadate, ammonium molybdate, triammonium phosphate, cuprous oxide, γ-alumina and anatase titanium dioxide, add them to 50ml deionized water together, and use oxalic acid as an acid-base regulator to adjust the slurry pH to 3.5, stir evenly for 1.5-2 hours, until the mixture is uniform, to obtain the impregnating solution;

[0046] (2) Dry the impregnating solution at 120°C for 4 hours, take it out, place it in a muffle furnace and bake it in sections, firs...

Embodiment 2

[0048] This embodiment provides a kind of catalyst, and its raw material comprises: ammonium metavanadate, ammonium molybdate, ammonium fluoride, lanthanum oxide, gamma-alumina and anatase titanium dioxide; By mass ratio, ammonium metavanadate:molybdic acid Ammonium: ammonium fluoride: lanthanum oxide: γ-alumina: anatase titanium dioxide = 1:2:0.2:1:1:24.

[0049] Present embodiment provides the preparation method of above-mentioned catalyst simultaneously, comprises the steps:

[0050] (1) After mixing ammonium metavanadate, ammonium molybdate, ammonium fluoride, lanthanum oxide, gamma-alumina and anatase titanium dioxide, they are added to 50ml deionized water together, and oxalic acid is used as an acid-base regulator to adjust the concentration of the slurry When the pH reaches 3.5, stir evenly for 1.5-2 hours, until the mixture is uniform, and the impregnation solution is obtained;

[0051] (2) Dry the impregnating solution at 120°C for 4 hours, take it out, place it in ...

Embodiment 3

[0053] This embodiment provides a kind of catalyst, and its raw material comprises: ammonium metavanadate, ammonium molybdate, ammonium fluoride, stannous oxide, gamma-alumina and anatase titanium dioxide; In terms of mass ratio, ammonium metavanadate: molybdenum Ammonium acid: ammonium fluoride: stannous oxide: γ-alumina: anatase titanium dioxide = 1:2:0.1:1:2:23.

[0054] Present embodiment provides the preparation method of above-mentioned catalyst simultaneously, comprises the steps:

[0055] (1) After mixing ammonium metavanadate, ammonium molybdate, ammonium fluoride, stannous oxide, γ-alumina and anatase titanium dioxide, add them to 50ml deionized water together, and use oxalic acid as an acid-base regulator to adjust the slurry pH to 4, stir evenly for 1.5 to 2 hours, until the mixture is uniform, and the impregnating solution is obtained;

[0056] (2) Dry the impregnating solution at 120°C for 4 hours, take it out, place it in a muffle furnace and bake it in section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com