Flame-retardant polyethylene cable material capable of preventing mould

A technology of flame-retardant polyethylene and cable materials, which is applied in the direction of circuits, electrical components, insulators, etc., can solve the problems affecting the physical and mechanical properties and processing of cable materials, achieve good flame-retardant performance, good anti-mold function, and avoid losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

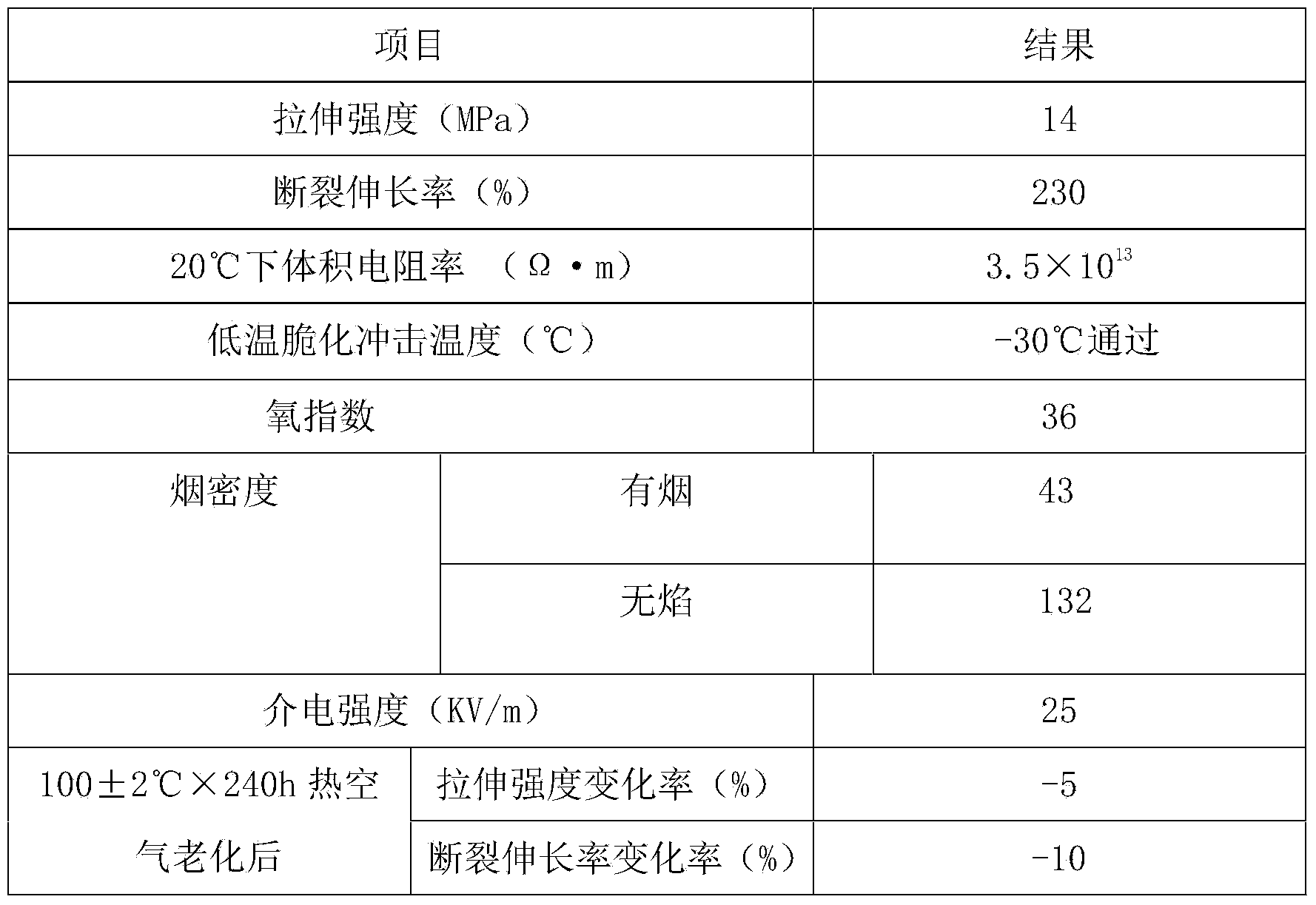

Examples

Embodiment Construction

[0017] A flame-retardant polyethylene cable material with anti-mold function, prepared from the following component raw materials in weight (kg):

[0018] High-density polyethylene resin 58, linear low-density polyethylene resin 35, polyester resin 12, silicone resin 9, dimethyl silicone oil 2, zinc oxide 1, wollastonite powder 6, barium sulfate 2, dolomite 5, attapulgite Soil 7, lapis lazuli 5, zinc hydroxide 11, triammonium phosphate 14, tricresyl phosphate TCP 11, propylene glycol adipate polyester 7, flavescens alcohol extract 2, pepper oil 0.5, OBPA antifungal agent 1, PVC Processing aid ACR-4011.0, modified filler 14,

[0019] Among them, the modified filler is prepared by the following method: a. Take the following raw materials by weight (kg): kaolin 200, diatomite 125, sepiolite 11, nano-carbon 2, zirconium fluoride 1, alum 2.5, Tibetan Fennel essential oil 2, ascorbic acid 1.5, sodium alginate 2.5, precipitated silica 32, tea polyphenol 3, acrylate-2-hydroxypropyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com