Denitration catalyst using rare earth and anion synergistically-modified titanium dioxide as carrier and preparation of catalyst

A synergistic modification, titanium dioxide technology, applied in the field of catalytic chemistry, can solve problems such as poor catalytic performance, achieve the effect of large high activity range, improve dispersibility, and avoid polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

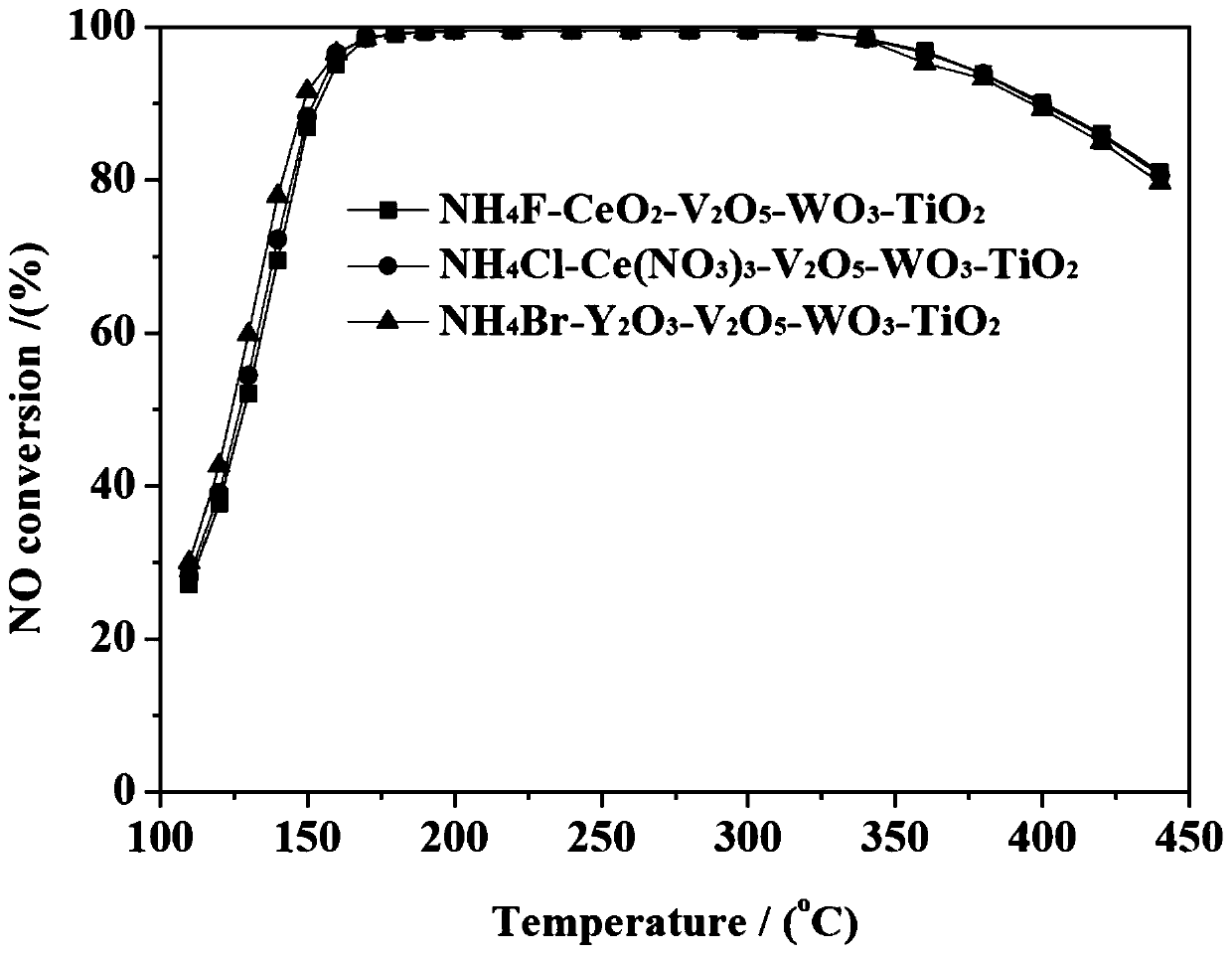

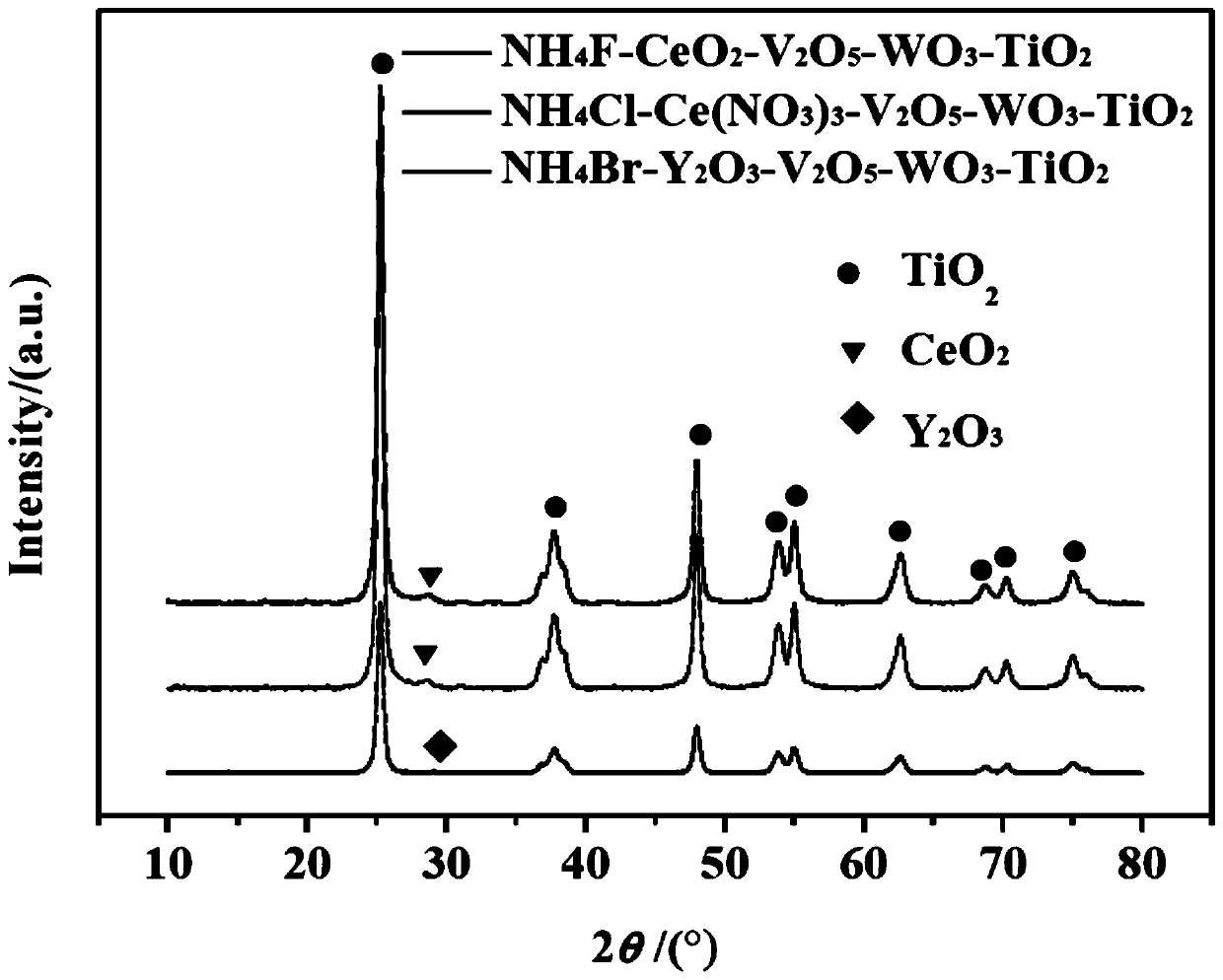

Embodiment 1

[0033] (1)CeO 2 and NH 4 F synergistically modified carrier TiO 2 preparation of

[0034] 1) Weigh 16g of industrial grade anatase TiO 2 Add 50ml deionized water, then add 0.5g NH 4 F and 1.4g CeO 2 , stirred at 50°C for 1.5 hours until it became viscous;

[0035] 2) Put the above viscous material into an oven, bake at 110°C for 3 hours, cool down to room temperature naturally, and grind it into powder;

[0036] 3) Put the ground powder into a muffle furnace, bake at 240°C for 2 hours, then bake at 450°C for 4 hours, take it out after cooling to room temperature, grind and sieve to 120 mesh.

[0037] (2) Loading of active components

[0038] 1) Weigh 1.5g of oxalic acid and dissolve it in 50ml of deionized water, stir and dissolve at 50°C, add 0.5g of ammonium metavanadate until it is completely dissolved into a blue clear solution. Then add 2g of ammonium tungstate and 0.3g of triammonium phosphate into the blue clear solution, and continue to stir at 50°C until compl...

example 2

[0044] (1)Ce(NO 3 ) 3 and NH 4 Cl Synergistically Modified Carrier TiO 2 preparation of

[0045] 1) Weigh 15.7g industrial grade anatase TiO 2 Add 50ml deionized water, then add 0.6g NH 4 Cl and 1.6g Ce(NO 3 ) 3 , stirred at 50°C for 1.5 hours until it became viscous;

[0046] 2) Put the above viscous material into an oven, bake at 110°C for 3 hours, cool down to room temperature naturally, and grind it into powder;

[0047] 3) Put the ground powder into a muffle furnace, bake at 240°C for 2 hours, then bake at 450°C for 4 hours, take it out after cooling to room temperature, grind and sieve to 120 mesh.

[0048] (2) Loading of active components

[0049] 1) Weigh 1.8g of oxalic acid and dissolve it in 50ml of deionized water, and stir to dissolve at 50°C, add 0.5g of ammonium metavanadate until completely dissolved to a blue clear solution. Then add 2g of ammonium tungstate and 0.3g of triammonium phosphate into the blue clear solution, and continue to stir at 50°C u...

example 3

[0055] (1)Y 2 o 3 and NH 4 Preparation of Br synergistically modified support

[0056] 1) Weigh 16.4g of industrial grade anatase TiO 2 Add 50ml deionized water, then add 0.5g NH 4 Br and 1.0 g Y 2 o 3 , stirred at 50°C for 1.5 hours until it became viscous;

[0057] 2) Put the above viscous material into an oven, bake at 110°C for 3 hours, cool down to room temperature naturally, and grind it into powder;

[0058] 3) Put the ground powder into a muffle furnace, bake at 240°C for 2 hours, then bake at 450°C for 4 hours, take it out after cooling to room temperature, grind and sieve to 120 mesh.

[0059] (2) Loading of active components

[0060] 1) Weigh 1.5g of oxalic acid and dissolve it in 50ml of deionized water, stir and dissolve at 50°C, add 0.5g of ammonium metavanadate until it is completely dissolved into a blue clear solution. Then add 2g of ammonium tungstate and 0.3g of triammonium phosphate into the blue clear solution, and continue to stir at 50°C until c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com