Iron-fortified food composition

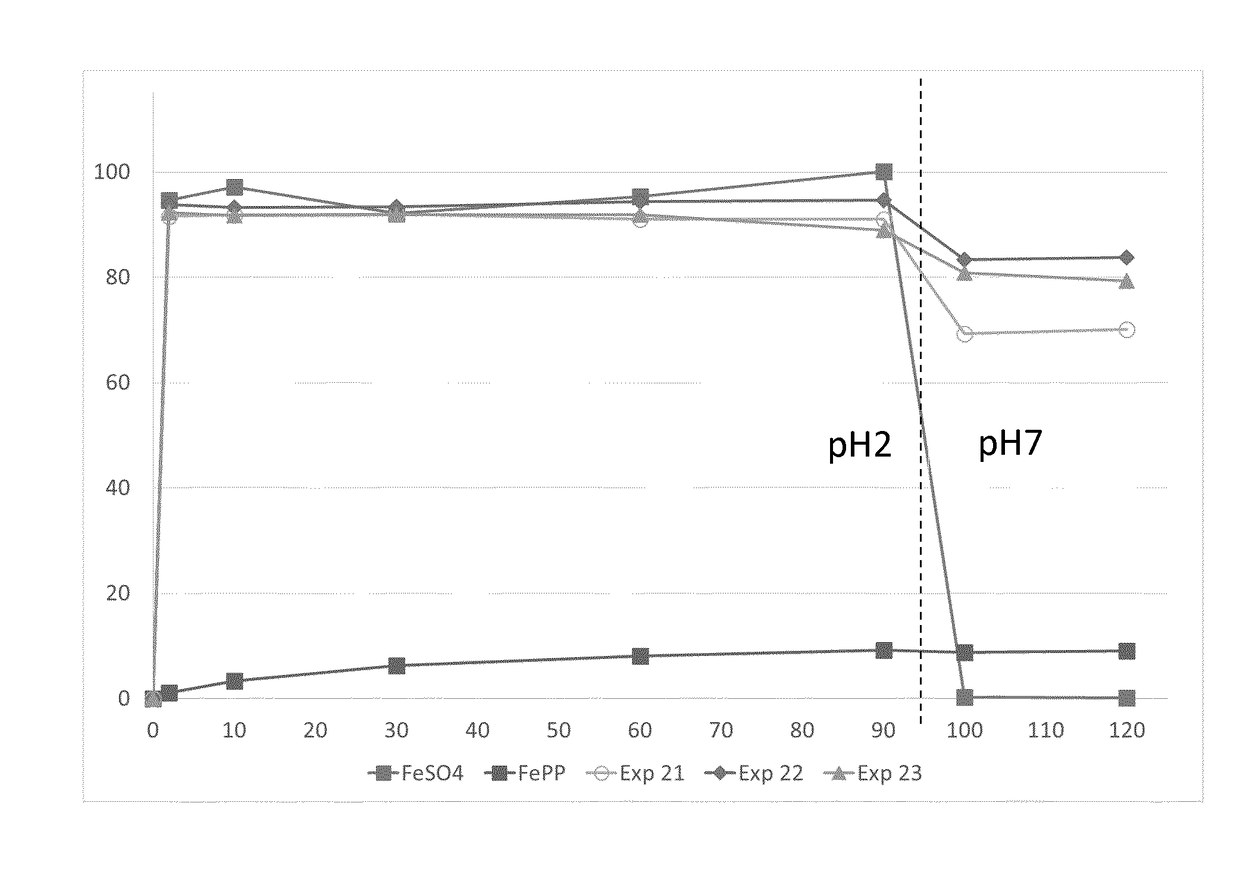

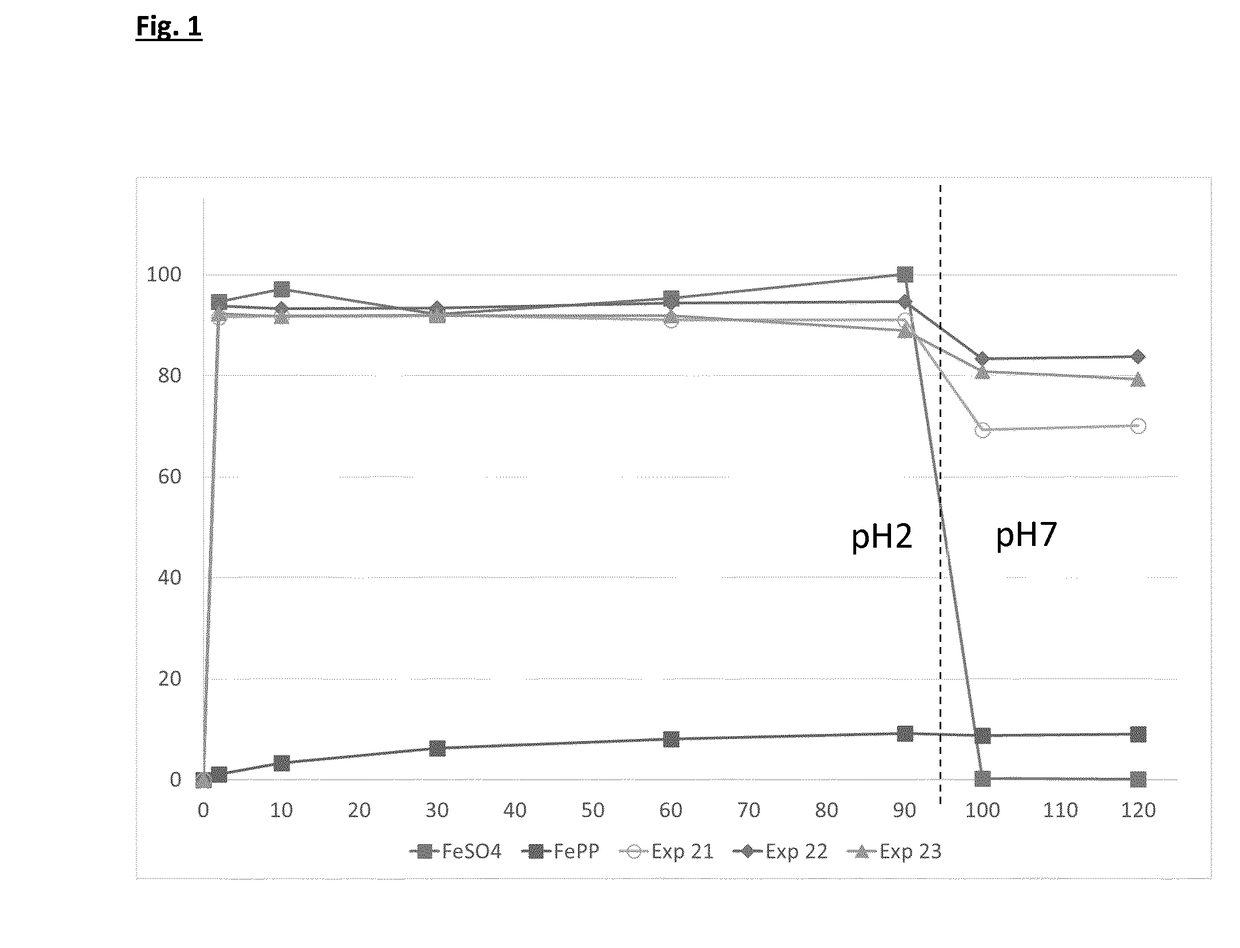

a technology of food composition and iron, applied in the field of compositions for fortifying food and/or beverages with iron, can solve the problems of difficult human digestion, and achieve the effect of increasing the bioavailability of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

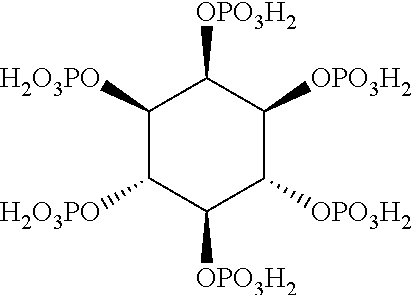

Fe: Phytic Acid: Amino Acid Complex

[0130]The ferric sulfate solution was added drop-wise to the phytic acid solution at pH 1.6 in a 500 mL glass bottle. The solution became turbid and a white precipitate was observed after a few seconds of the addition. The amino acid and / or ammonium hydroxide solutions were then added to this milky solution using the amounts reported in Table 2 until a final pH of 7±1 was reached. After stirring for between 24-48 h, the solution became clear and the product was freeze dried to provide a light yellow / white powder.

example 2

Fe: Phytic Acid: Amino Acid Complex with Heating

[0131]The ferric sulfate solution was added drop-wise to the phytic acid solution at pH 1.6 in a 500 mL glass bottle. The solution became turbid and a white precipitate was observed after a few seconds of the addition. The amino acid and / or ammonium hydroxide solutions were then added to this milky solution using the amounts reported in Table 3 until final pH of 7±1 was reached.

[0132]The bottle was then placed in a water bath at different temperatures of 60, 70 and 80° C. to accelerate the dissolution. The results are shown in Table 4.

[0133]The level of iron in Exp 13 was too high to be soluble with a molar ratio of amino acid to phytic acid of 0.5, but at a lower relative quantity of iron this molar ratio of amino acid to phytic acid is soluble (see Exp 20 in Example 8).

TABLE 4Dissolution time v. temperatureAmbienttemperature atABCExp. No.24 h60° C.70° C.80° C.13Not SolubleNot SolubleNot SolubleNot Soluble14Not Soluble8 hours8 hoursN....

example 3

Fe: Phytic Acid: Amino Acid Complex with Different Fe Ratios

[0134]80% pure ferric sulfate was solubilised in 50 mL of MilliQ water in a 500 mL glass bottle (in the varying amounts shown in Table 5) and added drop-wise to a 4.5% solution of phytic acid at pH 2.1 (100 mL, 6.8 mmol).

[0135]Histidine (8.42 g, 54 mmol) was then added drop-wise in combination with 13% ammonium hydroxide (20-30 mL) until a final pH of 7-7.5 was reached. The solution was stirred for 24-48 hours. The results are shown in Table 5.

TABLE 5Exp. No.17181920Fe:phytic acid ratio1.21.62.02.4Amount ferric22.73.44sulfate (g / 50 mLMilliQ water)Amount Fe3+81113.516(mmol)Final Fe content2.33.13.94.6(%)Results after 24-48 hSolubleSolublePartiallyPartially Solubleat roomSolubletemperature

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com