Method for preparing magnetic 4A zeolite with kaolin and red mud as raw materials

A technology of kaolin and red mud, which is applied in the field of preparing magnetic 4A zeolite, can solve the problems of weak magnetic properties and many steps of magnetic zeolite, achieve the effect of reducing wastewater treatment process, facilitating large-scale industrial preparation, and realizing large-scale industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0018] 2g of red mud and 20g of kaolin were mixed uniformly in a ball mill for 30min according to the mass ratio of 1:10; then they were calcined at 650°C for 1h under a nitrogen atmosphere, and then reduced by hydrogen for 1h; 2.2g of the reduced red mud and kaolin mixture, 0.36 Mix 1 g of sodium hydroxide and 20 g of water in a mass ratio of 6:1:50, stir evenly to form a gel-like mixture, then transfer it to a reaction kettle, heat and crystallize at 90°C, cool, wash with water, and dry to obtain the magnetic 4A zeolite.

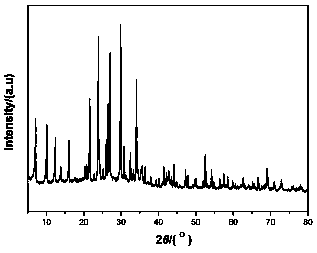

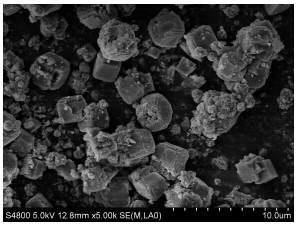

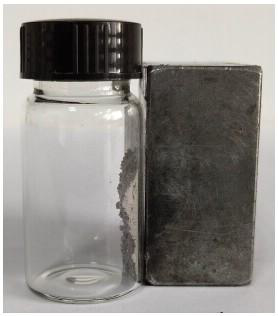

[0019] The XRD spectrum, SEM photos and magnetic separation photos of the magnetic 4A zeolite prepared in this embodiment are as follows: figure 1 , 2 and 3. It can be seen that the obtained zeolite is A-type zeolite with high crystallinity, and its shape is the cubic shape of 4A zeolite. It has good magnetic properties and can realize rapid separation under an external magnetic field.

Embodiment approach 2

[0021] 2.5g of red mud and 20g of kaolin were mixed uniformly in a ball mill for 45 minutes according to the mass ratio of 1:8; then calcined at 600°C for 2 hours under a nitrogen atmosphere, and then reduced by hydrogen for 1.5 hours; 2.2g of the reduced red mud and kaolin mixture , 0.55g sodium hydroxide and 20g water were mixed according to the mass ratio of 6:1.5:50, stirred evenly to form a gel-like mixture, then transferred to a reaction kettle, heated to crystallize at 100°C, cooled, washed with water, and dried to obtain magnetic 4A Zeolite.

Embodiment approach 3

[0023] 5g of red mud and 20g of kaolin were mixed uniformly in a ball mill for 50 minutes according to the mass ratio of 1:4; then they were calcined at 700°C for 3 hours under a nitrogen atmosphere, and then reduced by hydrogen for 2 hours; 2.2g of the reduced red mud and kaolin mixture, 0.44 Mix g sodium hydroxide and 20 g water according to the mass ratio of 6:1.2:50, stir evenly to form a gel-like mixture, then transfer it to a reaction kettle, heat and crystallize at 80°C, cool, wash with water, and dry to obtain magnetic 4A zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com