Patents

Literature

221 results about "Tollens' reagent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

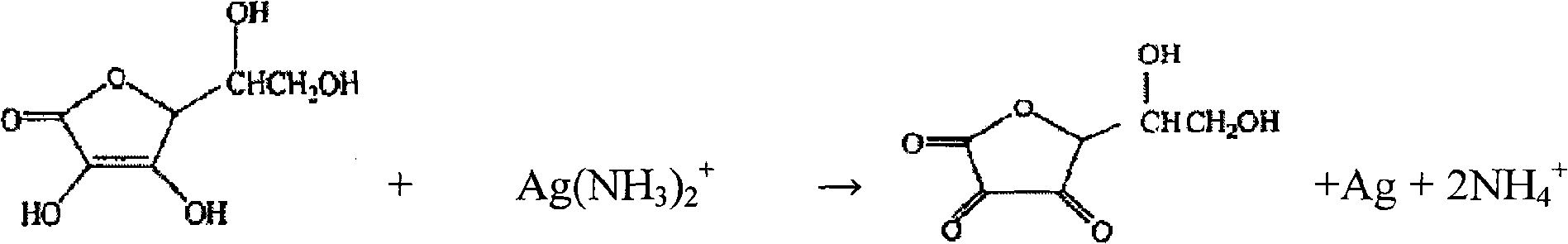

Tollens' Reagent is a chemical reagent used to determine the presence of aldehyde, aromatic aldehyde, and alpha-hydroxy ketone functional groups. The reagent consists of a solution of silver nitrate, ammonia and some sodium hydroxide (to maintain a basic pH of the reagent solution). It was named after its discoverer, the German chemist Bernhard Tollens. A positive test with Tollens' reagent is indicated by the precipitation of elemental silver, often producing a characteristic "silver mirror" on the inner surface of the reaction vessel.

Preparation method of graphene-silver nano particle composite material

InactiveCN102160998AEasy to insertNarrow distributionNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsFiltrationMaterials science

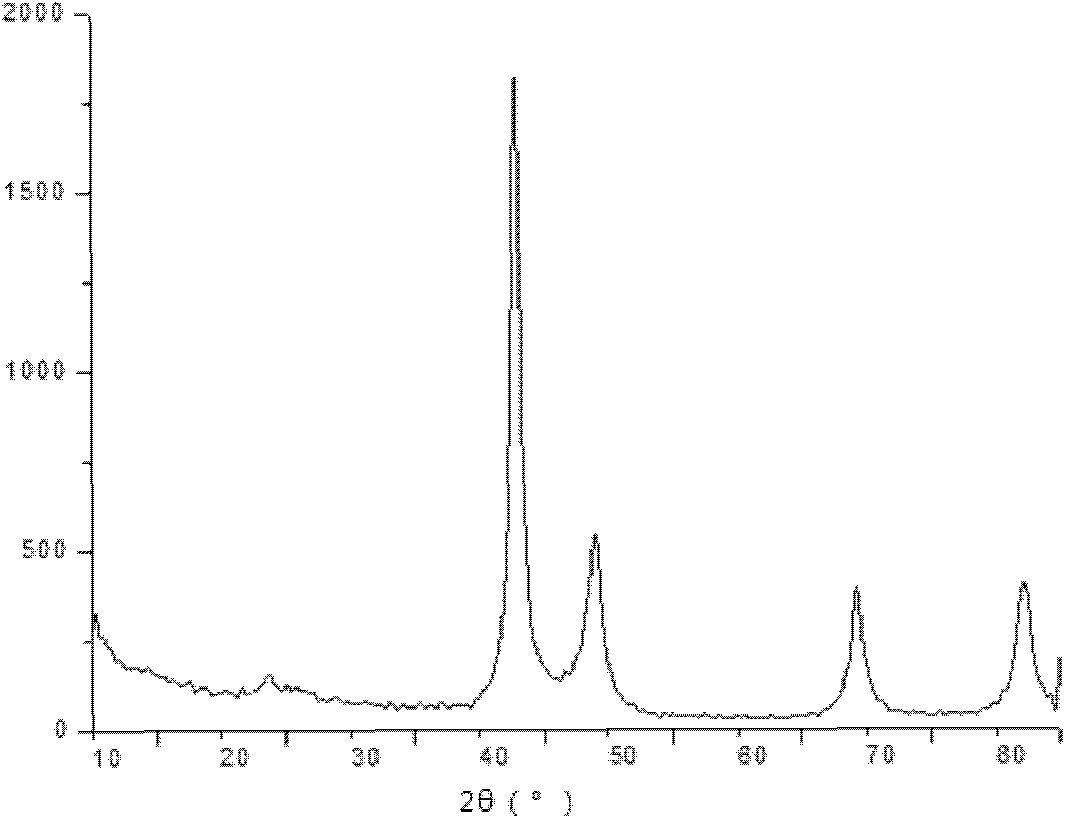

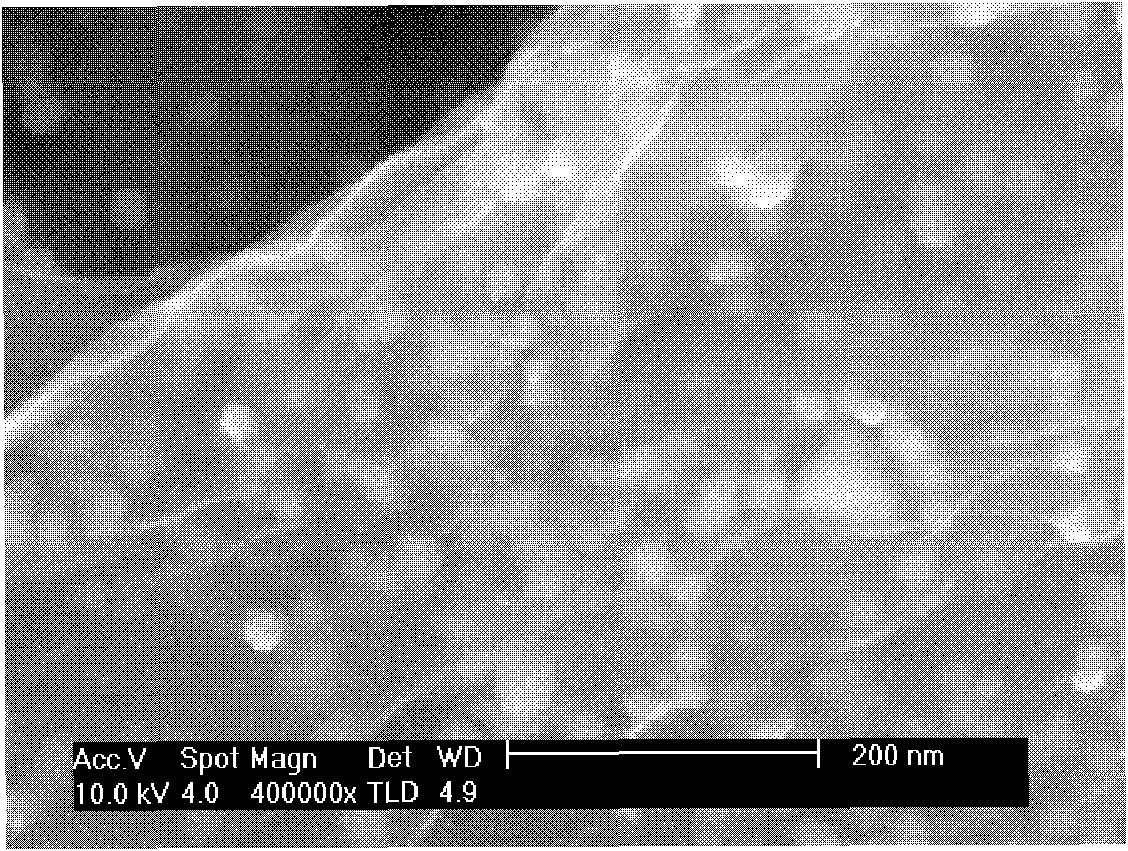

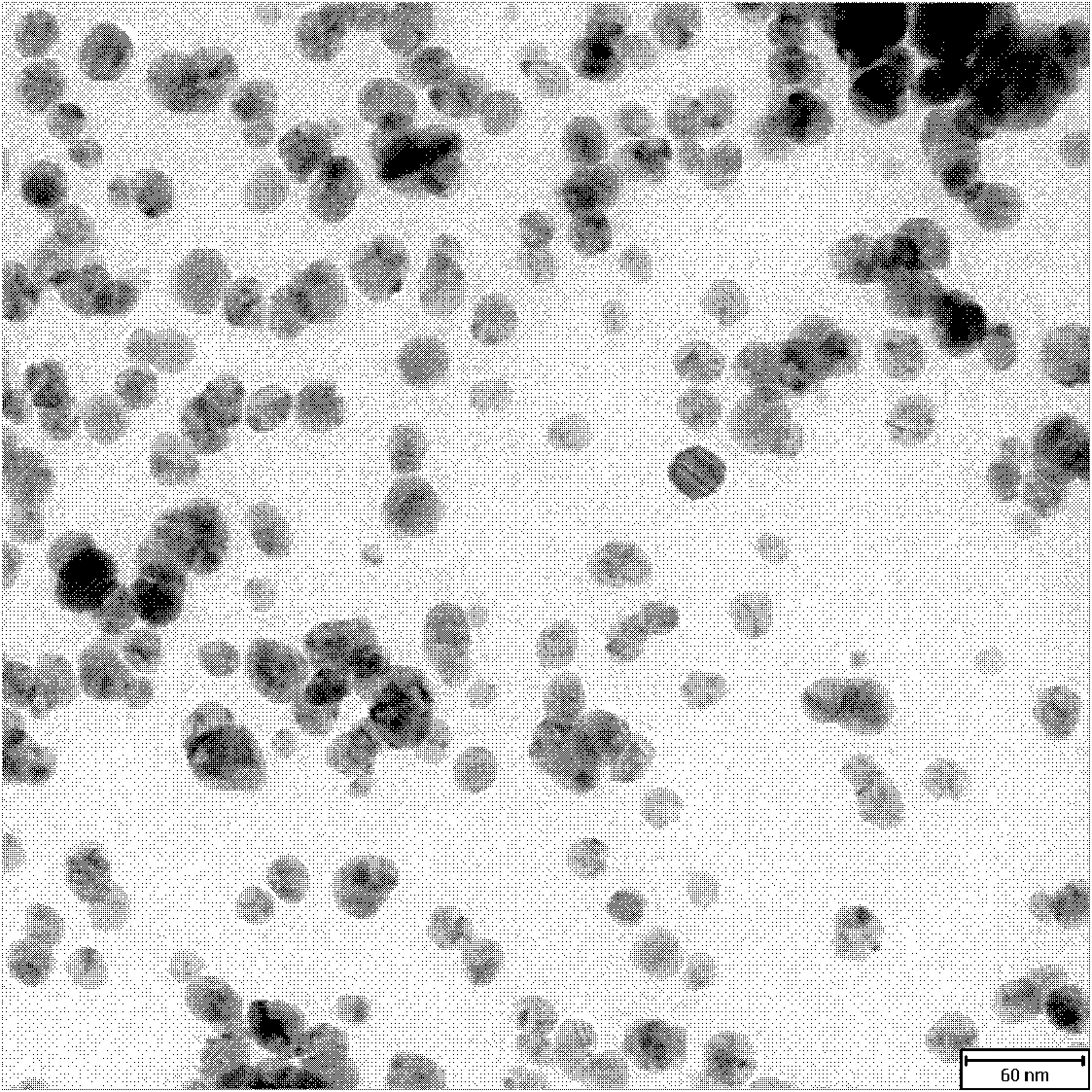

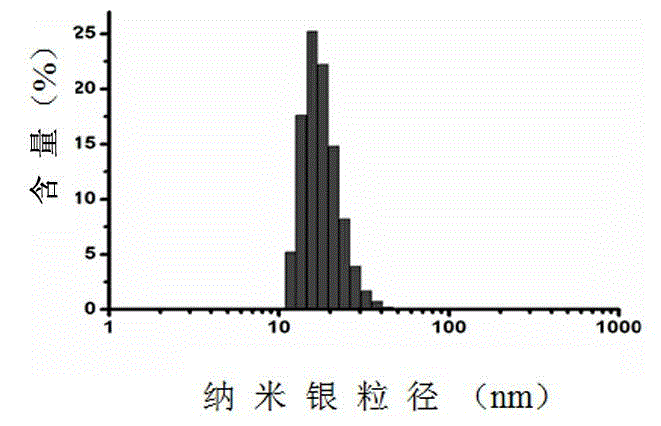

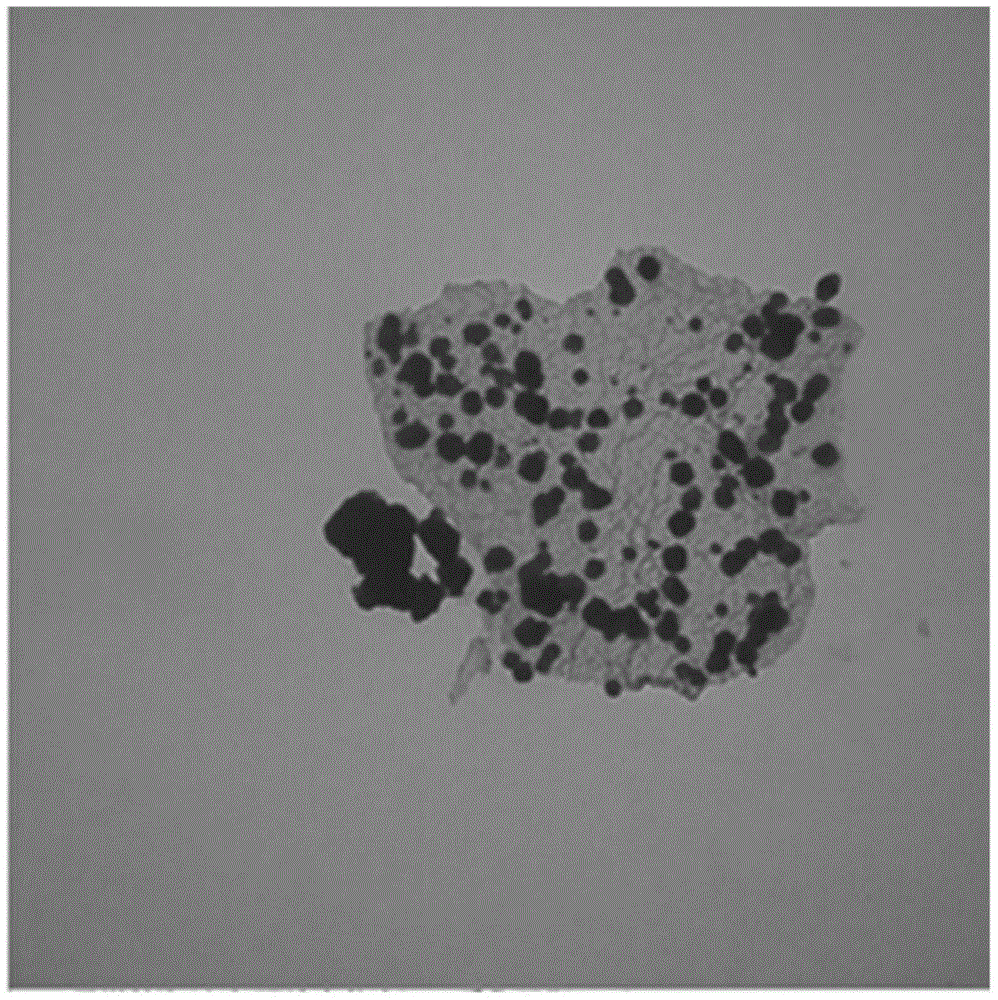

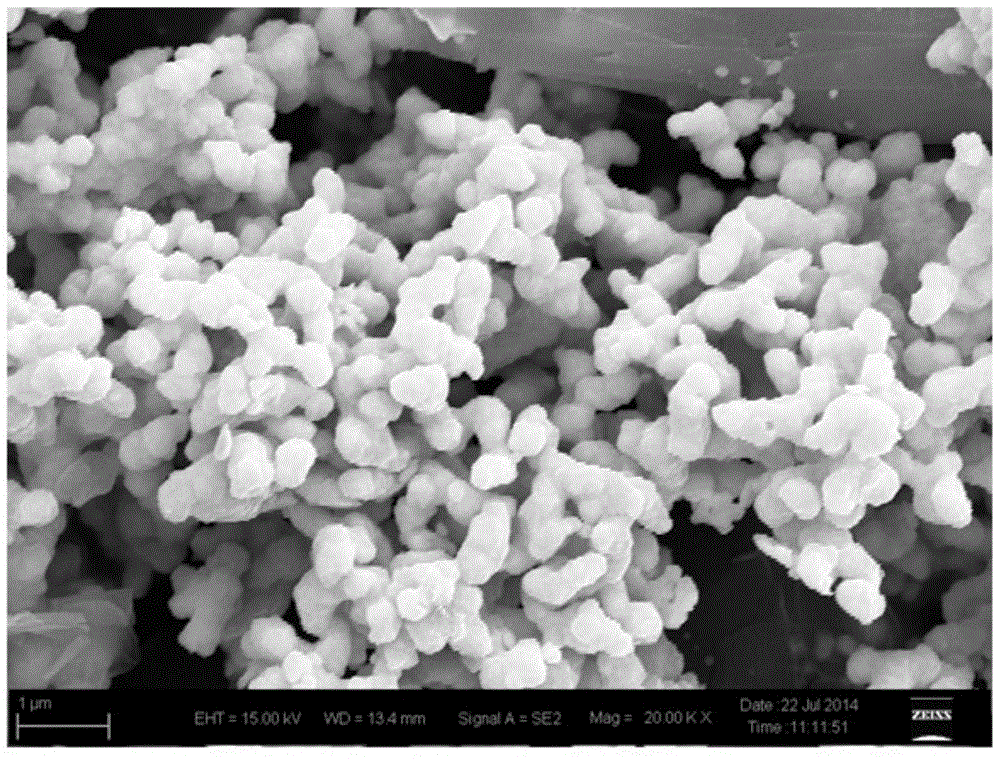

The invention provides a preparation method of a graphene-silver nano particle composite material. A specific preparation process comprises the following steps of: preparing solution of silver ammonia at certain concentration from the solution of silver nitrate and aqueous solution of dilute ammonia, adding the prepared solution of silver-ammonia into the solution of graphene oxide which is subjected to ultrasonic processing, preheating the solution at a certain temperature for a certain time; adding an appropriate amount of glucose into the mixed solution of graphene oxide and silver ammonia, and reacting the mixed solution at the set temperature for a certain time with stirring; performing suction-filtration on a reaction product by using deionized water for many times, and then drying the product to obtain the graphene-silver nano particle composite material. The method is simple, convenient, easy, environment-friendly and efficient; and silver nano particles in the prepared composite material are distributed narrowly, have a uniform particle size (about 25 nm), can be better inserted into graphene slices and can effectively prevent aggregation of the graphene.

Owner:BEIHANG UNIV

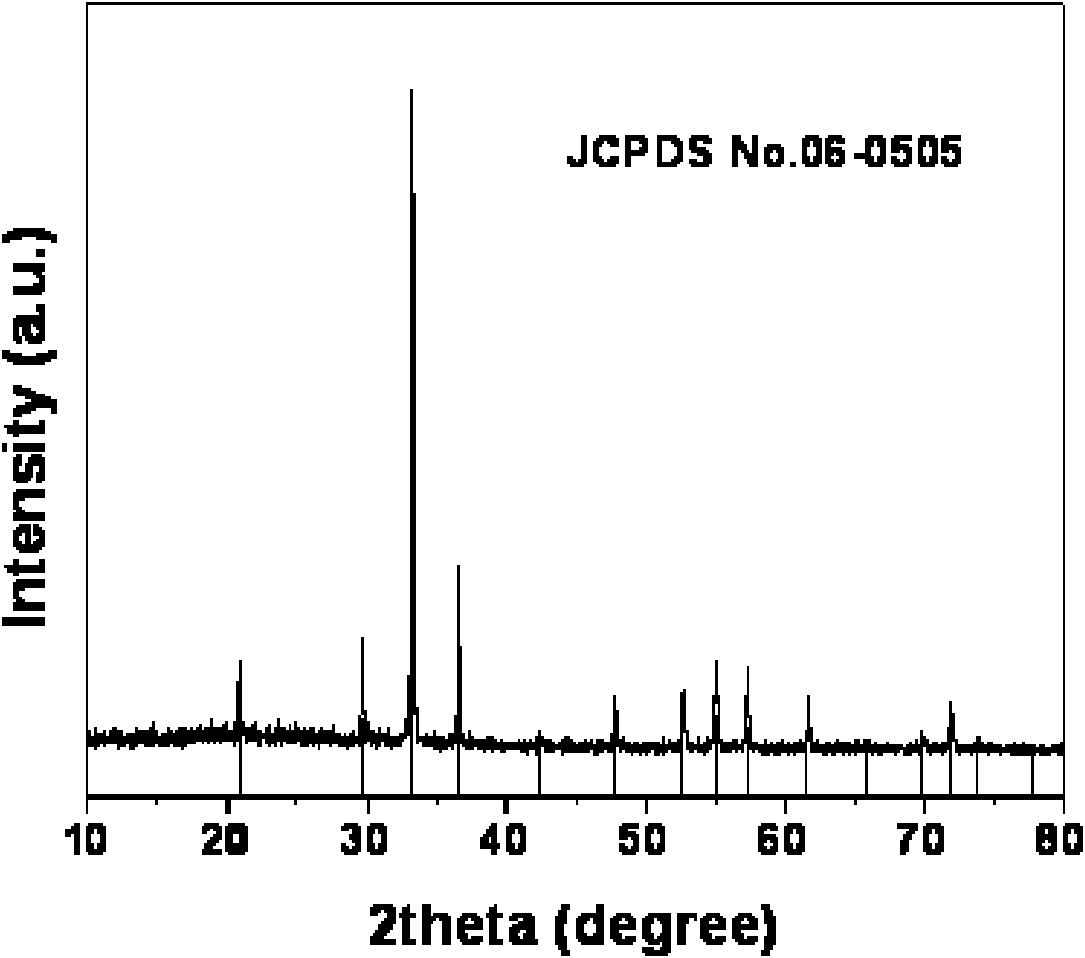

Novel visible catalyst-silver phosphate and preparation method thereof

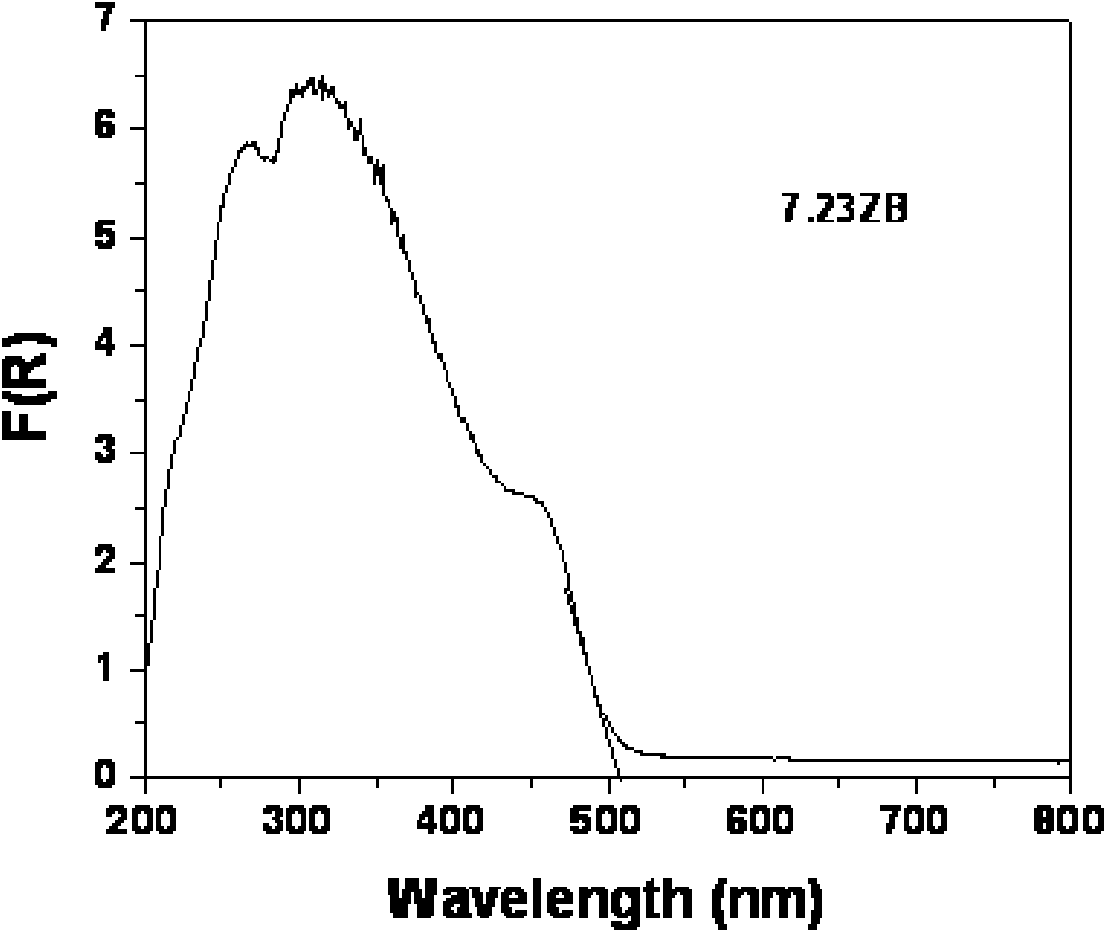

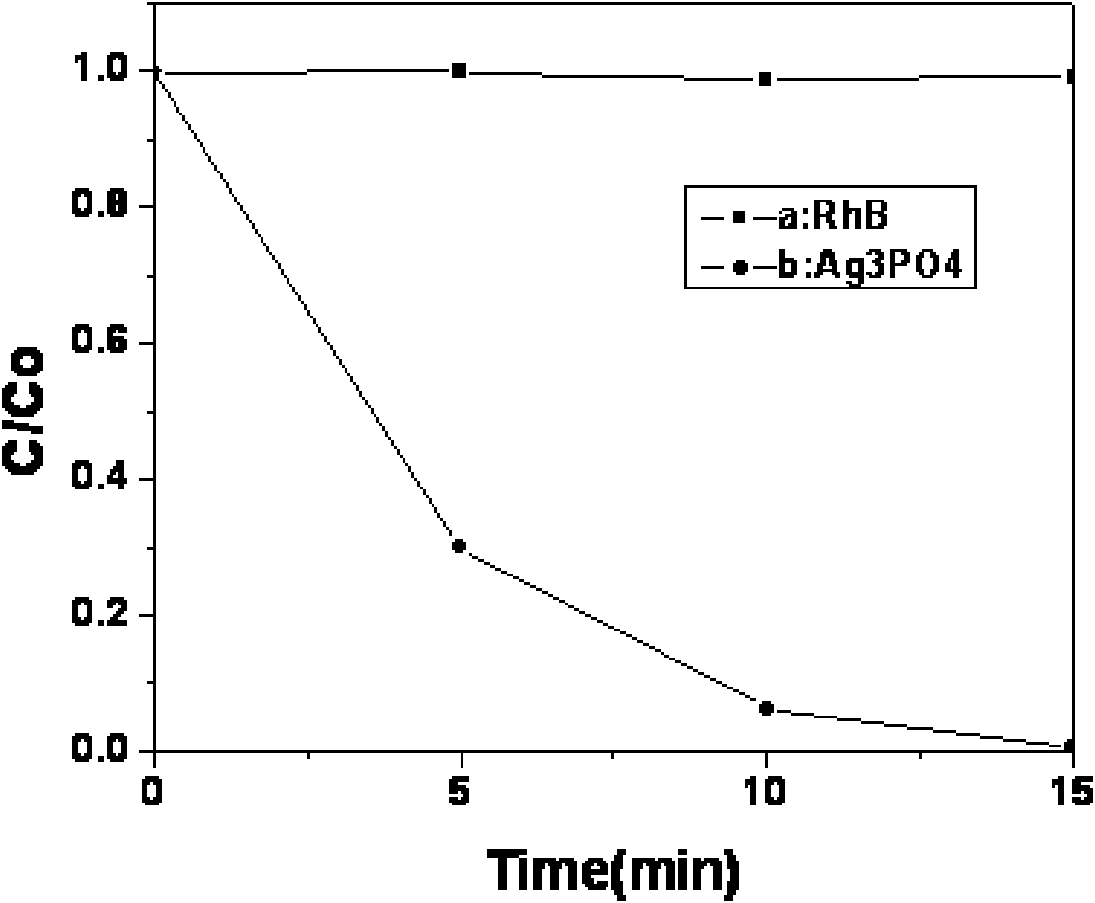

InactiveCN101648139AReduced band gapEfficient Photocatalytic ReactionPhysical/chemical process catalystsPhosphorus compoundsPhosphate ionAmmonium hydroxide

The present invention provides a novel visible catalyst-silver phosphate and a preparation method thereof, solving the problems of wide TiO2 forbidden band, no absorbability of visible weakness, and the like in the prior art and applying Ag3PO4 to the field of photocatalysis for the first time. In the invention, a silver ammonia solution for replacing a silver nitrate solution is used as a silversource, the reaction of silver ions and phosphate ions is slowed, and then the catalyst is obtained and has the effect of high-efficiency photocatalytic degradation. The preparing method of the invention is simple and is favorable to extensive popularization.

Owner:FUZHOU UNIV

Nano mirror spray coating

InactiveCN1944710AExtended use timeImprove adsorption capacityLiquid/solution decomposition chemical coatingPotassium borohydrideSpray coating

The nanometer mirror spraying process includes the following steps: 1. eliminating surface dust; 2. spraying primer; 3. sensitizing and activating treatment; 4. spraying solution A comprising silver nitrate solution, ammonia water solution and sodium hydroxide solution and solution B comprising sodium borohydride, potassium borohydride or p-methylaminophenol sulfate solution in the volume ratio of 1 to 1-1.7 to produce reduction; 5. shaping and developing; 6. blowing to dry; and 7. drying. The present invention has the advantages of diversified products, high corrosion resistance, suitability to mass production, high hardness, low cost, etc.

Owner:方宏亮

Preparation method of nanometer sliver colloid solution

The invention discloses a safe, environment-friendly and stable preparation method of a nanometer sliver colloid solution, comprising the following steps: mixing the alkylated cyclodextrin aqueous solution and the silver ammonia solution according to the volume ratio of 1:100-1:10, wherein the mass percent of the alkylated cyclodextrin aqueous solution is 0.1-10%, and the mass molar concentration of the silver ammonia solution is 0.01-1.0mol / L; and stirring for 1-120min at 10-100 DEG C to obtain the nanometer sliver colloid solution of which the average grain diameter is 1-100nm. The method of the invention has the advantages of simple preparation process and can ensure the application safety of the nanometer sliver colloid solution, and the prepared nanometer sliver colloid solution has the characteristics of good stability, small grain diameter of nanometer sliver, less dosage and high antibiosis efficiency in the function materials of the nanometer sliver.

Owner:ZHANGJIAGANG NELLNANO TECH

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

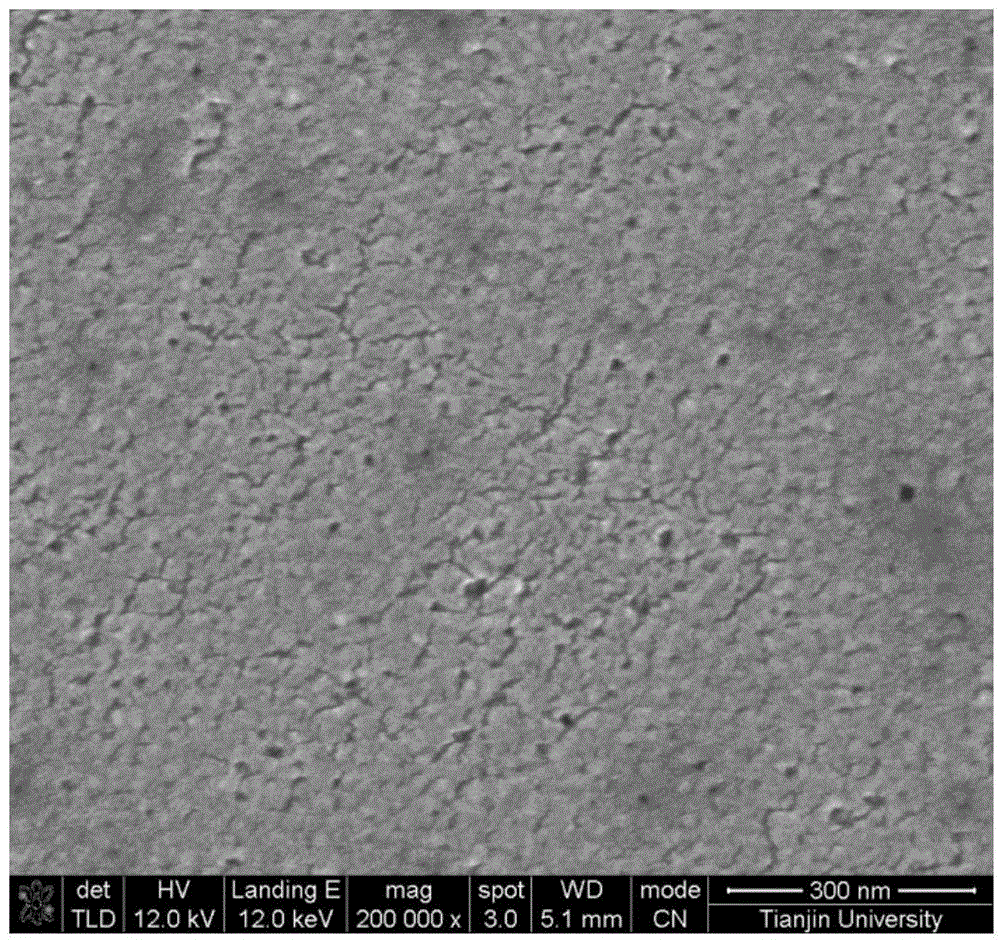

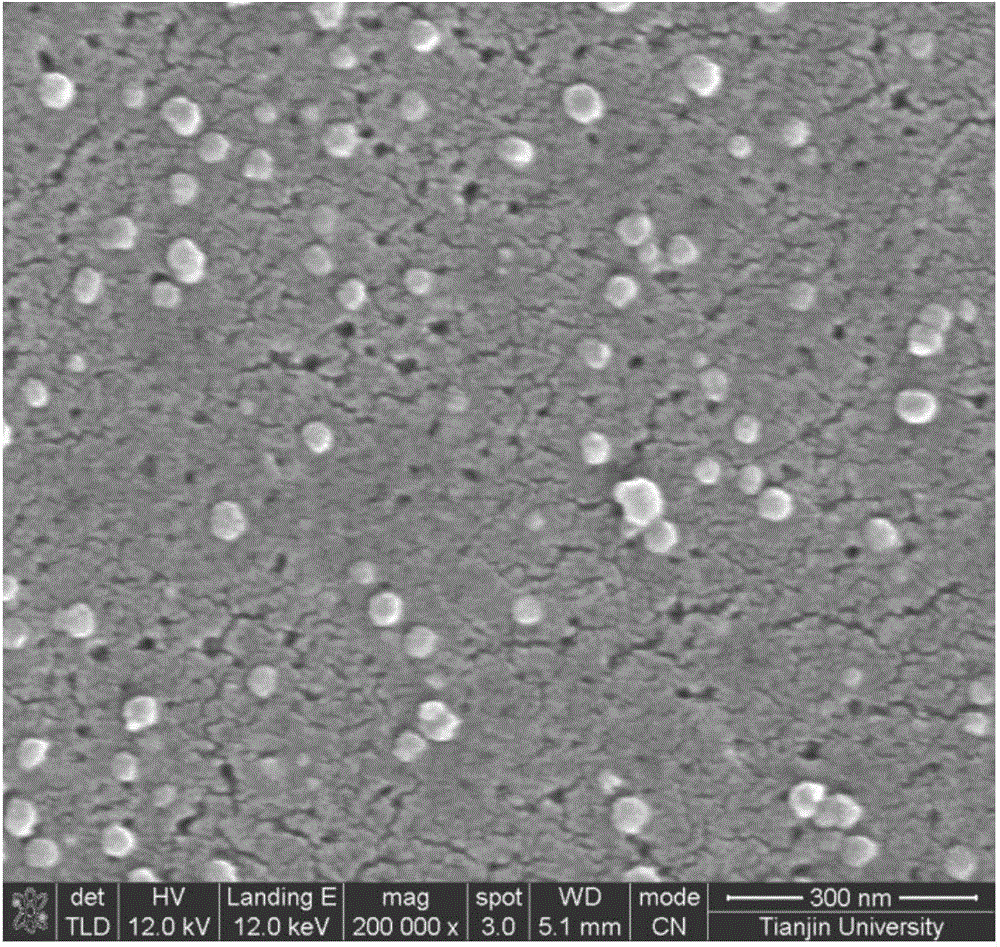

Polydopamine/silver modified polymer separating membrane and preparation method

InactiveCN104888631AIncreased pure water fluxImprove anti-pollution performanceSemi-permeable membranesEscherichia coliStaphylococcus aureus

The invention relates to a polydopamine / silver modified polymer separating membrane and a preparation method. A mixed solution of trihydroxymethyl aminomethane, dopamine hydrochloride and water is prepared; a polymer separating membrane is placed in the mixed solution and is vibrated to react for 0.2-5 h, then, a reaction liquid is poured out, the surface of the membrane is cleaned with water, and the polydopamine modified polymer separating membrane is obtained; a mixed solution containing a silver-ammonia solution, a stabilizing agent, a reduction agent and water is prepared; the polydopamine modified polymer separating membrane is placed in the mixed solution and is vibrated to react for 0.5-5 h, then, a reaction fluid is poured out, the surface of the membrane is cleaned with water, and the polydopamine / silver modified polymer separating membrane is obtained. The separating membrane has good hydrophily, osmosis selectivity performance, antifouling property and antibacterial performance; the operation is simple, and amplification is easy; the pure water permeability of the membrane is improved by 10%-40%, and the sterilizing rates of escherichia coli, staphylococcus aureus and bacillus subtilis are all higher than 90%.

Owner:TIANJIN UNIV

Method for preparing nano-silver hydrosol by using plant extract

The invention discloses a method for preparing nano-silver hydrosol by using a plant extract. The method comprises the following steps of: dissolving or dispersing soluble amylose into deionized water, stirring until the soluble amylase is completely gelatinized; adding a Tollens solution and mixing to obtain a starch-Tollens compound solution; freezing the compound solution into ice blocks and smashing the ice blocks into colloidal particle ice powder; and adding the colloidal particle ice powder into an alkaline plant blade extract and fully mixing to obtain the nano-silver hydrosol with the particle size of 1 to 100 nm. By the method, a silver ion and protecting agent compound solution is frozen and smashed; the obtained ice powder carried with silver ions is activated and reduced to obtain nano silver; the method is simple, convenient and high in controllability; and the prepared nano-silver hydrosol is high in stability and has the advantages of small nano-silver particle size, uniform distribution, high antibacterial efficiency and the like and can be widely applied to the field of electrons, textile, catalysis, medical materials, medical treatment and public health and the like.

Owner:SUZHOU UNIV

Method for modifying graphene through nano-sliver

The invention discloses a method for modifying graphene through nano-sliver. The method includes the steps of 1, adding graphene into water for ultrasonic treatment; 2, adding sodium hydroxide solution into silver nitrate solution, and dropping ammonia while stirring until obtained solution clarifies so that silver-ammonia solution is obtained; 3, mixing and dissolving tartaric acid and glucose in water, and performing stirring to allow dissolution; 4, heating the solution obtained in the step 3, and allowing the solution to cool to the room temperature; 5, adding ethyl alcohol into the solution obtained in the step 4, and mixing them well; 6, adding the solution obtained in the step 2 and the solution obtained in the step 5 successively into the solution made in the step 1, and allowing reaction under ultrasonic conditions; 7, subjecting a product of the step 6 to suction filtering, washing the filtered product with ethyl alcohol and water in turns, and performing drying to obtain nano-sliver modified graphene. The method has the advantages that reaction materials are simple and easy to obtain, reaction conditions are moderate, efficiency is high, the product has stable properties, and wider range of production is benefited; the graphene to be used is complete in structure and has few surface functional groups, and nano-sliver modification of the surface of the graphene is more benefited.

Owner:HARBIN INST OF TECH

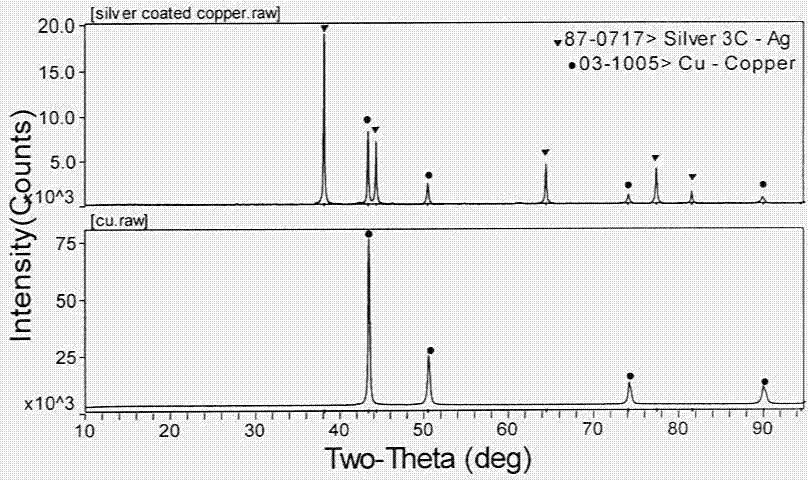

A method for preparing silver plated copper powder

InactiveCN1704502AWith room temperature oxidation resistanceFlat surfaceLiquid/solution decomposition chemical coatingSilver plateAmmonium hydroxide

The invention relates to a process for preparing silver-plated copper powder, which comprises using chelation extracting agent during the silver-plated copper powder production from silver ammonia solution, obtaining cheliform compounds with the obtained Cu2++ and loading into organic phase. The silver-plated copper powder have high oxidization resistance under normal temperature.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

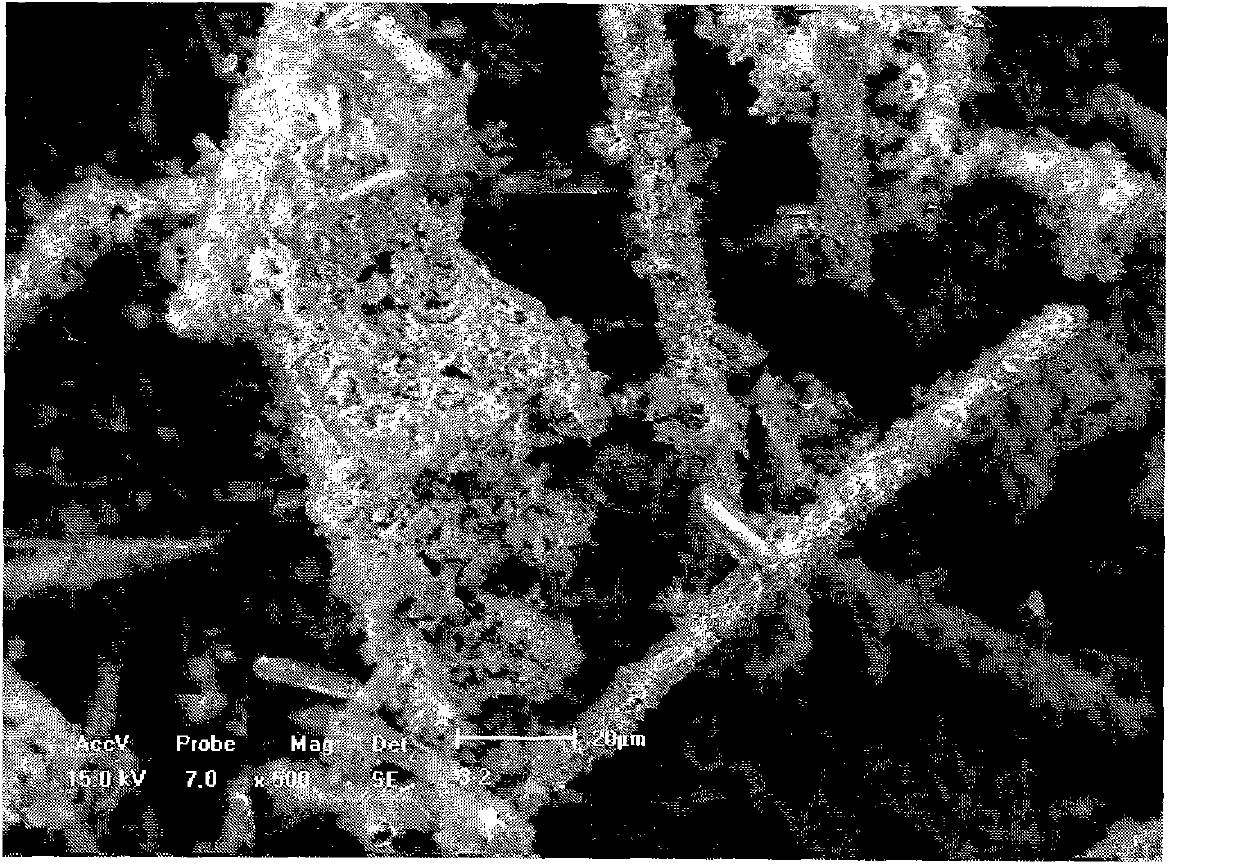

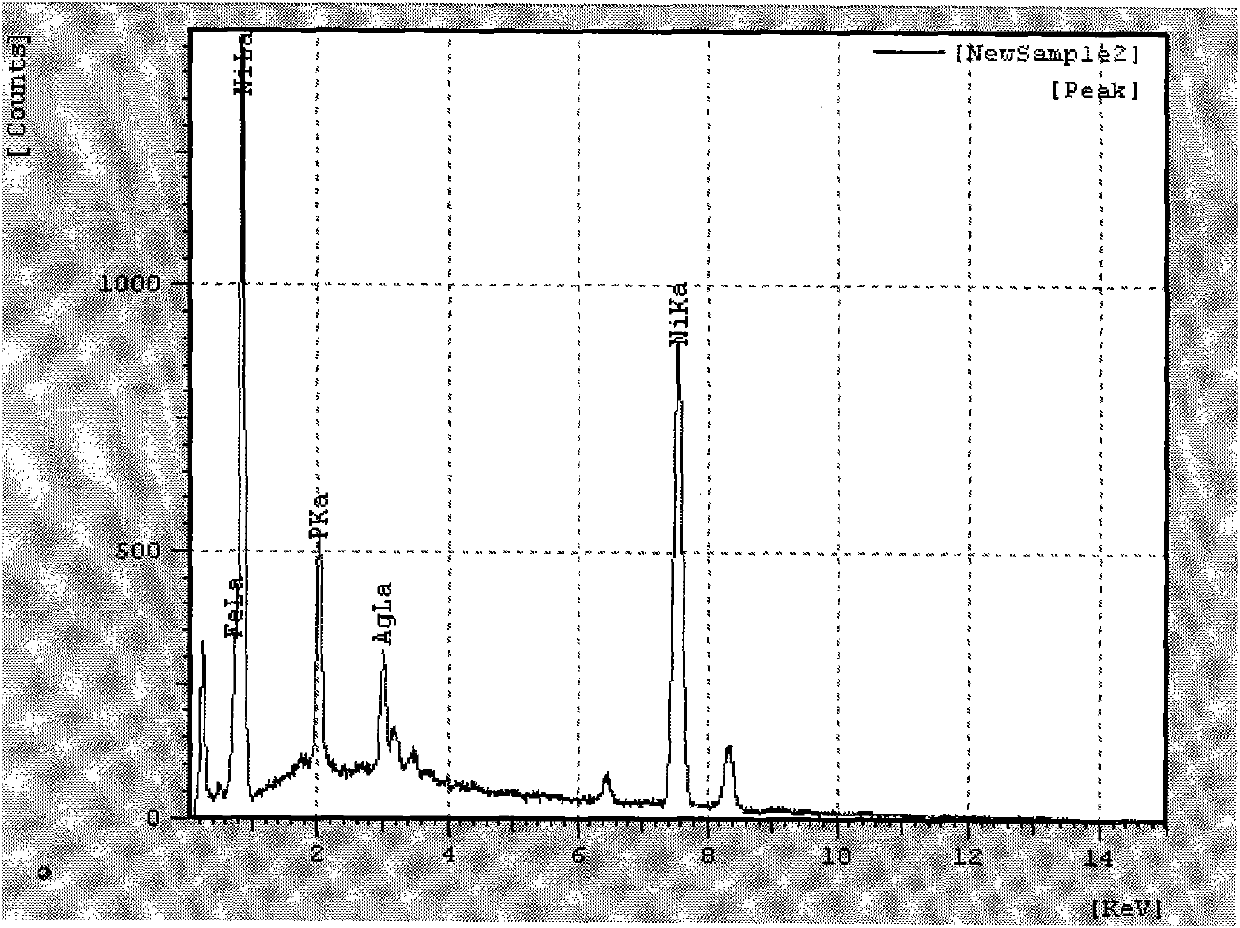

Synthetic method for supported silver phosphate/silver catalyst

InactiveCN102614902APromote absorptionImprove utilization efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationO-Phosphoric AcidPtru catalyst

The invention discloses a synthetic method for a supported silver phosphate / silver catalyst. The synthetic method includes steps of weighing 1-1.2mmol of silver nitrate to prepare 10-15mmol / L of solution at first and dripping weak aqua ammonia into the solution to obtain Tollens' reagent; then weighing 20g of bentonite; adding 80-100mL of distilled water into the bentonite to immerse the bentonite for 10 hours to 12 hours so as to obtain bentonite suspension; dripping the Tollens's reagent into the bentonite suspension, stirring, ageing in water bath at the temperature ranging from 80 DEG C to 85 DEG C for 24 hours, washing by four times to five times, and adding 30-50mL of distilled water; dripping 0.01-0.1mol / L of phosphoric acid in a product, stirring for 4 hours, leading the mole ratio of the adding quantity of the phosphoric acid to the used quantity of the silver nitrate to be 1:3, ageing in water bath at the temperature ranging from 60 DEG C to 65 DEG C for 24 hours after stirring is finished, and repeatedly washing until supernate is neutral; and finally drying at the temperature of 105 DEG C, grinding, and irradiating under an xenon lamp with the power of 400-500w for 50-80 minutes so as to obtain the supported silver phosphate / silver catalyst. Utilization efficiency to natural light is increased, stability of a system is guaranteed, a nanometer laminated structure of the bentonite is utilized, accordingly, absorption ability of the catalyst and a carrier is improved, and degradation efficiency is increased.

Owner:苏州拓丰市政工程有限公司 +1

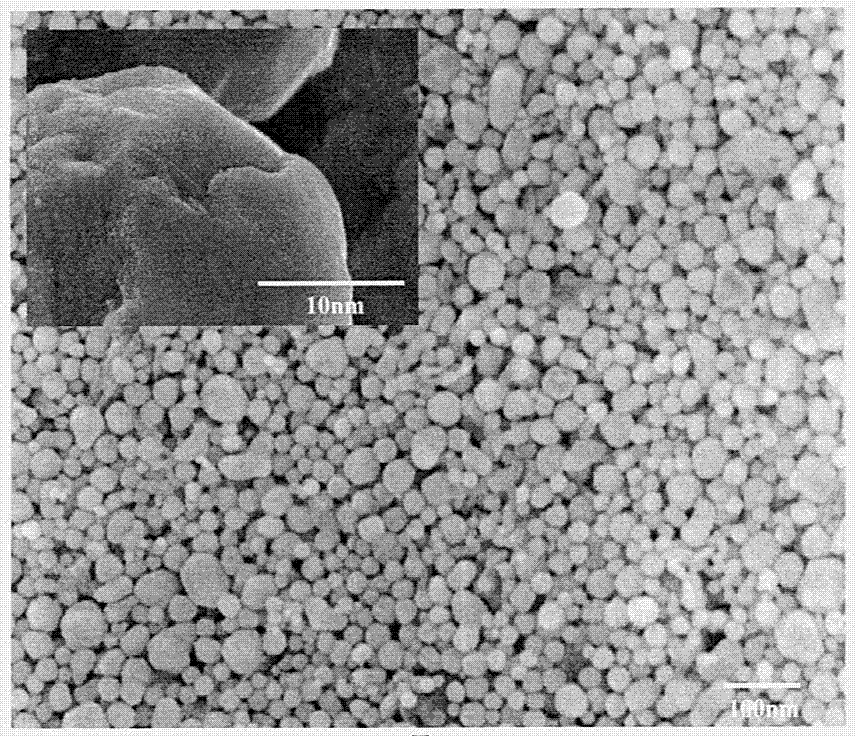

Substitution and chemistry deposition compound preparation method for nano silver coated copper powder

The invention discloses a method for preparing nano silver coated copper powder for conductive filler through reduction for a plurality of components; the method comprises the steps of preparing nano-copper powder through hydrate reduction method, adding Tollens' reagent and formaldehyde into the reaction system without separation and purification, and plating the silver on the surface of copper for preparing silver coated copper powder for electrocondution slurry through substitution-chemistry reduction compound method. The copper powder prepared by the invention can be plated with silver without separation and purification condition, so the pickling and sensitization process can be saved, the ammonium hydroxide is used for adjusting the pH of the solution as well as chelating agent for fitting the copper and silver, and the second type chelating agent is not needed, so the synthetic process is simplified and the cost is reduced. The silver coated copper powder is good in dispersibility, oxidation resistance and thermal stability, the electrical resistivity is 1*10<6> to 1*10<4>ohm*m, the nano silver coated copper powder is the spherical particle with core / shell structure, the core is copper and the shell is silver, the grain size is 20-100nm, the plating layer is even and compact and the silver content is 25-60%.

Owner:NANJING UNIV OF TECH

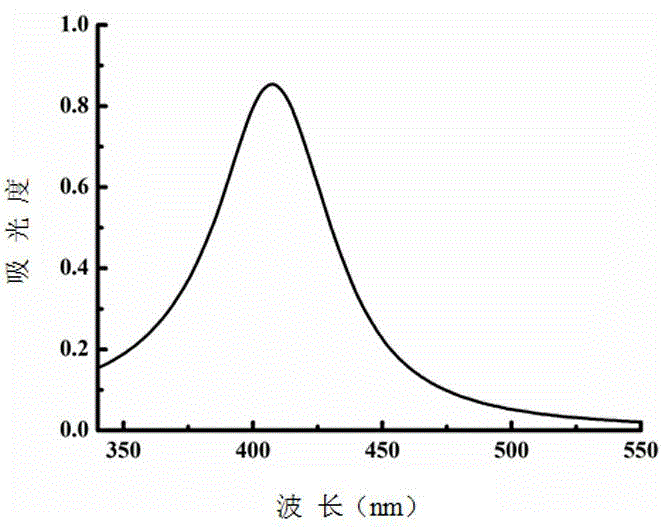

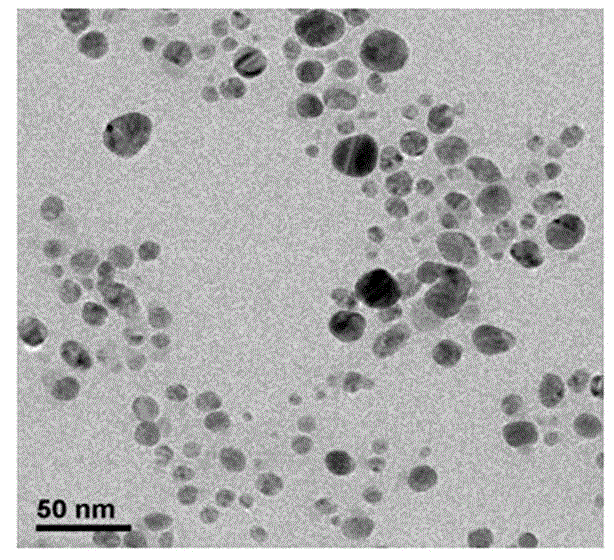

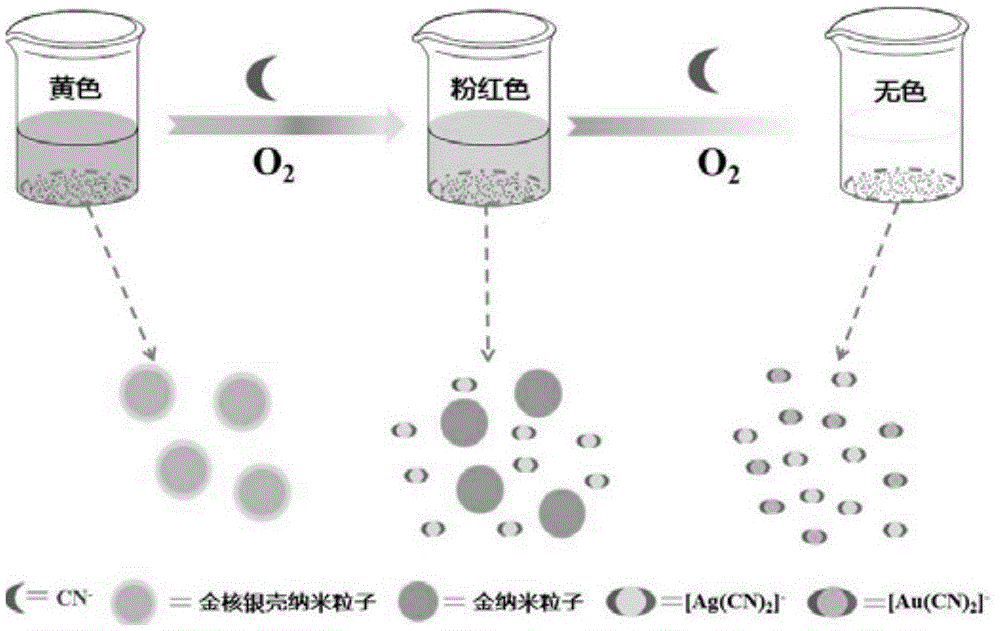

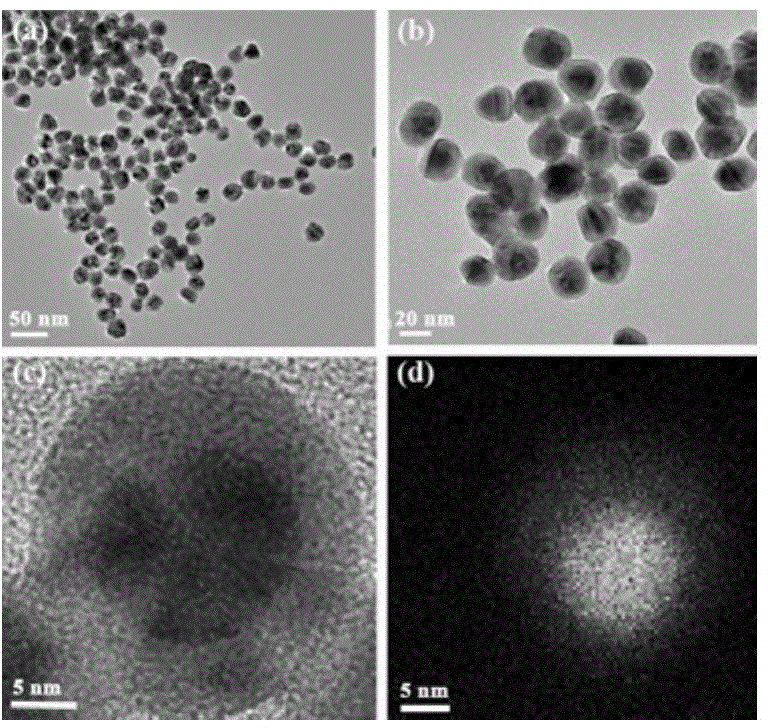

Gold-core silver-shell nanoprobe, preparation method thereof and application thereof in cyanide ion colorimetric detection

InactiveCN104096849AStable in natureEvenly dispersedMaterial analysis by observing effect on chemical indicatorNanotechnologyNanoparticleRoom temperature

The invention relates to a gold-core silver-shell nanoprobe, in particular to a gold-core silver-shell nanoprobe, a preparation method thereof and application thereof in cyanide ion colorimetric detection. The gold-core silver-shell nanoprobe is a spherical nanoparticle of a core-shell structure, a core is made of gold and 11-14nm in diameter, a shell is made of silver and 1.3-7.4nm in thickness, and stabilizers are citrate ions absorbed on the surface of the silver shell. The particle size of the gold-core silver-shell nanoprobe is 13.6-28.8nm. The preparation method includes: dissolving HAuCl4 in water to prepare an HAuCl4 solution, and heating the HAuCl4 solution to boiling to obtain a solution A; additionally dissolving sodium citrate in water, and heating the solution to boiling to obtain a solution B; mixing the solution A and the solution B, enabling the mixed solution to change from light yellow to wine red after heating, and cooling the mixed solution to room temperature so as to obtain a gold nanoparticle solution; dissolving the gold nanoparticle solution in water, sequentially adding a Tollens' reagent and formaldehyde, and making the solution to change to yellow after reaction so as to obtain the gold-core silver-shell nanoprobe.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Catalyst for use in synthesis methylglycollate and glycol and preparation method thereof

InactiveCN101816934AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationGas phaseReaction temperature

The invention belongs to the field of chemical techniques, in particular to a catalyst for continuously catalyzing the hydrogenation of gas-phase dimethyloxalate for preparing methylglycollate and glycol, and preparation method thereof. The catalyst of the invention is prepared by the following steps of: preparing ammonia solution of silver by using a soluble silver salt and adding polyvinylpyrrolidone, which serves as a protective agent and structure-directing agent, into the solution; stirring the solution, adding a reducer into the solution and keeping the reaction temperature between 20 and 90 DEG C; adding tetraethoxysilane, stirring the reaction solution for 1 to 24 hours, raising temperature to 60 to 90 DEG C, and keeping the pH value of the reaction solution at the end of the reaction between 6 and 10; and finally, washing and drying the resulting product, and roasting the reaction product at 100 to 900 DEG C for 1 to 24 hours. The prepared catalyst is used for continuously catalyzing the hydrogenation of gas-phase dimethyloxalate for preparing the methylglycollate and the glycol, can well solve existing problems, and can be used in the industrial production of the methylglycollate and the glycol.

Owner:FUDAN UNIV

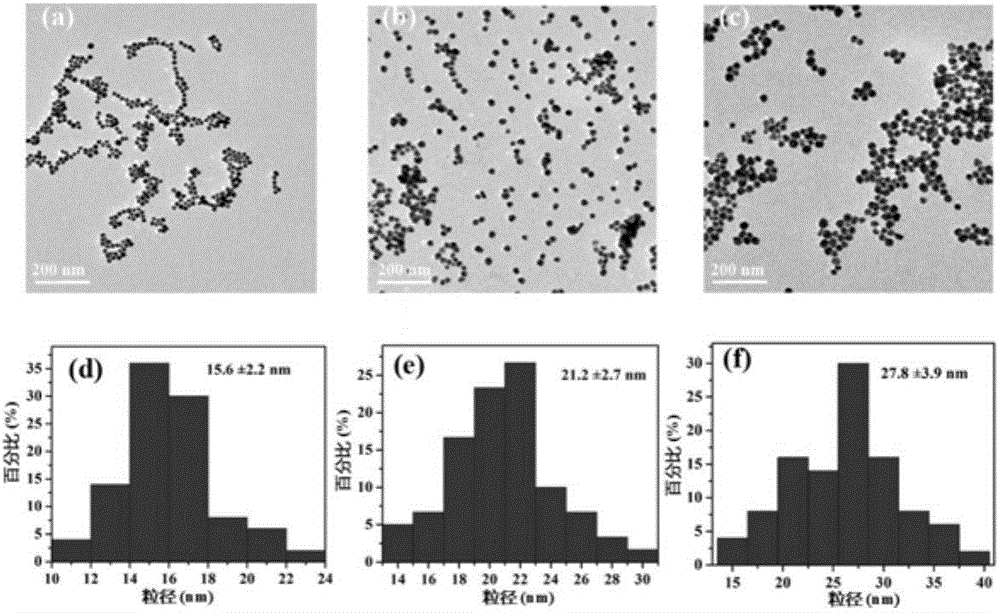

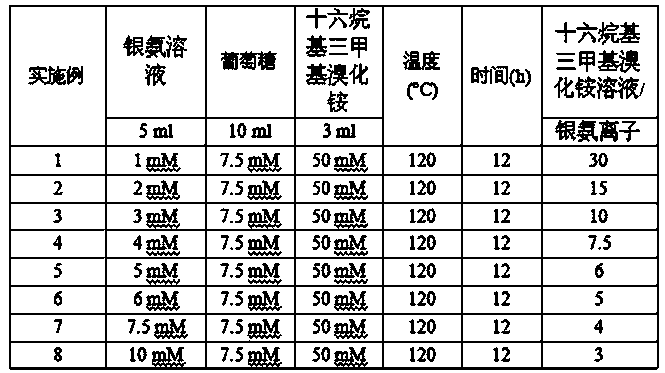

Method for preparing two-dimensional silver nanosheets of different shapes

InactiveCN103521777AUniform particle sizeGood water solubilityRaman scatteringNanotechnologyActive agentSurface-active agents

The invention discloses a method for preparing two-dimensional silver nanosheets of different shapes. Firstly, a silver mirror reaction is adopted, glucose serves as a reducing agent, a quantitative silver-ammonia solution and the quantitative glucose solution are sequentially added into a beaker to be mixed, then cetyl trimethyl ammonium bromide serves as a surface active agent, the cetyl trimethyl ammonium bromide solution is added into the mixed solution, then high-temperature reaction is carried out on the mixed solution, and a solution of the two-dimensional silver nanosheets of the different shapes is prepared by adjusting the concentration ratio of the cetyl trimethyl ammonium bromide solution and the silver-ammonia solution. The method has the advantages that operation is easy, cost is low, equipment is simple, and the prepared silver nanosheets are uniform in grain size, good in water solubility and free of obvious gathering.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for preparing nano-silver by taking modified chitosan as reducing agent

The invention relates to a method for preparing nano-silver by taking modified chitosan as a reducing agent. The method includes: dissolving chitosan in a 3% acetic acid solution with the bath ratio of 1:50, performing ultrasound treatment for 1-12h, then adding 2-10g / L of sodium periodate, performing photophobic reaction at the temperature of 40-80 DEG C for 10-60min, repeatedly cleaning with deionized water, and performing centrifuging and drying for standby application; then mixing chitosan liquid modified by 0.01-100g / L of sodium periodate with 0.01-100g / L of Tollens' reagent, performing ultrasound treatment at the temperature of 20-80 DEG C for 1-10h to obtain nano-silver colloidal solution, repeatedly cleaning with ethyl alcohol and deionized water, and performing centrifuging and drying treatment to obtain nano-silver. By taking chitosan modified with the sodium periodate as the reducing agent and a stabilizer, the method has the advantages of simple technology, mild reaction, greenness, environment friendliness and the like.

Owner:广州琶芙儿生物科技有限公司

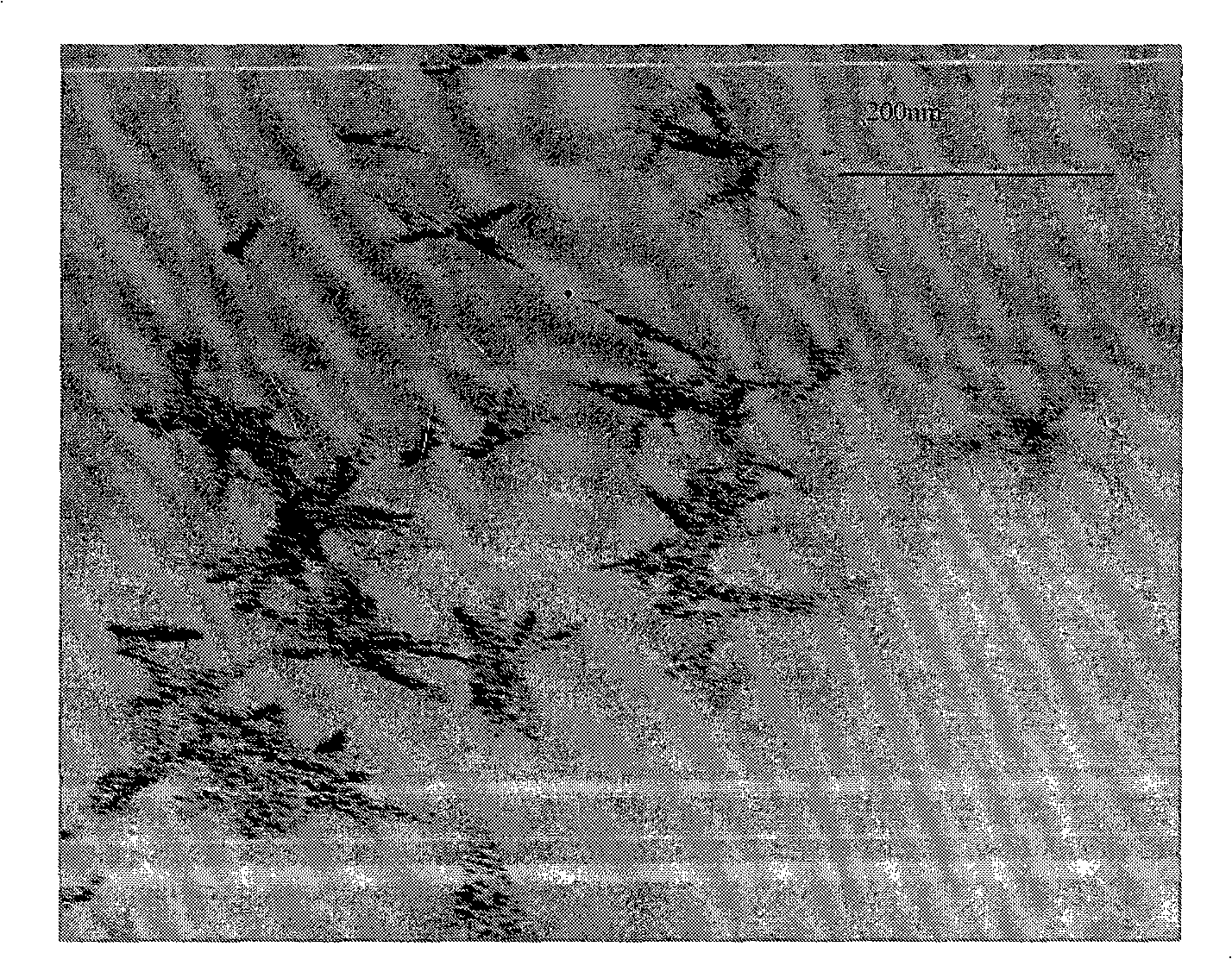

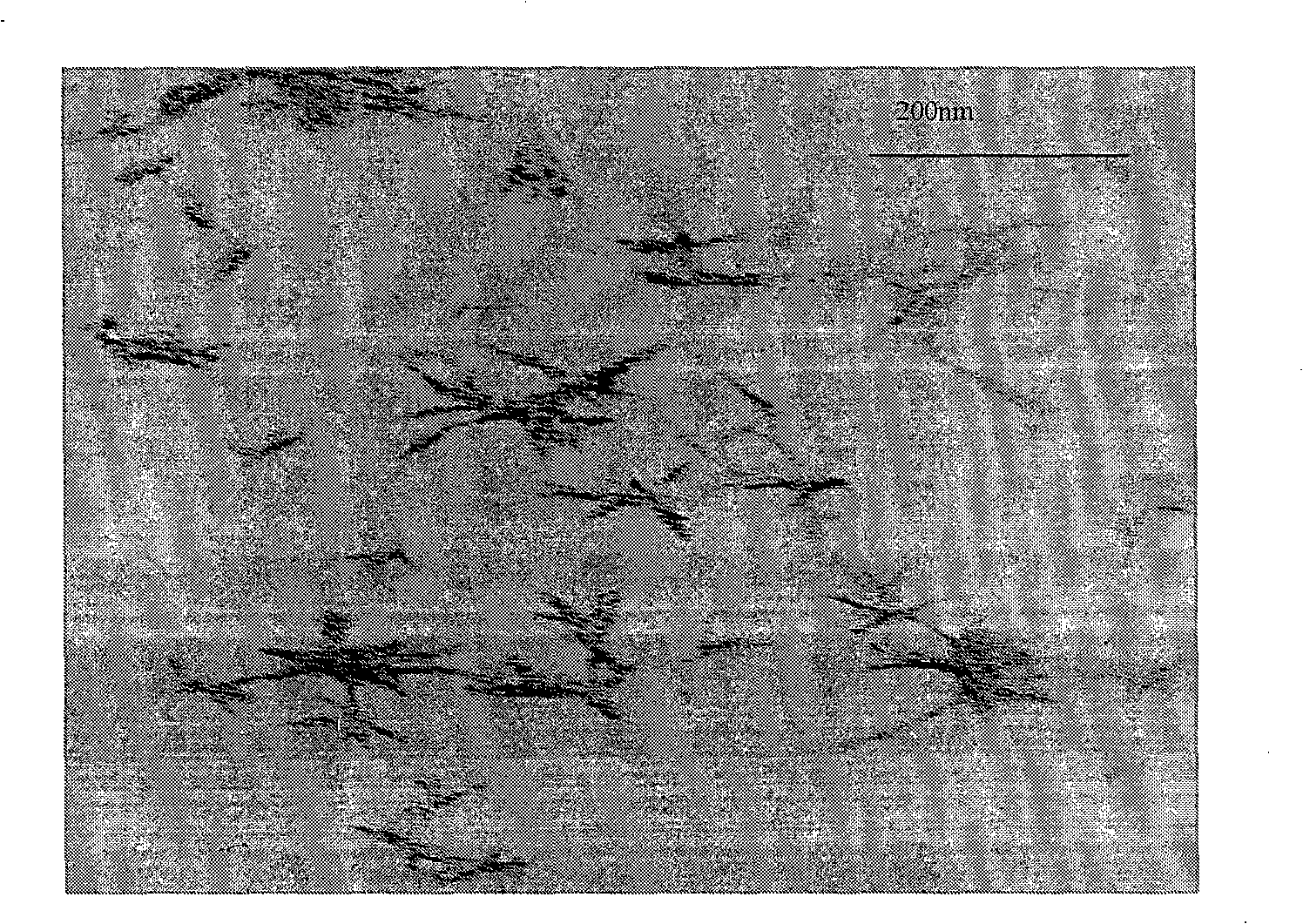

Method for preparing dendritic nano-silver by liquid phase synthesis

InactiveCN101353814AUniform particle sizeStable structurePolycrystalline material growthSingle crystal growth detailsGranularityAmmonium hydroxide

The invention relates to a method for preparing dendritic nano-silver by liquid-phase synthesis. The method is characterized by comprising the following steps: a silver-ammonia solution with silver-ammonia concentration of 0.1 mol / L to 0.5mol / L is prepared, then a crystal-formation guider and a nometer protective agent are added, stirring is carried out till the mixed solution is evenly mixed, and reaction solution is obtained; an ascorbic acid solution with concentration of 0.4mol / L to 0.8mol / L is dripped into the reaction solution to carry out reduction reaction, the solution after reaction is directly filtered by decompression, the solid phase after filtering is baked in an oven to remove water, so as to obtain the dendritic nano-silver. The method has simple preparation process, the reagent used is nontoxic and of environmental protection, the diameter of the dendritic nano-silver obtained is less than 30nm, the length of the dentrites is less than 100nm, the cluster length of the dentrites is less than 200nm, and the granularity of the dendritic nano-silver is even and the structure is stable. The dendritic nano-silver obtained by the method which is composite with polymers can improve conductivity, conductive circuit can be formed only with relatively little silver powder, filling quantity of silver powder can be reduced and cost of conductive agents can be saved.

Owner:NORTHEASTERN UNIV

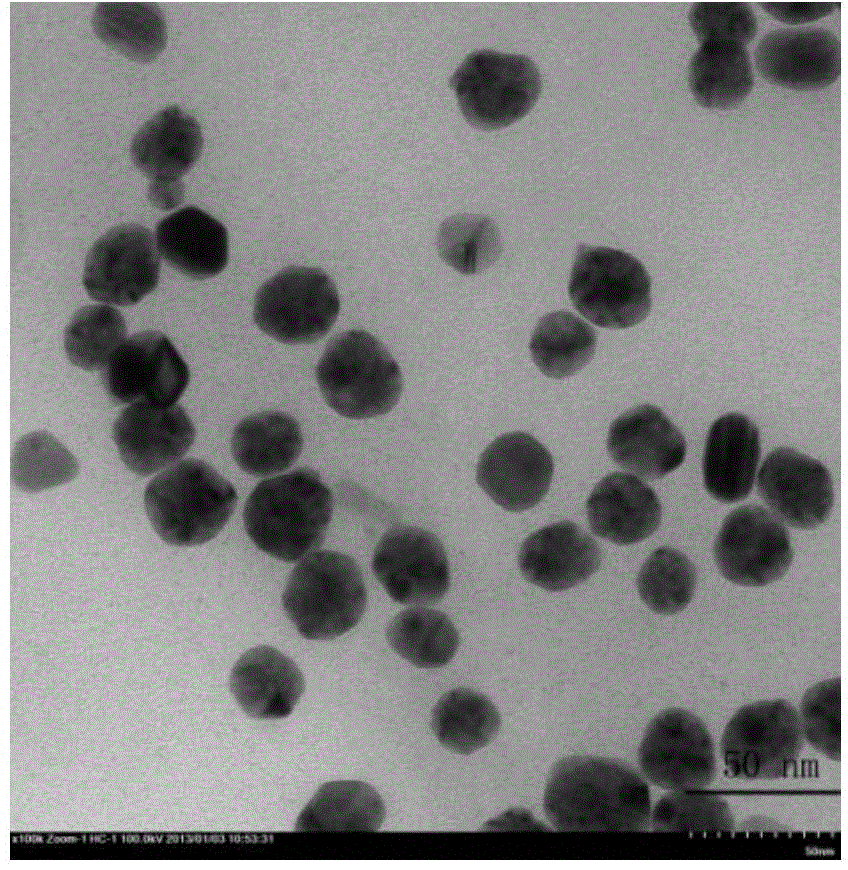

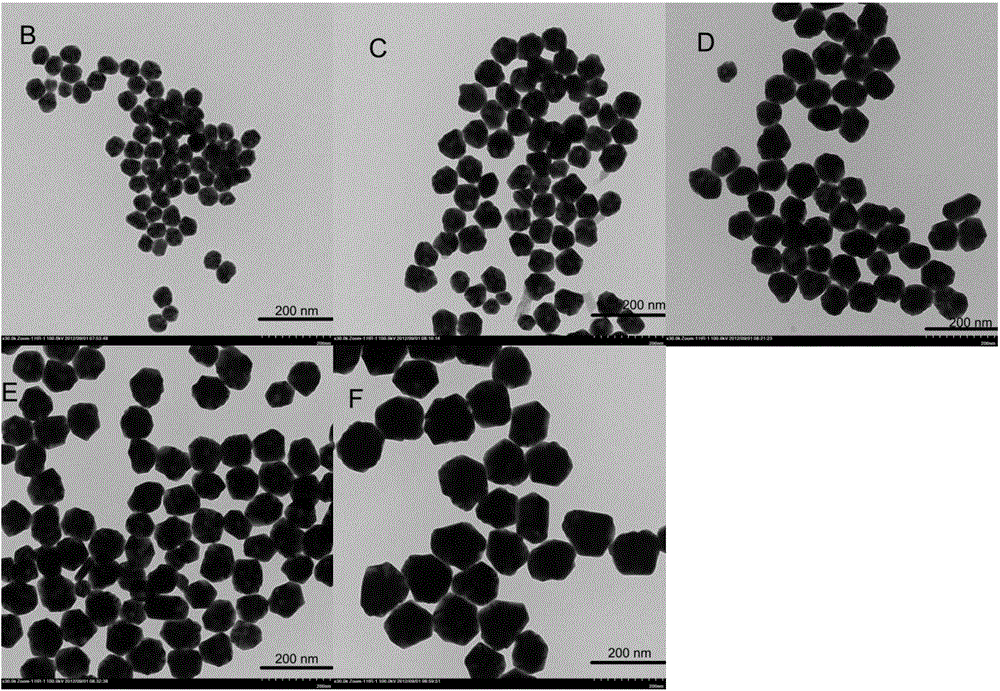

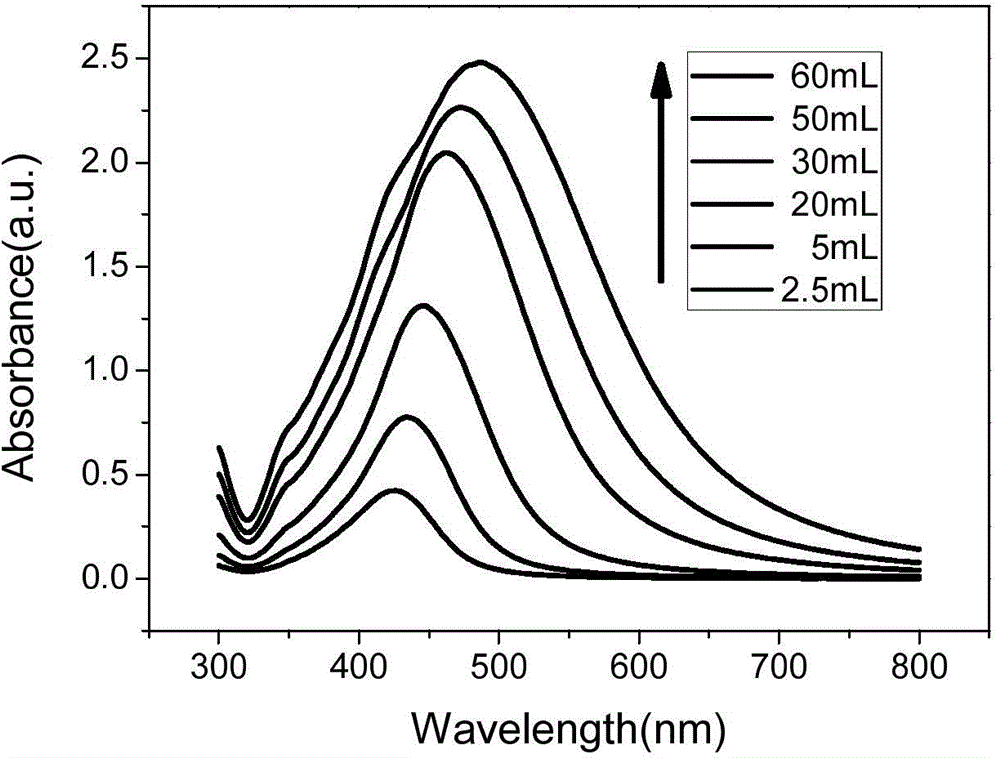

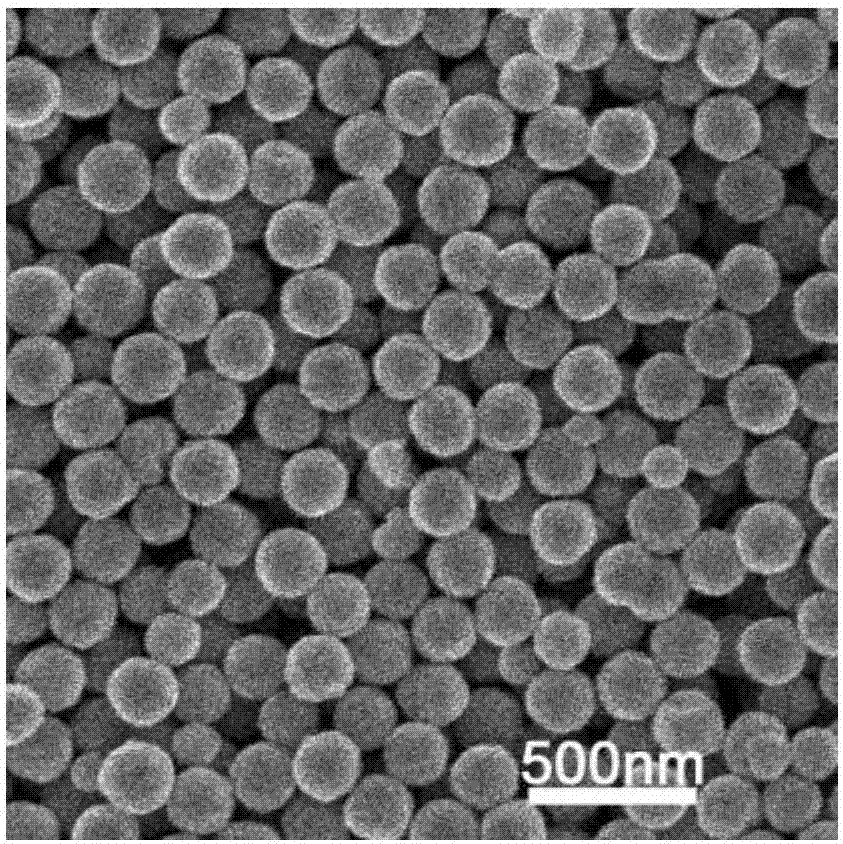

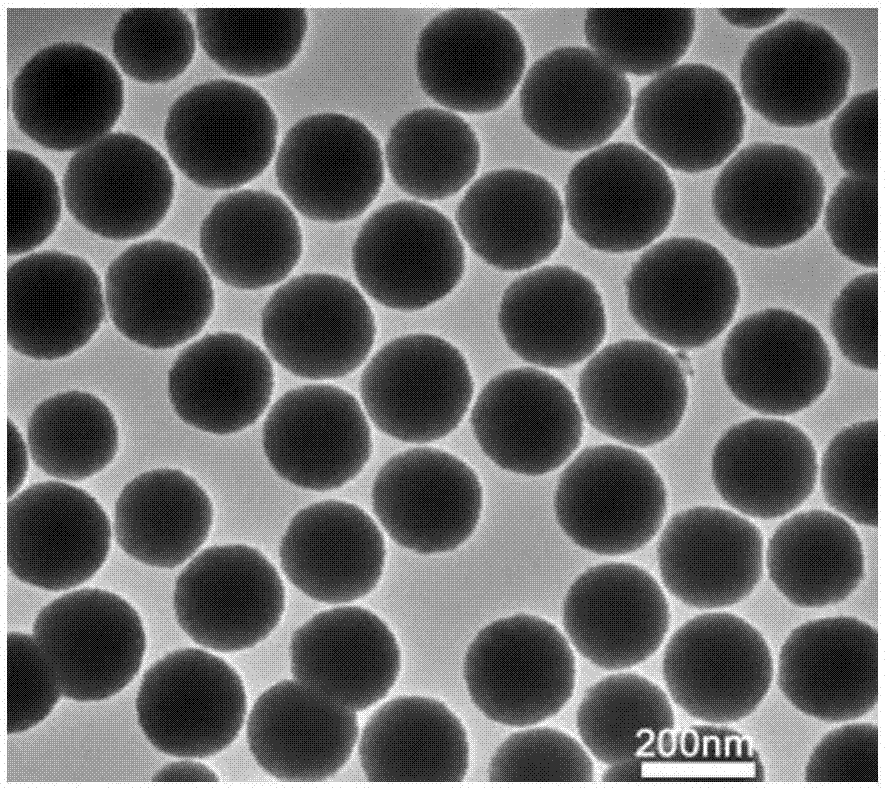

Method for preparing size-controllable silver nanoparticles

The invention discloses a method for preparing size-controllable silver nanoparticles. The method includes steps of adding sodium hydroxide or potassium hydroxide aqueous solution into mixed liquor comprising protective agents, water and weak reducing agents containing aldehyde groups and regulating a pH (potential of hydrogen) value of the mixed liquor until the pH value of the mixed liquor ranges from 8 to 10; adding Au seed crystal aqueous solution into the mixed liquor; then dripping silver and ammonia solution into the mixed liquor to carry out silver and ammonia reaction on the basis of gold seed crystals; acquiring sol containing the silver nanoparticles after reaction is completed. The method has the advantage that continuous growth of the Ag nanoparticles is controlled by a seed crystal growth process, so that the Ag nanoparticles with narrow size distribution (with relative standard deviation smaller than 20%) and the particle sizes which are continuously controllable within the range from 20nm to 120nm can be acquired.

Owner:TSINGHUA UNIV

Preparation method of visible-light-driven photocatalyst Fe3O4@PDA@Ag composite microsphere

ActiveCN107442178AHigh reuse rateAvoid secondary pollutionWater/sewage treatment by irradiationWater treatment compoundsSodium acetateWater baths

The invention belongs to the technical field of photocatalysts and specifically relates to a preparation method of a visible-light-driven photocatalyst Fe3O4@PDA@Ag composite microsphere. The preparation method comprises step 1 of respectively dissolving ferric chloride hexahydrate and sodium acetate into equivalent ethylene glycol, then evenly mixing and stirring two solutions, adding a 10 to 30wt% polyacrylic acid solution to continue stirring for 6 to 12h, putting into a reaction kettle, heating to 180 to 210 DEG C and keeping reaction for 4 to 12h to obtain a black product of ferroferric oxide; step 2 of dispersing the ferroferric oxide into an ethanol solution of polyvinyl pyrrolidone, then adding a water solution of dopamine hydrochloride, performing water bath and fully and ultrasonically dispersing to obtain a mixed solution b; step 3 of dropwise adding ammonium hydroxide into the mixed solution b, continuing ultrasonic reaction for 2 to 5 hours to obtain Fe3O4@PDA composite microspheres; step 4 of adding the prepared Fe3O4@PDA composite microspheres into ammonium hydroxide and silver nitrate to be prepared into a tollens' reagent, putting in a table concentrator to be vibrated for 8 to 16hours, performing magnetic separation and performing aftertreatment to obtain the Fe3O4@PDA@Ag composite microspheres. The Fe3O4@PDA@Ag composite microspheres have an obvious effect on degrading methyl orange and can be used repeatedly.

Owner:ZHEJIANG SCI-TECH UNIV

Production method of medical polyurethane antibacterial nano-silver coating

InactiveCN107583112AGood dispersionIncrease contentCatheterCoatingsVacuum dryingAntibacterial property

A production method of a medical polyurethane antibacterial nano-silver coating comprises the following steps: (1) dissolving dopamine in Tris-HCl buffer solution with the concentration being 0.015-0.025 mol / L and the pH value being 7.5-9, and carrying out a reaction at 20-30 DEG C in a dark environment for 25-35 min, wherein a dosage ratio of the dopamine to H2O is (800-1000) mg : 100 ml; (2) adding polyurethane to a solution obtained in the step (1), carrying out a reaction at 20-30 DEG C in a dark environment, taking out the polyurethane, flushing the polyurethane with plasma water, and drying the flushed polyurethan in a vacuum drying box; and (3) adding polyurethan obtained in step (2) into a silver ammonia solution, reducing silver nitrate with glucose as a reducing agent, and carrying out ultrasonic vibration cleaning to obtain the antibacterial polyurethane. The polyurethane nano-silver coating has the advantages of obvious antibacterial property, high content, high density, good dispersivity, no shedding and fast production speed.

Owner:NANCHANG UNIV

Method for preparing nano-silver by utilizing persimmon tannin as reductant

The invention relates to a method for preparing nano-silver by utilizing persimmon tannin as reductant. The method includes firstly, preparing persimmon tannin by an ultrasonic extraction method, mixing 1% of persimmon tannin water solution with 10-30mmol / L of silver ammonia solution by volume ratio of 5:1to 15:1, adjusting the pH (potential of hydrogen) value within 9-11, stirring for 10-120min at the temperature of 60-80 DEG C, and finally obtaining nano-silver solution with particle size ranging from 1nm to 50nm. The method adopting the persimmon tannin as capturing agent and reductant for silver ions has no demand for other stabilizer and protective agent and has the advantages of rich raw material resources, mild reaction, environment friendliness and the like.

Owner:SUZHOU ZHENGYECHANG INTELLIGENT TECH

Preparation method of nano-silver

The invention relates to a preparation method of nano-silver. The preparation method comprises the following steps: mixing drinks available in the market with silver-ammonia solution with a mass fraction of 0.01-100 g / L according to a volume ratio of 100:1 to 1:1; performing ultrasonic treatment for 1-10 hours under the temperature condition of 20-60 DEG C to obtain nano-silver colloidal solution; repeatedly cleaning with ethanol and de-ionized water; centrifuging; drying to obtain the nano-silver. The juice type drinks and tea type drinks available in the market are directly used as a reducing agent and a stabilizing agent without a complex plant and peel active matter extraction process; the method has the advantages of simple process, wide raw material source, mild reaction, environment friendliness and the like.

Owner:钱景

Preparation method of nanosilver-graphene composite material

The invention relates to a preparation method of a nanosilver-graphene composite material. The preparation method comprises the following steps: extracting persimmon tannin by an enzyme and ultrasonic-assisted extraction process, mixing 0.01%-10% by mass of a persimmon tannin aqueous solution and 0.01-100 g / L of a silver ammonia solution with 0.01-0.05 g / L of a graphene oxide solution according to a volume ratio of (100 to 10 to 1) to (1 to 1 to 1), ultrasonically processing at 40-80 DEG C for 1-24 hours, washing a reaction product by de-ionized water for multiple times, performing suction filtration, and drying in vacuum to obtain the nanosilver-graphene composite material. Compared with a conventional solvent extraction process, the enzyme and ultrasonic-assisted extraction process adopted for extracting persimmon tannin has the characteristics of no high temperature, good safety, short time and high efficiency; meanwhile, the nanosilver-graphene composite material is prepared in one step by adopting graphene oxide and silver ammonia as raw materials and environment-friendly persimmon tannin as a reducing agent.

Owner:SUZHOU ZHENGYECHANG INTELLIGENT TECH

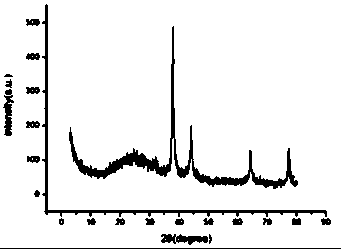

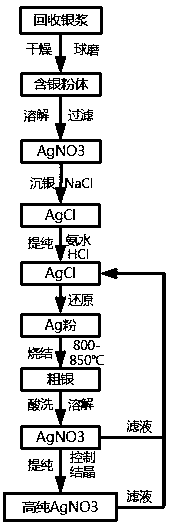

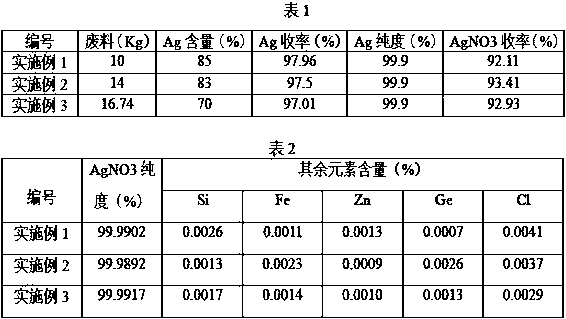

Method for preparing high-purity silver nitrate from photovoltaic waste silver paste

ActiveCN108190938ASolve the problem of recovery and purificationHigh yieldSilve compoundsRotary evaporatorDissolution

The invention relates to a method for preparing high-purity silver nitrate from photovoltaic waste silver paste, and belongs to the technical field of silver nitrate preparation. The method comprisesthe following steps: drying photovoltaic waste silver paste, carrying out ball milling to obtain powder; adding pure water, carrying out heating to boiling, then adding a nitric acid solution, and carrying out heating until the powder completely dissolves; carrying out cooling to 30-40 DEG C for filtering, adjusting the solution concentration, and adding a sodium chloride solution for precipitating silver; adding the obtained silver chloride filter cake in ammonia water for dissolution to obtain a silver-ammonia solution, adding hydrochloric acid into the silver-ammonia solution, and carryingout mechanical stirring for precipitating silver again; directly reducing the obtained silver chloride filter cake with hydrazine hydrate or a formaldehyde solution to obtain coarse silver powder, andsintering the silver powder; adding the silver powder into nitric acid of 40wt%-50wt% for dissolution, adding a regulator, and pouring the obtained solution into a rotary evaporator, and carrying outvacuum concentration until a small amount of crystals appear; and pouring the solution into a crystallizer for crystallization, filtering the remaining small amount of liquid during the crystallization, and drying the obtained crystals to obtain the high-purity silver nitrate. The method has high recovery rate, simple process, short recovery period and low cost, and is suitable for laboratories and industrial popularization.

Owner:KUNMING UNIV OF SCI & TECH

Chemical silvering method for PS (polystyrene) microspheres

ActiveCN102212801AIncrease profitLow densityLiquid/solution decomposition chemical coatingMicrospherePolystyrene

The invention provides a chemical silvering method for PS (polystyrene) microspheres, which comprises the following steps: coarsening the surfaces of PS microspheres; sensitizing and activating the coarsened PS microspheres; adding the treated PS microspheres into a silver-ammonia solution while stirring; adding a certain amount of reducer to finish the chemical surface silvering of the PS microspheres; and filtering, separating, washing, and drying in vacuum to obtain Ag / PS compound particles. The PS silvering method has a simple preparation process and simple composition of raw materials, and is easy to implement large-scale production; and the density of the prepared PS / Ag compound particles is less than 1.2*10<-3>kg.cm<-3>, and the resistivity is less than 4.2*10<-4>ohm.cm, thereby ensuring that the prepared PS / Ag compound particles have light weight and high conductivity.

Owner:ZHONGBEI UNIV

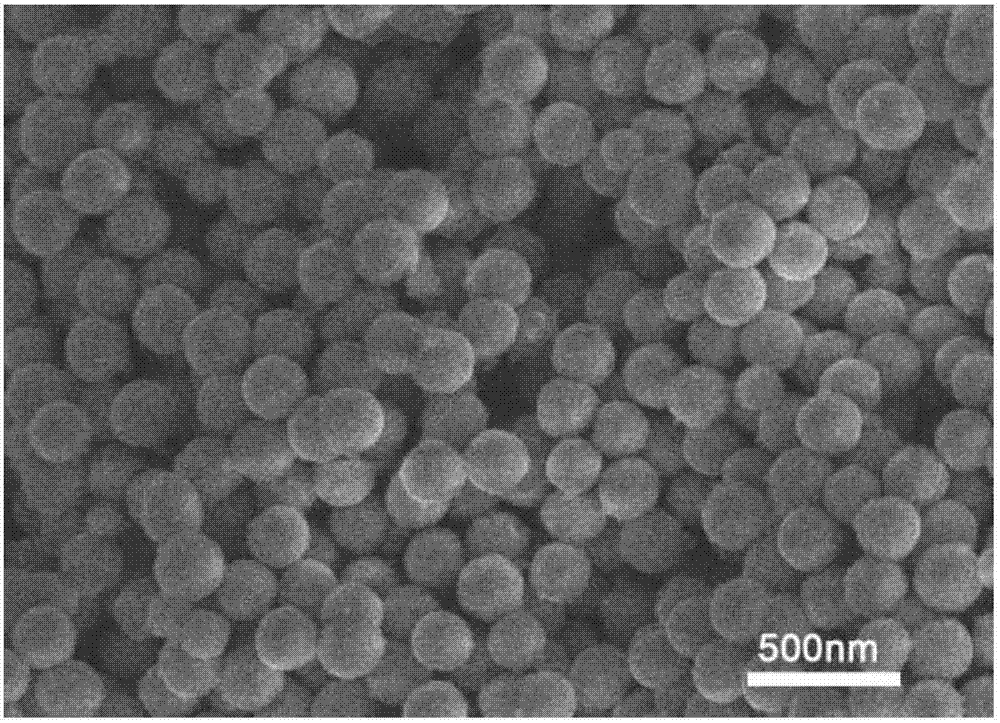

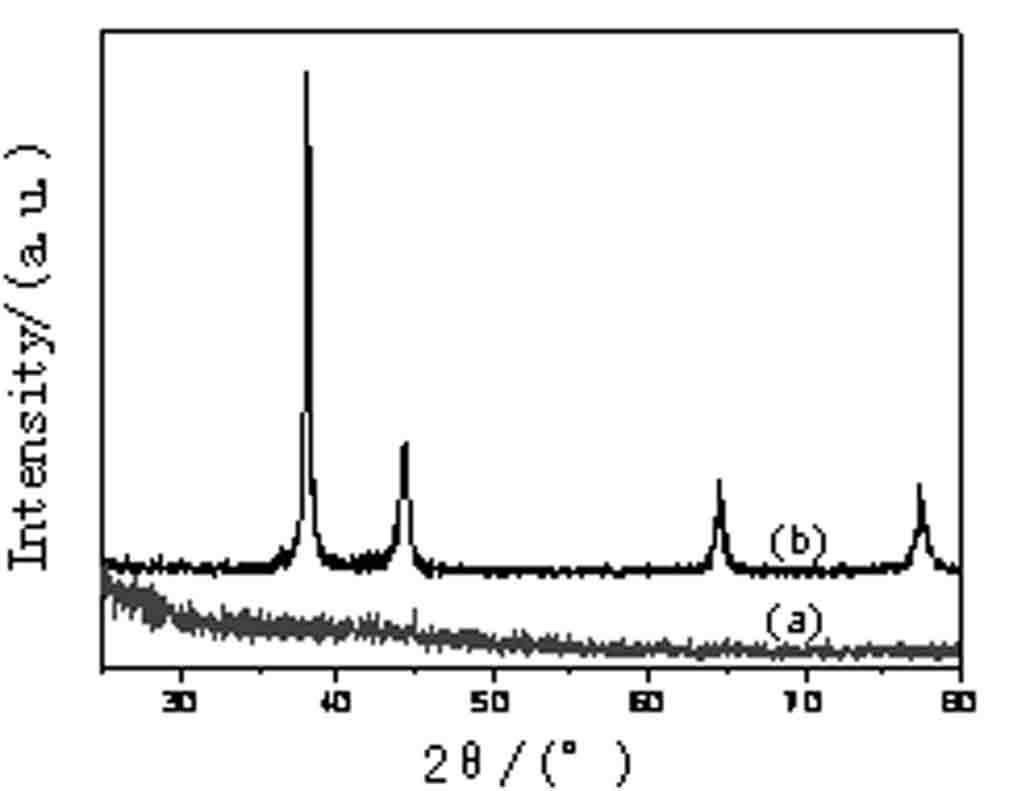

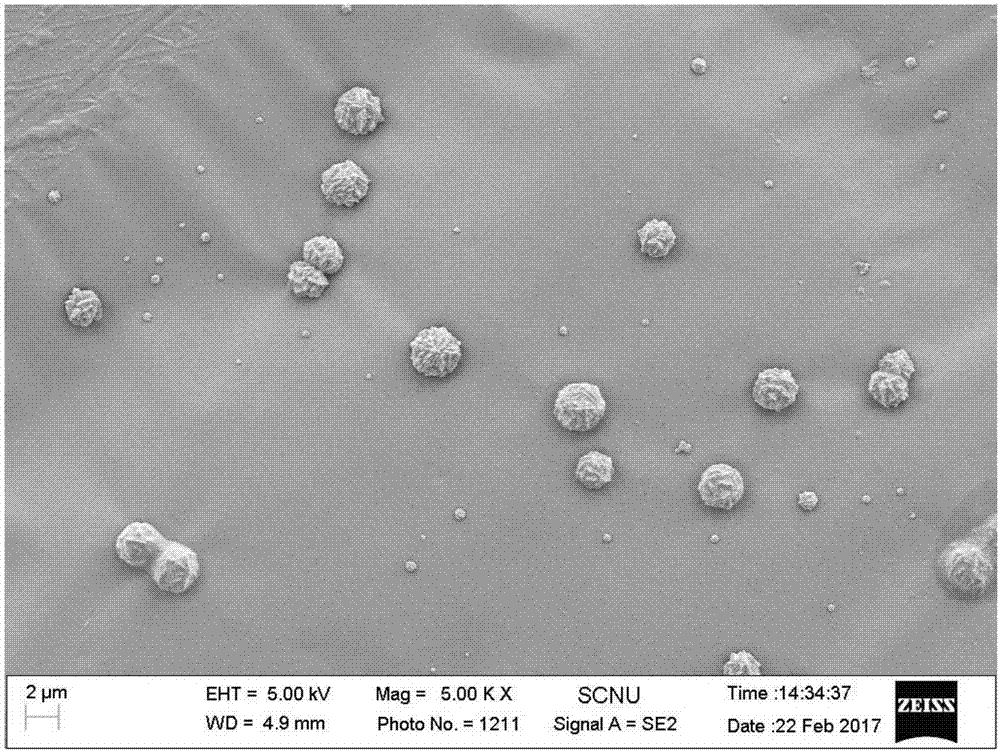

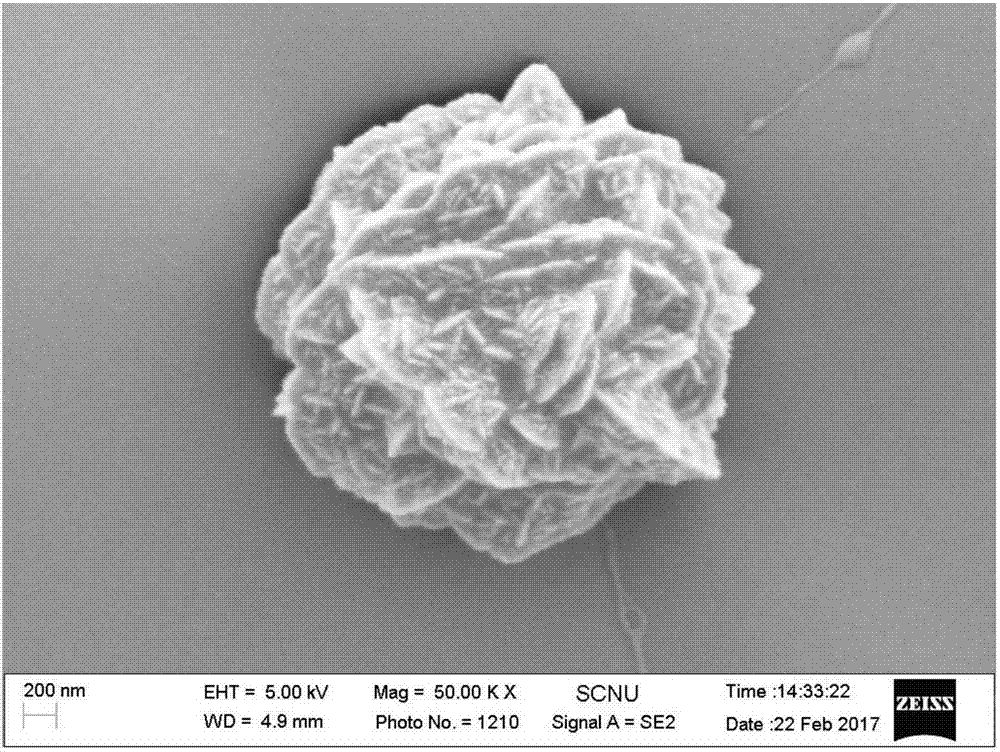

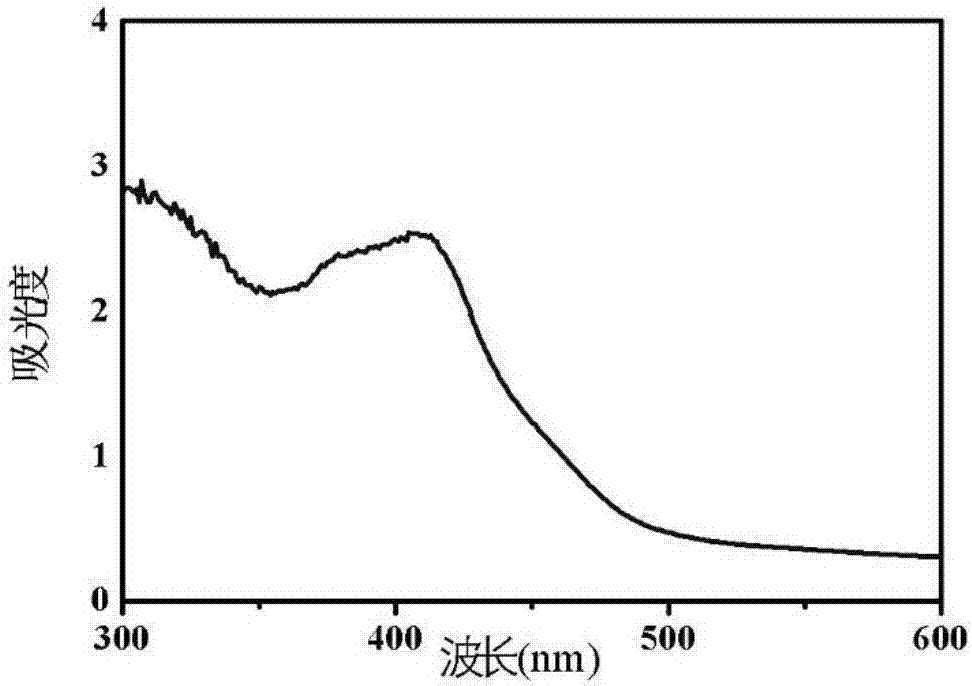

Flower-like nanometer silver sphere, preparation method and application thereof

ActiveCN107127355AExcellent optical propertiesImprove stabilityMaterial nanotechnologyTransportation and packagingZeta potentialReaction temperature

The invention provides a flower-like nanometer silver sphere, a preparation method and an application thereof. The preparation method comprises the following steps: adopting a pH value regulator for regulating pH value of an amino acid solution to 4-6, thereby acquiring a reducing agent solution, wherein the amino acid solution is selected from cysteine solution or reduced glutathione solution, and then mixing the reducing agent solution with a silver ammonium solution under a stirring condition and reacting, thereby acquiring the flower-like nanometer silver sphere. The mass ratio of silver ions in the reducing agent in the reducing agent solution and the silver ammonium solution is at (1:1) to (1:10); the reaction temperature is at 30-80 DEG C; the time is 5-10h. The method is characterized by mild reaction condition, simple and convenient operation and less environmental pollution. According to the method, the flower-like nanometer silver sphere has better optical characteristics and stability in the manner of controlling the dosage of the preparation raw materials and the reaction condition; the Zeta potential value of the flower-like nanometer silver sphere can reach up to +50mV; the raman effect is stronger.

Owner:GUANGDONG UNIV OF TECH

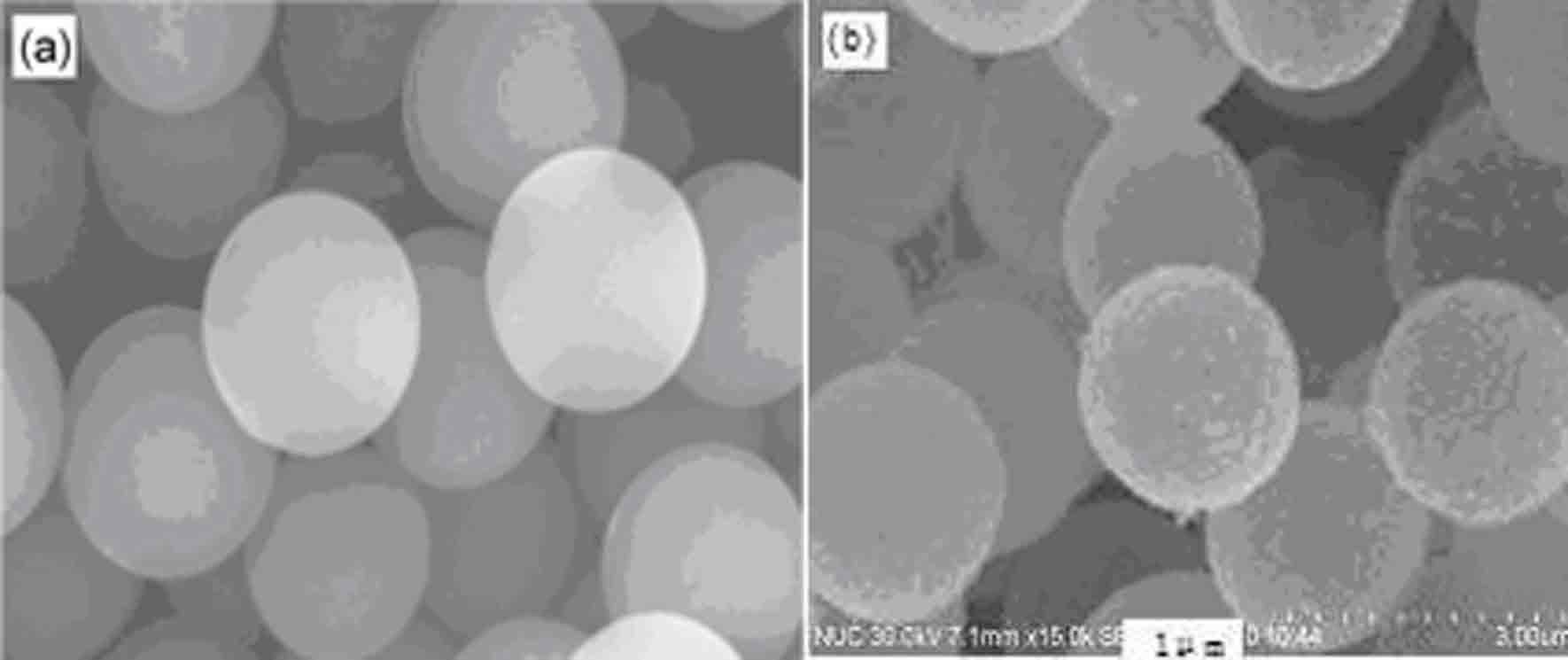

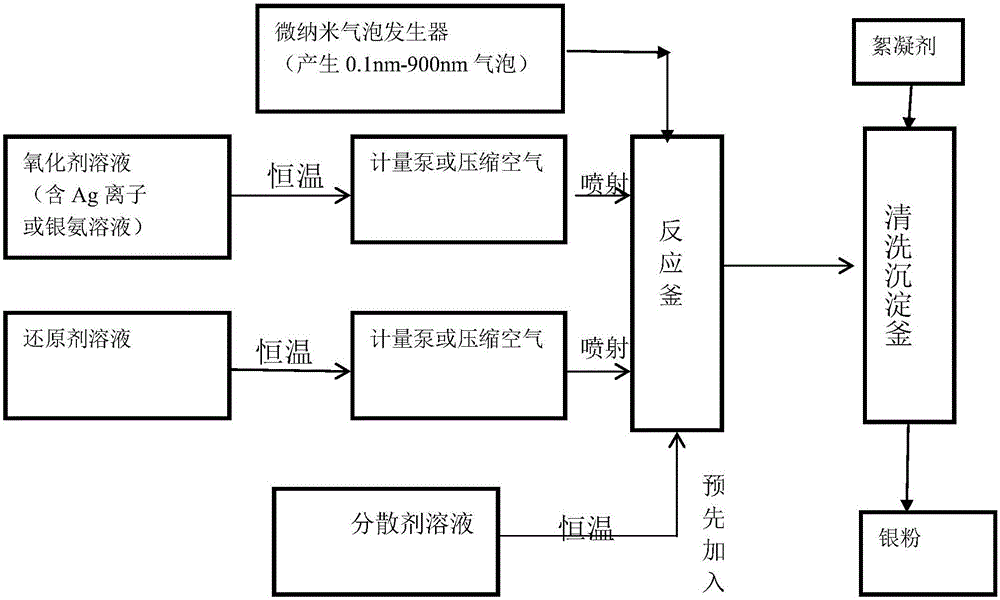

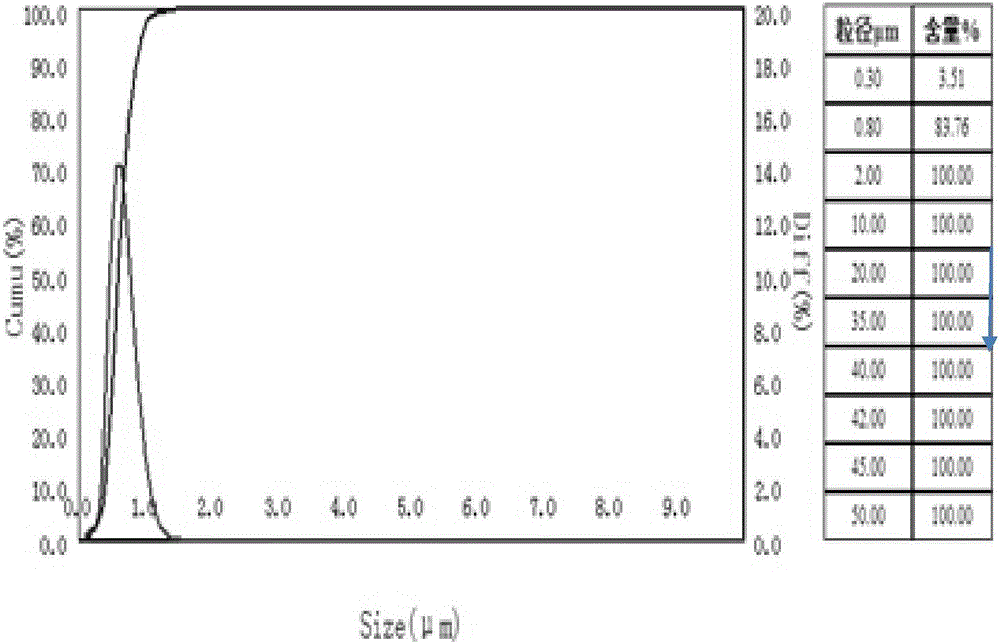

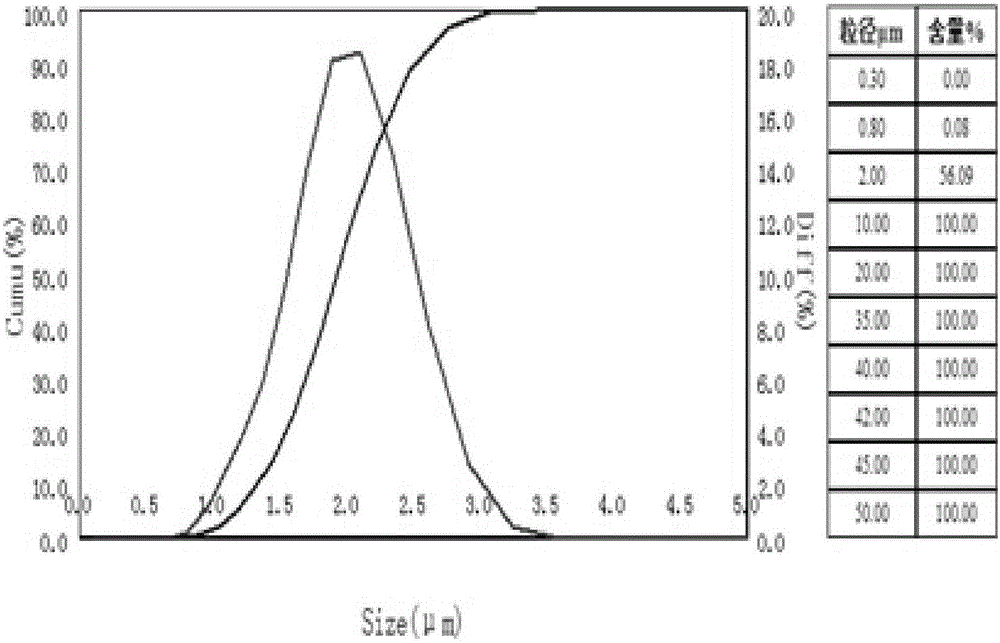

Preparation method for inductively producing silver powder by using micro-nano bubbles as crystal seeds

ActiveCN105834449AInhibition of agglomerationGood reduction rateTransportation and packagingMetal-working apparatusDispersityMicro nano

The invention discloses a preparation method for inductively producing spherical and sphere-like silver powder by using micro-nano sized bubbles as crystal seeds. The preparation method specifically includes the steps that a prepared dispersing agent solution is added into a reaction kettle in advance, a micro-nano bubble generator is started, and the controllable micro-nano bubbles (0.1-900 nm) are generated in the dispersing agent solution in the reaction kettle; then, a prepared oxidation solution (an aqueous solution containing silver ions or a silver-ammonia solution) and a prepared reduction solution (an aqueous solution containing one or more of hydroxylamine compounds or vitamin C or formaldehyde or hydrazine hydrate) are added at the same time, and a reduction reaction is performed under violent stirring; and the micro-nano bubbles pre-generated in the dispersing agent solution are used as the crystal seeds, and the micro-nano bubble crystal seeds can effectively control the particle size of reduced silver particles in the whole reduction reaction process. According to the method disclosed by the invention, the particle size of the particles in the production process of the silver powder can be controlled effectively, and meanwhile the crystal nucleus growing speed and dispersity are well controlled; the produced silver powder has quite good crystallinity and sphericity, high vibratory compaction performance and high dispersity; and particularly, loose structures in the particles of the silver powder are of great help to the activity of the silver powder.

Owner:SUZHOU SMART ADVANCED COATING TECH CO LTD

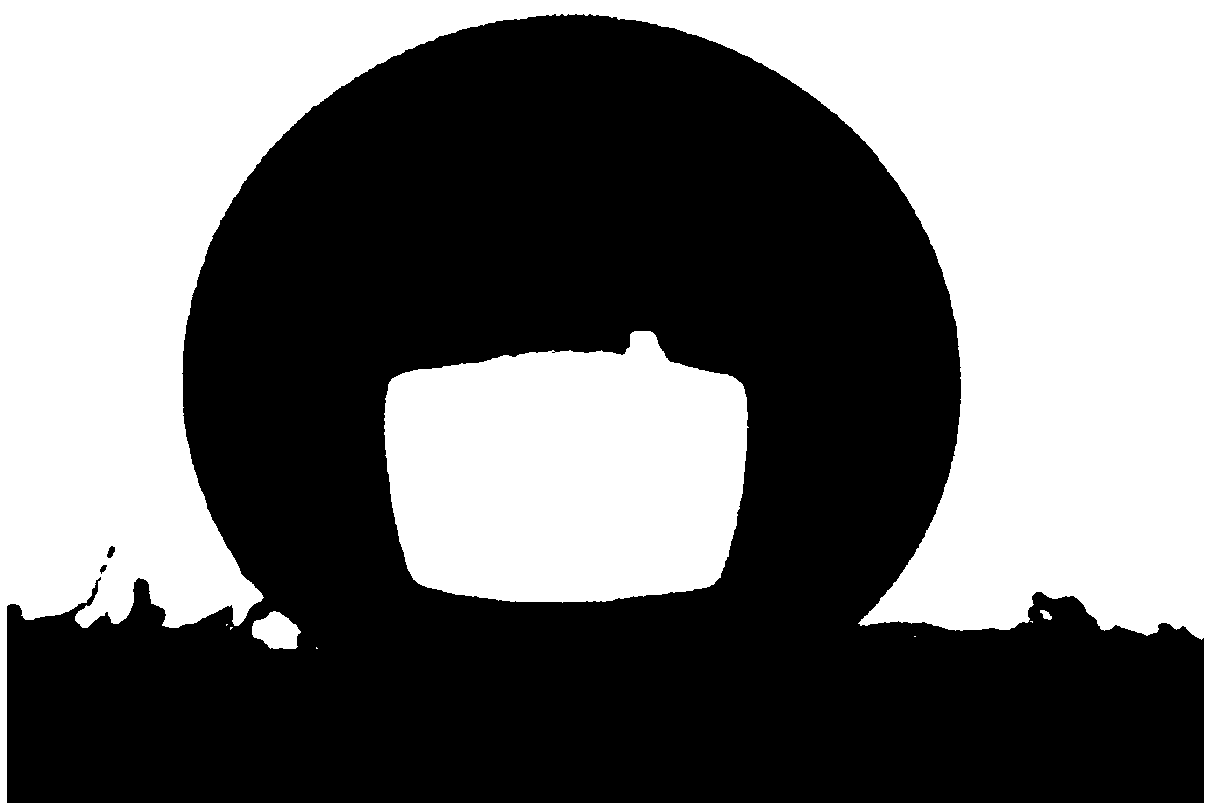

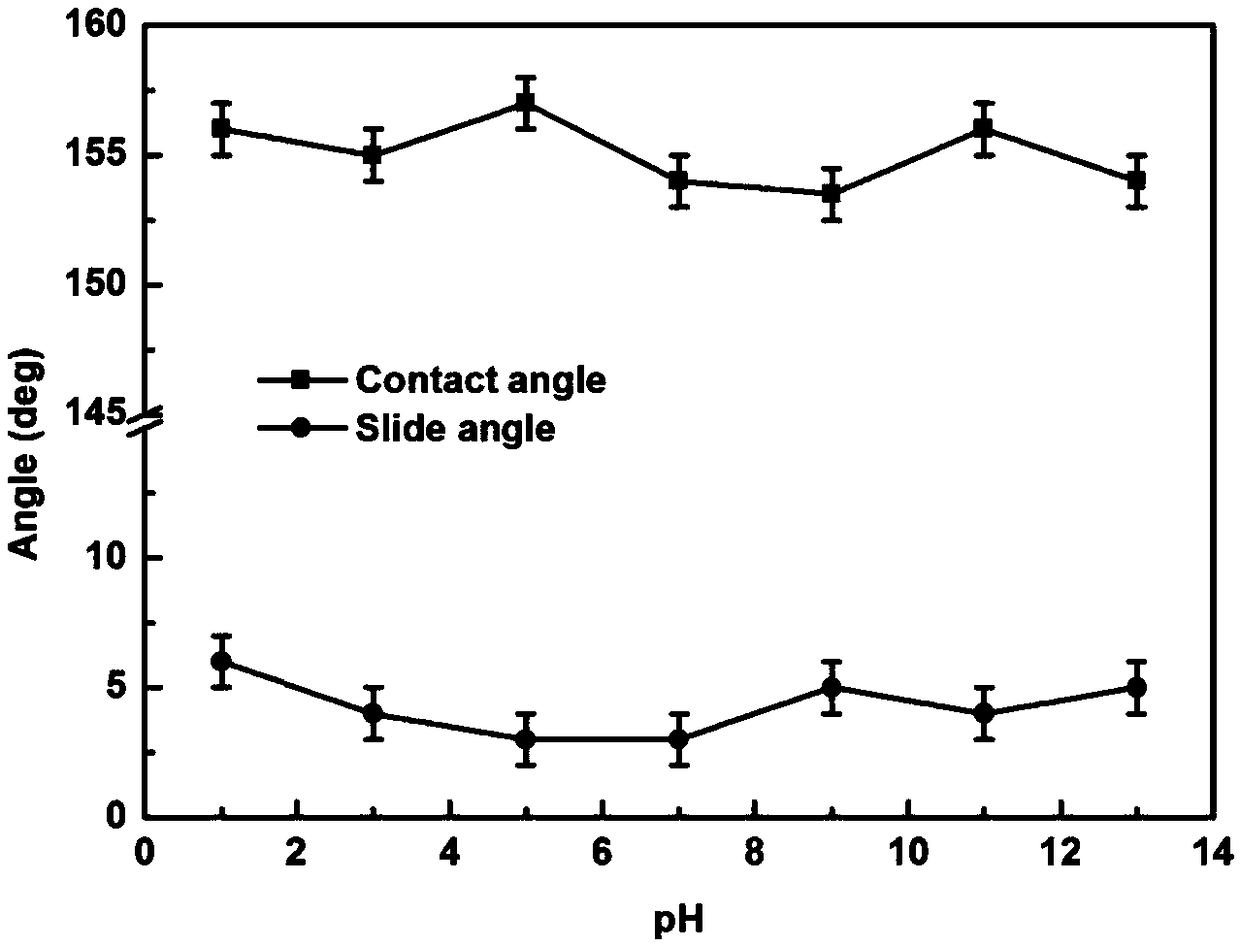

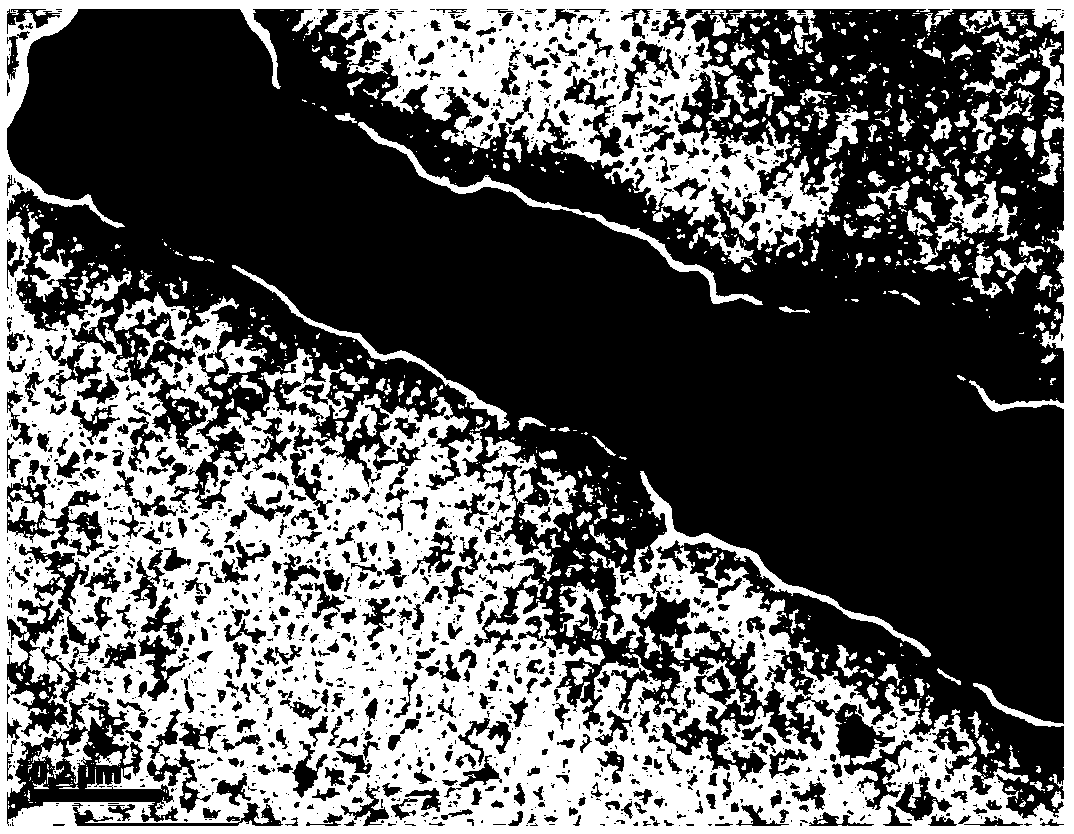

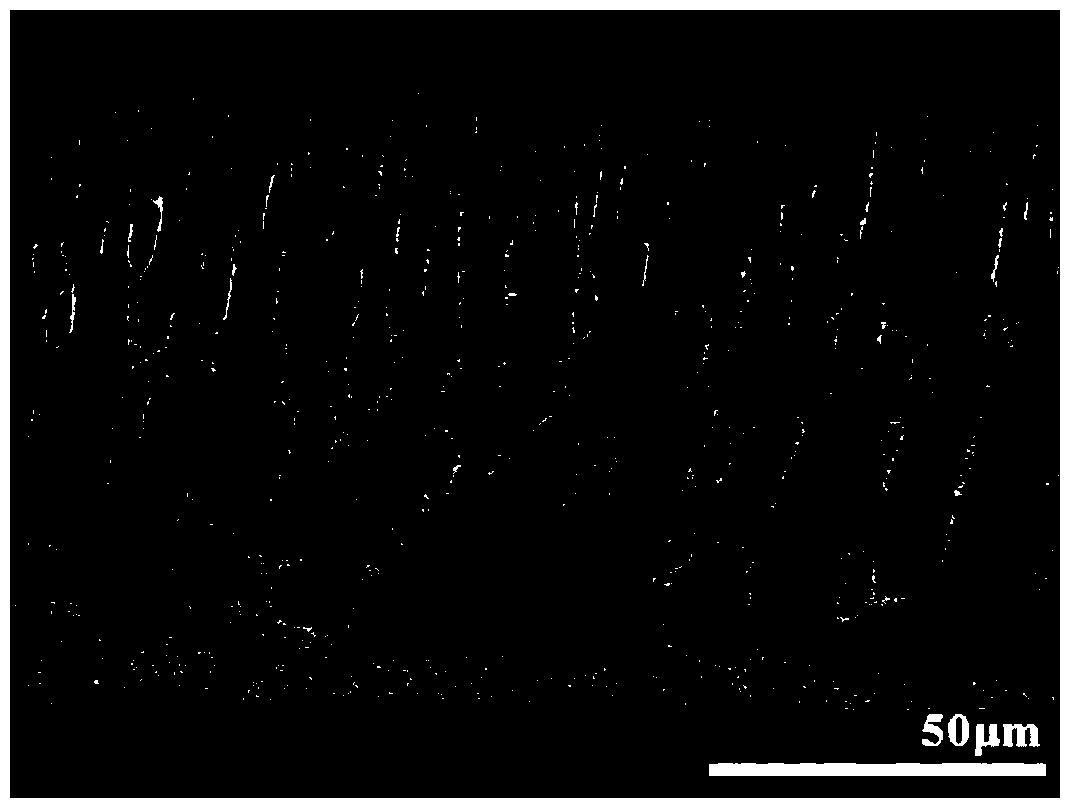

Method for preparing antibacterial super-hydrophobic fabric having stable properties by using silver-deposited nanoparticles

ActiveCN108755111AFree from destructionThe roughness is not easy to changeLiquid repellent fibresGrip property fibresNanoparticleSurface roughness

A method for preparing antibacterial super-hydrophobic fabric having stable properties by using silver-deposited nanoparticles comprises the steps that a fabric is soaked by adopting an EDTA solutionand then is dried; the dried fabric is impregnated in a silver-ammonia solution, then a glucose solution is added, and soaking and drying are performed; the fabric is put in an ethanol solution of aluminic acid ester under the stirring condition, and soaking and drying are performed to obtain the antibacterial super-hydrophobic fabric. According to the method, EDTA is adopted as a complexing agent, hydroxide radicals on the surface of the fabric can be bound with the EDTA, and silver particles can be complexed with the EDTA, so that the EDTA makes a substrate and the silver particles bound together through chemical bonds, the surface roughness is not likely to change, and the fabric has very good stability. The fabric and the silver particles are tightly grafted together, so that the stability of the fabric is improved. The fabric reacts with the cheap low-surface-energy substance aluminic acid ester easy to obtain, high-price organosilane is replaced, and the cost is reduced. In addition, the fabric has better antibacterial properties.

Owner:XIAN UNIV OF SCI & TECH

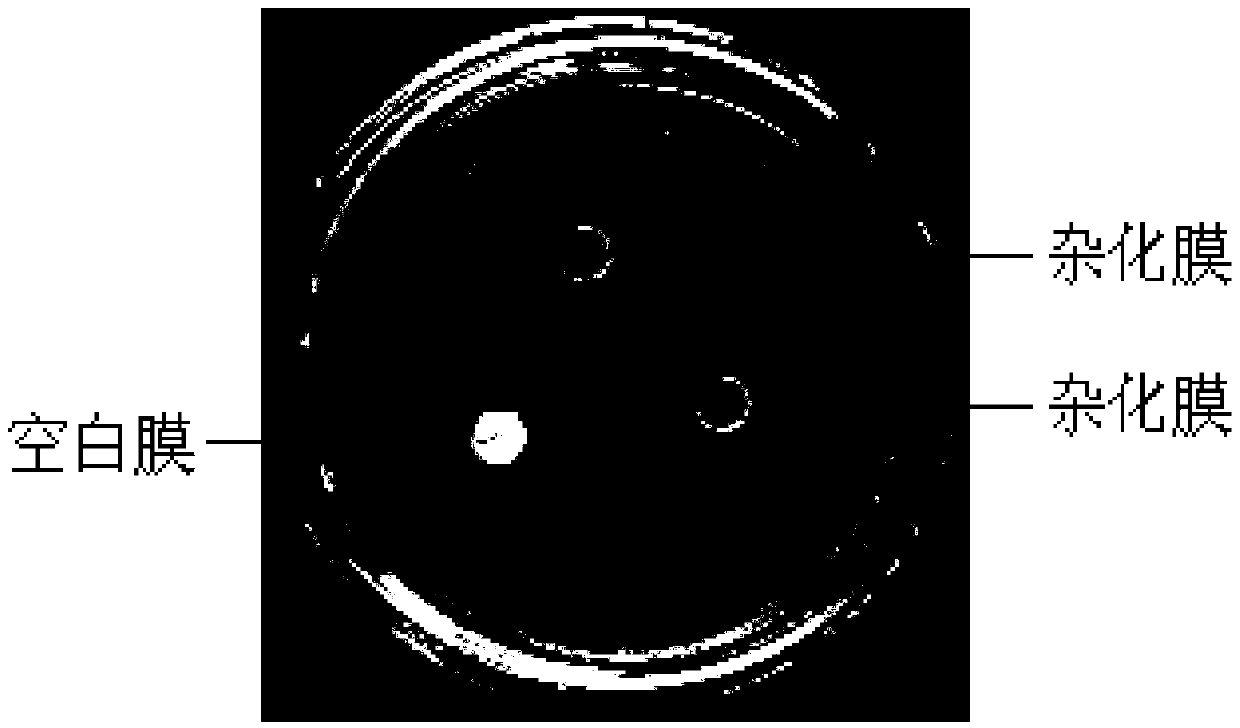

Silver nanoparticle-loaded hybrid membrane and preparation method and application thereof

ActiveCN105498558AAvoid churnExcellent plate antibacterial performanceMembranesUltrafiltrationOrganic solventUltrafiltration

The invention provides a silver nanoparticle-loaded hybrid membrane. A preparation method of the hybrid membrane comprises the steps that an inorganic filler is dispersed into a Tris-HCl buffer solution, levodopa is added, stirring is performed, suction filtration is performed to collect solid particles, washing and drying are performed, and then composite levodopa inorganic filler particles are obtained; the composite levodopa inorganic filler particles are dispersed into a tollens reagent, and then filtering, cleaning and drying are performed to obtain a silver nanoparticle-loaded composite material; the silver nanoparticle-loaded composite material and a membrane material are added in organic solvent, the materials are mixed to be uniform, and then standing and ultrasonic defoaming are performed to obtain a membrane casting solution; the membrane casting solution is prepared into a membrane, and after washing is performed, the hybrid membrane is obtained. The hybrid membrane can be used as a plate antibacterial membrane or ultrafiltration membrane; by fixing the silver nanoparticles to the surface of a cuprous oxide base body through the levodopa, loss of silver ions can be well prevented; in addition, by putting the composited cuprous oxide base body into the membrane, not only is the excellent plate antibacterial property achieved, but also the high throughput and the high interception are achieved.

Owner:ZHEJIANG UNIV OF TECH

Preparing method for silver tin oxide electric contact material based on chemical sedimentation method

InactiveCN106191495AReduce clumpingImprove wettabilityLiquid/solution decomposition chemical coatingHigh energyCopper oxide

The invention discloses a preparing method for a silver tin oxide electric contact material based on a chemical sedimentation method. The method specifically comprises the steps that lanthanum oxide or copper oxide or iron oxide or bismuth oxide or cerium oxide serves as an adulterant, nanometer doped tin oxide powder is combined, and doped nanometer tin oxide powder is prepared through a high-energy ball milling or hydro-thermal synthesis or gel method; secondly, a silver nitrate solution and ammonium hydroxide are utilized for preparing a silver-ammonia solution; thirdly, the doped nanometer tin oxide powder prepared in the first step and the silver-ammonia solution formed in the second step are uniformly mixed, and nanometer doped silver tin oxide composite powder is prepared through a reducing agent and through combination of the chemical sedimentation method; and fourthly, the nanometer doped silver tin oxide composite powder obtained in the third step is sequentially subjected to forming treatment and sintering treatment, and the silver tin oxide electric contact material is obtained. The preparing method for the silver tin oxide electric contact material solves the problems that in the existing electric contact material preparing process, the production cycle is long, oxide is prone to segregation, and the technology is complex.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Preparation method for fragrant microcapsule and silver-loaded multilayered microcapsule emulsion thereof

InactiveCN104841343AEffective control of wall thicknessMeet the requirements of green environmental protectionBiocideEssential-oils/perfumesHazardous substanceControllability

The invention discloses a preparation method for a fragrant microcapsule and a silver-loaded multilayered microcapsule emulsion thereof, which belongs to the technical field of microcapsule preparation and particularly relates to a silver-loaded fragrant microcapsule with the dual effects of durable resistance to bacteria and fragrant substance release and a preparation method thereof, and the fragrant microcapsule can be used in the preparation of textiles with fragrance and an antibacterial function. The main steps of the preparation method are as follows: (1) fragrant essential oil emulsion is prepared; (2) a certain amount of dopa compound is added into the fragrant essential oil emulsion for reaction, so that the fragrant microcapsule is obtained; (3) after reaction for a certain period of time, Tollens' reagent is then added to load silver; (4) finally, a certain amount of dopa compound is added for reaction again, and thereby the fragrant silver-loaded multilayered microcapsule is obtained. The microcapsule which is prepared by the preparation method utilizing the self-polymerization and crosslinking reaction of the dopa compound has high controllability, organic solvent is not used, no harmful substances, such as formaldehyde, are produced, no monomers remain, the used materials and process can better meet the requirements of environment protection and health, and the dual effects of fragrance and resistance to bacteria are achieved.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com