Preparation method for inductively producing silver powder by using micro-nano bubbles as crystal seeds

A technology of micro-nano bubbles and silver powder is applied in the field of materials, which can solve the problems of high cost and low yield, and achieve the effects of good crystal nucleus growth rate and good reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

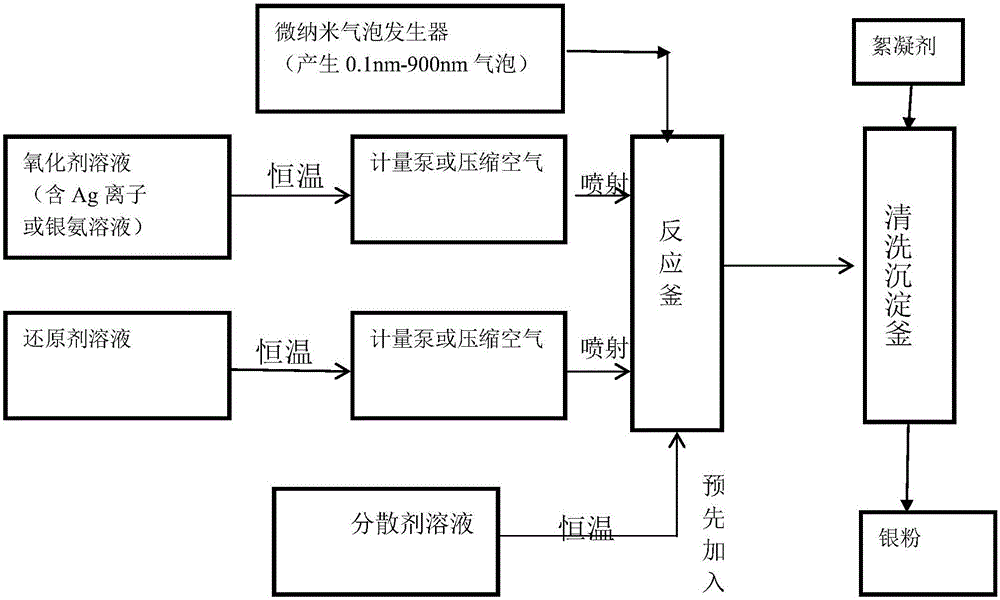

Method used

Image

Examples

Embodiment 1

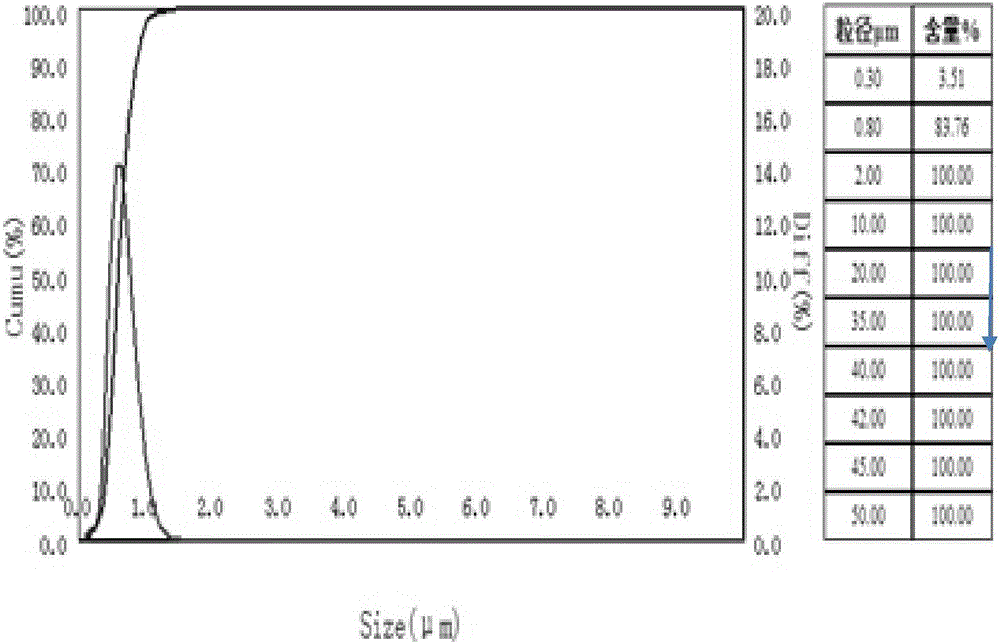

[0031] Embodiment 1 (silver powder S001)

[0032] (1) Preparation of oxidant solution containing silver nitrate solution, silver nitrate solid or equivalent silver nitrate liquid is dissolved in deionized water, and the molar concentration of silver ions in the solution [silver ion]=0.3mol / l is kept, and the solution is kept for 20-20 mol / l. 30°C constant temperature state;

[0033] (2) The reducing agent solution containing hydrazine hydrate is prepared, and the hydrazine hydrate solution is added in deionized water to make, according to the silver content in the silver-containing oxidant solution, keep the molar ratio [silver ion]:[hydrazine hydrate]=1 in the solution: 0.1~5, keep the solution at a constant temperature of 10~50°C;

[0034] (3) Preparation of dispersant solution: add one or more than two kinds of PVP or polyethylene glycol 400 to dissolve in deionized water, the content of which is 50-100g / l, stir well, and keep the solution at a constant temperature of 10-5...

Embodiment 2

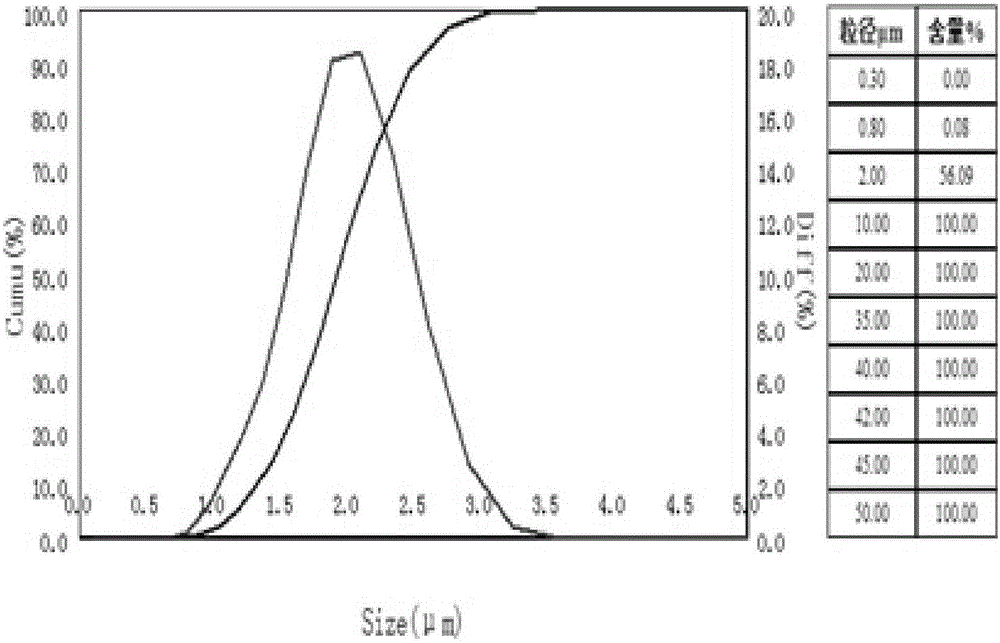

[0036] Embodiment 2 (silver powder S002)

[0037] Preparation of oxidant solution: prepare 500ml of silver nitrate solution containing 180g / L of silver in a 2000ml wide-mouth bottle, add 200ml of ammonia water with a mass percentage concentration of 18% to it to obtain silver ammonia solution, and heat it to 45°C for later use;

[0038]Preparation of reducing agent solution: prepare a solution containing vitamin C and hydroxylamine sulfate in another 2000ml jar: dissolve 50g of hydroxylamine sulfate and 50g of vitamin C in 500ml of deionized water, heat to 45°C for later use;

[0039] Dispersant solution preparation: Dispersant solution prepared in a 500ml jar: dissolve 65g of PVP and 40ml of Tween 40 in 250ml of deionized water, heat to 35°C for later use;

[0040] Use a metering pump to pre-pour the dispersant solution into a 5000ml wide-mouth bottle, and at the same time turn on the micro-nano bubble generator to generate controllable micro-nano bubbles in the dispersant so...

Embodiment 3

[0041] Embodiment 3: batch production (silver powder S003)

[0042] Add 250 kg of silver nitrate solid in a 1000L preparation tank, add 800L of deionization, fully stir and dissolve, then add 250L of ammonia water with a mass percentage concentration of 23% to obtain a silver ammonia solution, heat to 35°C for later use (oxidant solution) ;

[0043] Add 500L of deionized water into another 1000L preparation tank, then add 150 kg of vitamin C and 55 kg of hydroxylamine sulfate, fully dissolve and heat to 35°C for standby (reducing agent solution);

[0044] Dissolve 35kg of PVP in 400L of deionized water in a 500L preparation tank, stir well, and heat to 35°C for later use (dispersant solution);

[0045] Use a metering pump to inject the dispersant solution into the 3000L reaction kettle in advance, and at the same time turn on the micro-nano bubble generator to generate controllable micro-nano bubbles in the dispersant solution in the reaction kettle, and then quantitatively p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com