Novel visible catalyst-silver phosphate and preparation method thereof

A photocatalyst and silver phosphate technology, applied in the field of photocatalysis, can solve the problems of non-absorption of visible light and large band gap, and achieve the effect of improved photocatalytic activity, simple and easy preparation method, and conducive to large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation steps of the present invention are as follows:

[0014] (1) The preparation steps of silver ammonia solution are: dissolve 0.05-0.50mol silver nitrate solid in 200mL deionized water, stir for 10 minutes to obtain 200mL silver nitrate solution with a concentration of 0.25-2.5mol / L; take another 1-10mL Concentration is the strong ammonia water of 25.0w%, add deionized water and dilute to 50mL, the ammonia solution that will make is dripped in the above-mentioned silver nitrate solution slowly, when the color of solution just becomes colorless, stop dripping, continue to stir for 10 Minutes to obtain a colorless and transparent silver ammonia solution with a concentration of 0.2-2.0mol / L;

[0015] (2) Dissolve 0.02 to 0.2 mol of sodium dihydrogen phosphate solid in 100 mL of deionized water, stir for 10 minutes to obtain 100 ml of sodium dihydrogen phosphate solution with a concentration of 0.2 to 2.0 mol / L and transfer it to the dropping funnel, Slowly dr...

Embodiment 1

[0019] Preparation of Novel Visible Light Catalysts

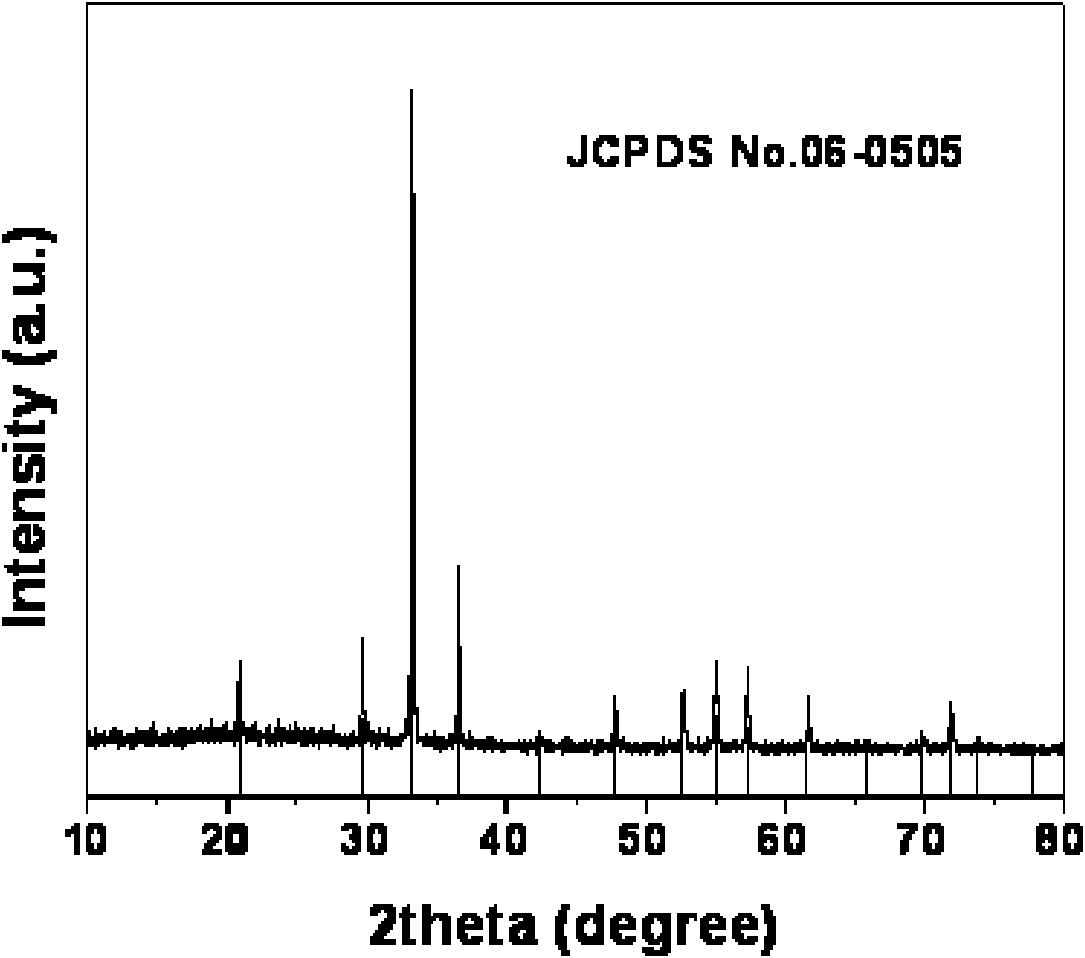

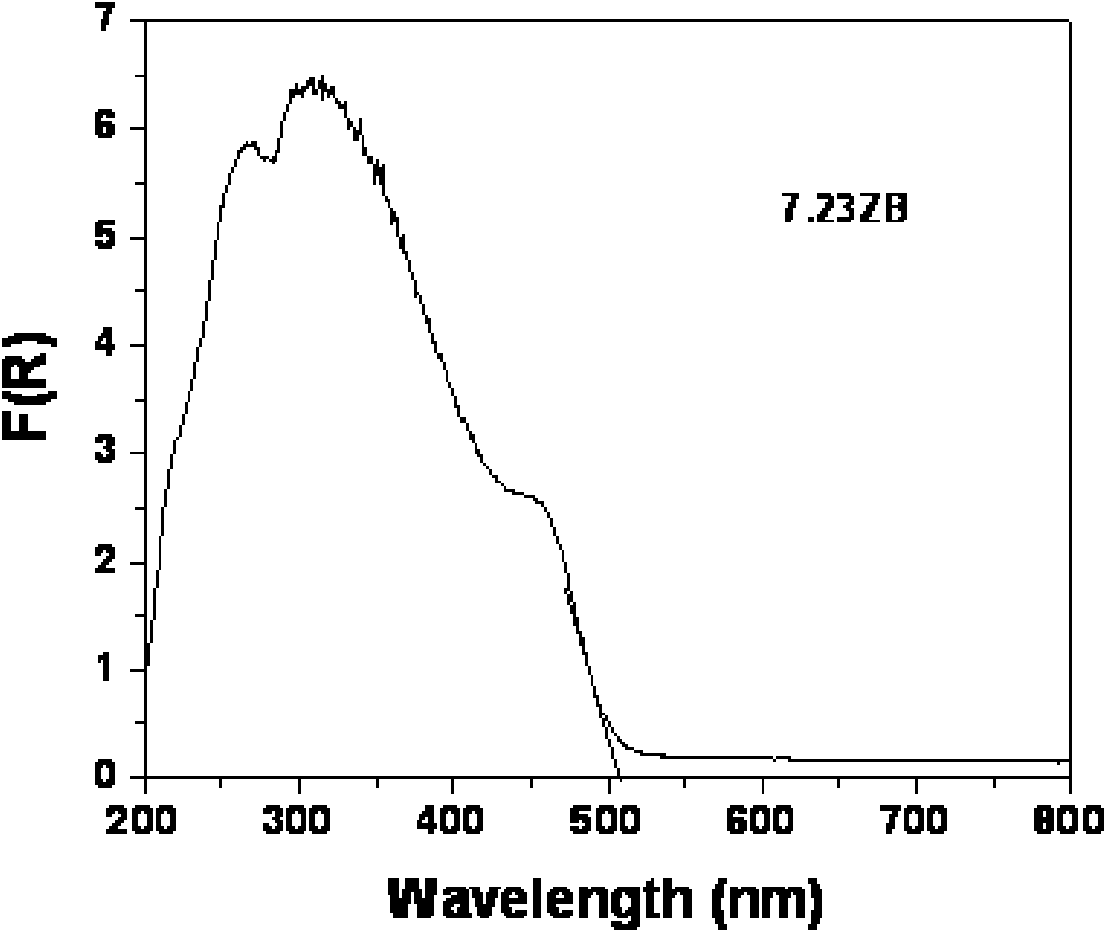

[0020] Weigh 0.15mol AgNO 3 The solid was dissolved in 200 mL of deionized water and stirred for 10 minutes to obtain AgNO 3 solution; in addition, use a pipette to measure 3mL of concentrated ammonia water (25%) and add 47ml of deionized water to dilute, stir evenly and slowly drop into the above AgNO 3 Solution, continue stirring for 10 minutes after the dropwise addition, to obtain a colorless and transparent silver ammonia solution. Weigh another 0.05mol NaH 2 PO 4 The solid was dissolved in 100 mL deionized water and stirred for 10 minutes to obtain NaH 2 PO 4 solution and transfer it to the dropping funnel, control the rate of addition (2-3 seconds per drop), slowly add dropwise to the above-mentioned silver ammonia solution, continue stirring for 5-6 hours after the addition, and centrifuge the obtained yellow turbid solution, Washing, drying at 60°C, and grinding to obtain yellow Ag 3 PO 4 powder. figure 1 ...

Embodiment 2

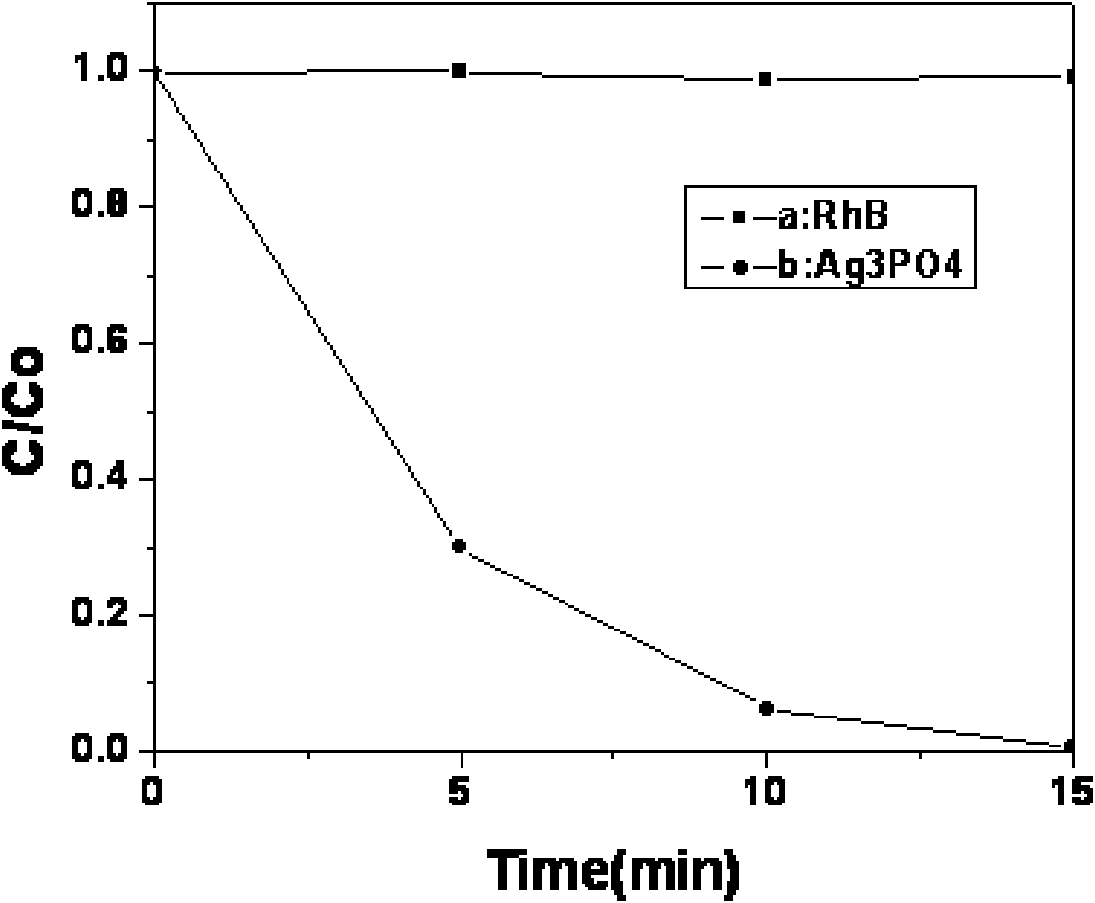

[0022] Novel Visible Light Catalyst Ag 3 PO 4 Degradation of rhodamine B

[0023] Ag will be obtained 3 PO 4 The powder was used as a photocatalyst to degrade Rhodamine B. Weighed 80 mg sample and added 80 mL RhB solution (10-5 mol / L), and stirred for 1 hour in the dark, so that the RhB solution reached adsorption / desorption equilibrium on the surface of the catalyst. Then turn on the light source to carry out the photocatalytic reaction, take 3mL of the reaction solution every 5min, and after centrifugation, the supernatant is detected by a Cary-500 spectrophotometer. The change of RhB concentration during the degradation process was determined according to the absorbance value at 554nm of the sample. The light of the reaction is a 500W halogen tungsten lamp placed in a double glass jacket (through condensed water), and a filter is used to ensure that the incident light is visible light (420nm image 3 As shown, it can be seen from the figure that when no catalyst is added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com