Method for modifying graphene through nano-sliver

A technology of graphene and nano-silver, which is applied in the direction of nano-technology, can solve problems such as difficult to obtain, and achieve the effect of complete structure, less surface functional groups, and nano-silver modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

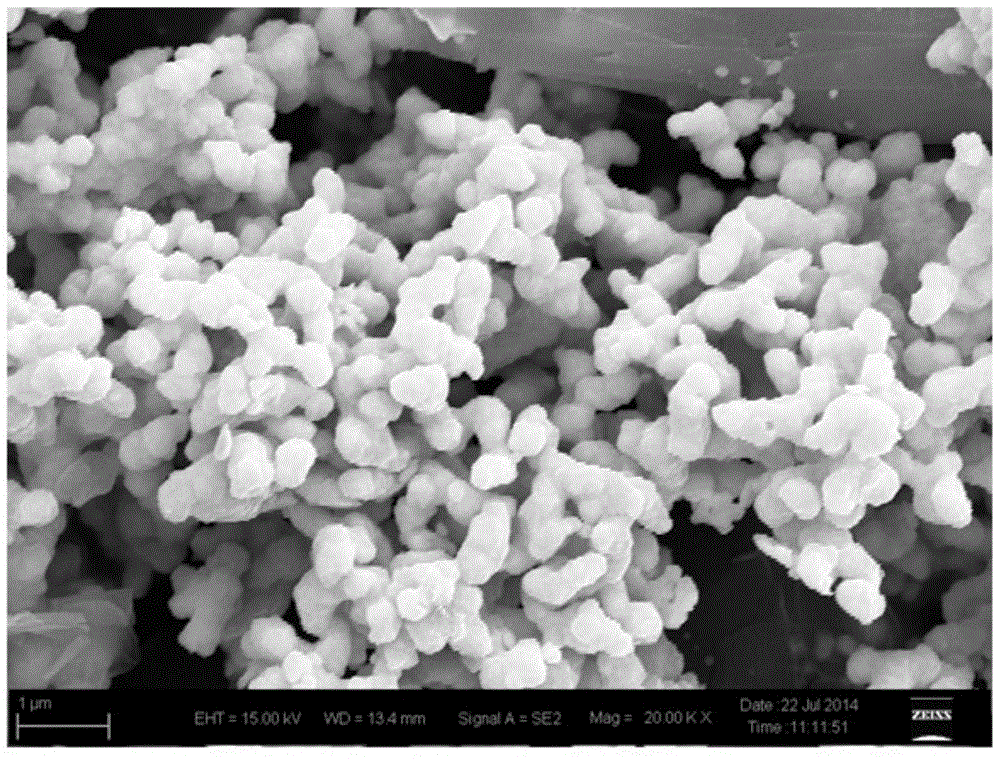

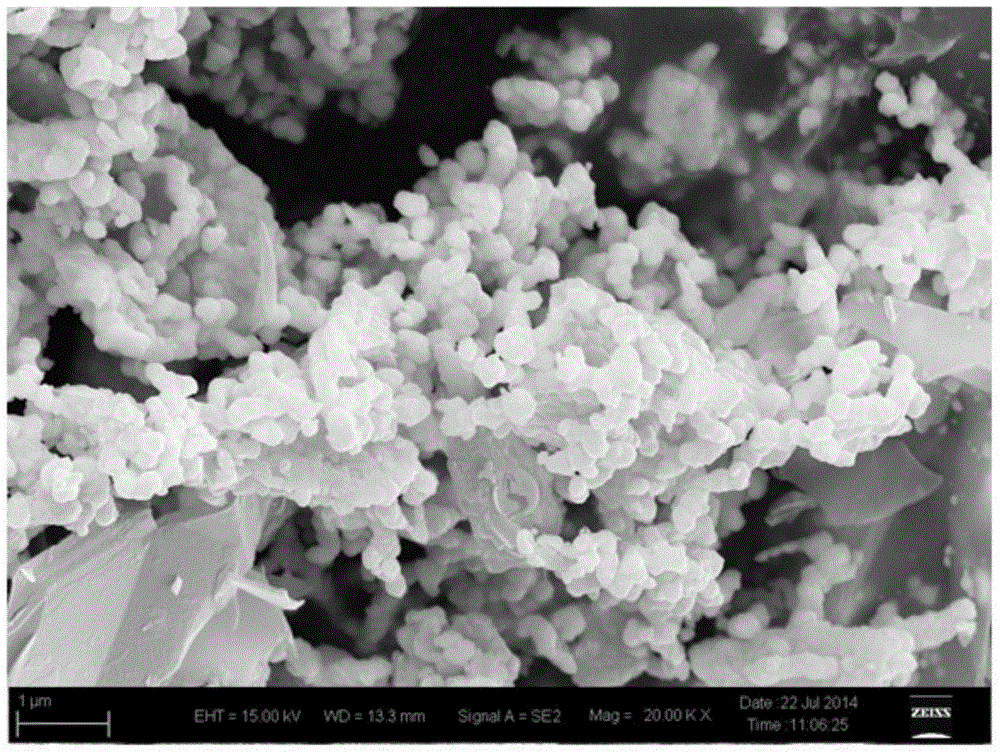

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: this embodiment provides a kind of method of nano-silver modified graphene, specifically realizes through the following steps:

[0025] 1. Graphene will be prepared with reference to 201310262842.X "A Method for Preparing Graphene by Foaming and Expansion Method". The ratio of graphene to water is 1g: 1L ~ 3g: 1L, ultrasonically dispersed, and the treatment time is 2 ~ 4h.

[0026] Two, silver nitrate and sodium hydroxide are weighed by the mass ratio of 1: 0.4~1, and configure 1~5wt.% sodium hydroxide aqueous solution and 1~10wt.% silver nitrate aqueous solution, mix the two again, finally Add 1-5 wt.% ammonia water dropwise while stirring until the solution is clear.

[0027] 3. The tartaric acid, glucose and water are mixed and dissolved in a mass ratio of 1:9 to 13:200 to 300, and stirred evenly.

[0028] 4. Heat the mixed aqueous solution of tartaric acid and glucose to 110-130°C, keep the temperature constant for 10-30 minutes, and then c...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass fraction of the silver nitrate aqueous solution described in the step 2 is 2~7%, the mass fraction of the sodium hydroxide aqueous solution is 2~4%, the ammoniacal liquor The mass fraction is 2 to 4%, the mass ratio of silver nitrate to sodium hydroxide is 1:0.5 to 0.8, and the others are the same as in Embodiment 1.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one and two is that the mass ratio of tartaric acid, glucose and water described in step three is 1: 10~12:240~260, and others are the same as specific embodiment one , Two are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com