Preparation method of nano-silver

A technology of nano-silver and silver-ammonia solution, applied in the field of nano-materials, to achieve the effect of preventing further growth and agglomeration, mild reaction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 20ml of oriental leaf green tea original flavor tea drink (manufactured by Nongfu Spring Co., Ltd., tea polyphenol content greater than or equal to 360mg / kg) with 1ml of silver ammonia solution with a mass fraction of 5g / L, and ultrasonicate for 2h at a temperature of 20°C , to obtain a nano-silver colloidal solution, washed repeatedly with ethanol and deionized water, centrifuged at a speed of 9000r / min for 10min, and dried under vacuum at 40°C for 20h to obtain nano-silver.

[0022] figure 1 It is the SEM picture of the nano silver prepared in this embodiment, as can be seen from the figure, the nano silver is spherical, and the distribution is uniform, and the average particle size is about 20nm.

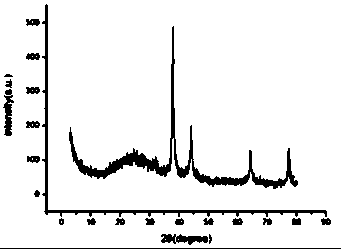

[0023] figure 2 It is the XRD diffraction pattern of the nano-silver prepared in this example, and there are 4 obvious characteristic peaks at 38.00°, 44.26°, 64.40°, and 77.32°, indicating that nano-silver is generated in the solution. .

Embodiment 2

[0025] Mix 50ml of Huiyuan orange juice (manufactured by Huiyuan Group Co., Ltd.) with 1ml of silver-ammonia solution with a mass fraction of 1g / L, sonicate at 20°C for 1h to obtain a nano-silver colloid solution, and wash it repeatedly with ethanol and deionized water , centrifuged at 8000r / min for 10min, and dried under vacuum at 40°C for 24h to obtain silver nanoparticles.

Embodiment 3

[0027] Mix 10ml of Minute Maid orange (produced by Coca-Cola) with 1ml of silver ammonia solution with a mass fraction of 10g / L, and ultrasonicate at 40°C for 5h to obtain a nano-silver colloid solution, and use ethanol and deionized water Repeated washing, centrifugation at 10,000 r / min for 15 min, and drying under vacuum at 40° C. for 4 h to obtain silver nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com