Chemical silvering method for PS (polystyrene) microspheres

A kind of microsphere chemistry and microsphere technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problem of excessive density of conductive fillers, and achieve low density, cost reduction, and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

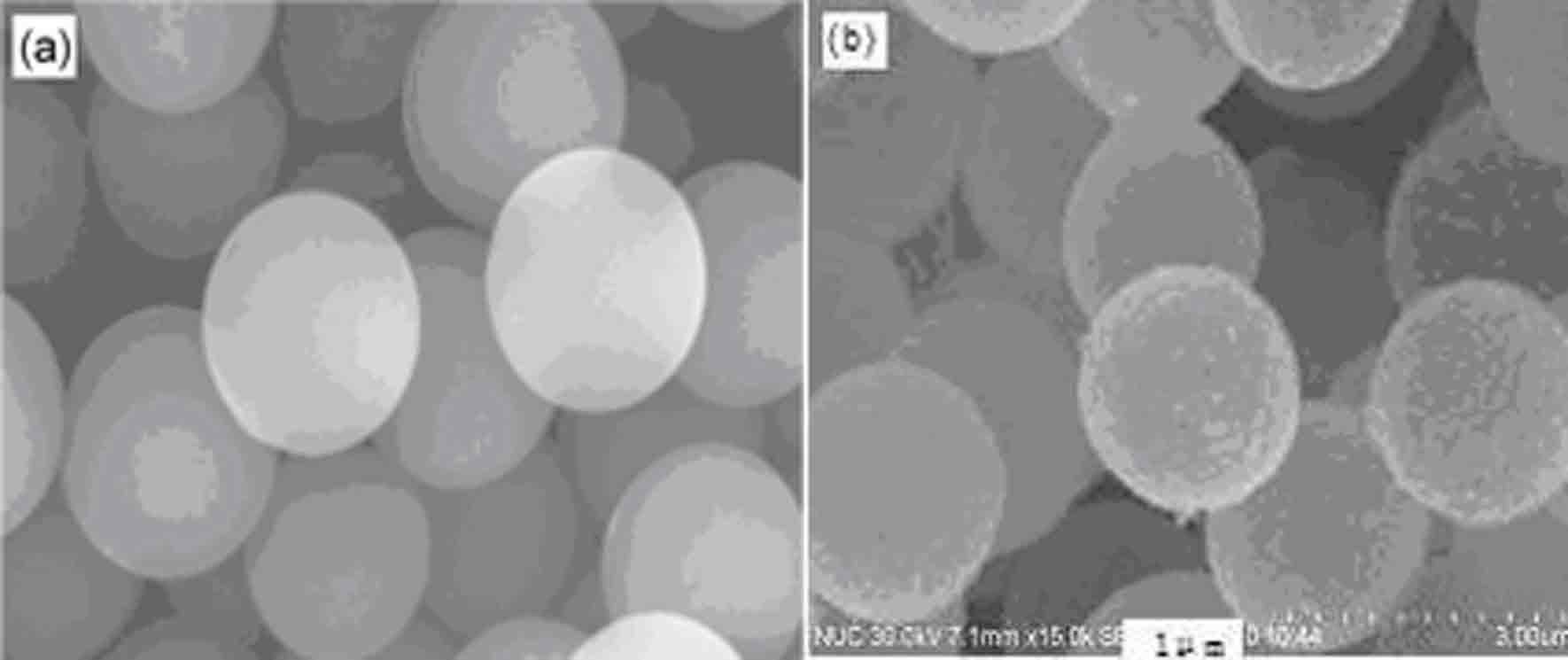

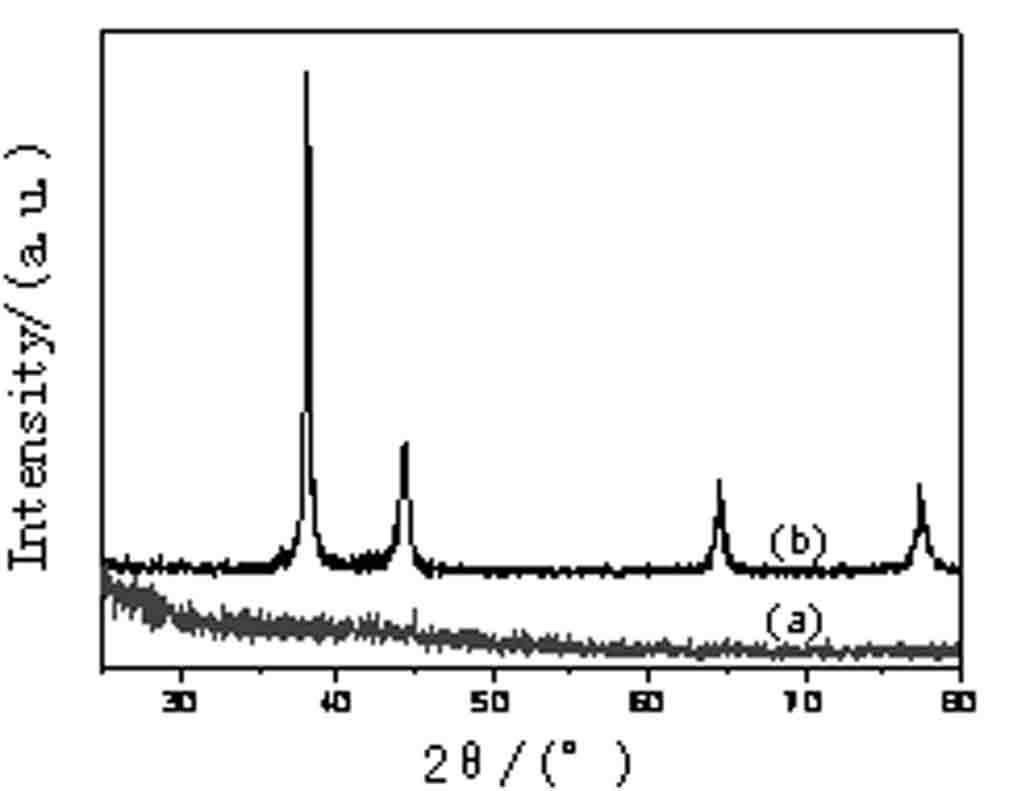

Image

Examples

Embodiment 1

[0024] Take 1g of PS microspheres, add them to the prepared 100ml roughening solution for roughening for 15min (30°C), take them out, and wash them with distilled water for 2-3 times. Then put it into 100ml sensitization solution for 15min (30°C), take it out, and wash it with distilled water 2-3 times. Put into 100ml activation solution to activate for 15min (30℃). Take it out, wash it 2-3 times with distilled water, and set it aside. Take 0.25gAgNO 3 Add to 100ml of distilled water, add 1.5ml of ammonia water (28%) to obtain a transparent silver ammonia solution. Add the treated PS microspheres to the silver-ammonia solution, add 0.5ml formaldehyde (37%) dropwise after stirring, keep stirring for 20min, wash with distilled water for 3 times after filtering, filter, and vacuum dry at 80°C to obtain Ag / PS Composite particles. In this embodiment, each step formula and test result are as follows:

[0025]

Embodiment 2

[0027] Take 2g of PS microspheres and add them to the prepared 30ml roughening solution to roughen for 15min (30°C). After taking them out, wash them with distilled water for 2-3 times. Then put it into 30ml of sensitizing solution for 15min (30°C), take it out, and wash it with distilled water for 2-3 times. Put it into 30ml activation solution to activate for 15min (30℃). Take it out, wash it 2-3 times with distilled water, and set it aside. Take 0.7gAgNO 3 Add to 100ml of distilled water, add 3.8ml of ammonia water (28%) to obtain a transparent silver ammonia solution. Add the treated PS microspheres to the silver-ammonia solution, add 1.8ml formaldehyde (37%) dropwise after stirring, keep stirring for 20min, wash with distilled water for 3 times after filtering, filter, and vacuum dry at 80°C to obtain Ag / PS Composite particles. In this embodiment, each step formula and test result are as follows:

[0028]

Embodiment 3

[0030] Take 2g of PS microspheres and add them to the prepared 100ml roughening solution for roughening for 15min (30°C). After taking them out, wash them with distilled water for 2-3 times. Then put it into 60ml of sensitization solution for 15min (30°C), take it out, and wash it with distilled water 2-3 times. Put it into 35ml activation solution to activate for 15min (30℃). Take it out, wash it 2-3 times with distilled water, and set it aside. Take 1gAgNO 3 , was added to 200ml of distilled water, and 4.5ml of ammonia water (28%) was added to obtain a transparent silver-ammonia solution. Add the treated PS microspheres to the silver-ammonia solution, add 2ml formaldehyde (37%) dropwise after stirring, keep stirring for 20min, wash with distilled water for 3 times after filtering, filter, and vacuum dry at 80°C to obtain the Ag / PS composite particle. In this embodiment, each step formula and test result are as follows:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com