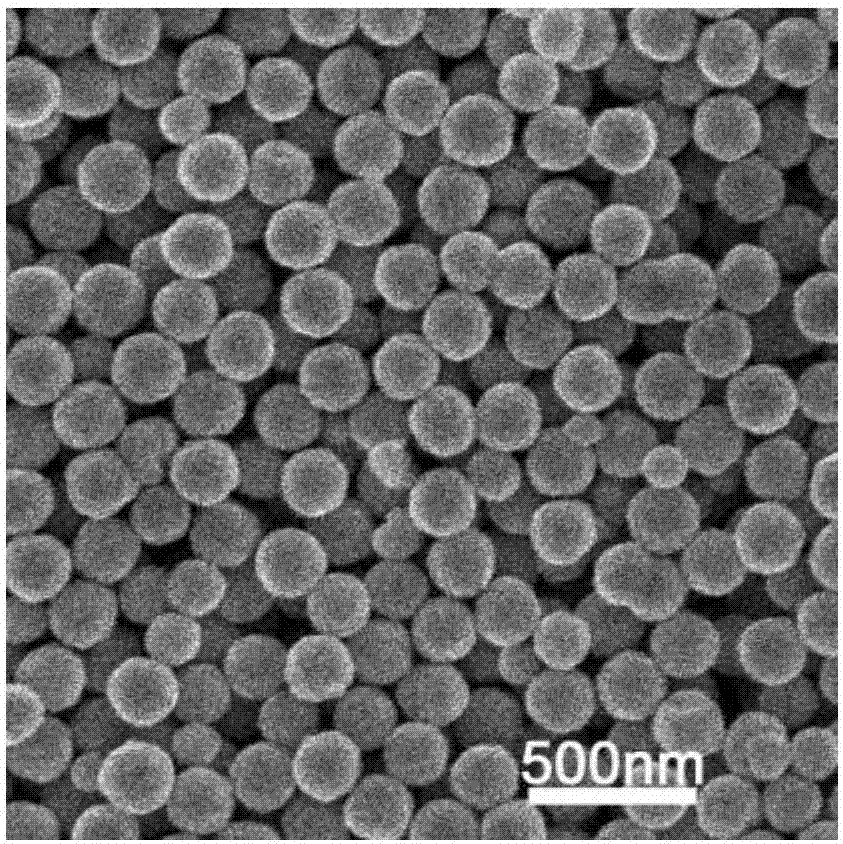

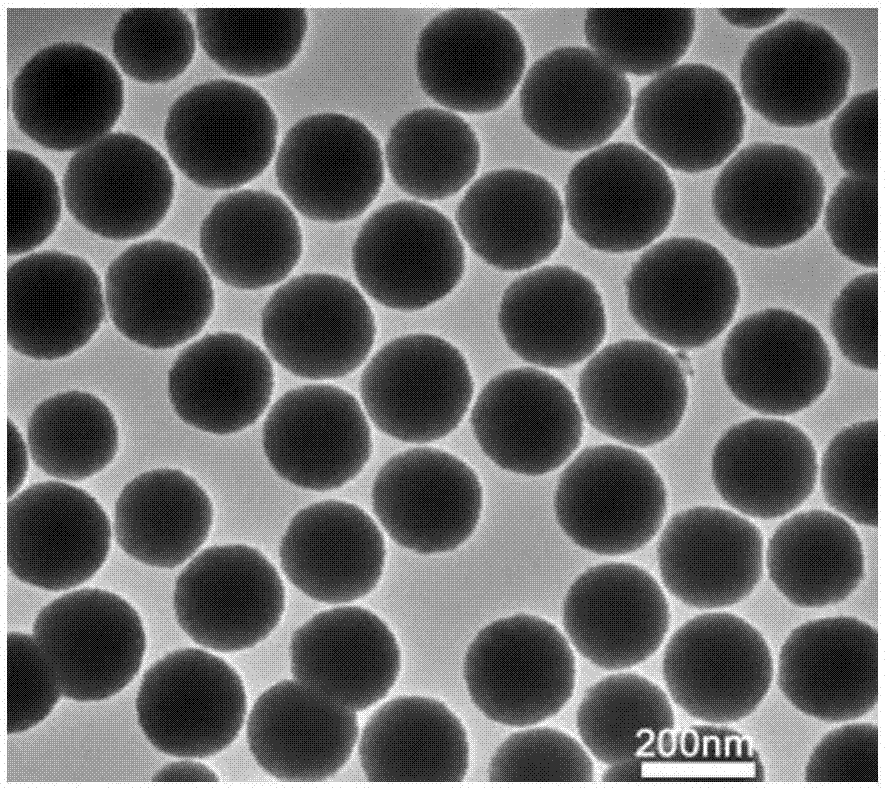

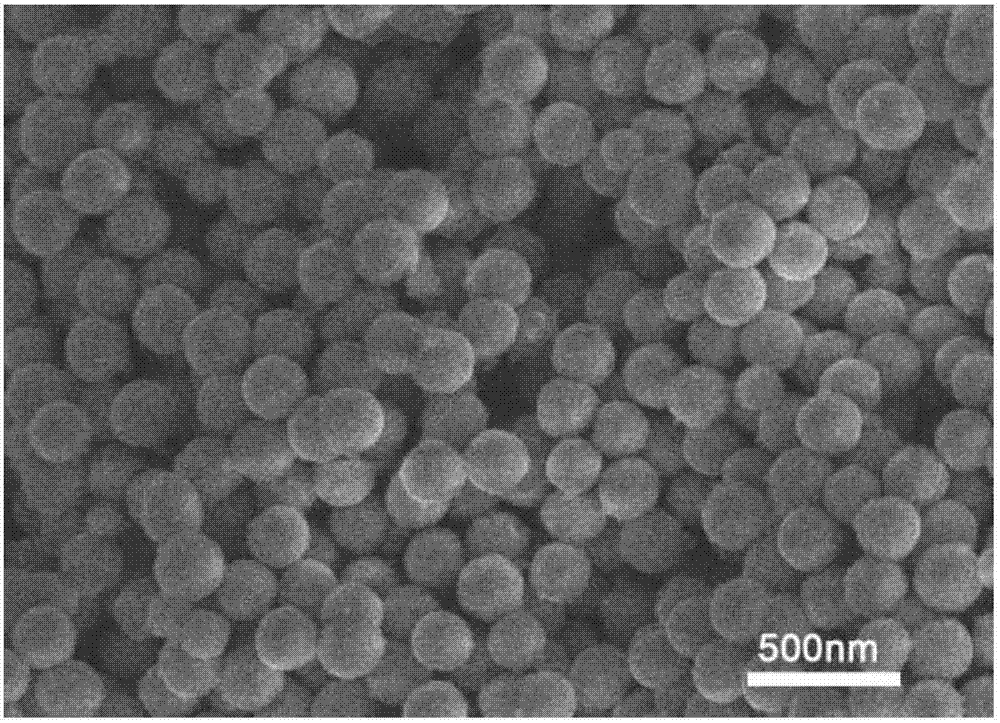

Preparation method of visible-light-driven photocatalyst Fe3O4@PDA@Ag composite microsphere

A composite microsphere and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of particle size increase, influence on magnetic properties, and magnetic reduction and other problems, to achieve the effect of convenient coating, cost saving and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A visible light catalyst Fe 3 o 4The preparation method of @PDA@Ag composite microspheres is characterized in that it comprises the following steps:

[0038] Step 1, dissolving ferric chloride hexahydrate and sodium acetate into equal amounts of ethylene glycol respectively, then mixing and stirring the two solutions evenly, adding 10-30wt% polyacrylic acid solution and continuing to stir for 6-12 hours to form a mixed solution a, and place the mixed solution a in a reaction kettle, keep the reaction at 180-210°C for 4-12 hours, and obtain the black product ferric oxide;

[0039] Step 2, dispersing iron ferric oxide into the ethanol solution of polyvinylpyrrolidone, then adding the aqueous solution of dopamine hydrochloride, water bath, and fully ultrasonically dispersing to form a mixed solution b;

[0040] Step 3, add ammonia water dropwise to the above mixed solution b, continue the ultrasonic reaction for 2-5 hours, and then magnetically separate and wash several ...

Embodiment 2

[0050] A visible light catalyst Fe 3 o 4 The preparation method of @PDA@Ag composite microspheres is characterized in that it comprises the following steps:

[0051] Step 1, dissolving ferric chloride hexahydrate and sodium acetate into equal amounts of ethylene glycol according to the molar ratio of 1:500, the molar ratio of sodium acetate to ethylene glycol is 1:200, and the two solutions Mix and stir evenly, add 10-30wt% polyacrylic acid solution and continue to stir for 8h, wherein the volume ratio of the total amount of ethylene glycol to 10-30wt% polyacrylic acid solution is 40:1, inject the mixed solution into the reactor at 203°C and keep the reaction Obtain black product ferric oxide in 12 hours;

[0052] Step 2, get ferric oxide and disperse it in the ethanol solution of polyvinylpyrrolidone, the mass ratio of ferric ferric oxide and polyvinylpyrrolidone is 1:1, the molar ratio of polyvinylpyrrolidone and ethanol is 1:100, then add hydrochloric acid The aqueous so...

Embodiment 3

[0058] A visible light catalyst Fe 3 o 4 The preparation method of @PDA@Ag composite microspheres is characterized in that it comprises the following steps:

[0059] Step 1, dissolving ferric chloride hexahydrate and sodium acetate into equal amounts of ethylene glycol according to the molar ratio of 1:350, the molar ratio of sodium acetate to ethylene glycol is 1:200, and then the two solutions Mix and stir evenly, add 10-30wt% polyacrylic acid solution and continue to stir for 8h, wherein the volume ratio of total ethylene glycol to 10-30wt% polyacrylic acid solution is 40:1, inject the mixed solution into the reactor at 203°C and keep the reaction for 8 hours Hour obtains black product ferric oxide;

[0060] Step 2, get ferric oxide and disperse it in the ethanol solution of polyvinylpyrrolidone, the mass ratio of ferric ferric oxide and polyvinylpyrrolidone is 1:1, the molar ratio of polyvinylpyrrolidone and ethanol is 1:80, then add hydrochloric acid The aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com