Method for preparing size-controllable silver nanoparticles

A technology of silver nanoparticles and particle size, applied in nanotechnology and other directions, can solve the problems of wide size distribution range and difficult to control the size of silver nanoparticles, and achieve the effect of controllable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of silver ammonia solution used is all as follows:

[0045] Configured to take 50mg AgNO 3 Add water to 10mL to obtain a silver nitrate aqueous solution with a concentration of 5mg / mL; add 100μL of a 1M NaOH aqueous solution (the molar ratio of silver nitrate to sodium hydroxide is 3:1) to form a brown precipitate, and then add 5% silver nitrate drop by volume Ammonia water, so that the formed AgOH brown precipitate just disappears, that is, a silver ammonia solution is formed; then the solution is diluted to AgNO 3 The concentration is 1mg / mL, obtained by filtering twice with a filter membrane with a pore size of 450nm, and set aside.

Embodiment 1

[0047] Dissolve 100mg of weak reducing agent glucose with aldehyde groups and 200mg of protective agent PVP in 150mL of deionized water, ultrasonically dissolve them completely, and filter twice through a filter membrane with a pore size of 450nm. After the pH value of the system was 9, 200 μL of gold seeds with a particle size of 5 nm were added (the concentration of gold seeds was 65 μg / mL), and then 2.5 mL of silver ammonia solution was added at a rate of 0.5 mL / min. The silver-ammonia reaction of the gold seed is completed after 5 minutes, and the sol containing the silver nanoparticles provided by the present invention is obtained.

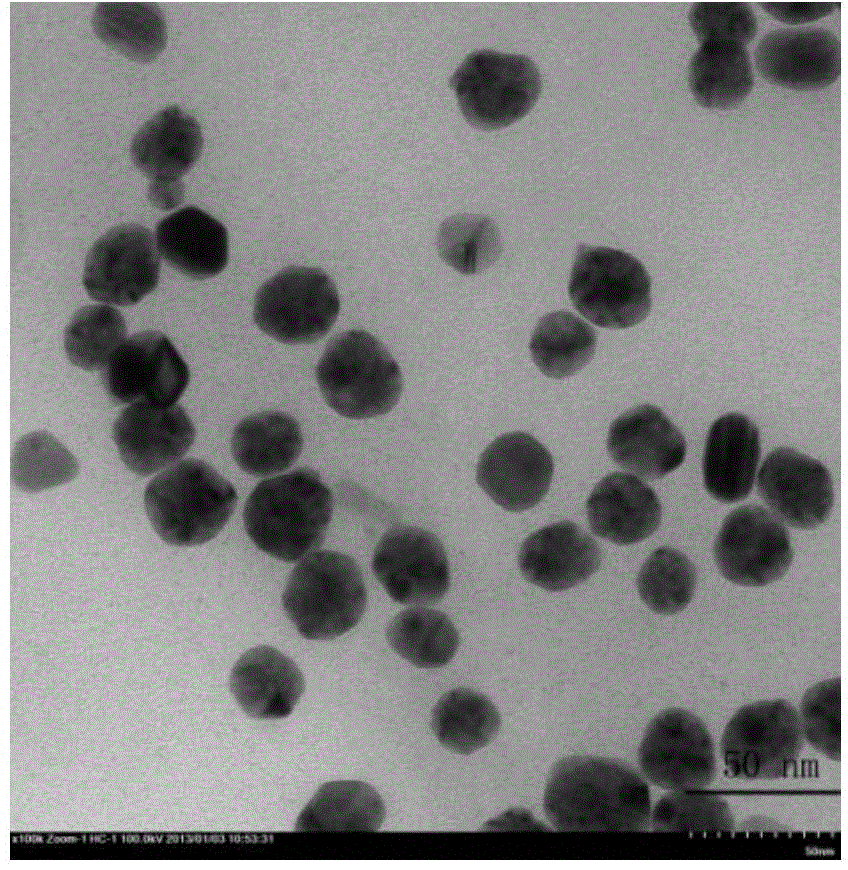

[0048] The TEM photograph of the silver nanoparticles is as figure 1 As shown, it can be seen from the figure that the particle size of the silver nanoparticles is 24nm.

Embodiment 2

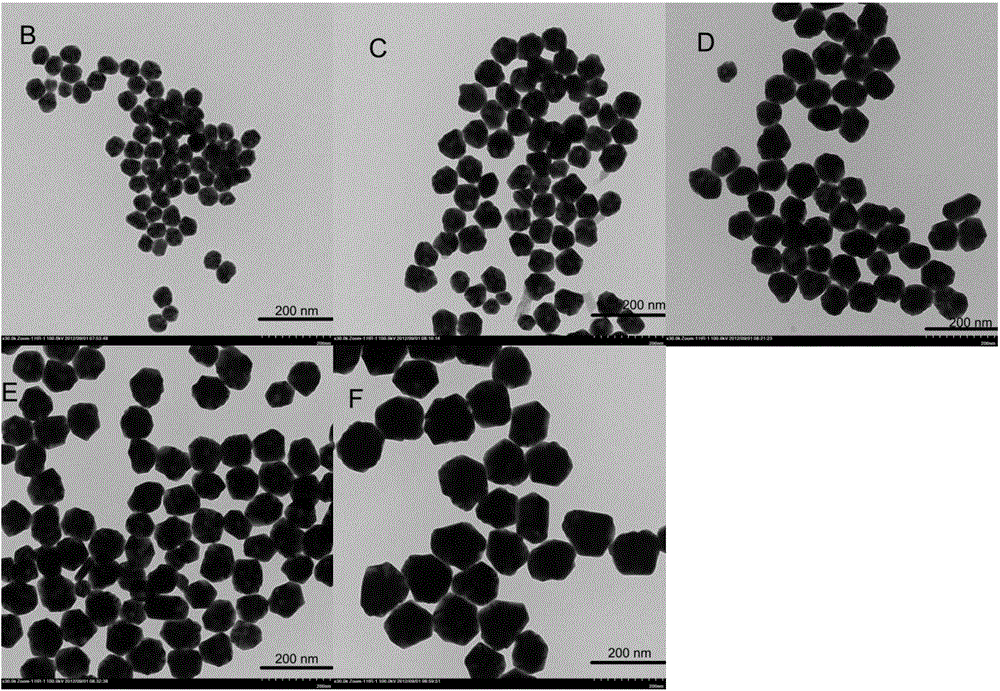

[0050]According to the same steps as in Example 1, only the reaction time of the silver-ammonia reaction step of the gold seed is replaced by 10, 40, 60, 100 and 120 minutes to obtain successively the following: figure 2 Silver nanoparticles with particle sizes of 50 nm, 70 nm, 90 nm, 105 nm and 120 nm are shown in B-F.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com