Patents

Literature

198 results about "Aqua vitae" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqua vitae /ˌækwə ˈvaɪtiː/ (Latin for "water of life") or aqua vita is an archaic name for a concentrated aqueous solution of ethanol. The term was in wide use during the Middle Ages and the Renaissance, although its origin is likely much earlier. This Latin term appears in a wide array of dialectical forms throughout all lands and people conquered by ancient Rome. Generally, the term is a generic name for all types of distillates, and eventually came to refer specifically to distillates of alcoholic beverages (liquors).

Wickerhamomyces anomalus strain and application thereof

ActiveCN103184167ASatisfy the requirements of ester fragranceFungiMicroorganism based processesBiotechnologyEthyl acetate

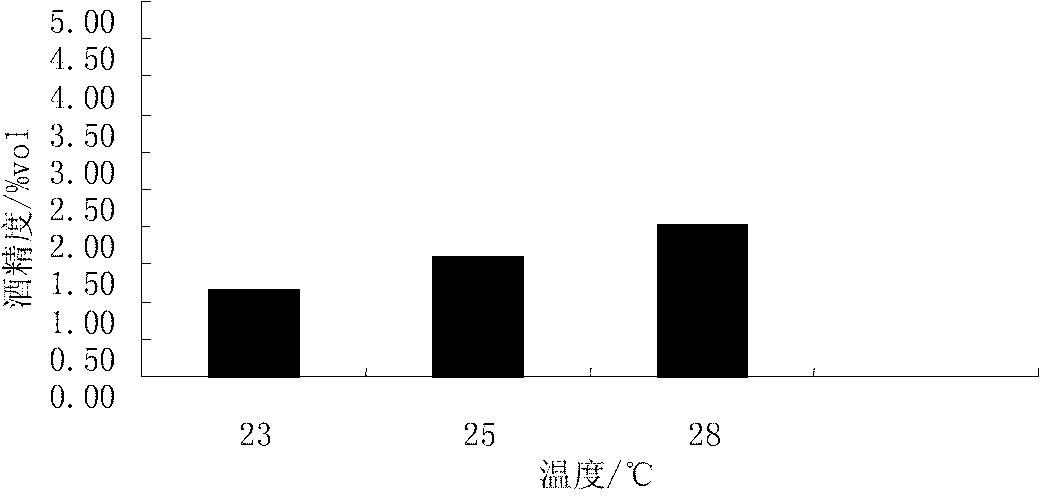

The invention discloses a wickerhamomyces anomalus which is preserved in China General Microbiological Culture Collection Center with preservation number of CGMCC NO.6983 on 12 December, 2012. The optimum fermentation process parameters of liquor-producing power of the strain are as follows: temperature: 29 DEG C, culture time: 59 h, inoculation amount: 5 percent, and pH: 6.5, and the alcohol content of a fermentation liquor is 2.8 percent (v / v). The optimum process parameters for the production of ethyl acetate are as follows: temperature: 28 DEG C, culture time: 65 h, inoculation amount: 5 percent, and pH: 4.5, and the content of the ethyl acetate reaches 50.2 mg / 100ml. The strain not only can produce a certain amount of alcohol, but also meet the requirements of spirit to ester aroma, has double characteristics of an alcohol yeast and an ester-producing yeast, and becomes an indispensable functional bacterium during the brewing process of dry wine; and the metabolic property of the strain is important for the formation of typical style characteristics of the Laobaigan liquor.

Owner:YUFENG IND HEBEI

Brewing process for pink wine

ActiveCN103451056AImprove qualityDecreased dipping temperatureWine preparationBiotechnologyLactic acid bacterium

The invention relates to a brewing process for pink wine, belonging to the brewing technical field of pink wine. The brewing process aims to solve the technical problem that a pink wine brewing method that dipping is performed at low temperature for a short time and malo-lactic fermentation time is short. The technical scheme adopted by the invention is as follows: the brewing process for pink wine comprises the following steps: dipping crushed grape dregs at 10-15 DEG C; heating a dipped grape clean liquid to 16-18 DEG C for alcoholic fermentation; controlling the fermentation temperature at 16-18 DEG C; converting wine after alcoholic fermentation to a malo-lactic fermentation tank; heating to 18-20 DEG C; adding lactic acid bacteria 31MBR; when the content of malic acid is reduced to zero, stopping fermentation. Ordinarily, malo-lactic fermentation time for common wine is 1-2 months, while just about 35 days are required for fermentation according to the process provided by the invention, so that the wine brewing time is extremely shortened. By adopting dipping at low temperature for the short time, the pink wine is relatively high in quality.

Owner:福建蓝家渡酒庄有限公司

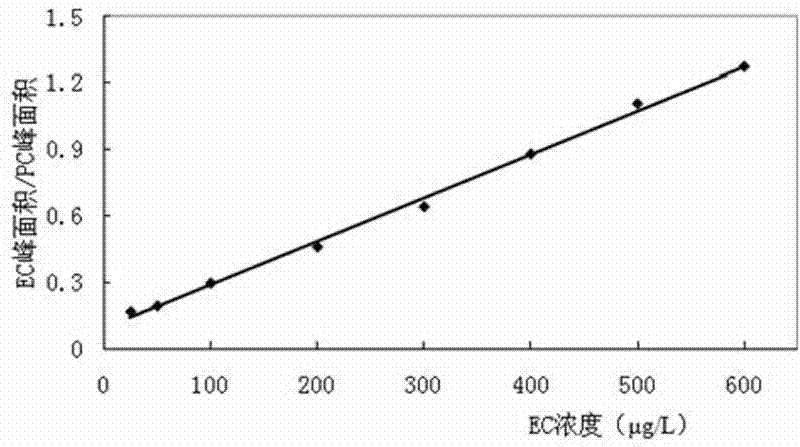

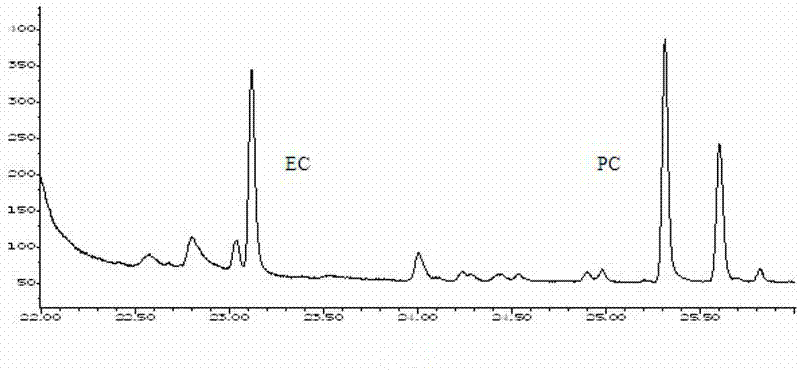

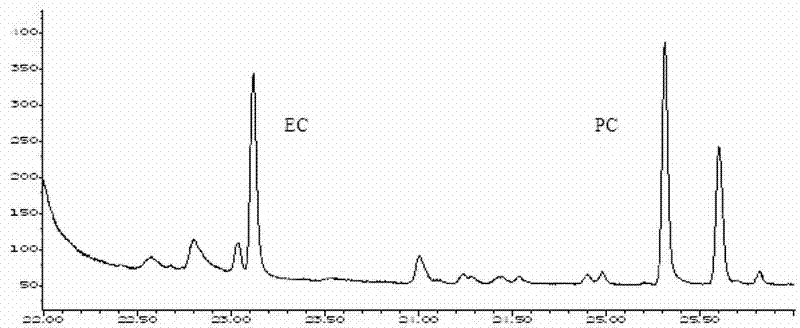

Method for quickly determining ethyl carbamate (EC) in alcoholic drink

InactiveCN102445505ARapid detection and accurate quantificationRapid quantitationComponent separationAlcohol contentAqua vitae

The invention discloses a method for quickly determining ethyl carbamate (EC) in alcoholic drink, which comprises the following steps of: diluting an alcoholic drink sample to be tested into the alcoholic drink sample with final alcoholic content of 4 percent to 20 percent (v / v) by double distilled deionized water; concentrating EC in the alcoholic drink sample through a head space solid-phase micro-extraction technology without a complex preprocessing process or organic solvent; carrying out detection and quantification analysis through a gas chromatography-mass spectrometer technology; and comparing with a standard curve to calculate the content of EC in the alcoholic drink sample. The method disclosed by the invention can be used for quickly testing and determining the EC in the alcoholic drink, the detection limit can reach as low as 1.19 mug / L, the linear correlation coefficient is larger than 0.99, the recovery rate is 90.21 percent to 99.07 percent, and the relative standard deviation is less than 10 percent. The method overcomes defects of the prior determining method, and can be used for detection and quantification analysis of the EC in the alcoholic drink.

Owner:JIANGNAN UNIV

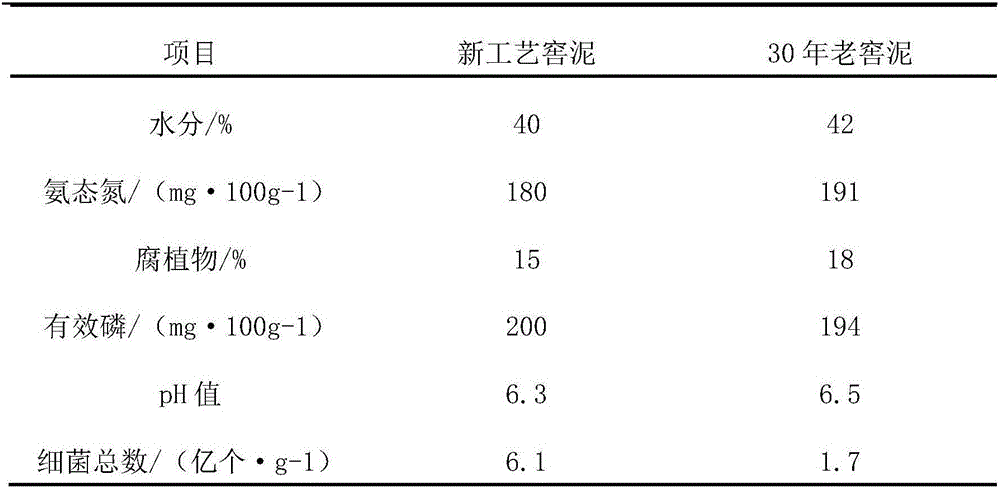

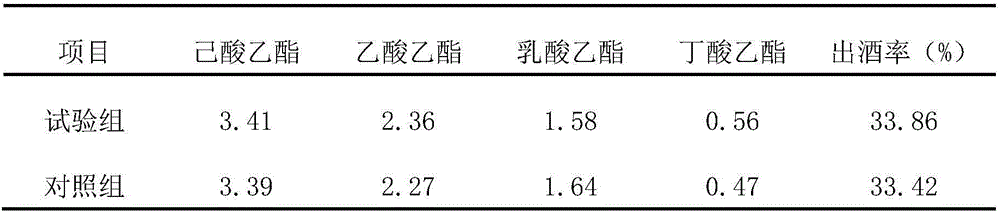

Preparing method and application of pit mud for improving flavor of baijiu in new pit

ActiveCN106085720AIncrease microbial contentPromote fermentationAlcoholic beverage preparationPeatFood flavor

The invention belongs to the field of wine brewing and particularly relates to a preparing method and application of pit mud for improving the flavor of baijiu in a new pit. The preparing method comprises the steps of preparation, and primary fermentation and secondary fermentation of raw materials. According to the preparing method, microorganisms in yellow-water-aged pit mud diluent are used for mass propagation in primary pit mud, starter microorganisms are properly added, and thus comprehensive composite pit mud function bacteria are obtained and replace a single strain to serve as a microorganism species source. Meanwhile, yellow-water-aged pit mud diluent is used for long-time soaking, a small amount of foreshot and after-run are supplemented, and thus certain organic acid and alcohol are increased, so that the original ecology of aged pit mud is simulated, and thus microorganism fermentation is better promoted. Black peat is further added to serve as humus and replace urea added by other factories as a nutrition source, and thus ethyl carbamate is avoided. On the aspect of pit mud aging, the prepared pit mud and the aged pit mud are mixed at the bottom of the pit, fermented mass fermentation is carried out for multiple turns to promote aging of the new pit mud, the circle is short, and higher practicability is achieved.

Owner:CHENGDU SHUZHIYUAN WINE

Wickerhamomyces anomalus strain low in urea yield and capable of producing flavor and application thereof to food production

ActiveCN105861346AReduce outputReduce formationFungiMicroorganism based processesFlavorMicroorganism

The invention discloses a Wickerhamomyces anomalus strain low in urea yield and capable of producing flavor and application thereof to food production and belongs to the fields of wine brewing and food safety. The Wickerhamomyces anomalus is separated from a baijiu fermentation environment (yeast for making hard liquor), named as Wickerhamomyces anomalus JZ420 and preserved in the General Microbiology Centre of Microbial Preservation Management Committee in China on May 6th, 2016 with the preservation number being CGMCC NO. 12416. The strain has the advantages of being low in urea yield, capable of producing flavor, resistant to ethyl alcohol and resistant to acid, is an excellent liquor-making functional strain and can be applied to the fields of fermented wine, distilled liquor and other food, and food safety is guaranteed.

Owner:JIANGNAN UNIV

Method for the Production of Wine and Wine Obtained from Such a Method

InactiveUS20080026100A1High specificity of actionPrevent oxidationWine preparationFood preparationMicroorganismCompound (substance)

A method is described for the production of wine, comprising the steps of:a) preparing a grape must;b) subjecting said grape must to clarification; andc) subjecting said clarified grape must to alcoholic fermentation to obtain said wine;characterized in that it comprises the step of adding to said clarified grape must, in sequence 1) at least one tannin and 2) a lysozyme. The use of tannin and lysozyme according to the invention enables to eliminate the sulfiting step involved in traditional methods and the sulfite-free wine thus obtained exhibits good chemical and microbiological stability.

Owner:SAINT SIMEON MARKETING E INVESTIMENTOS LTA

Litchi ice wine and production method thereof

ActiveCN101906365AIncrease Natural BrixHigh alcohol contentAlcoholic beverage preparationMicroorganism based processesLitchi fruitCold storage

The invention relates to the field of fruit wine brewing, particularly to a brewing method of litchi ice wine through freezing concentration and then low-temperature fermentation of litchis as raw materials. The method comprises the following steps of: processing the litchis as the raw materials, shelling and de-nucleating, pressing and extracting juice, clarifying, carrying out freezing concentration, carrying out temperature-controlled fermentation, ageing in an oak barrel, carrying out cold storage, clarifying for the second time, and filtering to finally obtain the litchi ice wine. The method has low cost and simple process. The alcohol (V / V) of the litchi ice wine is 10-15 percent; the total sugar (calculated by glucose) is 2.0-3.5g / L; the total acid (calculated by tartaric acid) is 6.0-7.5g / L; the volatile acid (calculated by acetic acid) is 0.45-0.75g / L; the litchi ice wine is golden in color and luster and is elegant and pleasant; the fragrance is mellow litchi fruit fragrance, and the fruit fragrance is coordinated with the wine fragrance; and the litchi ice wine has elegant and exquisite taste and a coordinated wine body.

Owner:GUANGDONG ZHENZHOU LYCHEE IND

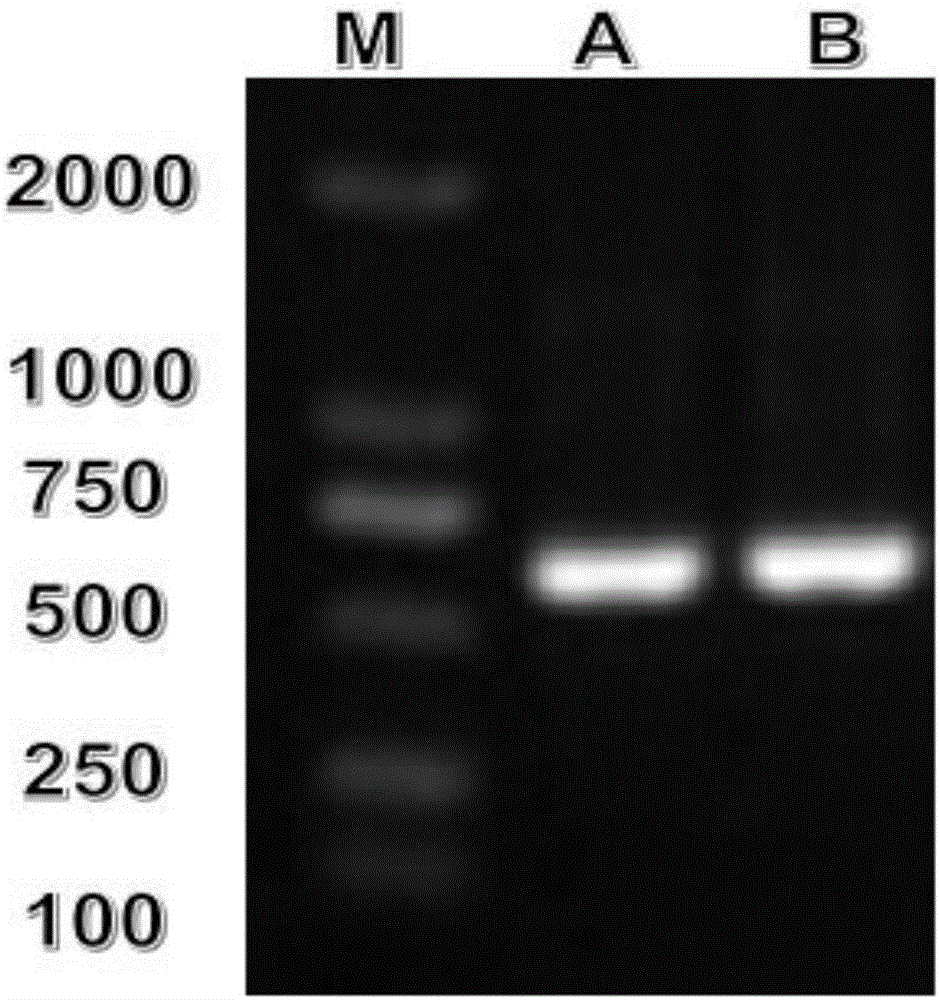

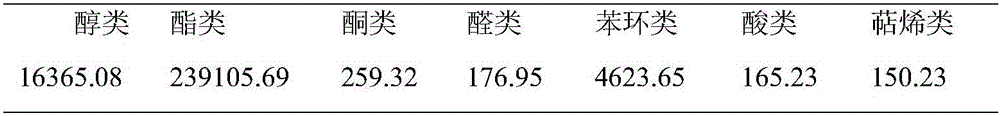

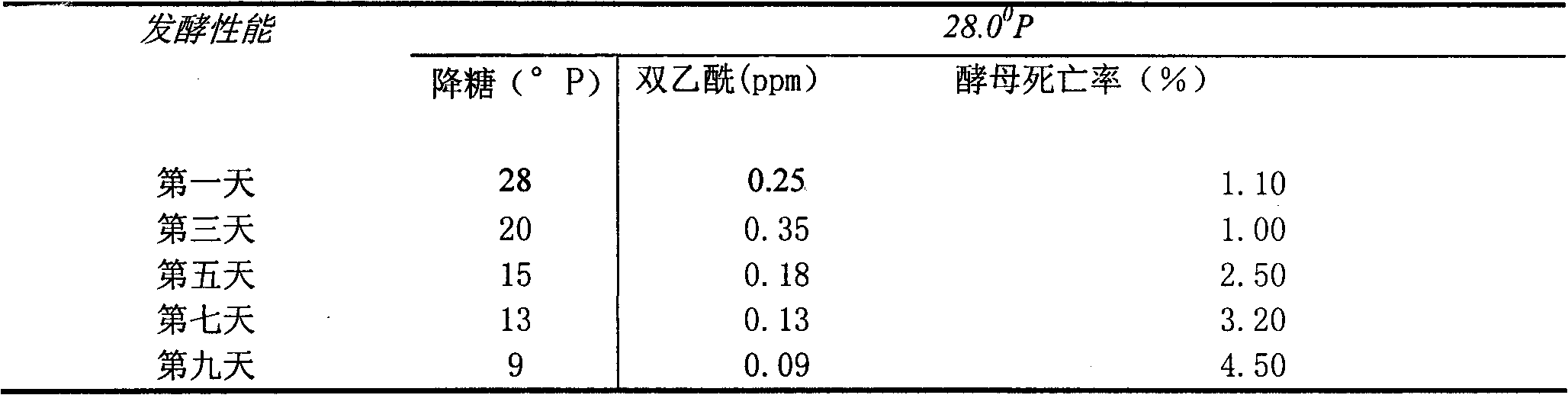

Method for brewing ultrahigh-gravity beer by ultrahigh-gravity Saccharomyces cerevisiae

The invention provides a culture and a method which are suitable for brewing ultrahigh-gravity beer. In the invention, mutagenesis, domestication, anti-alcohol test, cultivation, continuous separation, sieving, assessment and the like are adopted, so that culture 625 (Saccharomyces cerevisiae) which can resist 2-deoxy-D-glucose, has a strong diacetyl reduction ability, is alcohol-resisting, and is suitable for ultrahigh wort of 28degrees can be obtained, the culture G25 (Saccharomyces cerevisiae) is stored in Chinese General Microbiological Culture Collection Center, and the preservation number is CGMCC NO. 4,792. By the culture and process method to produce ultrahigh beer, not only is the equipment utilization rate greatly improved by 100-120%, but also the production cost is reduced; and compared with the beer brewed by general-gravity fermentation, the mouthfeeling of the beer is better, and the taste of the beer is cleaner.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

A kind of mulberry biological wine and its brewing process

InactiveCN102286328ANo feeling of thirstSober upMicroorganism based processesAlcoholic beverage preparationBiotechnologyAlcohol content

The invention relates to a mulberry biological wine and a brewing process thereof. Glutinous rice and rice are used as main raw materials in a weight ratio of 1.8-2.2:1, and saccharification extract, alcoholic yeast, bioenergetic element and mulberries are added. The mulberry bio-wine of the present invention has an alcohol content equivalent to that of white wine, and is not produced by a blending process in the brewing process, but is completely brewed from grains and plants. At the same time, the alcohol content of the mulberry bio-wine of the present invention is formed at one time during the brewing process , the prepared mulberry bio-wine has no alcohol smell in the mouth after drinking, no feeling of thirst, sobers up quickly, does not hurt the body, the brewing process of the mulberry bio-wine is reasonable and simple, the wine-making time is short, the wine yield is high, and food is saved.

Owner:DALIAN SANJUN LIQUOR IND CO LTD

Sulfur-dioxide-free full juice fermented kiwifruit wine and production process thereof

ActiveCN104130904AGuaranteed normal fermentationInhibit G+ bacteriaAlcoholic beverage preparationVitamin CFruit juice

The invention provides a sulfur-dioxide-free full juice fermented kiwifruit wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of crushing and juicing, adjusting the acidity of the juice, removing turbidity, resisting bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base and transiting and storing. The kiwifruit wine has the beneficial effects that an innovative process of replacing SO2 with a composite of six non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan, vitamin C and ethanol materials (refined alcohols and the like) is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the kiwifruit wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:万源市大面山酒业有限公司

Preparation of Nanguo pear vinegar

The invention relates to a method for preparing pome south vinegar, comprising the following steps: the pome south is crushed and pulped as well as is subjected to color protection and enzymolysis, active dry yeast is taken as yeast wine to perform the alcohol fermentation, As.1.41 acetic acid bacteria are taken as parent bacterial strains, the composite mutagenesis consisting of ultraviolet mutagenesis and pulsed light mutagenesis is adopted to culture excellent acetic acid bacterial strain so as to perform the acetic acid fermentation, and the health care fruit vinegar is prepared by matching raw materials such as a sweetening agent, an acidity regulator, a flavoring agent and oligose. The process flow comprises the following steps of selecting pome south, cleaning the pome south, crushing and pulping the pome south, protecting the color, performing the enzymolysis, filtering and clearing, adjusting the component, performing the alcohol fermentation, performing the acetic acid fermentation, filtering, matching, evening materials, bulking, sterilizing and preparing the pome south vinegar. The technical proposal is feasible. The produced pome south vinegar has rich nutrient value, simple technique, low cost and easy industrialized production.

Owner:SHENYANG AGRI UNIV

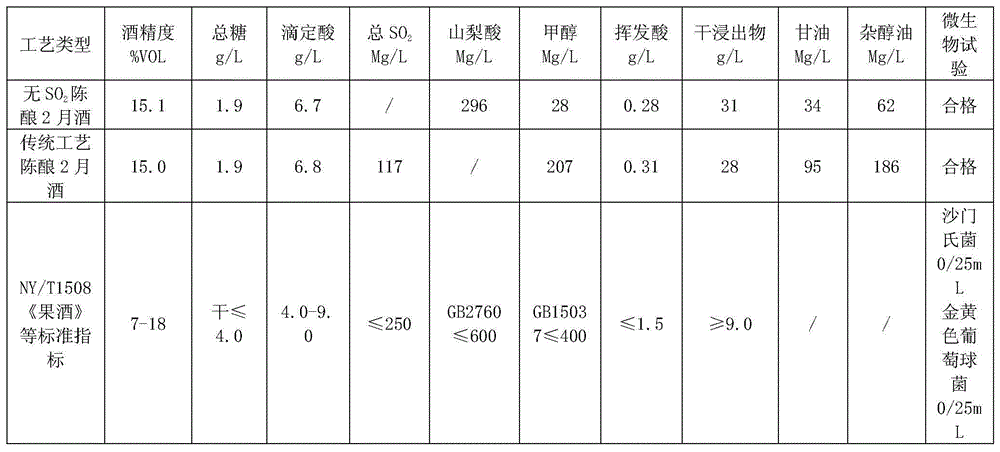

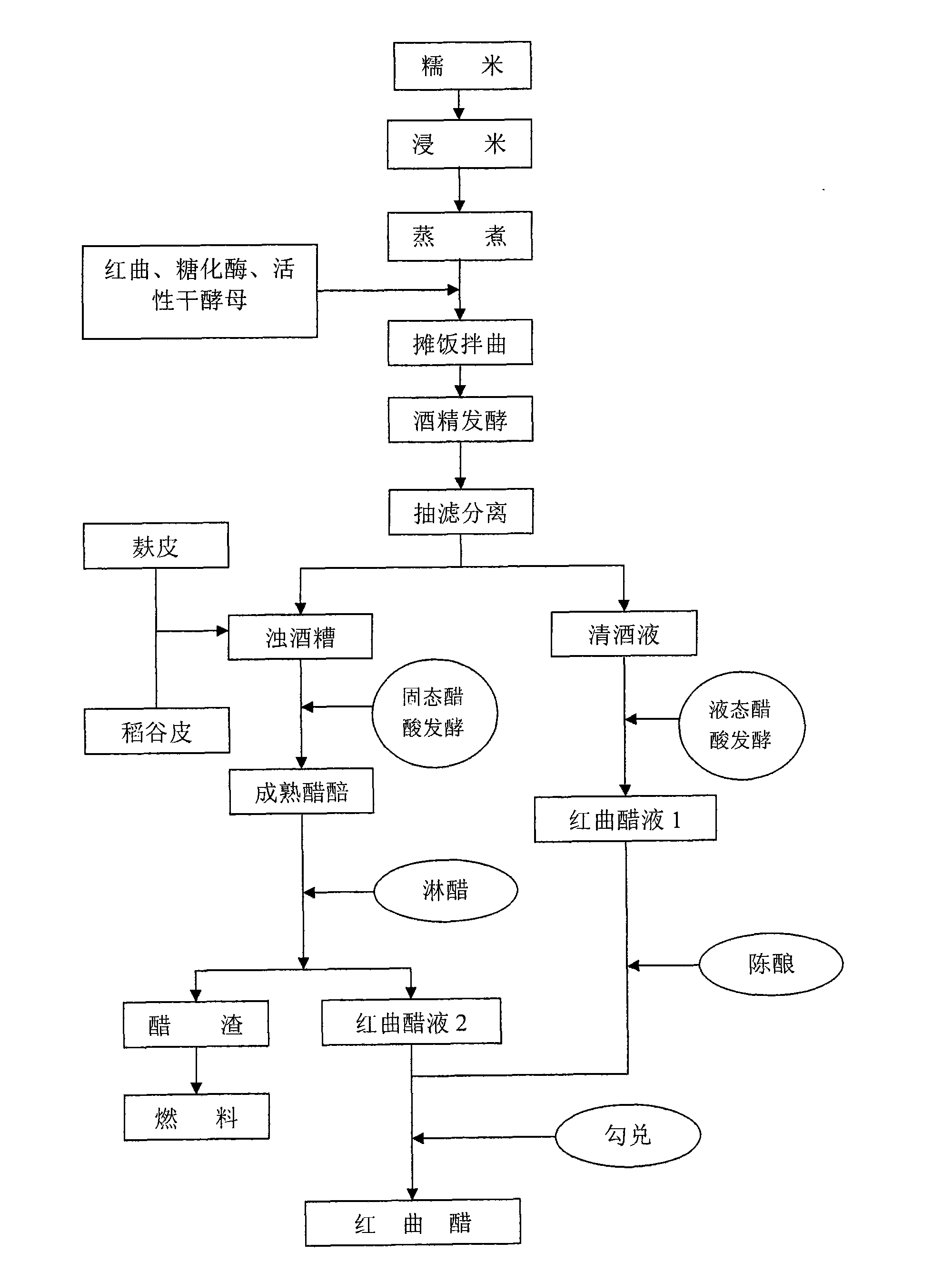

Clean production method for brewing monascus vinegar

InactiveCN101580793AShorten the fermentation cycleIncrease profitMicroorganism based processesVinegar preparationFiltrationFood flavor

The invention relates to a food processing method, in particular to a clean production method for brewing monascus vinegar. In order to realize the object, the technical proposal is characterized in that a filtration and separation step after the alcoholic fermentation step is added in the traditional methods such as sticky rice cooking, saccharification leaven, alcoholic fermentation, acetic acid fermentation and ageing and blending; two methods of liquid acetic acid fermentation and solid acetic acid fermentation are respectively adopted on the clear alcohol liquid and turbid grainstillage filtered and separated out of the monascus wine generated after alcoholic fermentation to prepare a monascue vinegar liquid 1 and a monascue vinegar liquid 2 respectively; and finally, the two vinegar liquids are blended to form the monascue vinegar. The method for brewing the monascus vinegar shortens the fermentation period, improves the utilization ratio of the raw material, improves the flavor of the monascus vinegar, complies with the requirements of clean production process, reduces the contamination from the headstream, realizes zero discharge of solid wastes, and solves the environmental pollution problem as a large amount of monascus grainstillag and vinegar slag are generated by the monascus vinegar brewing factory for brewing the vinegar.

Owner:YONGCHUN AGED VINEGAR

Wine and production method thereof

InactiveCN101486960AQuality assuranceSufficient and easy to find raw materialsAlcoholic beverage preparationBiotechnologyAqua vitae

The invention relates to wine and a production method thereof; the production method consists of the following steps subsequently: A. immersing the rice and steaming; B. fermentation; C. distillation; D. second fermentation by adding enzyme for saccharification; E. settlement; F. aging; G. blending; and H. filtration and sterilization, thus obtaining the finished wine. The wine is produced by the above method. The invention has the advantages that: based on the traditional technology, the process uses modern science technology and provides more security on the wine quality, and the raw materials are abundant and easy to find. The method effectively retains the nutritious ingredients of the raw materials, and produces a plurality of amino acids, microelements and vitamins during the fermentation process, thus having unique health-care functions. The unique and characteristic second fermentation is the key process of the method, reduces the normal alcoholic strength, in addition to the prominent reduce of anaphylactic reaction for the crowd having allergy on alcohol, and greatly reduces the harm of the normal alcohol to the human. The aging accelerates the maturation of the wine. The wine has superior flavor, color and taste, and is suitable for wider range of consumer groups.

Owner:JUANCHENG GUOKANG BIOLOGICAL BREWING

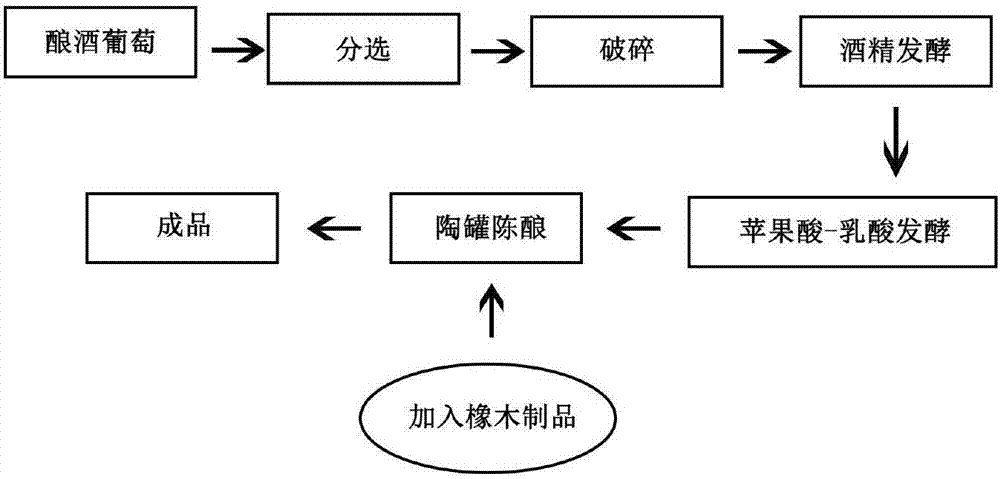

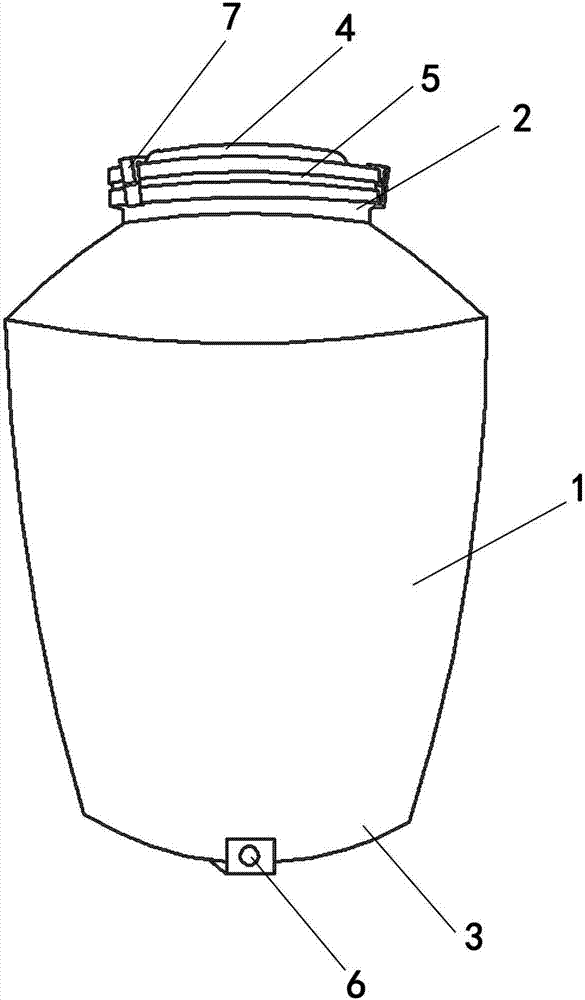

Method for aging grape wine by pottery jar and pottery jar for aging grape wine

InactiveCN107151586AImprove breathabilityAccelerated maturationWine preparationChemistryLactic acid fermentation

The invention discloses a method for aging grape wine by a pottery jar and the pottery jar for aging the grape wine. The method comprises the following steps of sorting, crushing, performing alcoholic fermentation, and performing malic acid and lactic acid fermentation, and is characterized in that grape fermenting mash subjected to malic acid and lactic acid fermentation is directly sent into the pottery jar for aging the grape wine to age. The pottery jar comprises a jar body, wherein the whole jar body is provided with an upper thick part and a lower sharp part; the jar body comprises a jar mouth and a jar bottom, the jar mouth is arranged in the upper end of the jar body, and the jar bottom is arranged at the lower end of the jar body; the jar mouth is a conical opening, and the size of the jar mouth is slightly smaller than the size of the jar bottom; a jar cover is arranged on the jar mouth and is matched with the jar mouth, and a sealing gasket is arranged between the jar mouth and the jar cover; the bottom part of the jar bottom is provided with a wine outlet. The method has the advantages that for the aged grape wine, the mouth feel is harmonious, the sourness is moderate, the tannin is smooth, the wine body is mellow and full, the complicated age fragrance is realized, the technical problem of aging of the grape wine by the pottery jar is solved, the grape wine simultaneously has the pottery jar and oak barrel brewing flavors, and the production cost is reduced.

Owner:宁夏天得葡萄酒业有限公司

Tartary buckwheat wine and preparation process thereof

ActiveCN105219590ASimple preparation processThe preparation process is simple, and the obtained product has a simple wine bodyAlcoholic beverage preparationBiotechnologyChaptalization

The invention relates to tartary buckwheat wine and a preparation process thereof and belongs to the technical field of wine brewing. The preparation process of the tartary buckwheat wine comprises the nine steps of raw material preparation, material steaming and curing, yeast addition and inoculation, culture saccharification, alcoholic fermentation, distillation, aging, blending and canning. As to a prepared product, a wine body is mellow and strong in taste and makes a drinker feel soft, cool and smooth without hurting the head of the drinker; protein, vitamins, mineral substances and flavonoid compounds in the raw materials can be fully utilized, and the beneficial elements can completely fuse in wine by means of fermentation to form health care wine containing bioactive substances beneficial to a human body. Tartary buckwheat biological flavones extracted from tartary buckwheat bran are added to the product, and the content of flavones and rutin in the prepared product is far higher than that in common tartary buckwheat wine; by drinking the tartary buckwheat wine, the effects of clearing away heat and toxic materials, promoting blood circulation to remove blood stasis, softening blood vessels and improving microcirculation can be achieved; the tartary buckwheat wine is easy to popularize and apply.

Owner:宁蒗县泸沽湖农旅产业有限公司

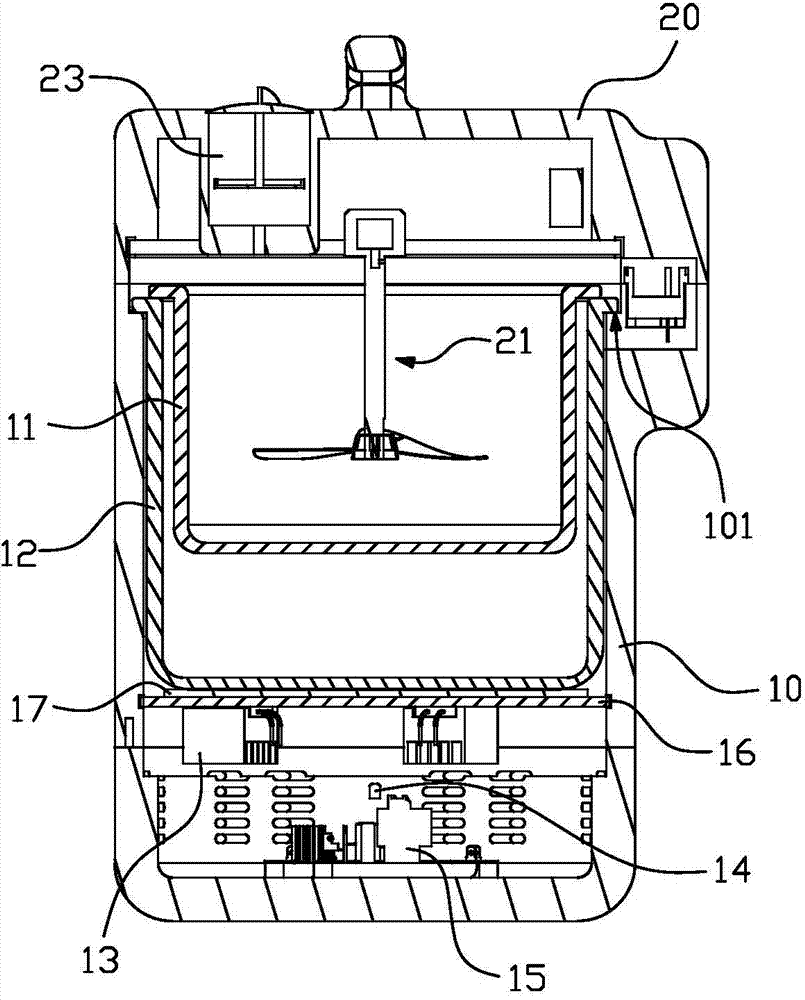

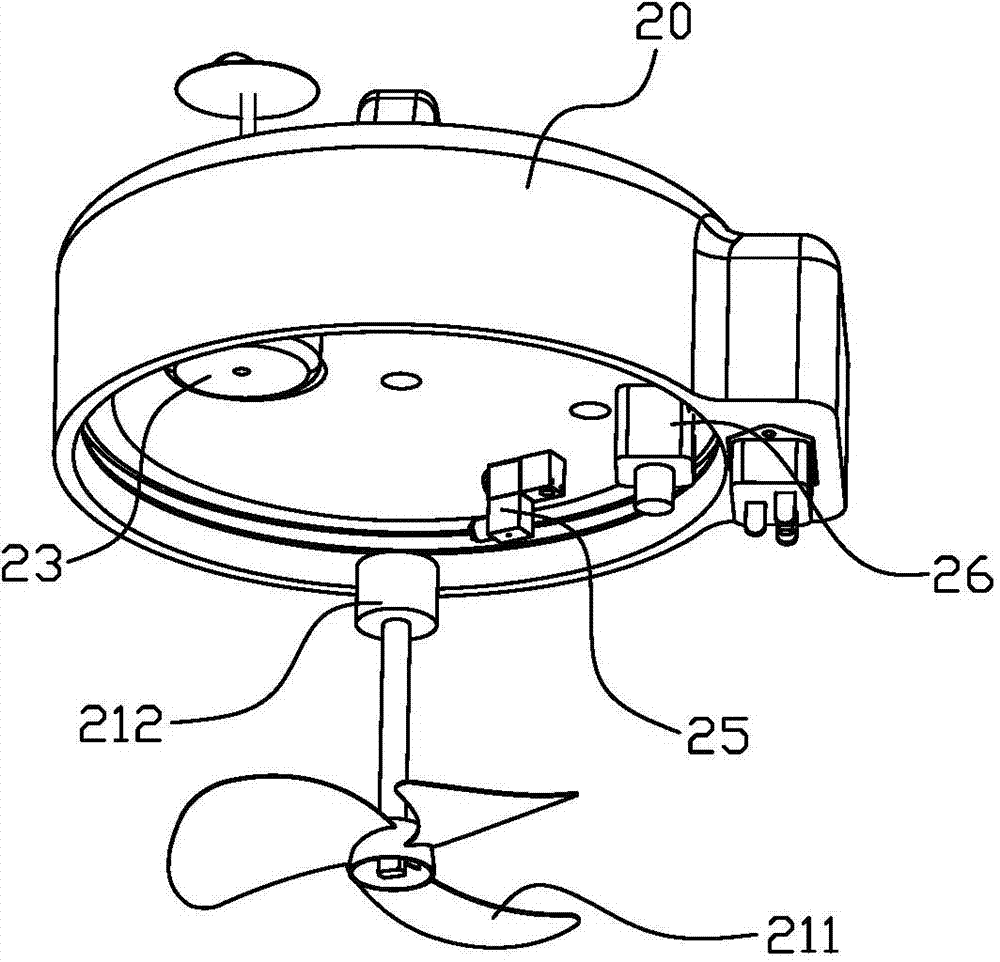

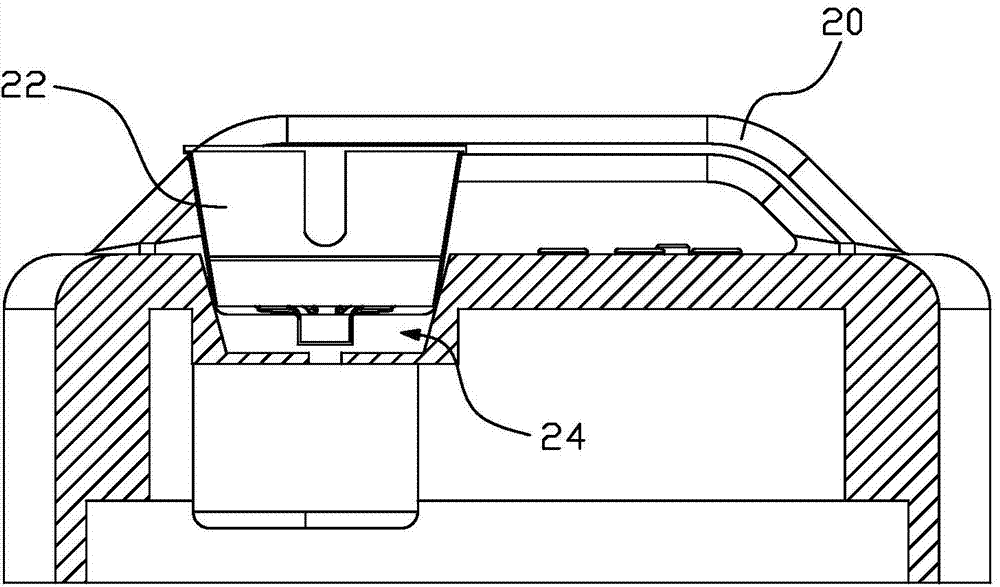

Automatic wine brewing device and control method thereof

InactiveCN104762165AAvoid complexityAvoid controllabilityAlcoholic beverage preparationAlcoholControl signal

The invention relates to the technical field of household appliances, and particularly relates to an automatic wine brewing device and a control method thereof. The device comprises a pot received in an outer barrel, wherein a cover capable of being freely opened and closed covers the upper opening part of the pot; a stirring unit is arranged on the pot or the cover and used for stirring articles in the pot; heating units and refrigeration units are arranged at the sides or the bottom of the pot and used for heating and refrigerating the articles in the pot respectively. The device further comprises a yeast box, temperature sensors, an alcohol monitoring probe and a main control unit, wherein the main control unit receives a signal and outputs control signals to control the start-up and the shut-down of the heating units, the refrigeration units and the stirring unit, and control adding for a yeast in the yeast box. By arranging the plurality of sensors, heating units and refrigeration units, the main control unit realizes the automation of rice wine brewing according to a wine brewing manufacturing process stored in the main control unit and the information acquired by the sensors, thus avoiding the shortages of a complex process for brewing a rice wine, uncontrollability and the like, and enabling everyone to automatically brew the rice wine.

Owner:合肥徳铭电子有限公司 +1

Vitis heyneana wine preparation method

InactiveCN105316148AMaintain aroma propertiesGuaranteed health benefitsWine preparationBiotechnologySucrose

The invention discloses a vitis heyneana wine preparation method. Vitis heyneana wine is prepared from, by weight, 80-100 parts of vitis heyneana, 20-30 parts of saccharose and 3-5 parts of saccharomyces cerevisiae. The vitis heyneana wine preparation method includes the steps of stemming and crushing fresh mature vitis heyneana to prepare vitis heyneana juice, adding the saccharose and sulfur dioxide into the vitis heyneana juice, inoculating the saccharomyces cerevisiae, and performing alcoholic fermentation at the fermentation temperature of 22-25 DEG C for 3-5 days hermetically so as to obtain primary fermentation broth; fermenting the primary fermentation broth in a hermetic vessel at the fermentation temperature of 25-28 DEG C for 20-30 days so as to obtain secondary fermentation broth; fermenting the secondary fermentation broth in the hermetic vessel for fermentation for 6-8 months until wine sediments sink naturally so as to obtain raw vitis heyneana wine; freezing, clarifying, filtering and sterilizing the raw vitis heyneana wine so as to obtain a finished product. The vitis heyneana wine preparation method has the advantages that final alcoholicity of the vitis heyneana wine product is increased, so that the vitis heyneana wine is mellower and fuller in taste, and the original healthcare effect of a vitis heyneana fruit wine product is kept.

Owner:LUOCHENG MULAO AUTONOMOUS COUNTY YONGFU ECOLOGICAL PLANTING & BREEDING FARMERS SPECIALIZED COOP

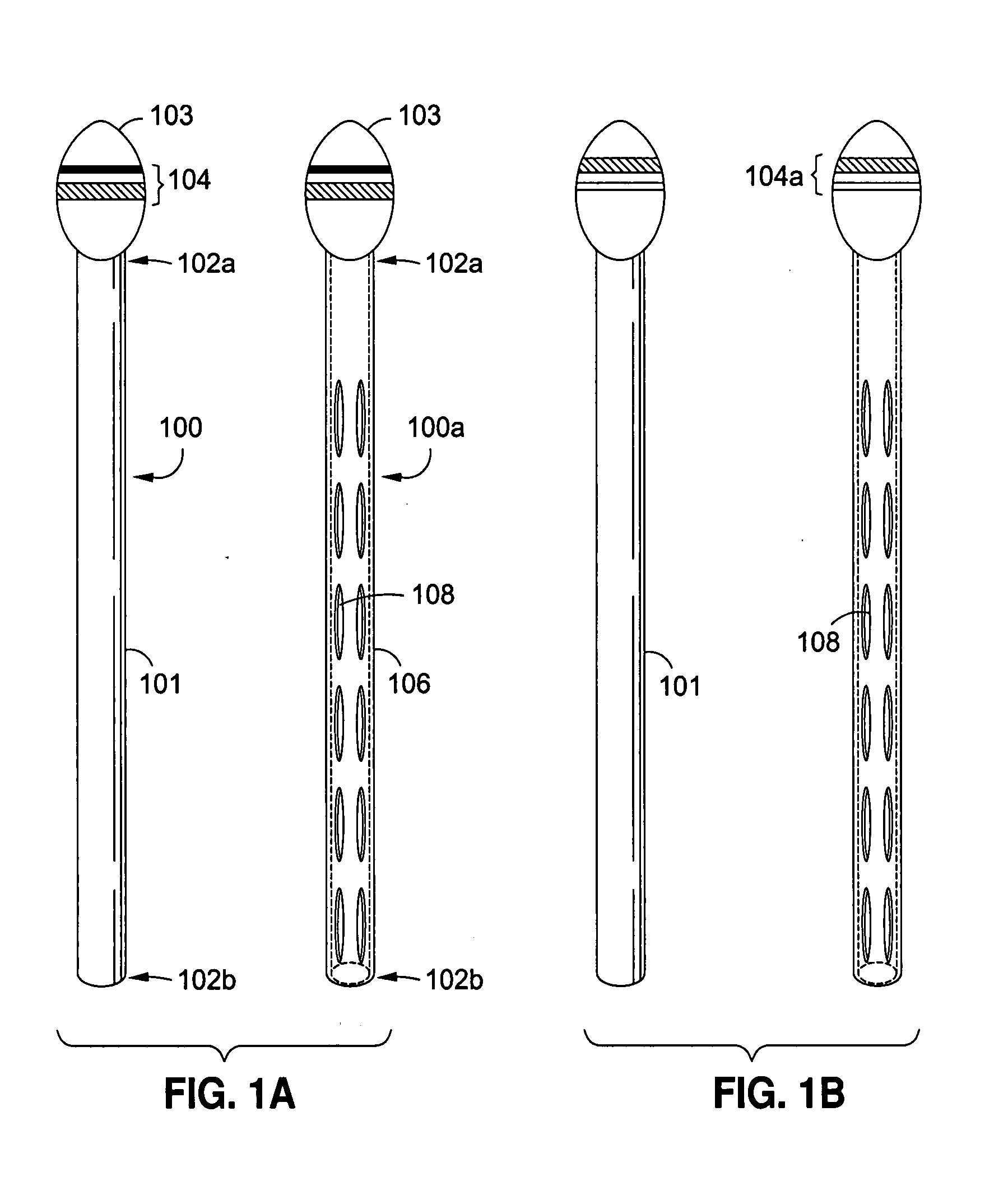

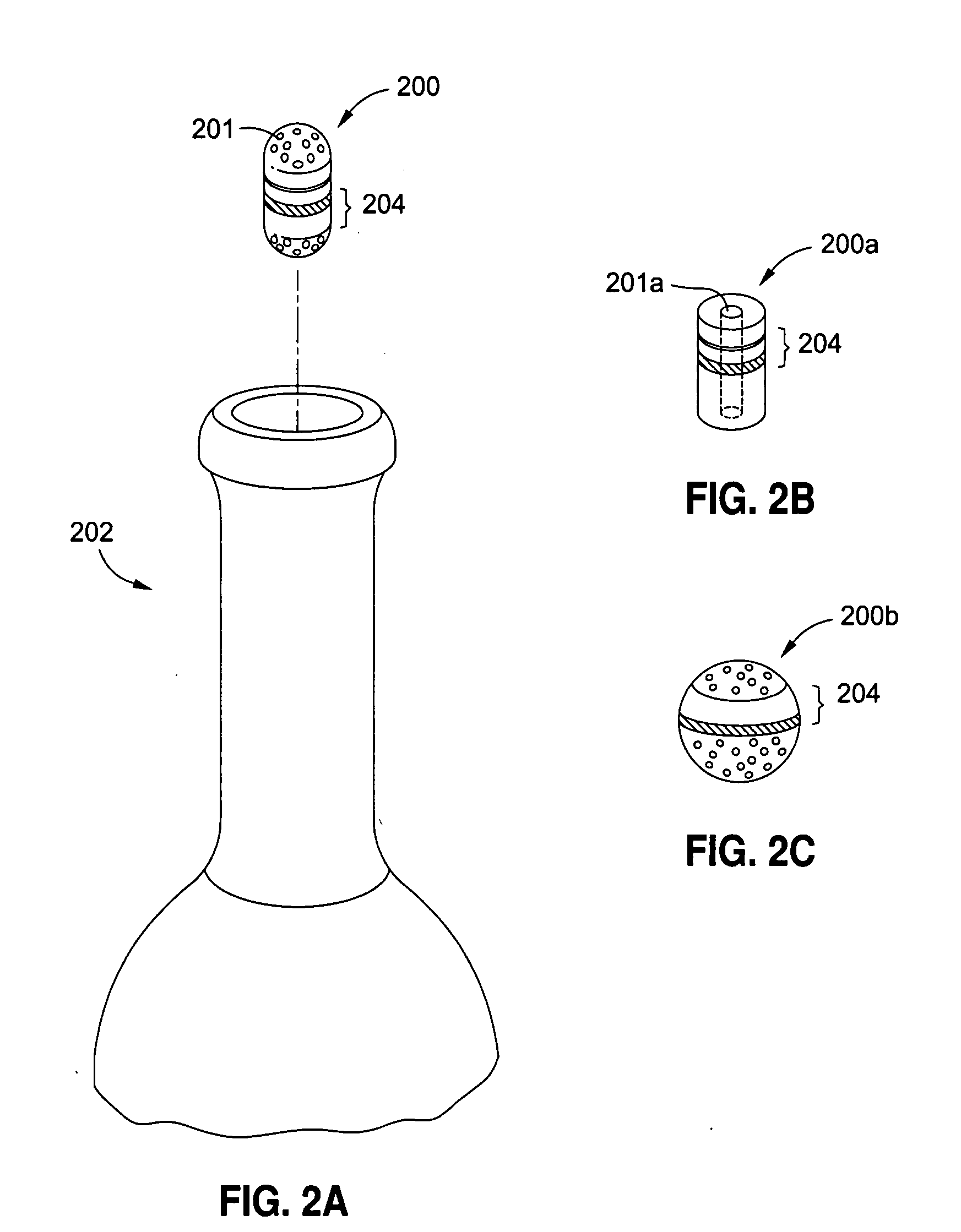

Method and apparatus for removing contaminants from a beverage

Methods and devices of the invention may be utilized to remove or reduce the quantity of one or more contaminants from a foodstuff, and particularly an alcoholic beverage. A contaminant removing material is formed into an object or is associated with an object. The beverage and the object are placed into contact with one another, such as by placing the object in the beverage or pouring the beverage over, through or into the object. The invention has particular applicability to removing or reducing the sulfite content of an alcoholic beverage. The contaminant removing object may be marked with information which identifies the one or more contaminants to be removed. A material may also be introduced to change other properties of the foodstuff, such as the color of a beverage.

Owner:BELLA VINO

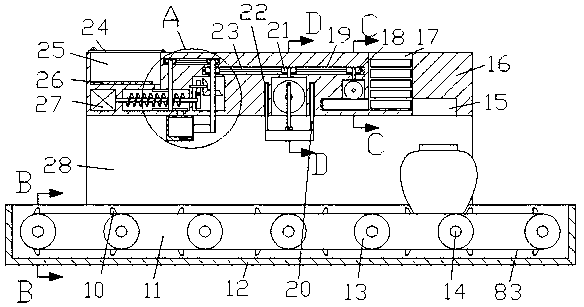

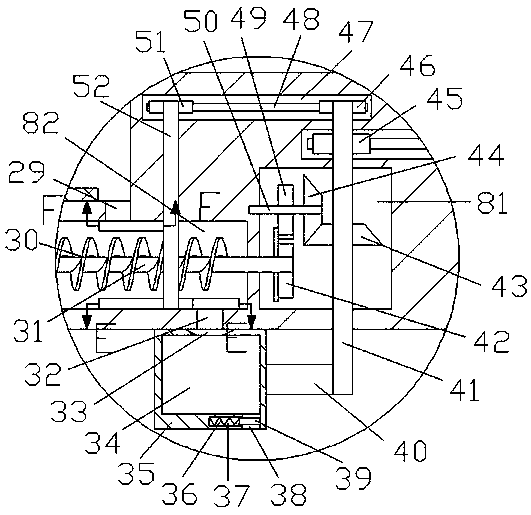

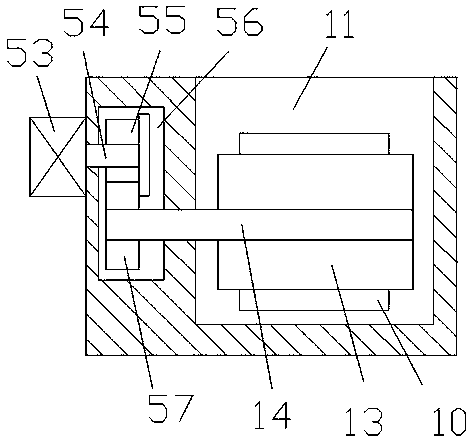

Automatic wine jar sealing device

InactiveCN110980612AAvoid churnDosage controlClosure membersThreadless stopper insertionAqua vitaeElectric machinery

The invention discloses an automatic wine jar sealing device which comprises a conveying box. A conveying cavity opened upward is formed in the conveying box, a first motor is fixedly connected to theback end surface of the conveying box, a sealing box is fixedly connected to the upper end surface of the conveying box, a sealing cavity communicating to the conveying cavity downward and penetrating left and right sides is formed in the sealing box, a wood plug through port communicates to the upper side of the sealing cavity, and a wood plug storage cavity opened upward communicates to the left side of the wood plug through port. Automatic feeding and automatic sealing are finished by matching two scored pulleys, so that the automatic wine jar sealing device is simple to operate. A wood plug is discharged automatically by reciprocating a rack. The wood plug is compacted by reciprocating a pressing plate up and down. The wood plug is compacted fully by a machine, so that alcohol volatilization and loss caused by a gap is prevented. Meanwhile, the dosage of beewax is controlled while full sealing is guaranteed by pouring liquid beewax quantatively at a fixed trajectory, so that the waste is prevented and the cost is lowered.

Owner:慈溪市纵深包装有限公司

Brewing method of hibiscus sabdariffa honey wine

ActiveCN104498253AImprove sensory qualityHigh light transmittanceAlcoholic beverage preparationMicroorganism based processesBiotechnologyPectinase

The invention belongs to the technical field of alcoholic beverage, and specifically discloses a brewing method of hibiscus sabdariffa honey wine. The brewing method comprises following steps: hibiscus sabdariffa calyx is cut into pieces; the processed hibiscus sabdariffa calyx is delivered into a fermentation cylinder, boiling water is added for immersion, and after cooling, sugar degree is adjusted to 16Bx with honey so as to obtain hibiscus sabdariffa honey juice; yeast and pectase are added for 6 days of fermentation at a temperature of 20 to 25 DEG C, and then fermentation is stopped, an obtained mixture is filtered so as to obtain raw wine; the raw wine is mixed with the hibiscus sabdariffa honey juice at a volume ratio of 1:(3-10) so as to obtain a mixed material, the mixed material is subjected to fermentation at 20 DEG C, and liquor returning is performed for three times; a solution obtained via three times of liquor returning is subjected to ageing for 3 to 6 months, and then is subjected to filtration, sterilization, and bottling so as to obtain the hibiscus sabdariffa honey wine. The hibiscus sabdariffa honey wine prepared via the preparation method possesses strong and pleasing flower fragrance and wine fragrance, is bright red, is clear and transparent, is sour, sweet, and delicious, is fresh in mouthfeel, is soft and mellow in wine quality, possesses typical fragrance of the hibiscus sabdariffa honey wine, and is rich in a plurality of phenols, amino acids, organic acids, vitamins, and mineral elements such as sodium and calcium.

Owner:佛山桂承生物科技有限公司

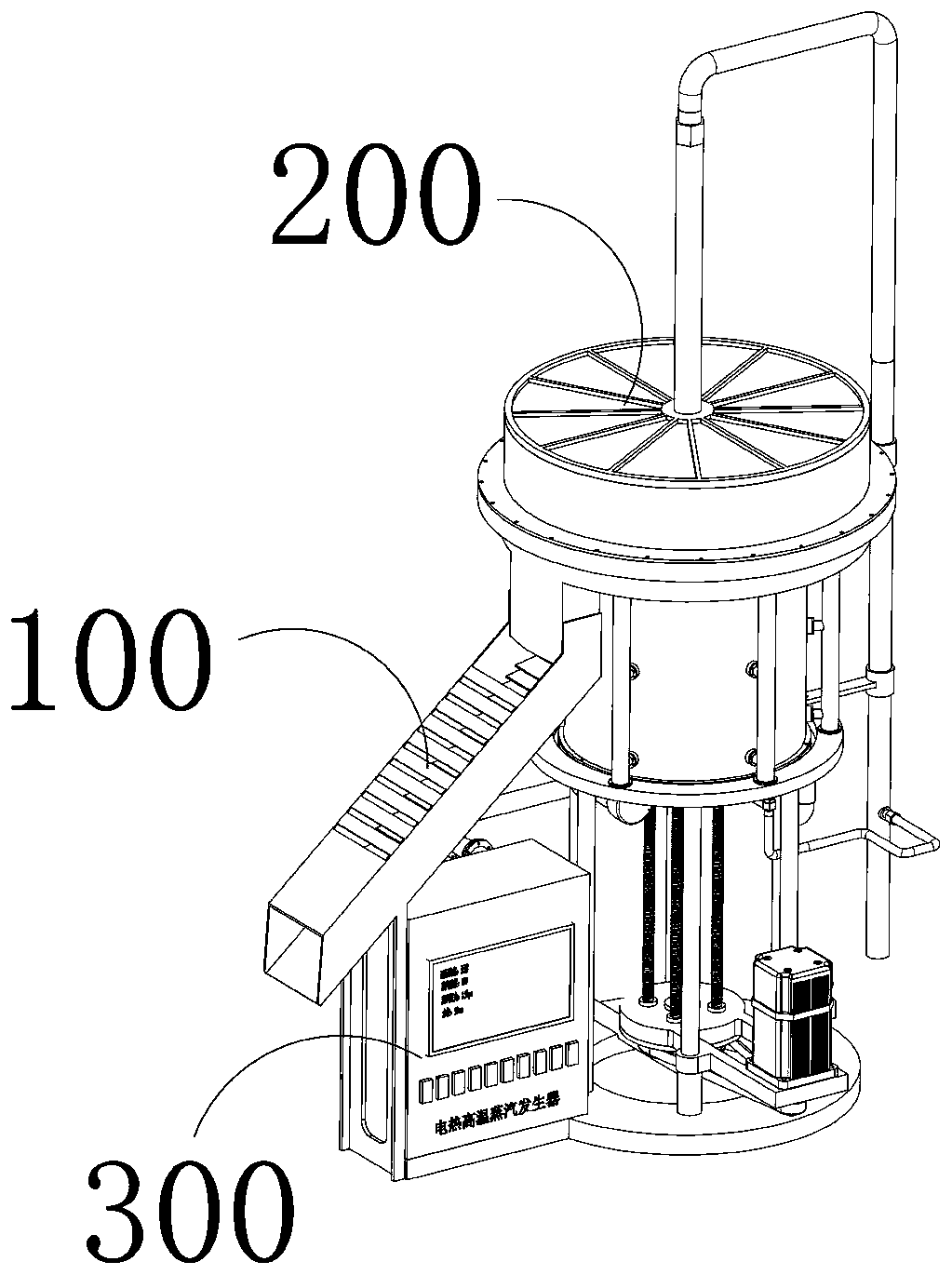

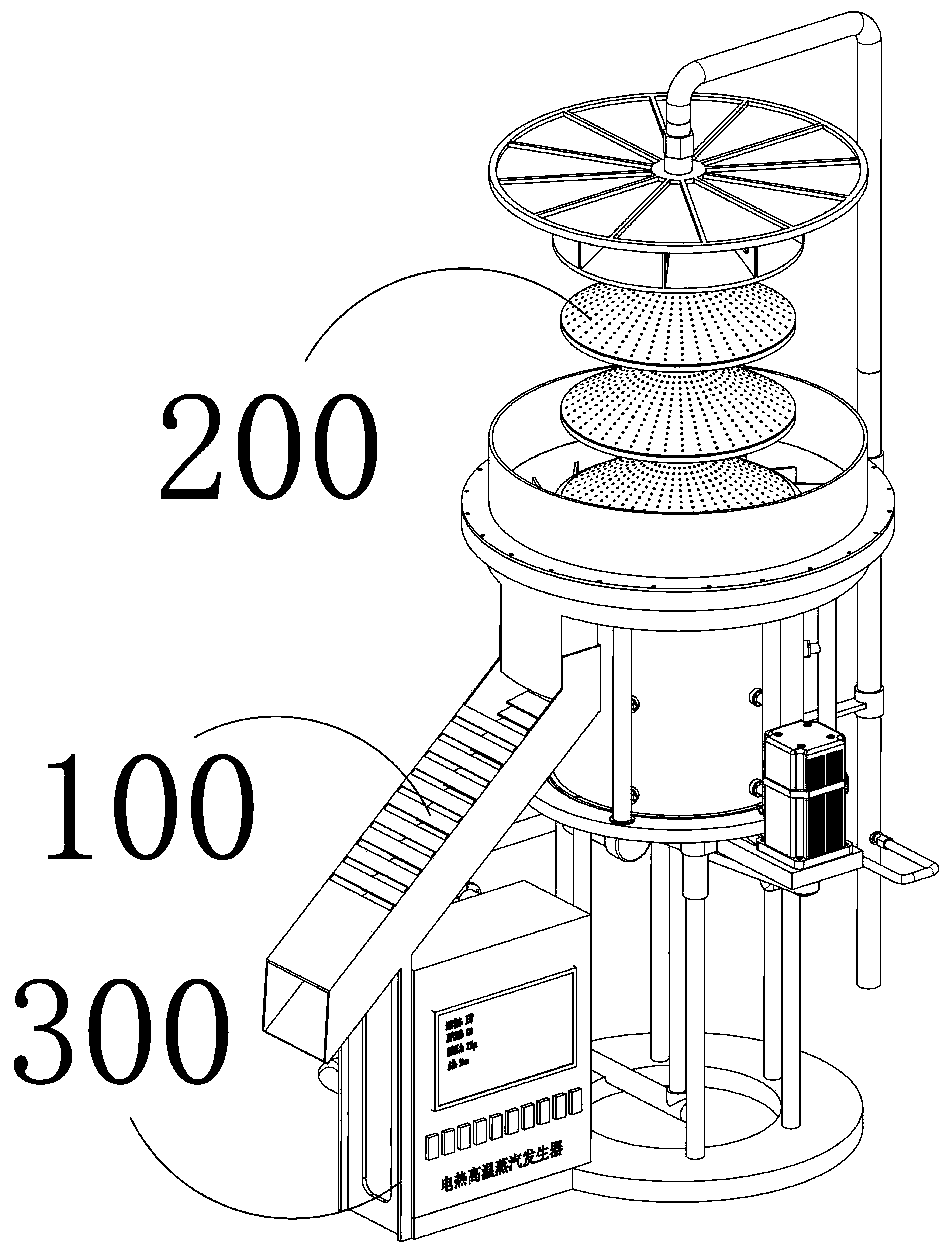

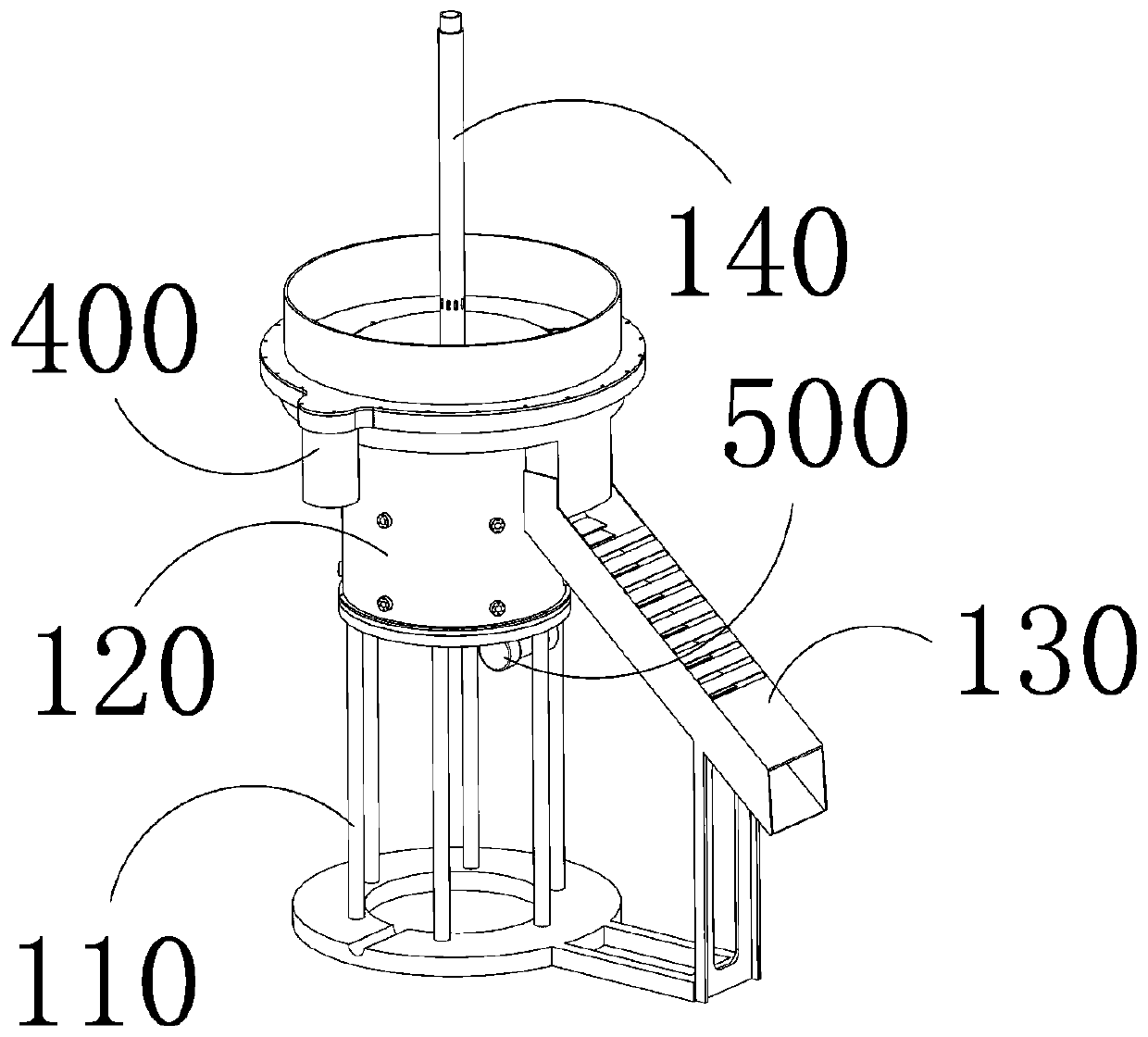

Method for alcohol distillation and extraction on fermented wine material

InactiveCN111218377AImprove loading and unloading efficiencyImprove the distillation effectAlcoholic beverage preparationAqua vitaeAlcohol

The invention discloses a method for alcohol distillation and extraction on a fermented wine material. The method comprises the steps that a jacking mechanism drives a wine material loading mechanismto rise until a bottom wine material loading assembly is located in a main housing, rest wine material loading assemblies are located outside the main housing, and then wine materials are dumped to the inner part of the main housing; the jacking mechanism drives the wine material loading mechanism to fall until the wine material loading assembly which is the second from bottom to top is located inthe main housing, and the rest wine material loading assemblies above the wine material loading assembly are located outside the main housing; the wine material is dumped into the main housing, and the operations are reciprocated; high-temperature vapour flows to the inner part of the main housing, and alcohol steam is traced to flow to condensing equipment; after distillation is completed, the jacking mechanism drives the wine material loading mechanism to slowly rise, and personnel stir the waste wine material to the inner part of a discharging housing through tools of scoops and the like;and besides, discharging structural members are assisted for pushing the waste wine materials in the discharging housing to a discharging cylinder, and the waste wine materials are finally led by a cylinder housing to be discharged.

Owner:六安七茗道机电科技有限公司

Method for brewing wine by using peel residue

InactiveCN104152317ARealize comprehensive utilizationGreat tasteAlcoholic beverage preparationBiotechnologyVitis vinifera

The invention relates to a method for brewing wine by using peel residue. The method comprises the following steps of firstly putting peel residue which is remained after acanthopanax fruits and / or short-stem acanthopanax fruits are subjected to juicing or fermented juicing and peel residue which is remained after grapes are subjected to juicing or fermented juicing, into a container, mixing, sequentially adding water, sugar as well as tartaric acid and yeast into the container, fermenting for 3-12 days while controlling the internal temperature of the container to 23-30 DEG C, then, putting liquid generated by distillation into stainless-steel or oaken barrels, and preserving for 1-4 years, thereby obtaining finished wine. According to the method for brewing the wine by using the peel residue, alcohol is generated through fermenting the peel residue which serves as a raw material, and then is distilled so as to prepare the wine, and thus, the wine is similar to brandy and has a very good taste; through brewing the mixture of the acanthopanax fruit peel residue and the grape peel residue, the wine has a certain amount of nutritional ingredients, and waste utilization can be achieved.

Owner:高耸 +3

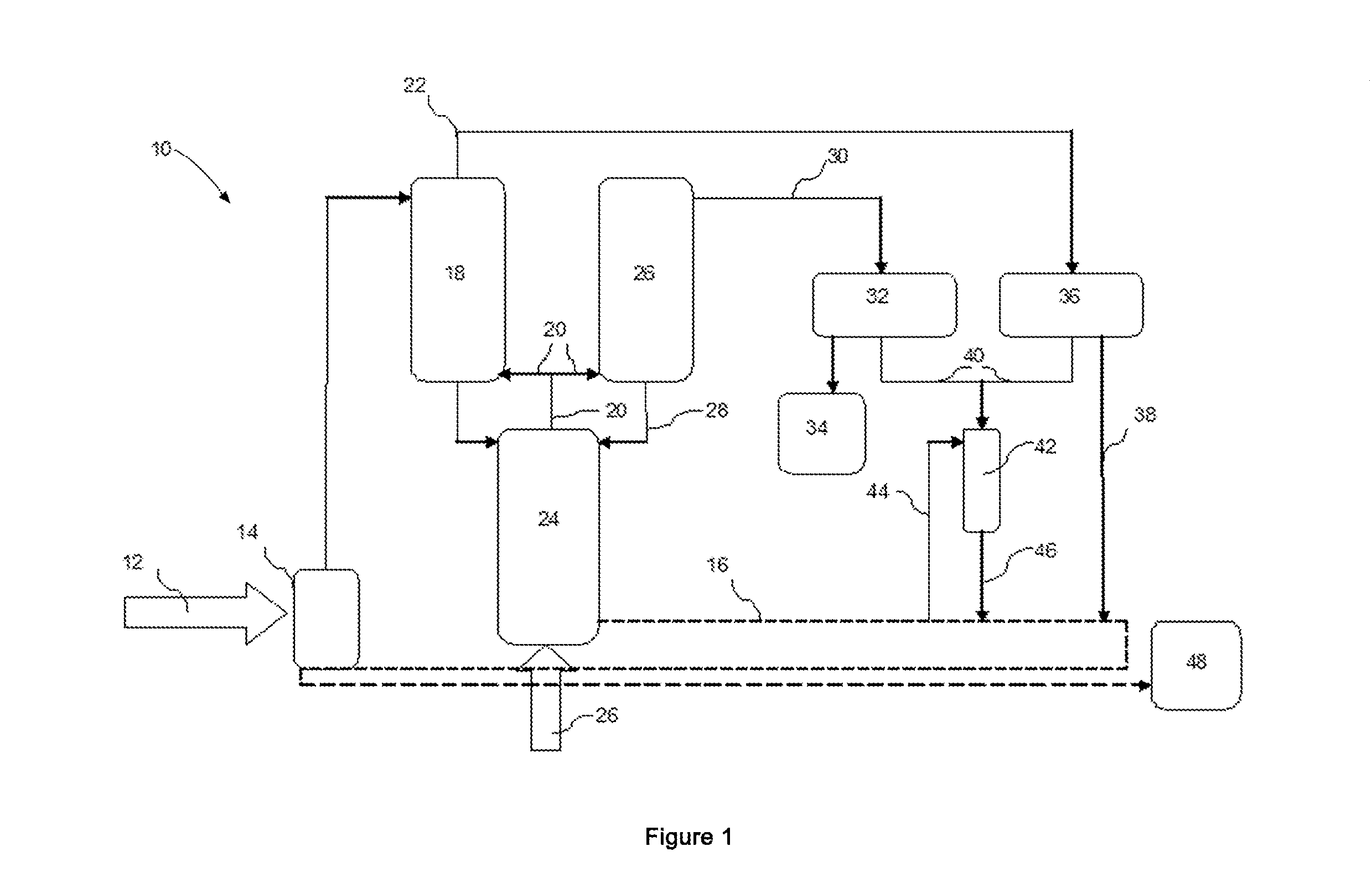

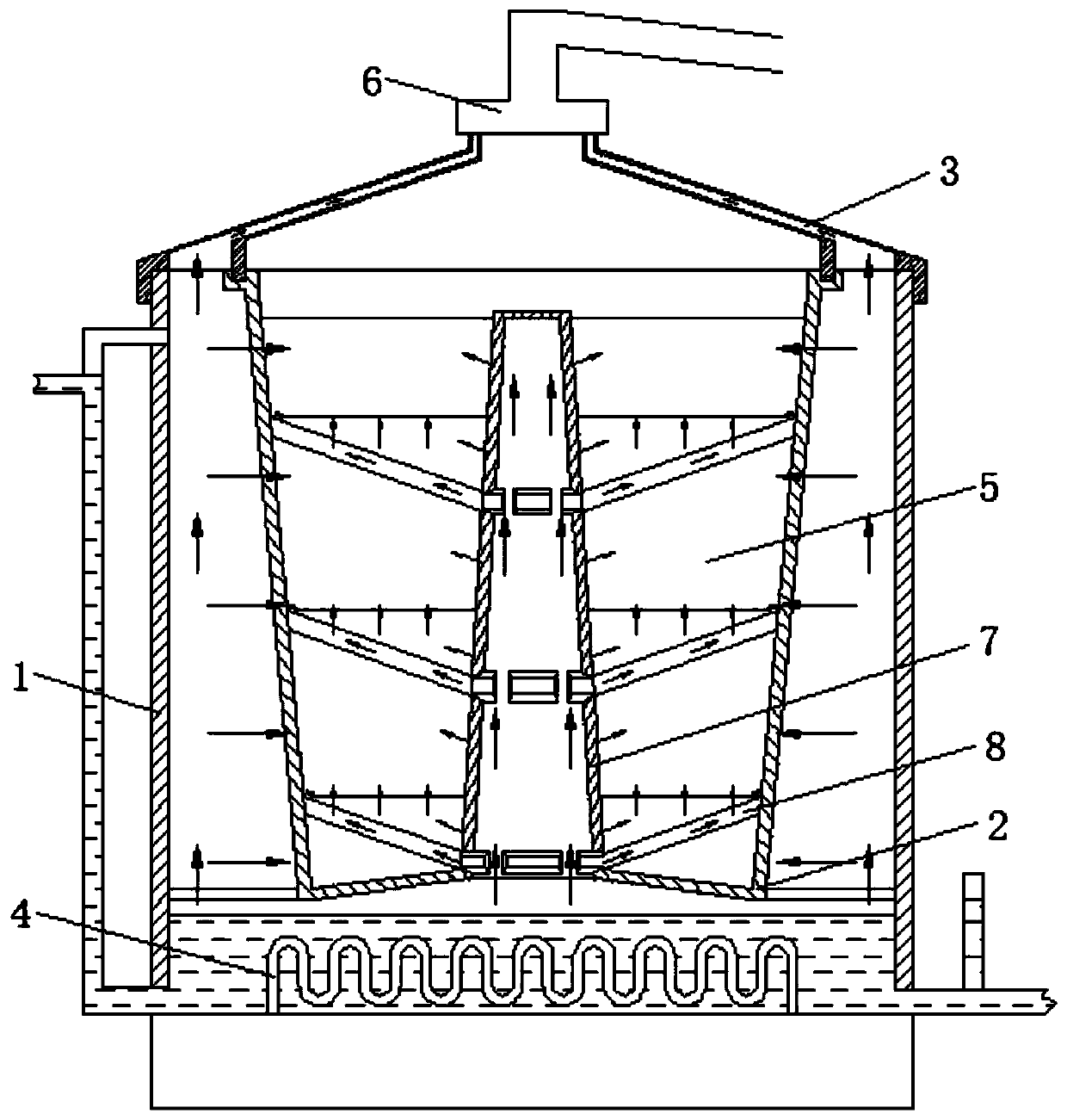

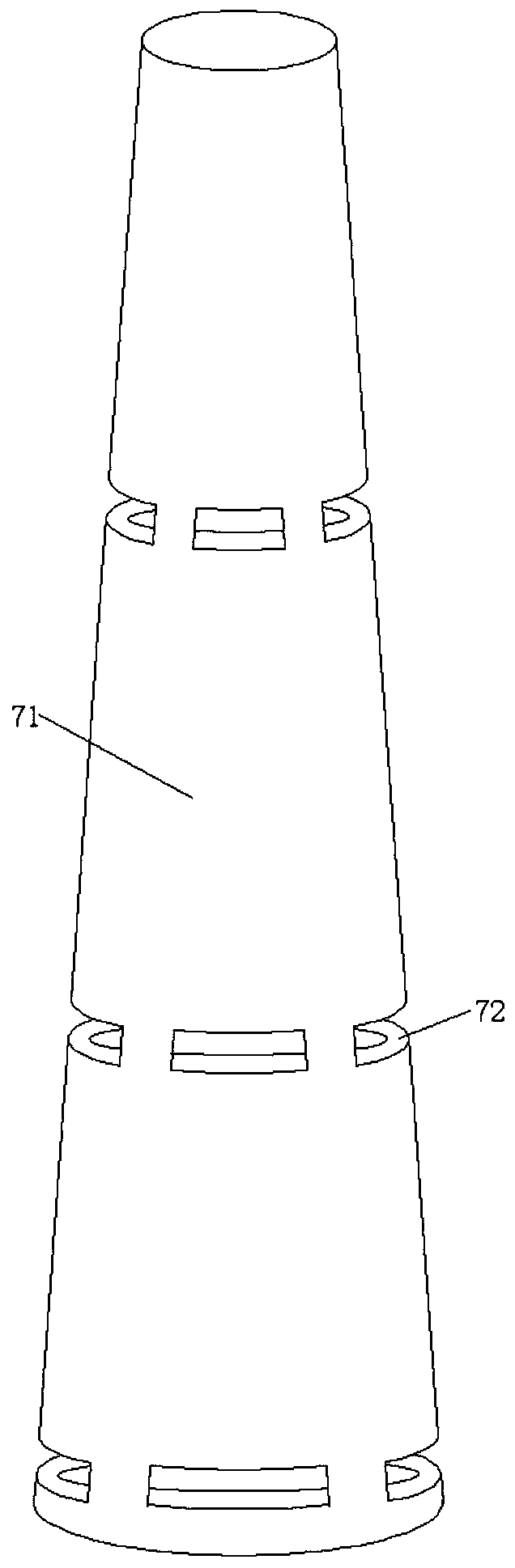

Process and Apparatus for the Reduction of Alcohol in Fermented Beverages

ActiveUS20150132459A1Reducing alcoholFermented solutions distillation/rectificationAlcoholic beverage preparationBiotechnologyFlavor

A process is disclosed for reducing alcohol in a fermented beverage without heat damage and without degrading the original flavor profile of the fermented beverage. The process generally includes the steps of: (i) removing aromatics from the wine; (ii) removing alcohol from the wine; (iii) refluxing a portion of the alcohol removed from the wine to increase the alcohol concentration of the alcohol vapour and return at least a portion of the condensed / recovered water to the wine; and (iv) condensing the aromatics removed from the wine and returning at least a portion thereof to the wine.

Owner:LOGICHEM PROCESS

Pearl wine and preparation method thereof

InactiveCN104673614AUniform particle size distributionEasy to operateAlcoholic beverage preparationMicroorganism based processesHuman bodyAlcohol

The invention discloses pearl wine and a preparation method thereof. The method comprises the steps of crushing pearls, and then carrying out the high-pressure microjet supermicron crushing treatment, fermentation and mixing to obtain a finished product. The prepared pearl wine has an effect for adjusting the immunity, enhancing the immunity and resistance of a human body and reducing the harm of alcohol for liver, and the de-alcoholic effect is remarkable.

Owner:广西还珠海洋生物科技有限公司

Compound seasoning cooking wine and preparation method thereof

The invention discloses compound seasoning cooking wine and a preparation method thereof, belonging to the technical field of production of seasonings. The invention aims at solving the problems that the traditional seasoning cooking wine is mostly prepared only by using one or two wines and is also subject to the existing seasoning cooking wine spice formula, so that the effects of removing fishiness, eliminating greasiness and enhancing flavor are poor, and better effects can be achieved by further adding other seasonings for assisting the traditional seasoning cooking wine or increasing the dosage of the traditional seasoning cooking wine. According to the compound seasoning cooking wine provided by the invention, multiple wines are compounded, and beer is used as a main base flavor solvent, so that the compound seasoning cooking wine is better in effects of removing fishiness, enhancing flavor and eliminating greasiness compared with the existing method which mainly uses yellow wine and alcohol; the cooking wine is seasoned with fruit wine, thus being richer in flavor; furthermore, the compound seasoning cooking wine is made from multiple spices, and the tastes of the spices can be enhanced by each other by proportioning the spices, so that food cooked by using the compound seasoning cooking wine is better in taste.

Owner:徐克明 +1

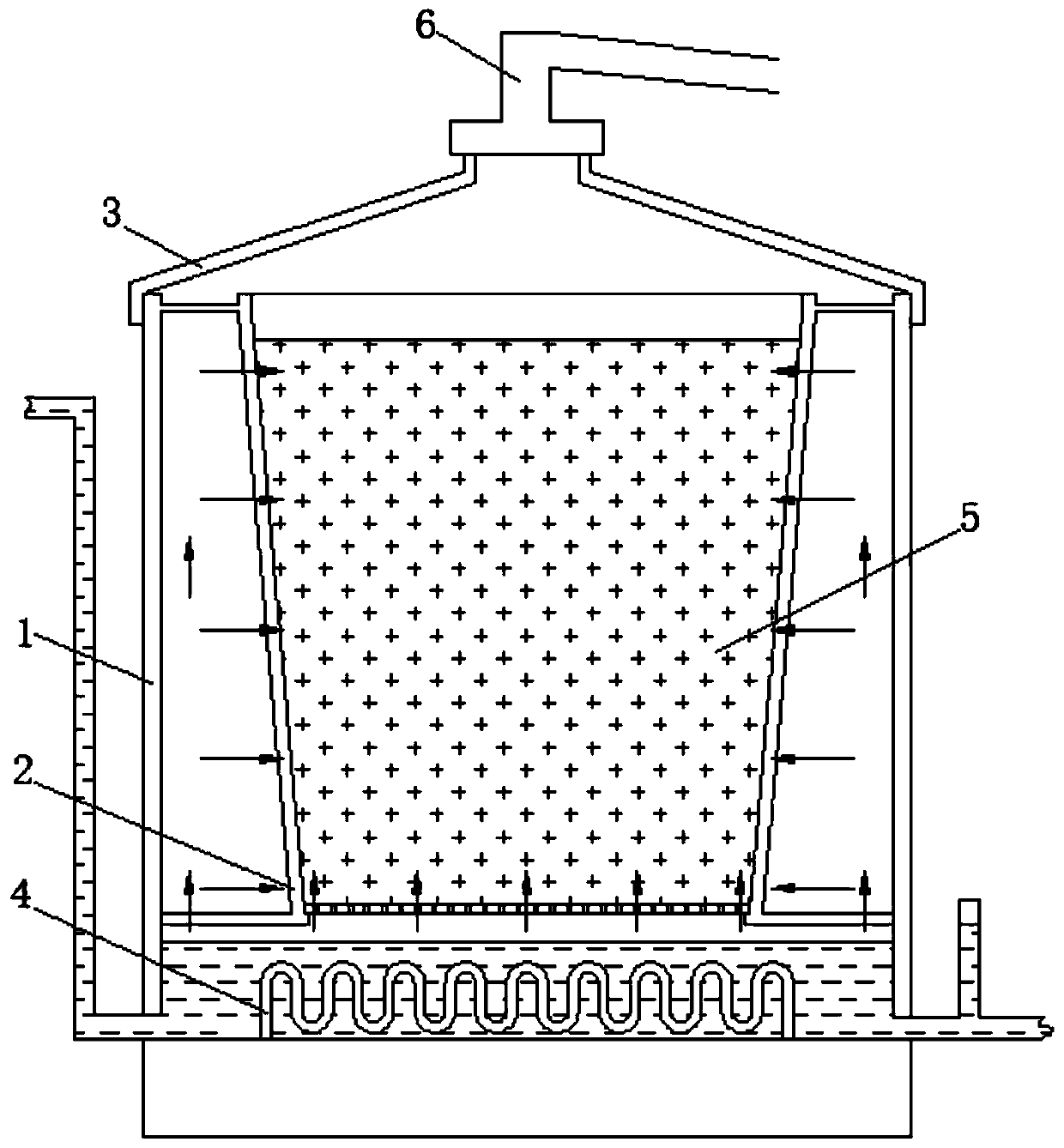

Wine brewing distillation equipment

InactiveCN110684635AQuality improvementSolve quality problemsAlcoholic beverage preparationAqua vitaeThermodynamics

The invention relates to the technical field of wine brewing and discloses wine brewing distillation equipment which comprises a distillation shell and a heating device fixedly installed at the bottomof the distillation shell; and the bottom of the left side of the distillation shell communicates with a water inlet pipe. For the wine brewing distillation equipment, through connection of a centercolumn with an inclined disc at the bottom of a wine retort, hot air produced by the heating device can heat a center region of the wine retort through the center column, and distillation of alcohol in the center region and a peripheral region of the wine retort can be ensured to be performed at the same time, so that the retort boundary effect is eliminated, the contents of water and water-soluble ethyl acetate in the alcohol can be reduced, the alcohol concentration is increased and the alcohol quality is improved; and through connection of a funnel grate and the center column, layered heating can be performed on the wine retort, and a heating area of the wine retort is enlarged, so that distillation of the alcohol in various areas is performed at the same time, the concentration of thewine is further increased, the conduction time of the hot air in the wine retort is reduced at the same time, and the alcohol distillation efficiency is accelerated.

Owner:魏双清

A kind of longan biological wine and its brewing process

InactiveCN102277267ANo feeling of thirstSober upAlcoholic beverage preparationMicroorganism based processesBiotechnologyAlcohol content

The invention relates to a longan bio-wine and its brewing process. Glutinous rice and rice are used as main raw materials in a weight ratio of 1.8-2.2:1, and saccharification extract, alcoholic yeast, bioenergetics and longan are added. The longan bio-wine of the present invention has an alcohol content equivalent to that of white wine, and is not produced by a blending process in the brewing process, but is produced entirely from grains and plants, and at the same time, the alcohol content of the longan bio-wine of the present invention is formed at one time during the brewing process , the prepared longan bio-wine has no alcohol smell in the mouth after drinking, no feeling of thirst, sobers up quickly, does not hurt the body, the brewing process of the longan bio-wine is reasonable and simple, the brewing time is short, the yield is high, and food is saved.

Owner:DALIAN SANJUN LIQUOR IND CO LTD

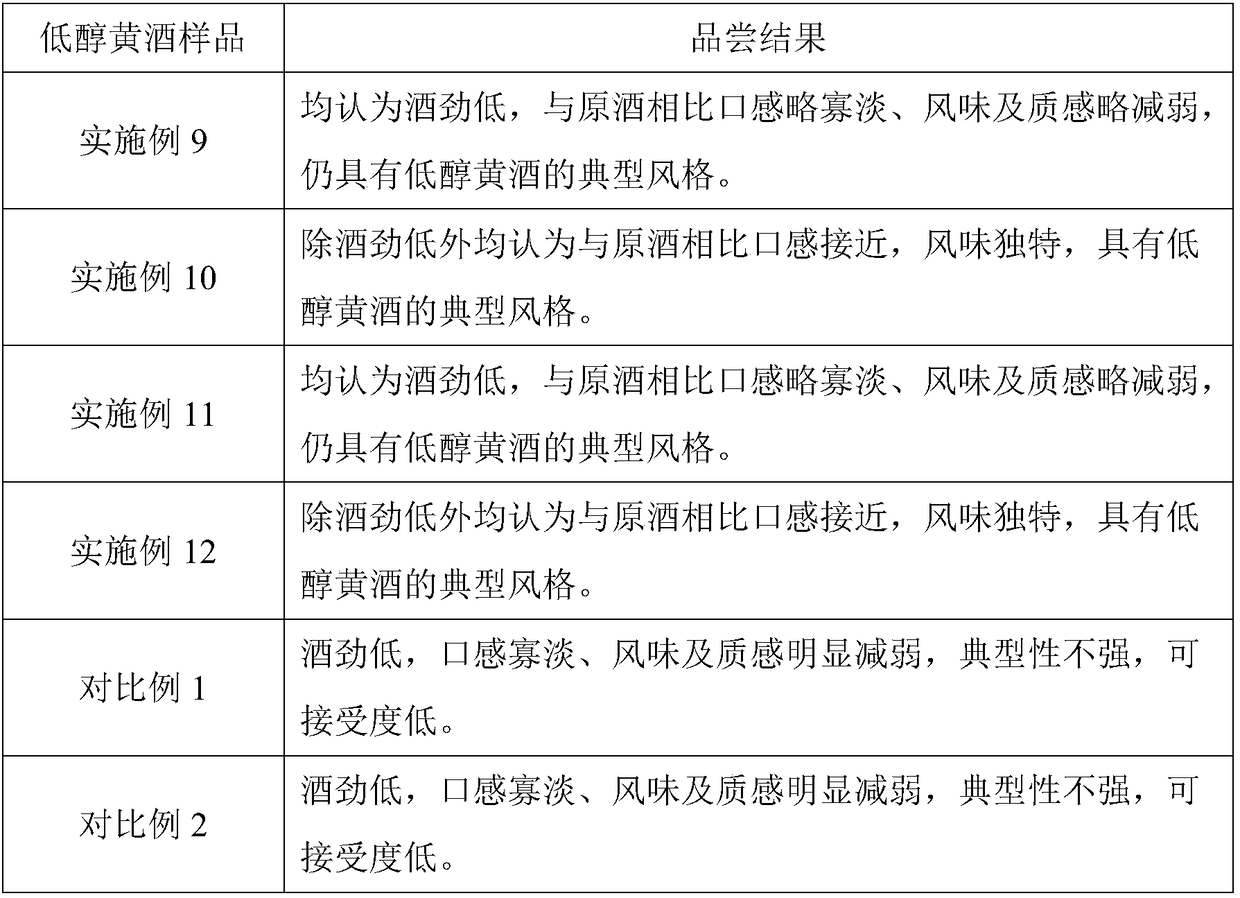

Low-alcohol yellow rice wine and a production process thereof

PendingCN109182054ATypicalStrong typicalAlcoholic beverage preparationUltra high pressureMicrowave power

The invention relates to a low-alcohol yellow rice wine and a production process thereof. The invention lowers the temperature of yellow rice wine to below 15 DEG C, and the microwave power is 100-250W, ultrasonic power 500-800W, vacuum degree close to 0.1 MPa, vacuum distillation temperature <= 50 DEG C; when the temperature of liquor body is higher than 50 DEG C, stopping distillation, cooling yellow rice wine to below 15 DEG C, and vacuum distillation is carried out again according to the above conditions; when the temperature of liquor body is higher than 50 DEG C, the distillation is stopped, the temperature of yellow rice wine is lowered to below 15 DEG C, and the vacuum distillation is carried out again according to the above conditions. This is repeated until the desired alcohol level is reached. The invention discloses a microwave vacuum distillation combined with ultrasonic treatment method, which can remove alcohol without destroying or losing flavor substances and nutrientsin yellow rice wine. Especially the combination of low temperature treatment before vacuum distillation and ultra-high pressure treatment after distillation is more conducive to maintaining the original taste and quality of yellow rice wine.

Owner:GANSU WUSHANCHI YELLOW WINE

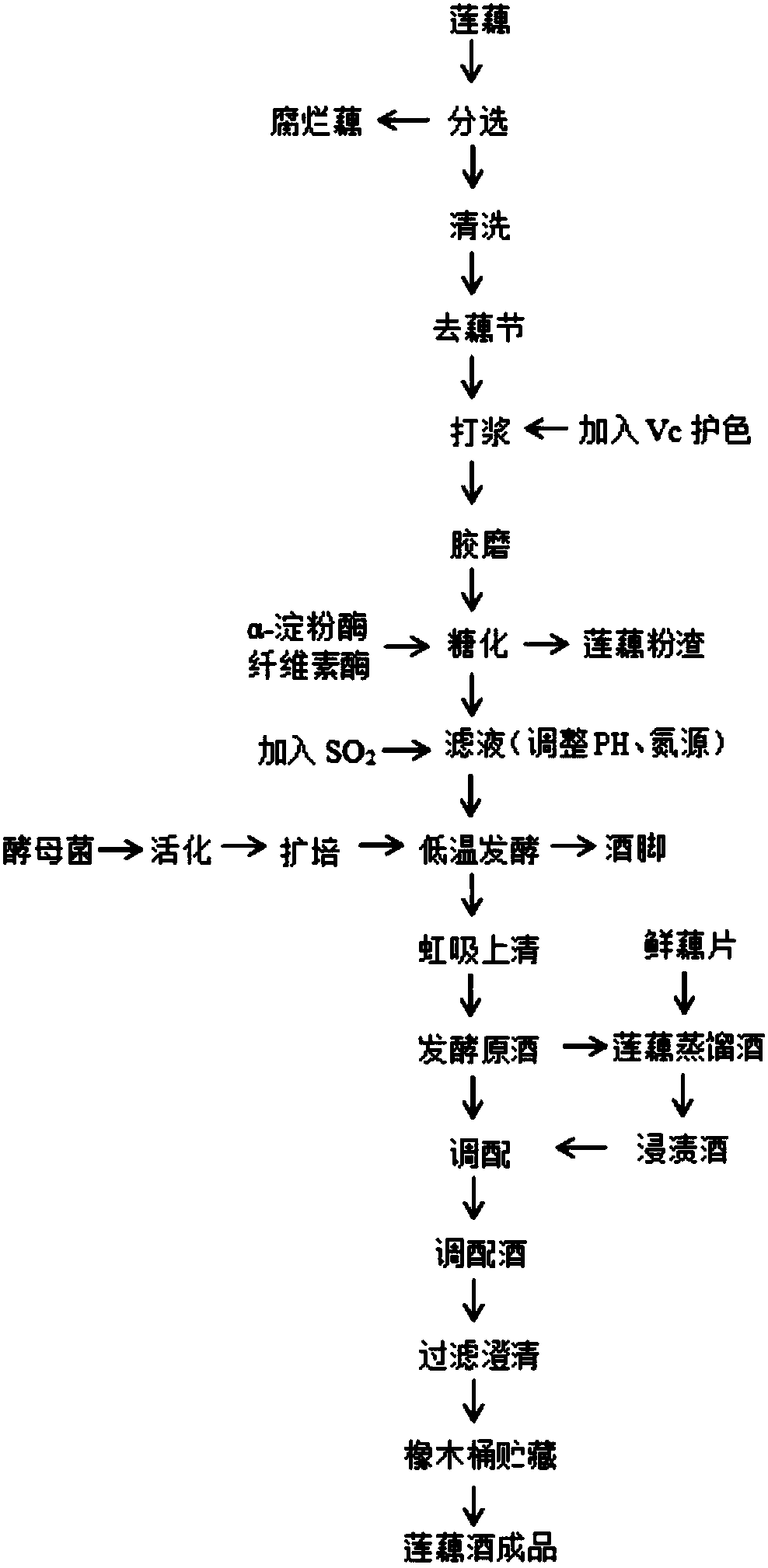

Brewing method of lotus root wine

InactiveCN107746770AKeep the flavors basicProtect NutrientsAlcoholic beverage preparationMicroorganism based processesFruit wineAlpha-amylase

The invention relates to a brewing method of lotus root wine, also relates to the brewed lotus root wine, and belongs to the field of alcoholic beverage preparation. The method concretely comprises the following steps: (1) picking; (2) cleaning; (3) lotus root removal; (4) pulping; (5) glue grinding; (6) double-enzyme joint saccharification; (7) pH value and nitrogen source regulation; (8) low-temperature fermentation; (9) wine leg separation for lotus root fermentation raw wine obtaining; (10) fresh lotus root soaking in lotus root distilled wine for soaking wine obtaining; (11) proportioningof lotus root fermentation raw wine and soaking wine; (12) clarification; (13) storage for lotus root wine obtaining. On the basis of conventional fruit wine brewing, a alpha-amylase and cellulase double-enzyme joint saccharification technology, a low-temperature fermentation technology and a raw wine fermentation and soaking wine blending combination technology are used, the lotus root wine witha gold clear and transparent wine body, pure and rich wine fragrance, strong mellow feeling and harmonious sour and sweet taste is brewed in a way of maintaining the flavor of lotus root to the maximum degree. The invention provides a novel idea for the lotus root wine development and also has important development significance on the fruit and vegetable alcoholic beverage industry development.

Owner:MOUTAI INST

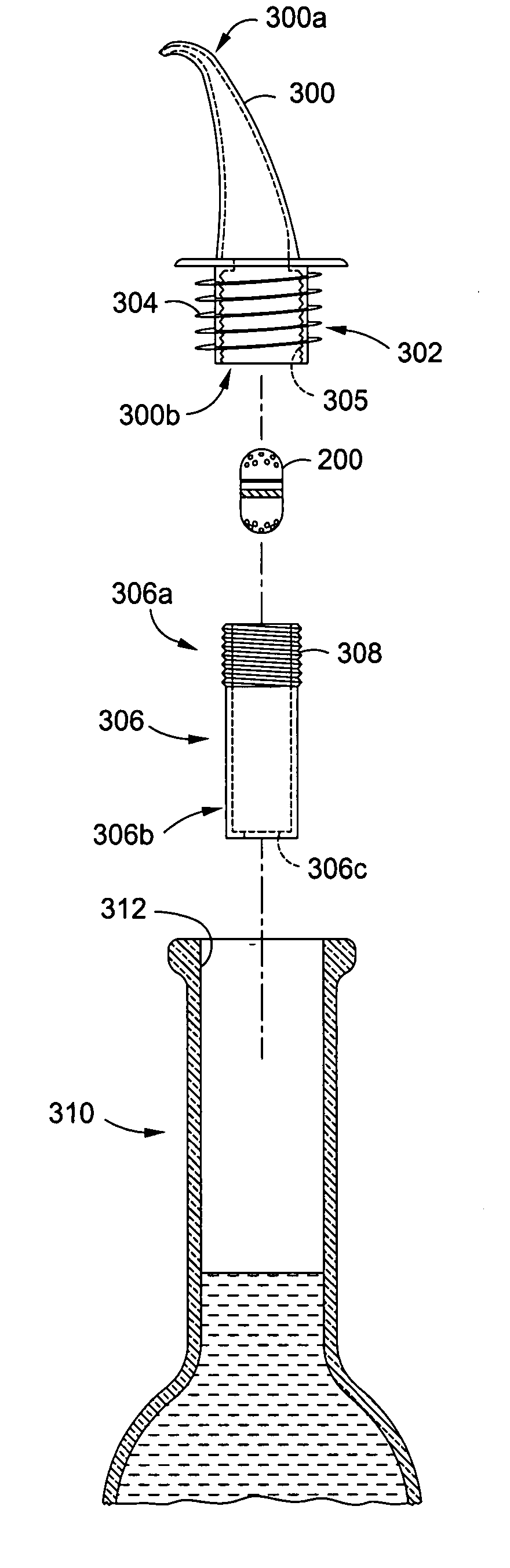

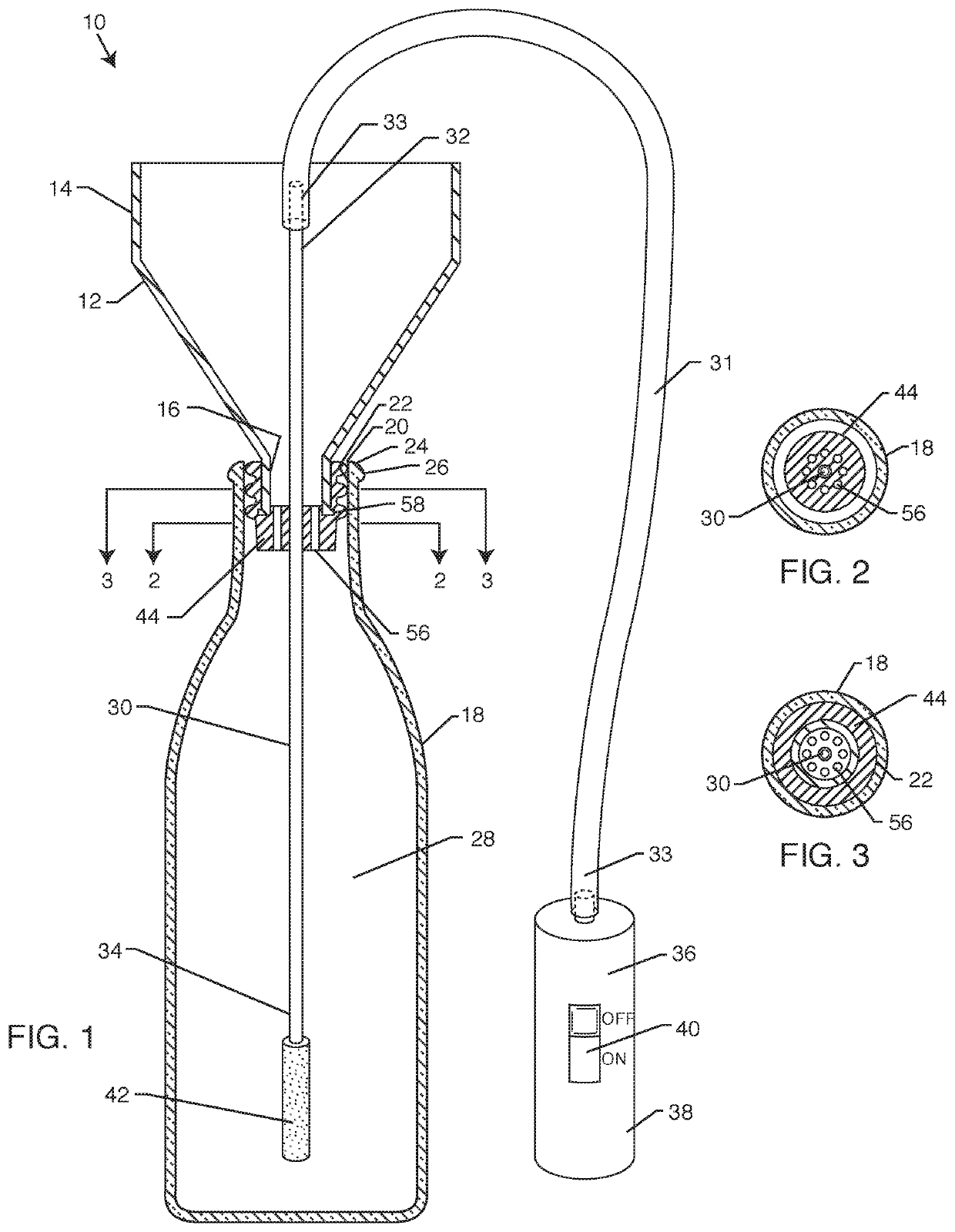

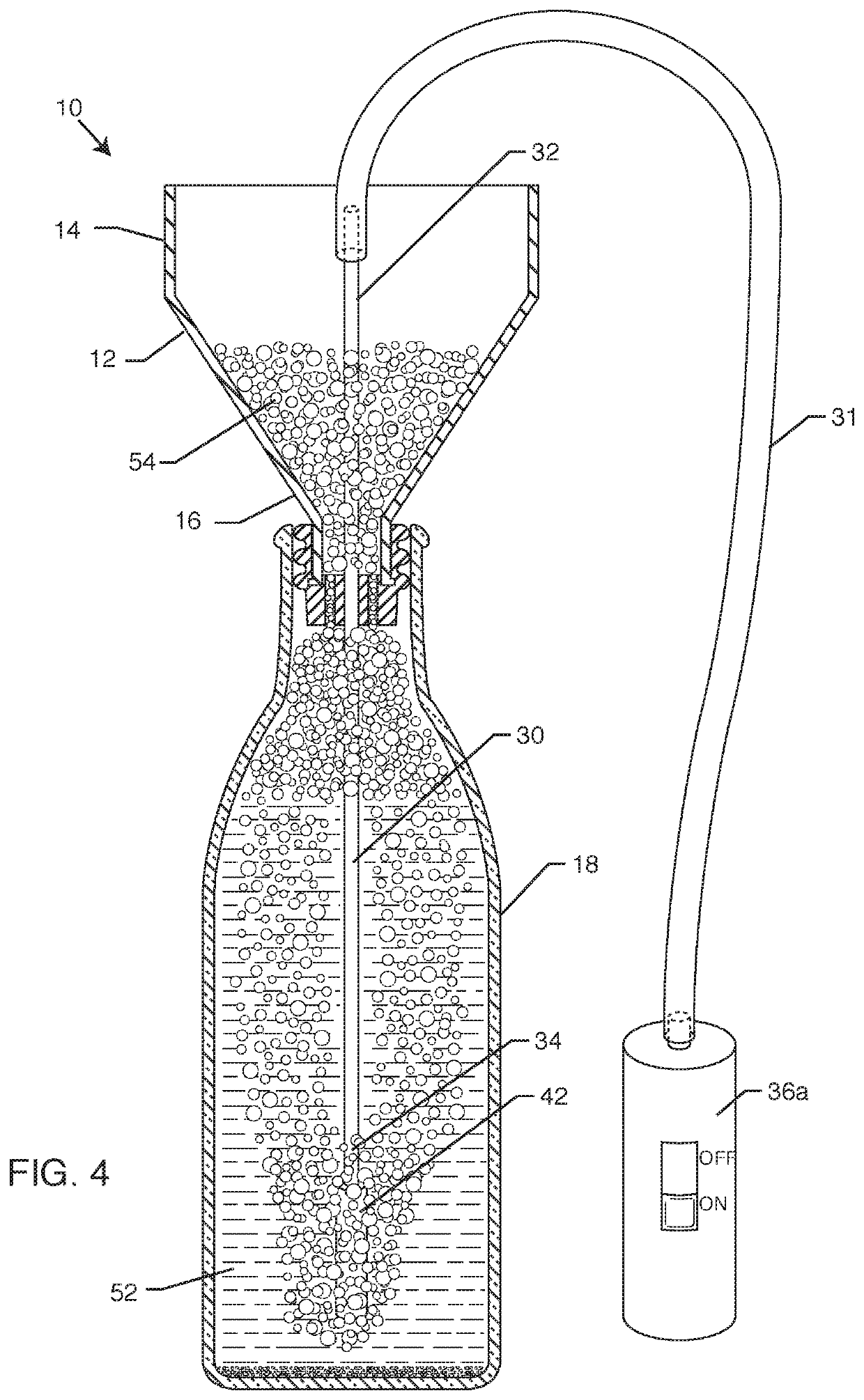

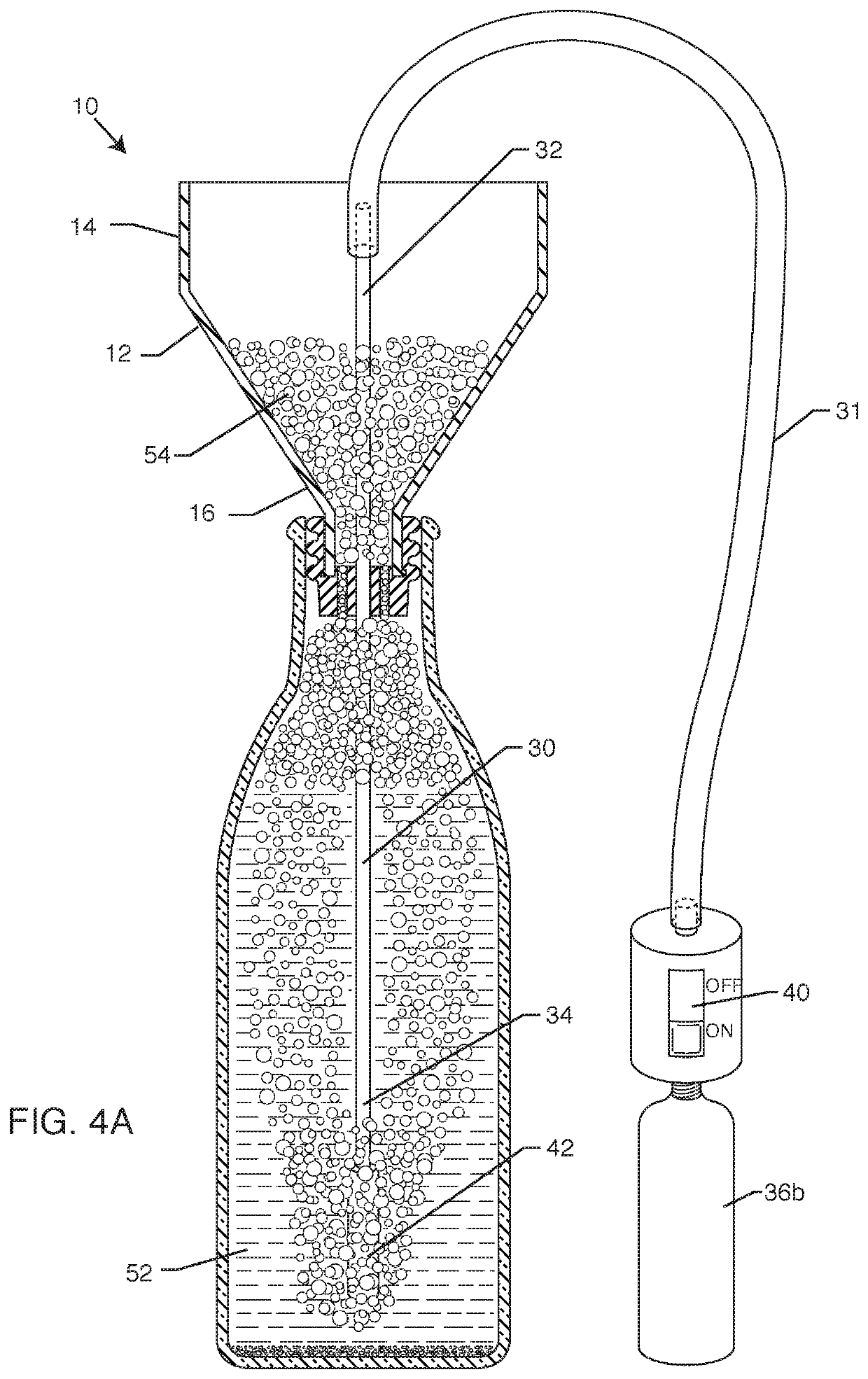

Wine bottle aerator

An aeration assembly for aerating liquids including wine and other alcoholic beverages includes an expansion chamber and an aerating device. The expansion chamber is configured to be in fluid communication with an inside of the uncorked and / or opened bottle when engaged by a bottom portion of the expansion chamber. The aerating device comprises a gas conduit having a proximal end in fluid communication with a distal end. The distal end is disposable below the bottom portion of the expansion chamber. A gas source is in fluid communication with the proximal end of the gas conduit. The expansion chamber is configured to temporarily contain an expansion of bubbles during an aeration process. The expansion chamber and aerating device are not permanently connected, wherein the aerating device can be fully removed from the expansion chamber before, during or after the aeration process.

Owner:STEVENSON ROBERT A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com