Low-alcohol yellow rice wine and a production process thereof

A production process and a technology for rice wine, which are applied to the field of low-alcohol rice wine and its production process, can solve the problems of decreased content of flavor substances, weakened flavor and texture, etc., and achieve the effects of normal koji fragrance, mellow wine body and clear wine body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

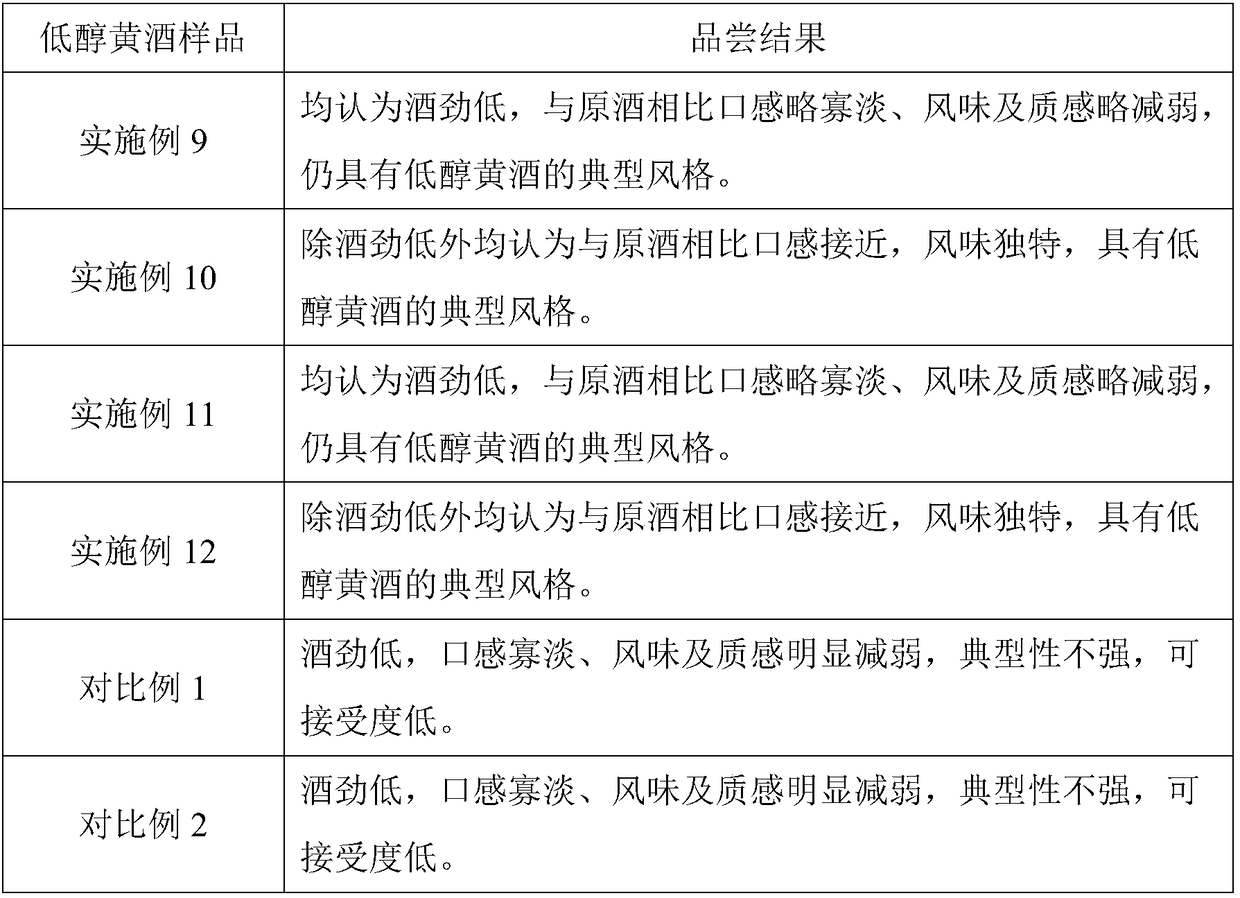

Examples

Embodiment 1

[0059] A kind of northern rice wine, its production technology comprises the steps:

[0060] 1. Preparation of fermented rice mash

[0061] 1) Soaking: Screen the rhubarb rice to remove impurities, add water and soak the rhubarb rice for 5 days;

[0062] 2) steamed rice: steam the soaked rhubarb rice to get rhubarb rice;

[0063] 3) Drain rice and build a nest for fermentation: Spray the rhubarb rice with water and drench the rice, so that the temperature of the rhubarb rice is controlled at 35-38°C; mix in barley koji, stir evenly, and build a nest for fermentation; when the temperature of the wine grains exceeds 38°C, open the rake to cool down; Ferment for 25 days to obtain fermented mash of mature rhubarb rice; the amount of wheat koji is 8% of the dry weight of rhubarb rice;

[0064] 2. Preparation of highland barley fermented mash and oat fermented mash

[0065] 1) Soaking: Screen highland barley and oats to remove impurities, crush each grain to 2-8 petals, then add ...

Embodiment 2

[0075] A kind of northern rice wine, its production technology comprises the steps:

[0076] 1. Preparation of fermented rice mash

[0077] 1) Soaking: Screen the rhubarb rice to remove impurities, add water and soak the rhubarb rice for 3 days;

[0078] 2) steamed rice: steam the soaked rhubarb rice to get rhubarb rice;

[0079] 3) Drain rice and build a nest for fermentation: Spray the rhubarb rice with water and drench the rice, so that the temperature of the rhubarb rice is controlled at 35-38°C; mix in barley koji, stir evenly, and build a nest for fermentation; when the temperature of the wine grains exceeds 38°C, open the rake to cool down; Ferment for 20-22 days to obtain fermented mash of mature rhubarb rice; the amount of wheat koji is 10% of the dry weight of rhubarb rice;

[0080] 2. Preparation of highland barley fermented mash and oat fermented mash

[0081] 1) Soaking: Screen highland barley and oats to remove impurities, crush each grain to 2-8 petals, then ...

Embodiment 3

[0091] A northern rice wine, the difference between its production process and that of Example 1 lies in: the fermented fermented mash of mature rhubarb rice, fermented barley and mature oats are mixed according to the weight ratio of 100:10:20 and fermented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com