Method for determining sulfide in spirit

A sulfide and liquor technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming and labor-intensive sensitivity, poor selectivity, and limited sensitivity, so as to improve the quality of liquor, avoid decomposition, and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

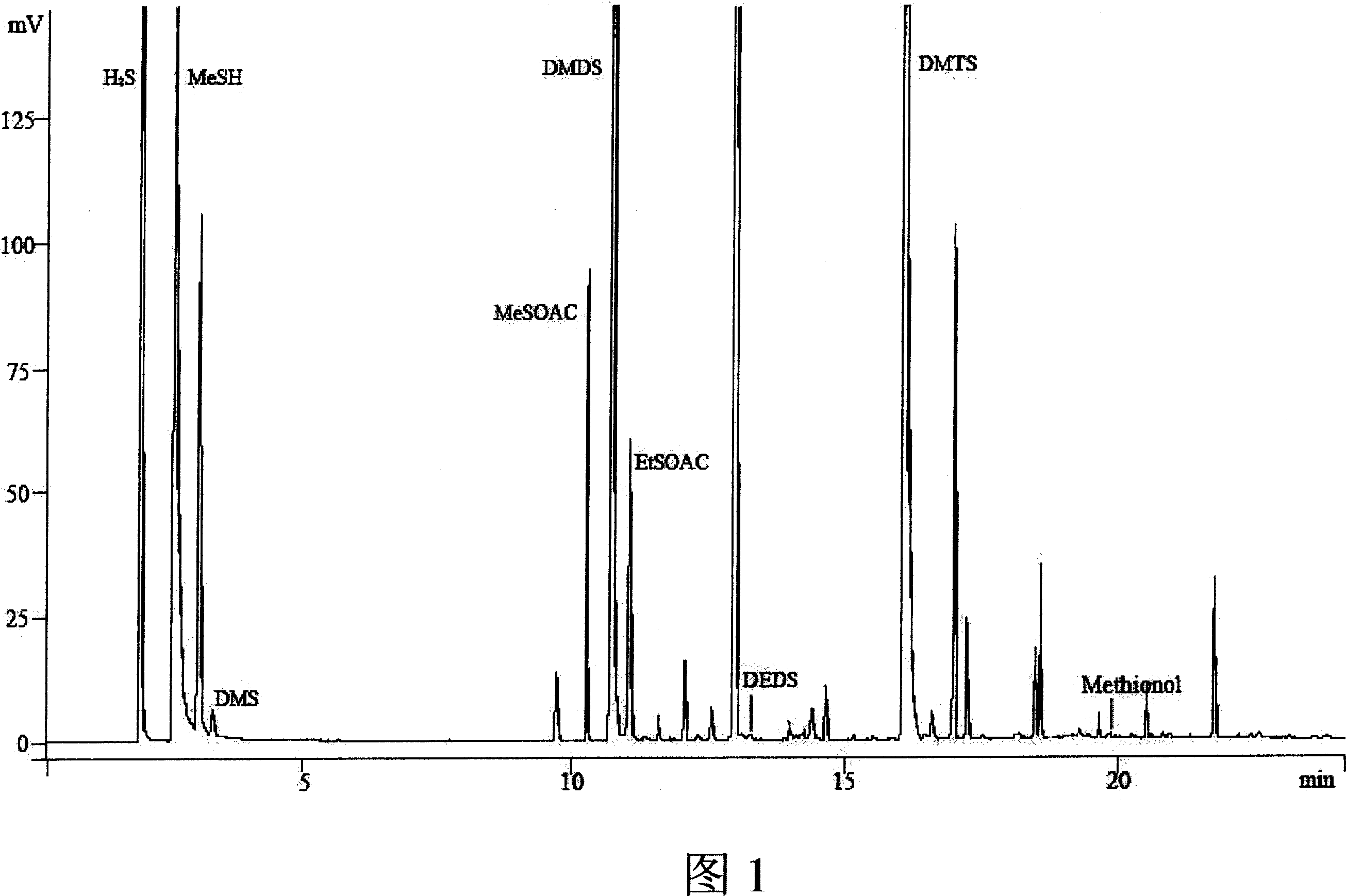

Embodiment 1

[0028] Dilute 53% (v / v) Moutai liquor with deionized water to 14% alcohol (v / v), draw 5mL liquor sample into a 20mL headspace bottle, add 100μL internal standard solution, and saturate with sodium chloride , screw on the cap. Stir and balance in a water bath at 30°C at a speed of 500rpm for 30min, insert a 85μm Carboxen-PDMS fiber head, and extract at 30°C and 250rpm for 15min. Then insert the extraction head into the gas phase inlet, and desorb at 300 °C for 7 min in splitless mode. Using DB-FFAP, the column temperature was maintained at 35°C for 3 minutes, raised to 150°C at a rate of 10°C / min, maintained for 5 minutes, then raised to 220°C at a rate of 20°C / min, and maintained for 3 minutes. Nitrogen was used as the carrier gas with a constant flow of 2 mL / min. The temperature of the detector is 300°C, and it is supplied with 14mL / min of hydrogen, 17mL / min of air 1 and 10mL / min of air 2. The detector voltage is 500V, the gate delay is 6ms, and the gate width is 20ms.

...

Embodiment 2

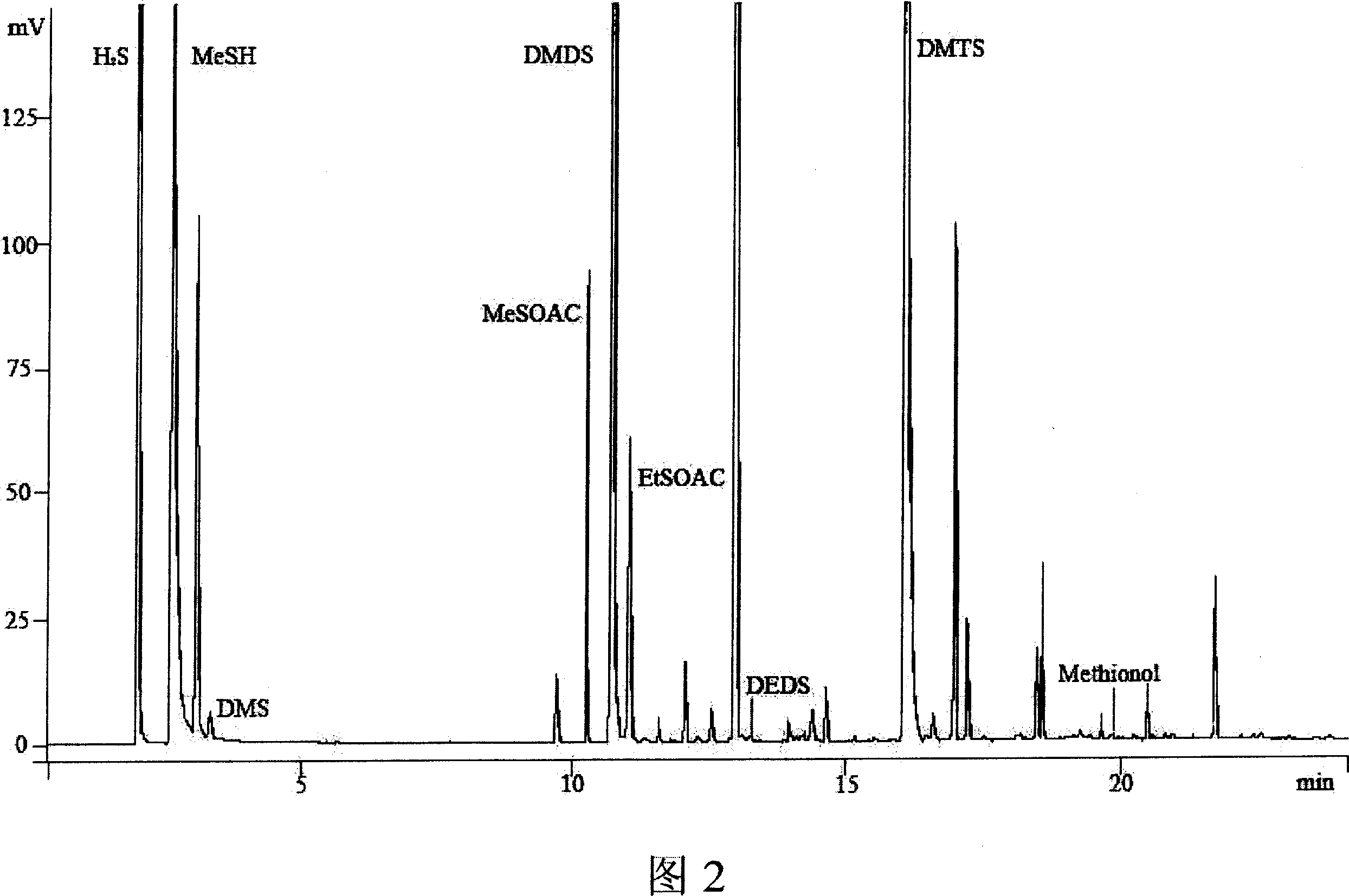

[0031] The 52% (v / v) Wuliangye was detected, and the detection conditions were the same as in Example 1. Fig. 2 is the gas chromatogram of this wine sample, and the sulfide that detects has hydrogen sulfide (H 2 S) 176.17μg / L, methyl mercaptan (MeSH) 28.93μg / L, dimethyl sulfide (DMS) 6.30μg / L, methyl thioacetate (MeSOAc) 39.60μg / L, dimethyl disulfide (DMDS) 1.68μg / L, ethyl thioacetate (EtSOAc) 19.73μg / L, diethyl disulfide (DEDS) 0.05μg / L, dimethyl trisulfide (DMTS) 21.45μg / L, 3 - methionol 0.36 mg / L.

Embodiment 3

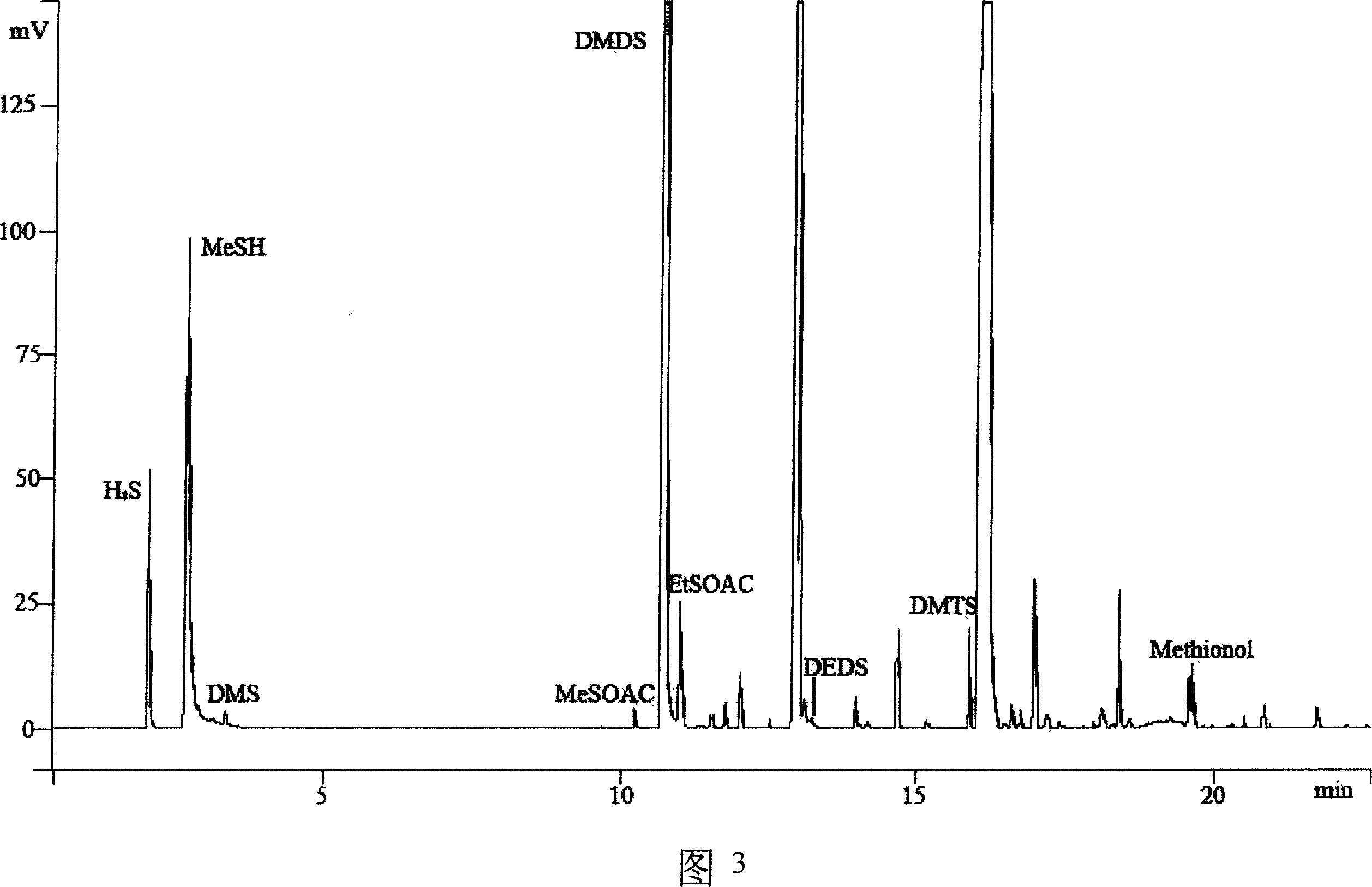

[0033] 46% (v / v) of Yanghe Daqu was detected, and the detection conditions were the same as in Example 1. Fig. 3 is the gas chromatogram of this wine sample, and the sulfide detected has hydrogen sulfide (H 2 S) 17.50μg / L, methyl mercaptan (MeSH) 14.46μg / L, dimethyl sulfide (DMS) 2.52μg / L, methyl thioacetate (MeSOAc) 1.60μg / L, dimethyl disulfide (DMDS) 1.52μg / L, ethyl thioacetate (EtSOAc) 5.33μg / L, diethyl disulfide (DEDS) 0.04μg / L, dimethyl trisulfide (DMTS) 14.56μg / L, 3 - methionol 0.81 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com