Method for rapidly measuring ethyl carbamate content in distilled liquor

A medium-carbamate, rapid measurement technology, applied in the field of analysis and detection, can solve problems such as unfavorable health of analysts, cumbersome, uneconomical and environmental protection, and achieve the effect of automatic extraction and sample injection, fast and efficient, and fast and simple detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

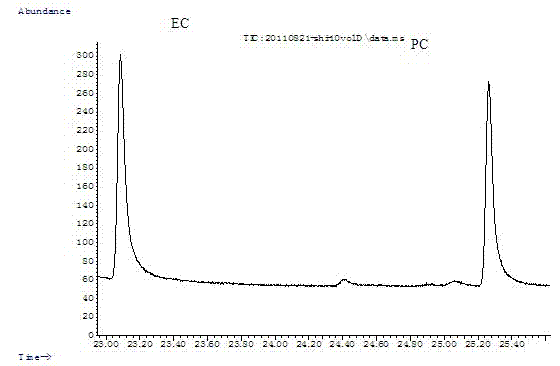

[0024] The optimization of embodiment 1 solid-phase microextraction condition:

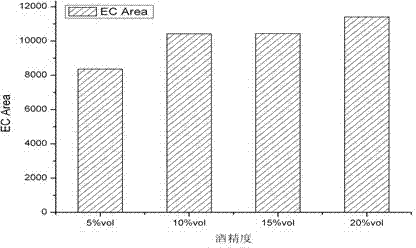

[0025] Sample preparation is required prior to HS-SPME extraction. If the direct dilution of the sample was used to obtain the appropriate alcohol content in previous reports, the EC concentration would be too low to be detected. Considering the water solubility and boiling point of EC, it is determined to remove most of the alcohol and some low-boiling point interferences in the wine by rotary evaporation. After rotary evaporation, the alcohol content of the sample is basically around 10%vol. When the alcohol content was 10%-15%, the adsorption effect of PA head on EC was similar, that is, the EC peak area did not change much.

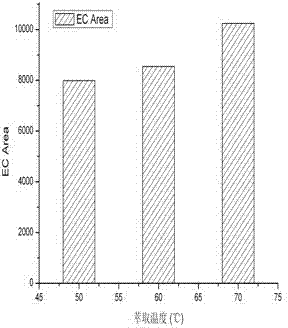

[0026] Extraction temperature is an important factor affecting extraction speed and efficiency. Although as the temperature increases, more analytes will escape from the matrix into the headspace, which is beneficial for headspace adsorption. However, when the tem...

Embodiment 2

[0029] The rapid determination of EC in the embodiment 2 distilled spirits

[0030] Measure 20 mL of wine sample, rotary evaporate to 10 mL, wash the rotary evaporation bottle with ultrapure water three times, dilute to the original volume, draw 8 mL into a 20 mL headspace bottle, add 5 μL PC internal standard solution (150 mg / L), then add 3 g of sodium chloride, tighten the bottle cap, insert the PA extraction head for headspace solid-phase microextraction and gas chromatography-mass spectrometry to detect EC content. The measured EC content is shown in Table 3.

[0031] The invention is suitable for quantitative detection of EC in distilled liquor with high alcohol content.

[0032] Table 1 Linearity and detection limit of EC quantification method

[0033] R 2 n Linear range (μg / L) linear equation LOD (μg / L) 0.9986 8 7.81~1000 y = 2.6985x + 0.1117 1.16

[0034] Table 2 Method precision (n = 3) and recovery

[0035] sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com