Method for preparing high-purity silver nitrate from photovoltaic waste silver paste

A technology of silver nitrate and silver paste, which is applied in chemical instruments and methods, silver compounds, silver compounds, etc., can solve the problems of limited high-purity yield, high production cost, and long process flow, and achieve uniform silver chloride particles, Improved purity and yield, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

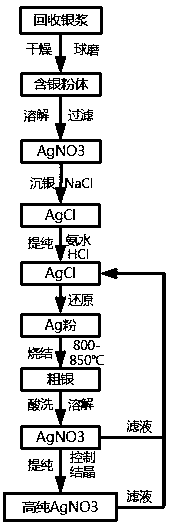

[0052] Such as figure 1 Shown, the method for preparing high-purity silver nitrate from photovoltaic waste silver paste, its concrete steps are as follows:

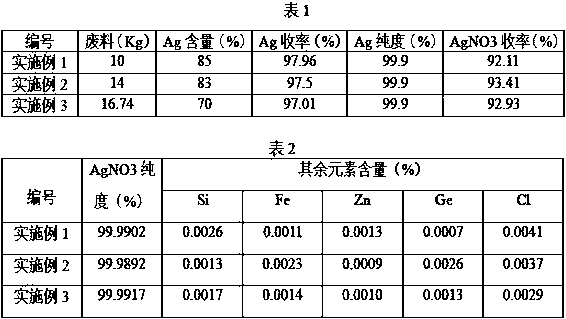

[0053] Step 1. Take 10Kg of photovoltaic waste silver paste (from a positive silver paste factory, the main components of photovoltaic waste silver paste are: silver powder 85%, glass powder (SiO 2 、 Bi 2 o 3 , PbO, MnO 2 、Al 2 o 3 etc.) 10%, organic matter 5%) at 100°C for 2 hours and ball milled for 2 hours to obtain powder;

[0054] Step 2, add pure water to the powder obtained in step 1 according to the mass ratio of 1:1.5 and heat to boiling, then add nitric acid solution with a concentration of 60wt%, the amount of nitric acid solution added is 1.0 times the mass of the powder (add in 4 times , add a total of 9.5kg), heat until the powder is completely dissolved to obtain a solution;

[0055] Step 3. Cool the solution obtained in step 2 to 30°C and filter, dilute the filtrate with water to contain 40g / L of si...

Embodiment 2

[0062] Such as figure 1 Shown, the method for preparing high-purity silver nitrate from photovoltaic waste silver paste, its concrete steps are as follows:

[0063] Step 1. Take 14Kg of photovoltaic waste silver paste (from a positive silver paste factory, the main components of photovoltaic waste silver paste are: silver powder 83%, glass powder (SiO 2 、 Bi 2 o 3 , PbO, Al 2 o 3 etc.) 5%, organic matter 10%) to obtain powder after drying at 100°C for 3 hours and ball milling for 3 hours;

[0064] Step 2, add pure water to the powder obtained in step 1 according to the mass ratio of 1:1.5 and heat it to boiling, then add nitric acid solution with a concentration of 60wt%, the amount of nitric acid solution added is 1.4 times the mass of the powder (add in 12 times , add a total of 18kg), heat until the powder is completely dissolved to obtain a solution;

[0065] Step 3. Cool the solution obtained in step 2 to 40°C and filter, dilute the filtrate with water to contain 50...

Embodiment 3

[0072] Such as figure 1 Shown, the method for preparing high-purity silver nitrate from photovoltaic waste silver paste, its concrete steps are as follows:

[0073]Step 1. Take 16.74Kg of photovoltaic waste silver paste (from a positive silver paste factory, the main components of photovoltaic waste silver paste are: 70% silver powder, glass powder (SiO 2 、 Bi 2 o 3 , PbO, Al 2 o 3 etc.) 3%, organic matter 15%) to obtain powder after drying at 100°C for 3 hours and ball milling for 3 hours;

[0074] Step 2. Add pure water to the powder obtained in step 1 according to the mass ratio of 1:1.5 and heat it to boiling, then add nitric acid solution with a concentration of 63wt%, and the amount of nitric acid solution added is 1.1 times the mass of the powder (add in 12 times) , add a total of 13.4kg), heat until the powder is completely dissolved to obtain a solution;

[0075] Step 3. Cool the solution obtained in step 2 to 40°C and filter, dilute the filtrate with water to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com