Method for preparing two-dimensional silver nanosheets of different shapes

A technology of silver nanosheets and morphology, which is applied in the field of preparing two-dimensional silver nanosheets, can solve the problem of temperature control, etc., and achieve the effects of simple equipment, simple operation and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

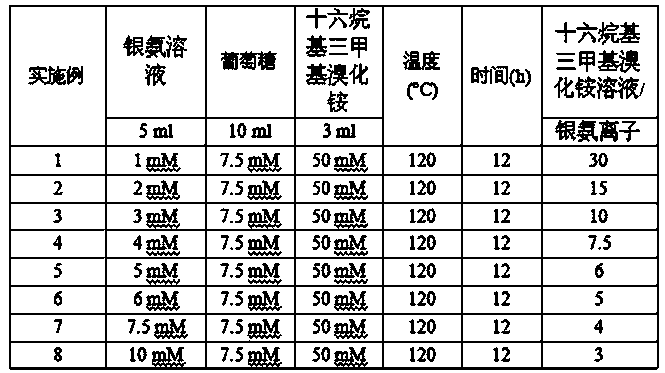

Embodiment 1

[0015] First, using the silver mirror reaction, 5 ml of silver ammonia solution with a mass concentration of 1 mM was added to the beaker, and then, using glucose as a reducing agent, 10 ml of a glucose solution with a mass concentration of 2-9 mM was added to the beaker and heated at 35 Stir in a water bath at ~45°C for 3-5 min, and finally, use cetyltrimethylammonium bromide as a surfactant, add 3 ml cetyltrimethylammonium bromide solution with a mass concentration of 50 mM Add the above mixed solution and stir in a water bath at 35-45°C for 3-5 minutes, transfer the mixed solution in the beaker to the reactor and react at 100-150°C for 10-12 hours, take out the reacted solution, centrifuge and disperse it by ultrasonic A two-dimensional silver nanosheet solution was prepared.

[0016] The silver nanosheet solution was characterized by transmission electron microscopy, and the particle size of the silver nanosheets was between 15 and 30 nm, mainly concentrated at 20 nm.

Embodiment 2

[0018] First, using the silver mirror reaction, 5 ml of silver ammonia solution with a mass concentration of 1 mM was added to the beaker, and then, using glucose as a reducing agent, 10 ml of a glucose solution with a mass concentration of 2-9 mM was added to the beaker and heated at 35 Stir in a water bath at ~45°C for 3-5 min, and finally, use cetyltrimethylammonium bromide as a surfactant, add 3 ml cetyltrimethylammonium bromide solution with a mass concentration of 50 mM Add the above mixed solution and stir in a water bath at 35-45°C for 3-5 minutes, transfer the mixed solution in the beaker to the reactor and react at 100-150°C for 10-12 hours, take out the reacted solution, centrifuge and disperse it by ultrasonic A two-dimensional silver nanosheet solution was prepared.

[0019] The silver nanosheet solution was characterized by transmission electron microscopy, and the particle size of the silver nanosheets was between 15 and 30 nm, mainly concentrated at 20 nm.

Embodiment 3

[0021] First, using the silver mirror reaction, 5 ml of silver ammonia solution with a mass concentration of 1 mM was added to the beaker, and then, using glucose as a reducing agent, 10 ml of a glucose solution with a mass concentration of 2-9 mM was added to the beaker and heated at 35 Stir in a water bath at ~45°C for 3-5 min, and finally, use cetyltrimethylammonium bromide as a surfactant, add 3 ml cetyltrimethylammonium bromide solution with a mass concentration of 50 mM Add the above mixed solution and stir in a water bath at 35-45°C for 3-5 minutes, transfer the mixed solution in the beaker to the reactor and react at 100-150°C for 10-12 hours, take out the reacted solution, centrifuge and disperse it by ultrasonic A two-dimensional silver nanosheet solution was prepared.

[0022] The silver nanosheet solution was characterized by transmission electron microscopy, and the particle size of the silver nanosheet was between 20 and 60 nm, mainly concentrated at 40 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com