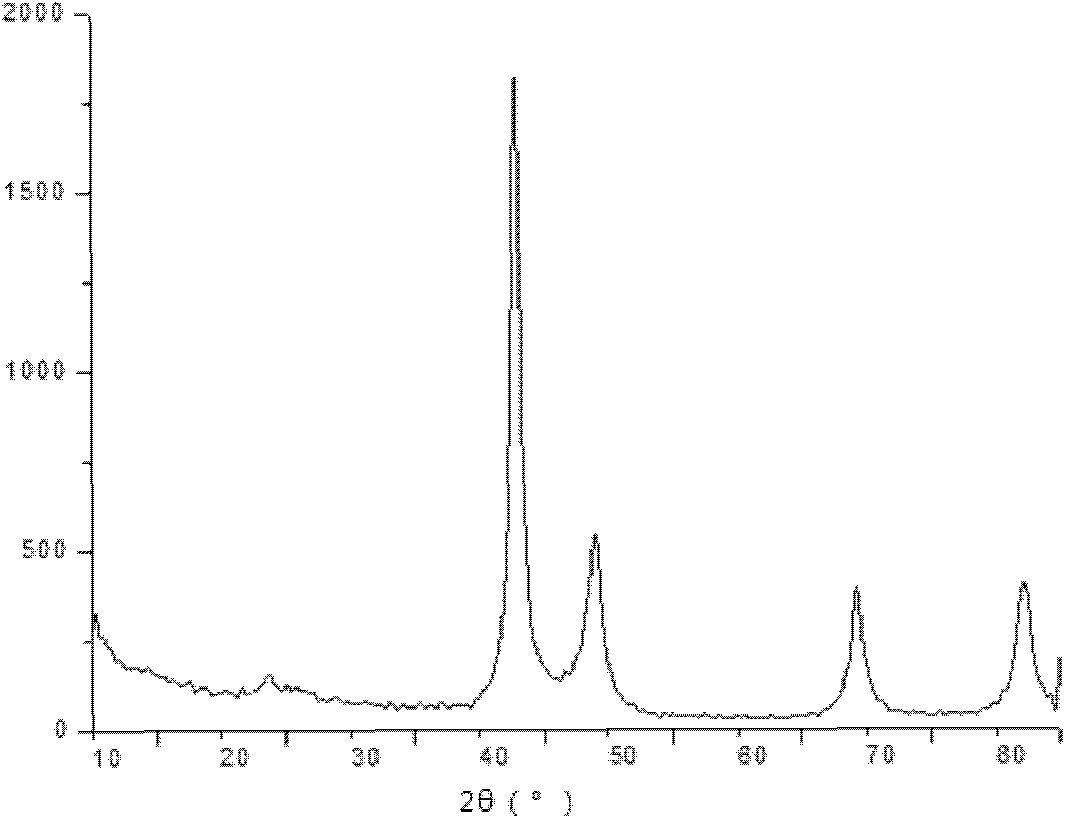

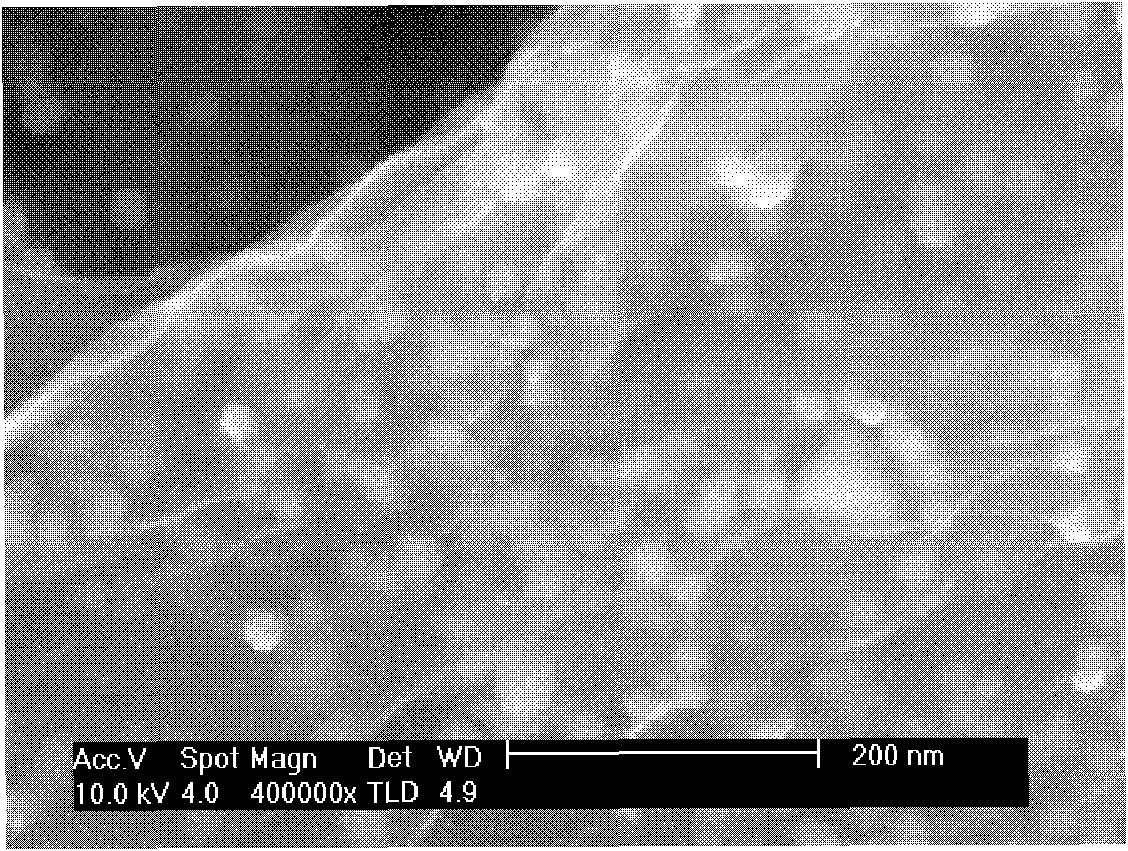

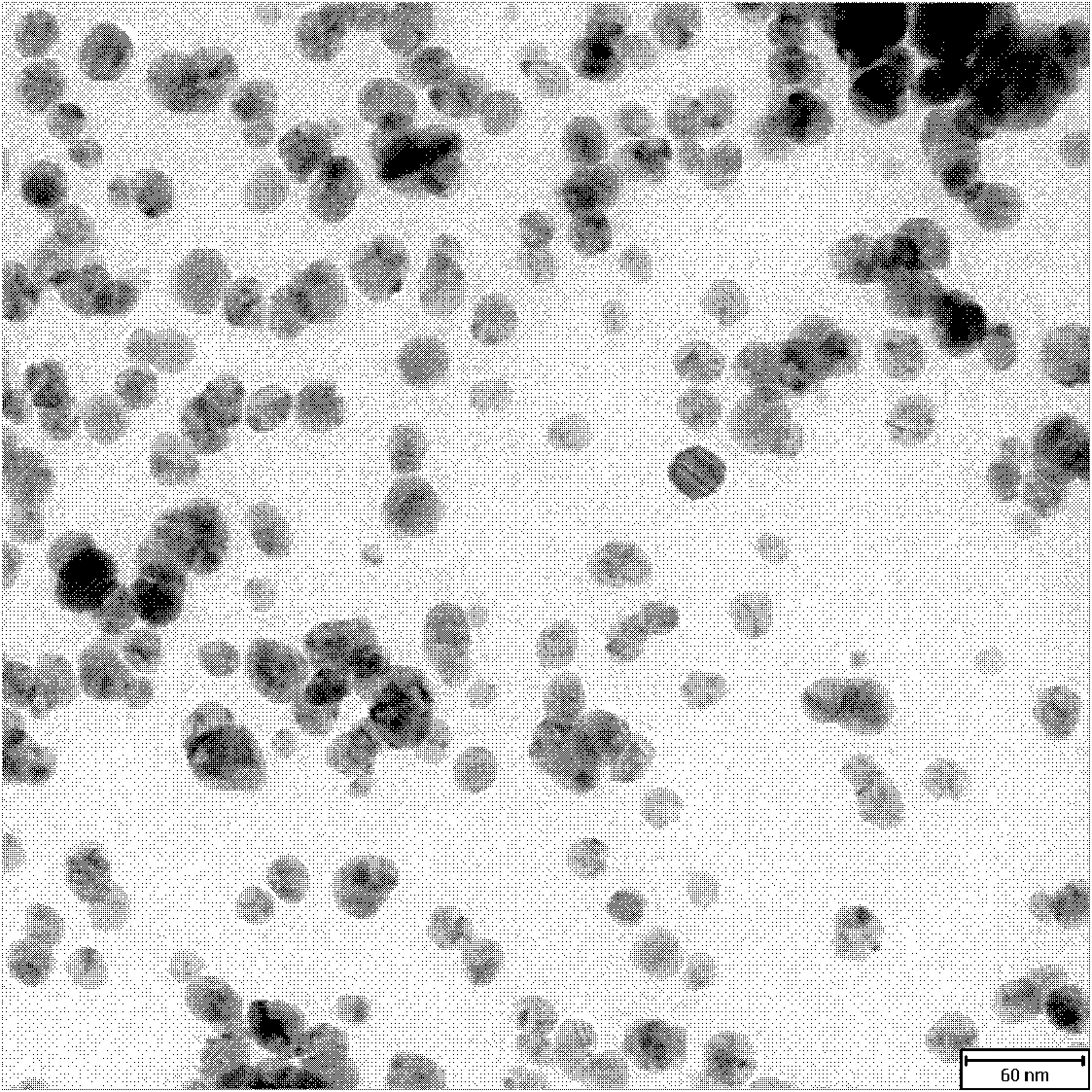

Preparation method of graphene-silver nano particle composite material

A technology of silver nanoparticles and composite materials, applied in the field of preparation of graphene-silver nanoparticle composite materials, can solve problems such as toxic strong reducing agents hydrazine and sodium borohydride, and achieve the effect of narrow distribution range and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Disperse 50mg of graphite oxide in 100mL of deionized water, and ultrasonicate at 50KHz, 500W power for 10min. Dissolve 40 mg of silver nitrate in 5 mL of deionized water, and add dilute ammonia water with a mass fraction of 2% into the silver nitrate solution dropwise until the formed precipitate just disappears completely. Add the configured silver ammonia solution to the graphene oxide solution that has been sonicated, and stir and preheat in a water bath at 40°C for 10 minutes. 50 mL of aqueous solution dissolved with 85 mg of glucose was added to the preheated mixture of graphene oxide and silver ammonia solution, and the reaction was stirred at 85° C. for 1 h. After the reaction was complete, the product was filtered and washed with deionized water and ethanol several times.

Embodiment 2

[0024] 100 mg of graphite oxide was dispersed in 100 mL of deionized water, and ultrasonically treated at 50 KHz, 500 W power for 30 min. Dissolve 120 mg of silver nitrate in 5 mL of deionized water, and add 3% dilute ammonia water dropwise into the silver nitrate solution until the formed precipitate just disappears completely. Add the configured silver ammonia solution to the graphene oxide solution that has been sonicated, and stir and preheat in a water bath at 50°C for 20 minutes. 50 mL of aqueous solution dissolved with 500 mg of glucose was added to the preheated mixture of graphene oxide and silver ammonia solution, and the reaction was stirred at 95° C. for 4 h. After the reaction was complete, the product was filtered and washed with deionized water and ethanol several times.

Embodiment 3

[0026]100mg of graphite oxide was dispersed in 100mL of deionized water, and ultrasonically treated at 50KHz, 500W power for 40min. Dissolve 157 mg of silver nitrate in 10 mL of deionized water, and add 3% dilute ammonia water dropwise into the silver nitrate solution until the formed precipitate just disappears completely. Add the configured silver ammonia solution to the graphene oxide solution that has been sonicated, and stir and preheat in a water bath at 60°C for 30 minutes. 100 mL of aqueous solution dissolved with 1330 mg of glucose was added to the preheated mixture of graphene oxide and silver ammonia solution, and the reaction was stirred at 95° C. for 8 h. After the reaction was complete, the product was filtered and washed with deionized water and ethanol several times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com