Polydopamine/silver modified polymer separating membrane and preparation method

A polydopamine and polymer technology, applied in the field of membrane separation, can solve the problems of organic matter and microbial contamination, lack of bacteriostatic and bactericidal ability, etc., and achieve the effects of improved anti-pollution ability, good osmotic selectivity, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

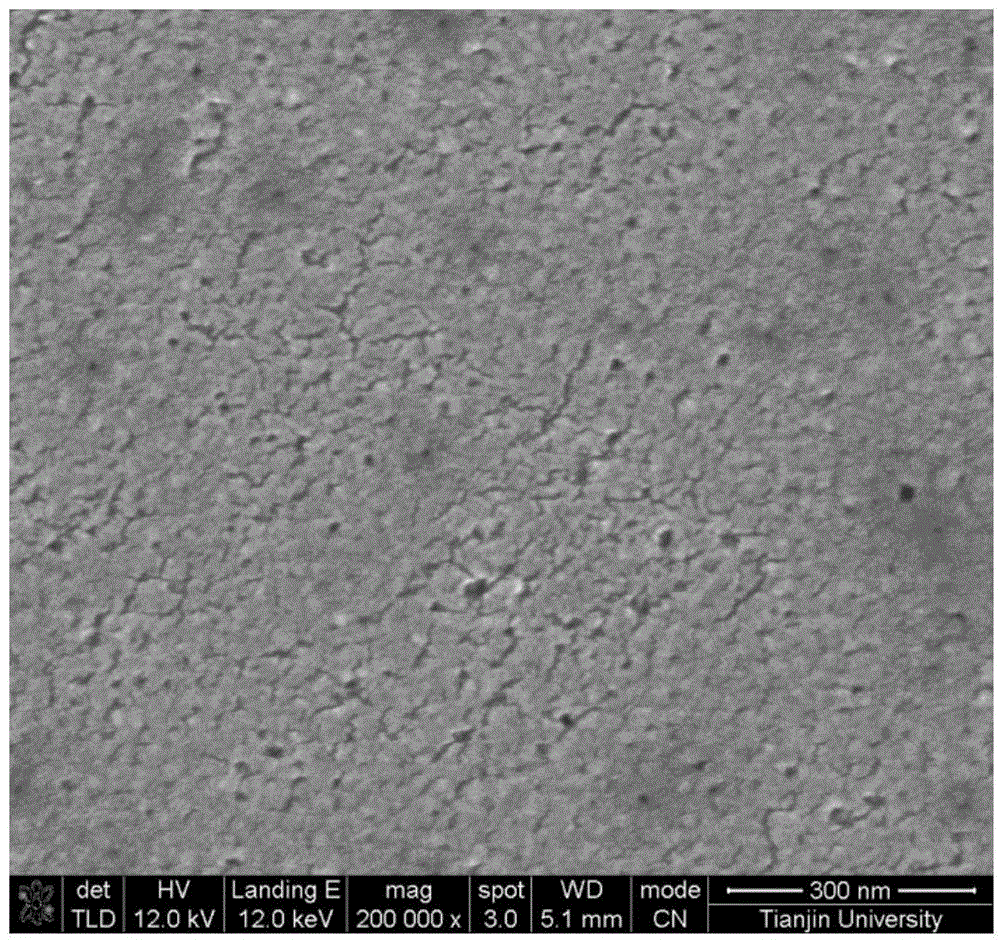

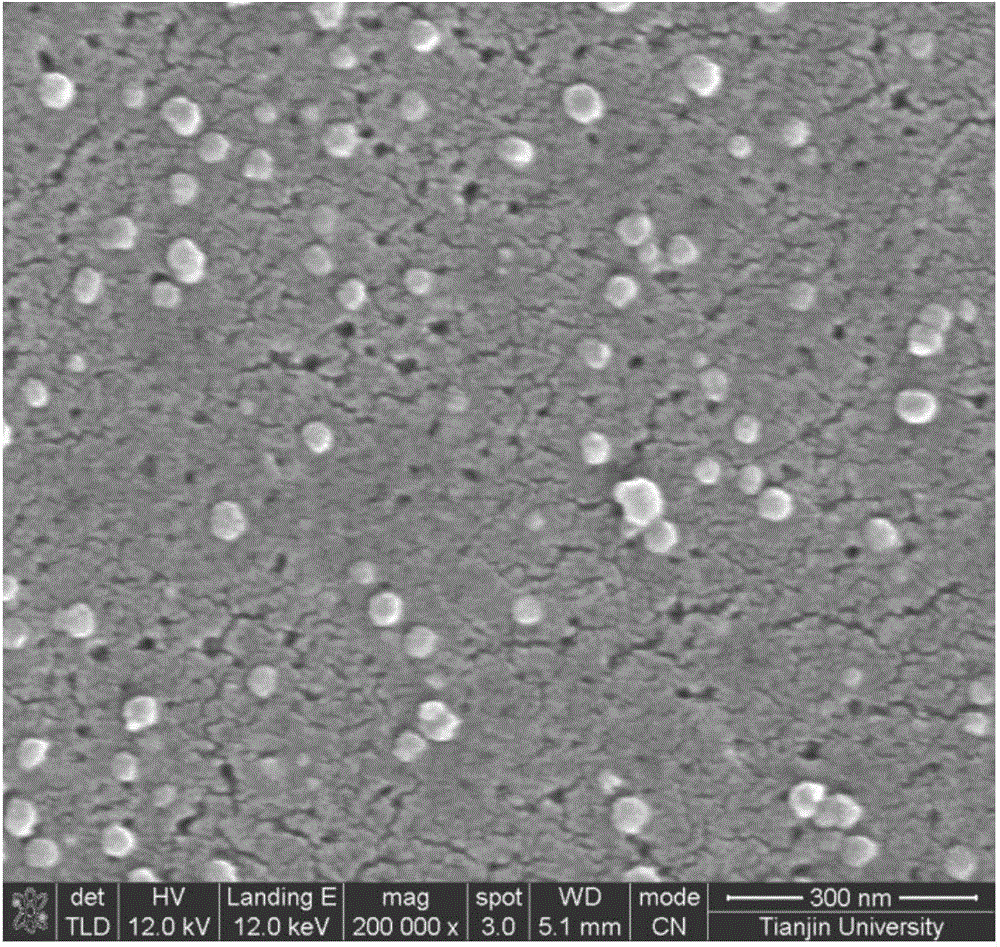

Embodiment 1

[0020] (1) Prepare a mixed solution of Tris, dopamine hydrochloride and water. Based on the volume of water (L), the concentration of Tris is 1.5g / L, and the concentration of dopamine hydrochloride is 1g / L. The polysulfone porous membrane is placed in the mixed solution, shaken and reacted for 1 hour, then the reaction solution is poured off, and the surface of the membrane is washed with water to obtain a polydopamine-modified polymer separation membrane. Prepare a mixed solution containing silver ammonia solution, polyvinylpyrrolidone, glucose and water. The concentration of silver nitrate was 2 g / L, the concentration of polyvinylpyrrolidone was 2 g / L, and the concentration of glucose was 1 g / L. The polydopamine-modified polysulfone membrane is placed in the mixed solution, shaken and reacted for 1 hour, and then the reaction solution is poured off, and the surface of the membrane is washed with water to obtain a polydopamine / silver-modified polysulfone porous membrane. Th...

Embodiment 2

[0023] (1) Prepare a mixed solution of Tris, dopamine hydrochloride and water. Based on the volume of water (L), the concentration of Tris is 0.5g / L, and the concentration of dopamine hydrochloride is 0.5g / L. The polyethersulfone porous membrane is placed in the mixed solution, shaken and reacted for 5 hours, and then the reaction solution is poured out, and the surface of the membrane is washed with water to obtain a polydopamine-modified polymer separation membrane. Prepare a mixed solution containing silver ammonia solution, polyethylene glycol, sodium borohydride and water. The concentration of silver nitrate is 0.5g / L, the concentration of polyethylene glycol is 1g / L, and the concentration of sodium borohydride is 0.5g / L. The polydopamine-modified polyethersulfone porous membrane was placed in the mixed solution, shaken and reacted for 5 hours, and then the reaction solution was discarded, and the surface of the membrane was washed with water to obtain a polydopamine / sil...

Embodiment 3

[0026] (1) Prepare a mixed solution of Tris, dopamine hydrochloride and water. Based on the volume of water (L), the concentration of tris was 2g / L, and the concentration of dopamine hydrochloride was 3g / L. The polyvinylidene fluoride porous membrane is placed in the mixed solution, shaken and reacted for 0.2 h, and then the reaction solution is poured out, and the surface of the membrane is washed with water to obtain a polydopamine-modified polymer separation membrane. Prepare a mixed solution containing silver ammonia solution, polyether, glucose and water. The concentration of silver nitrate is 5g / L, the concentration of polyether is 0.5g / L, and the concentration of glucose is 2g / L. The polydopamine-modified polyvinylidene fluoride membrane was placed in the mixed solution, shaken and reacted for 0.5 h, and then the reaction solution was poured out, and the surface of the membrane was washed with water to obtain a polydopamine / silver-modified polyvinylidene fluoride membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com