Patents

Literature

60results about How to "High flux recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

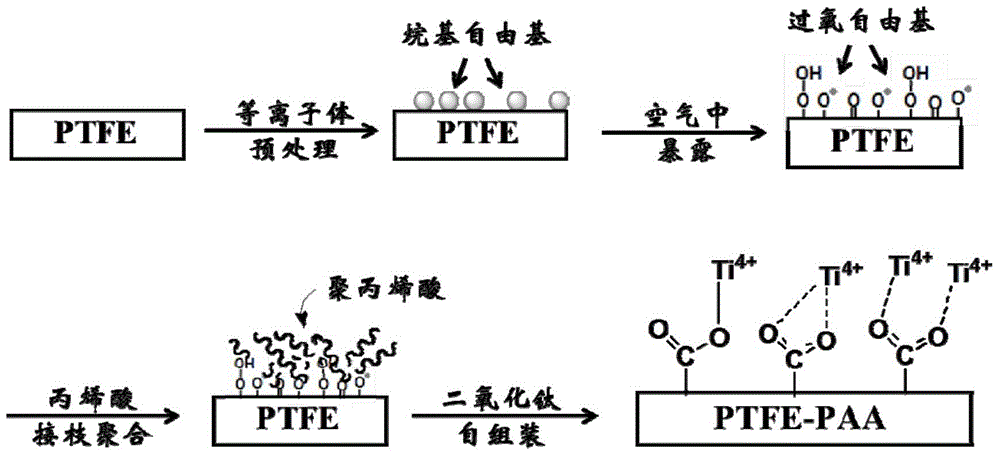

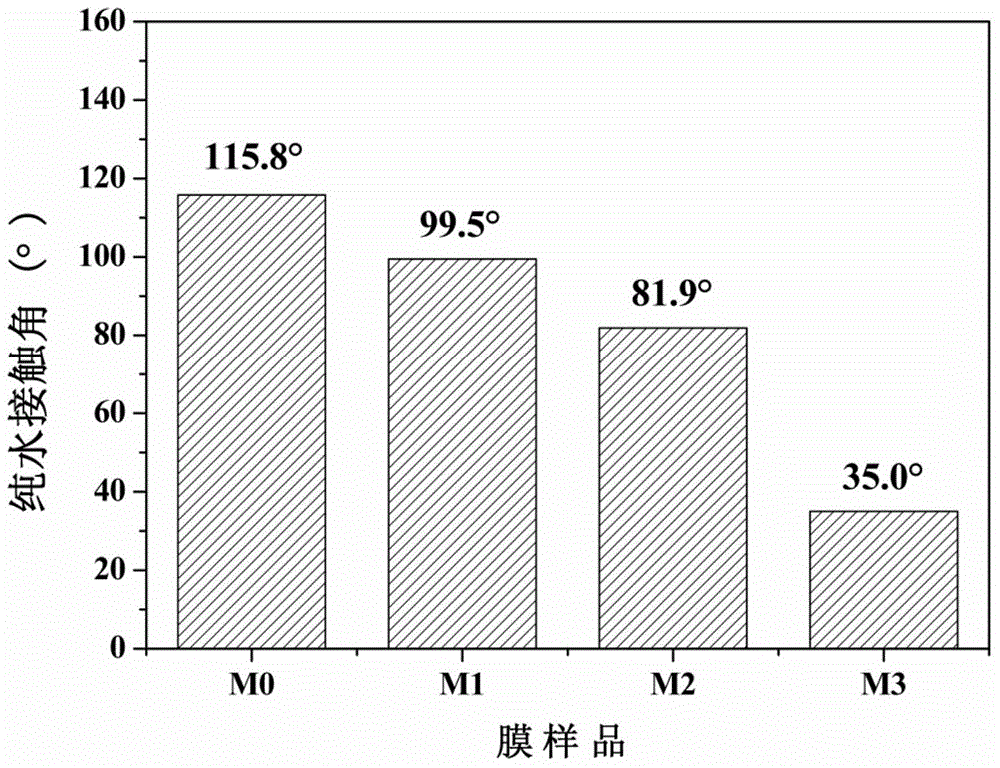

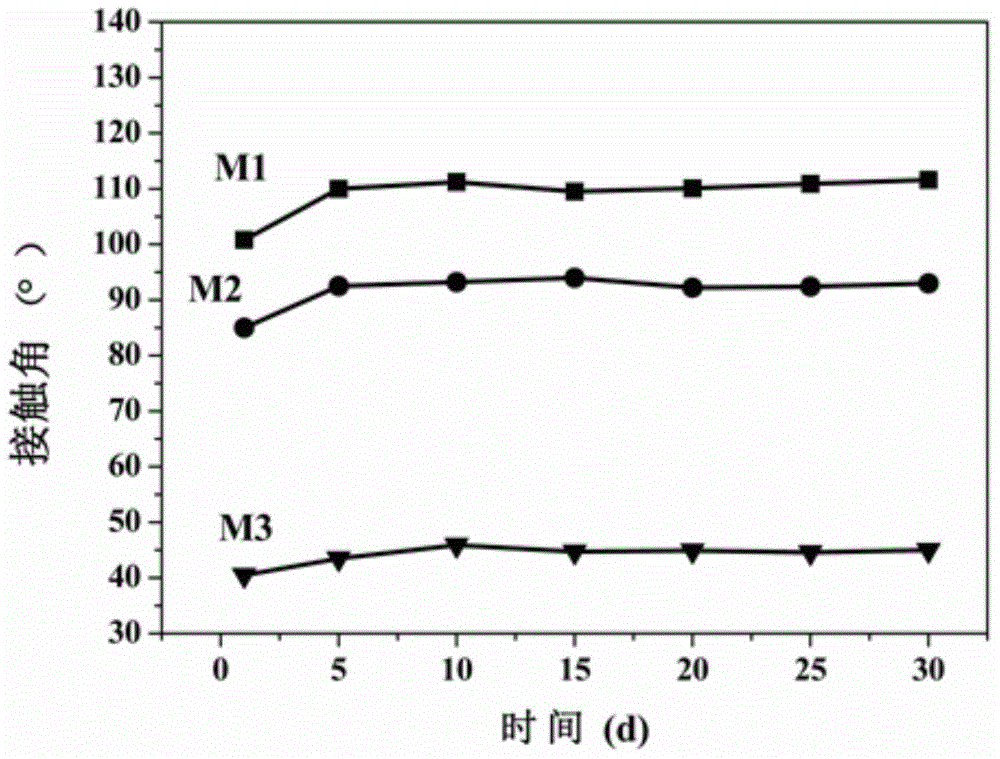

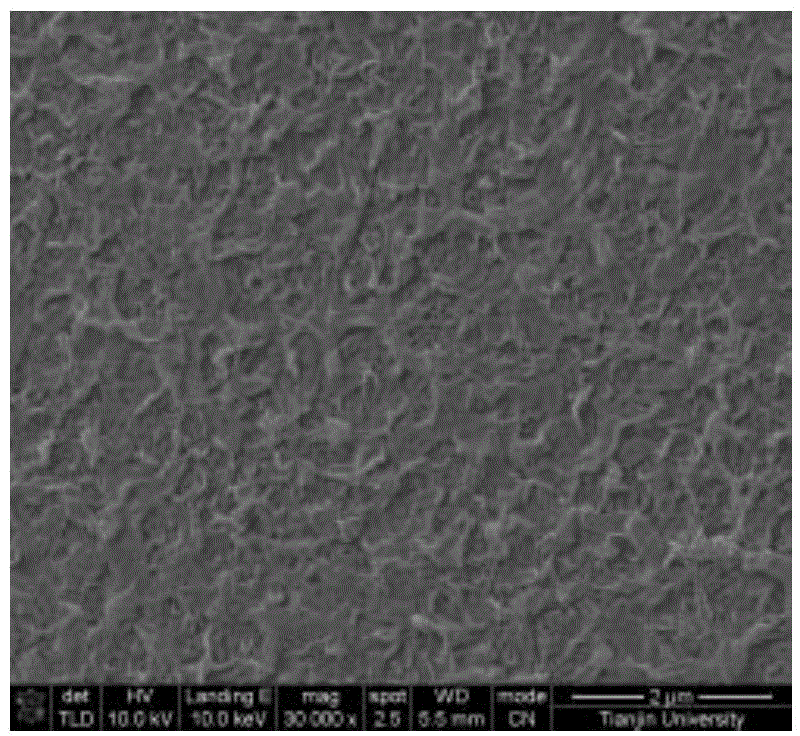

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

Reverse osmosis membrane with polyvinylamine grafted on surface, and preparation method thereof

InactiveCN104815567AWide variety of sourcesReduced surface negative charge densityReverse osmosisActivation methodReverse osmosis

The present invention relates to a reverse osmosis membrane with polyvinylamine grafted on the surface, and a preparation method thereof. According to the reverse osmosis membrane with polyvinylamine grafted on the surface, the carboxy on the surface of an aromatic polyamide composite reverse osmosis membrane and the primary amine group of polyvinylamine are connected, the high cation density hydrophilic polymer polyvinylamine is grafted on the surface of the aromatic polyamide composite reverse osmosis membrane by using a carboxy activation method using 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride and N-hydroxysuccinimide, and the primary amine of the polyvinylamine reacts with the carboxy on the membrane surface so as to form the firm amide bond. The reverse osmosis membrane of the present invention has characteristics of surface negative charge density reducing and hydrophilicity increasing, and provides anti-pollution performances for proteins, surfactants and other contaminants. After the reverse osmosis composite membrane of the present invention is polluted, the flux decline rate is low, and the flux recovery rate is high after cleaning, such that the good anti-pollution performance is provided. In addition, the preparation method has characteristics of wide raw material source, mild reaction condition, and simple method.

Owner:TIANJIN UNIV

Preparation method of photo-Fenton self-cleaning film and application thereof

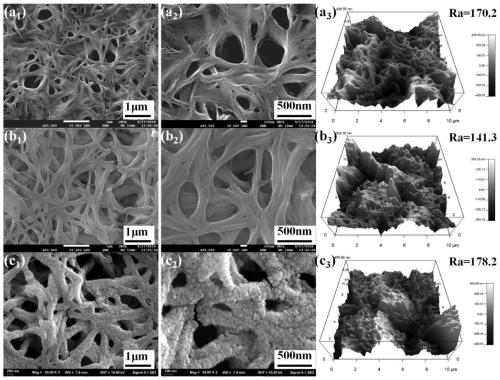

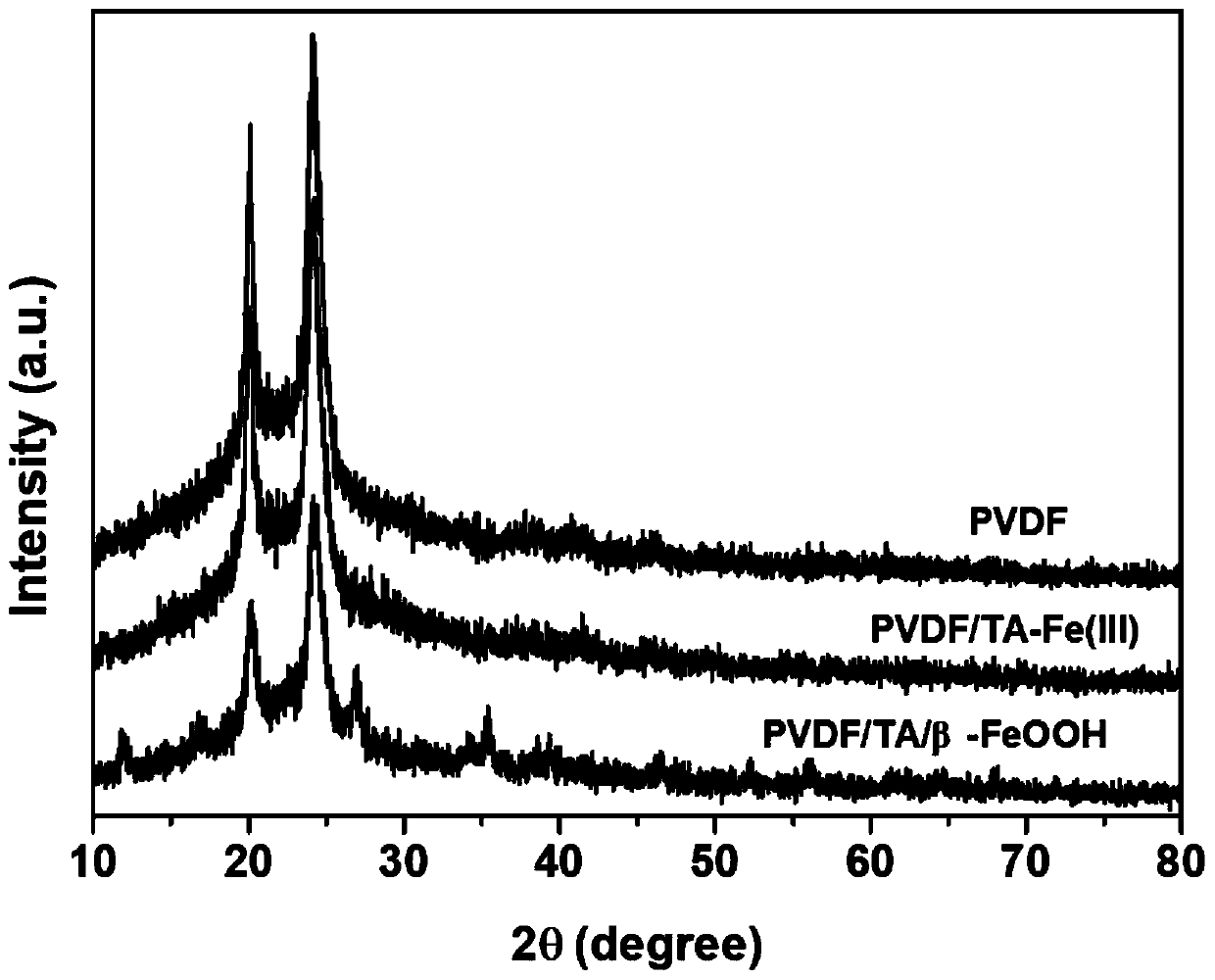

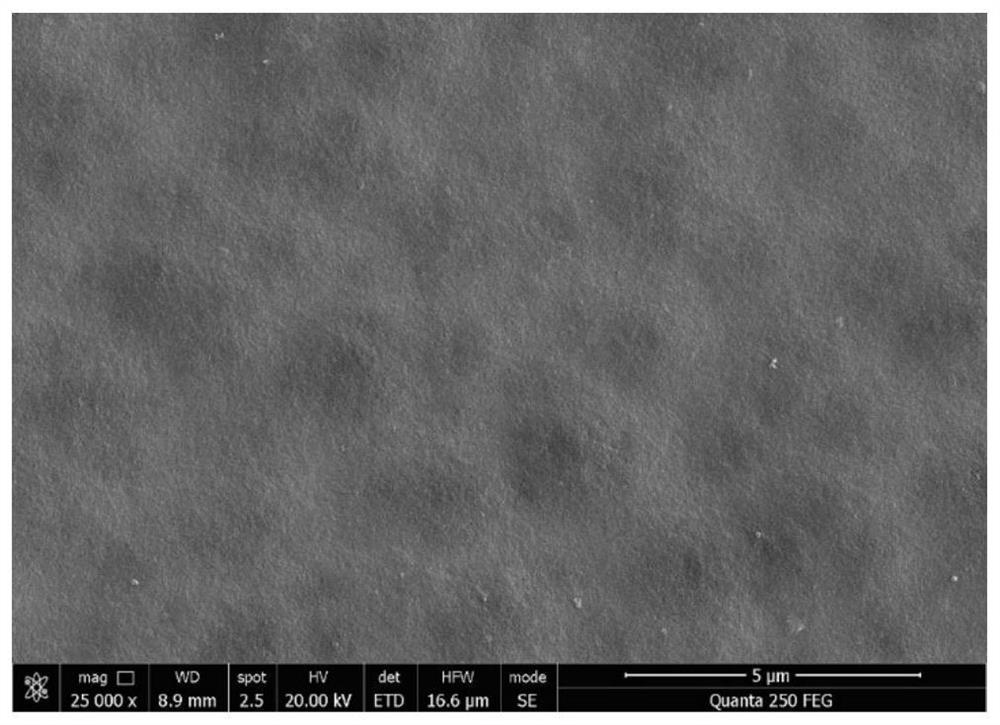

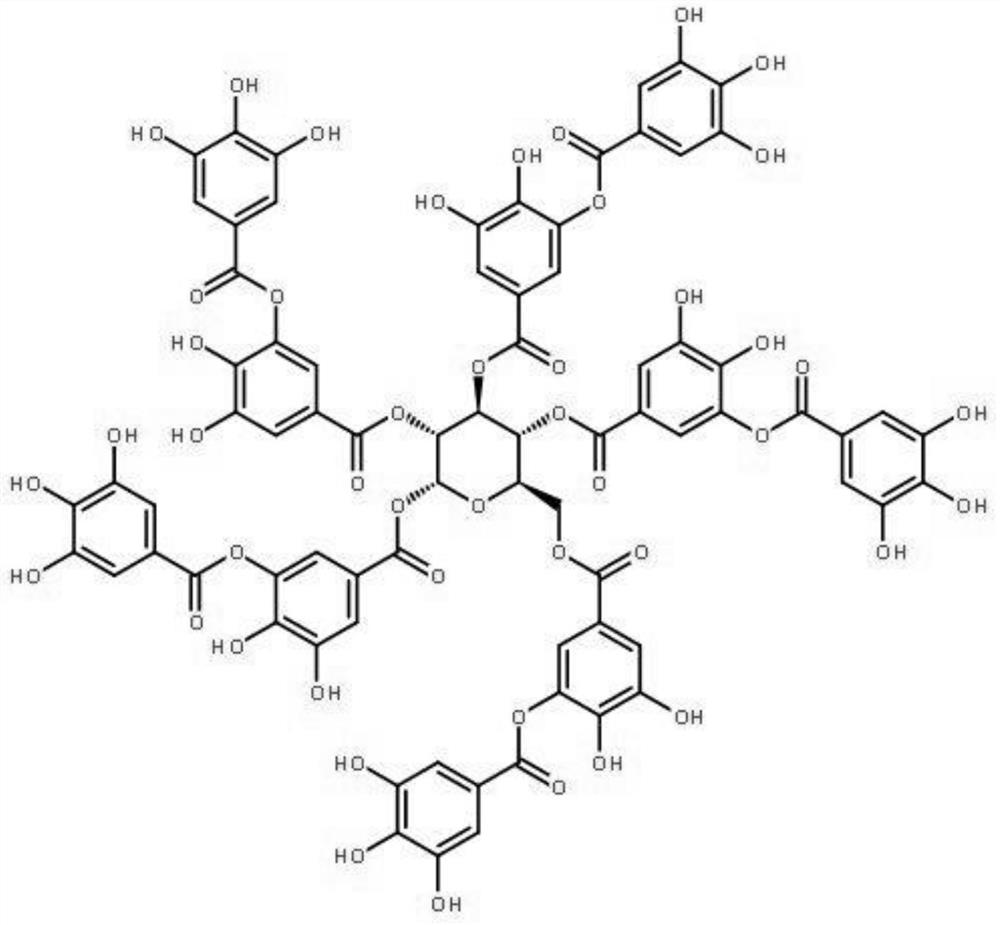

ActiveCN109925894AEasy to prepareEasy to controlSemi-permeable membranesWater/sewage treatment by irradiationIonPolyvinylidene fluoride

The invention belongs to the technical field of preparation of environmental functional materials, and particularly relates to a preparation method of a photo Fenton self-cleaning film and applicationthereof. The method comprises the following steps: pre-soaking a polyvinylidene fluoride film with ethanol, and then soaking the polyvinylidene fluoride film in a tannic acid aqueous solution to obtain a PVDF / TA film; cleaning the PVDF / TA film with deionized water, transferring the PVDF / TA film to a ferric trichloride hexahydrate aqueous solution for soaking, cleaning, and drying to obtain a PVDF / TA-Fe (III) film; soaking the PVDF / TA-Fe (III) film in the ferric trichloride hexahydrate aqueous solution, incubating at a certain water bath temperature, taking out the film, rinsing the PVDF / TA-Fe(III) film with deionized water, and drying to obtain the self-cleaning film material, which is recorded as PVDF / TA / beta-FeOOH. According to the invention, the photo-Fenton reaction is coupled with afilm separation technology, so that the anti-fouling performance of the film is improved; the photo Fenton self-cleaning film can effectively separate different oil-water emulsions, the film flux recovery rate within 10 min is as high as over 98%, the service life of the film is prolonged, and the cost is reduced.

Owner:JIANGSU UNIV

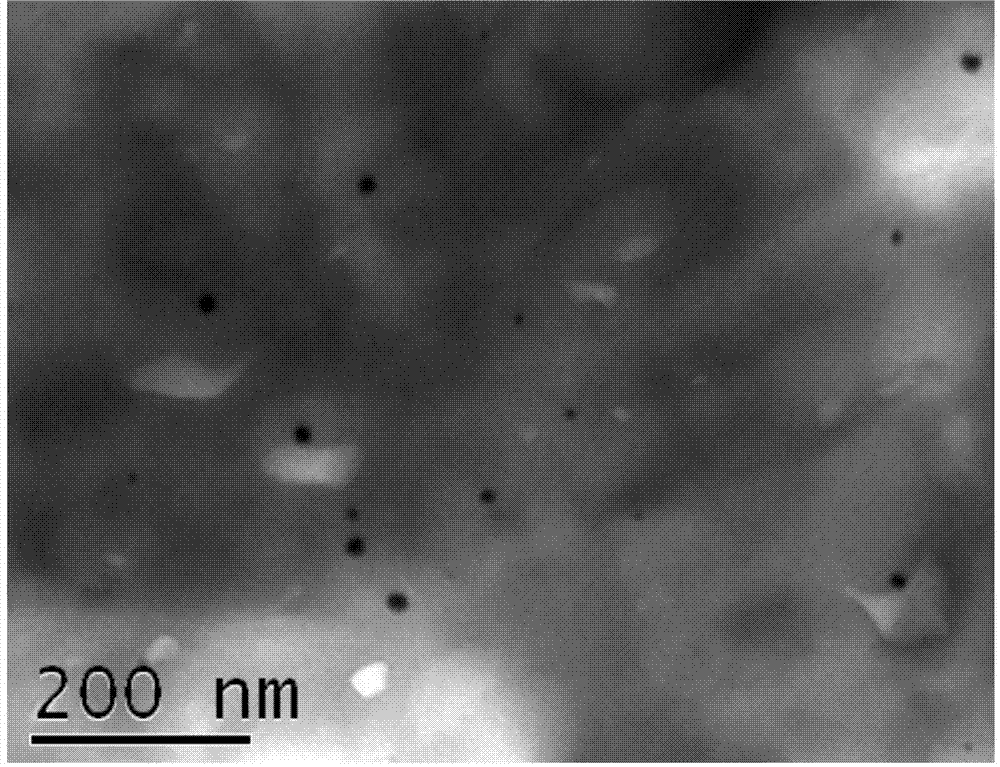

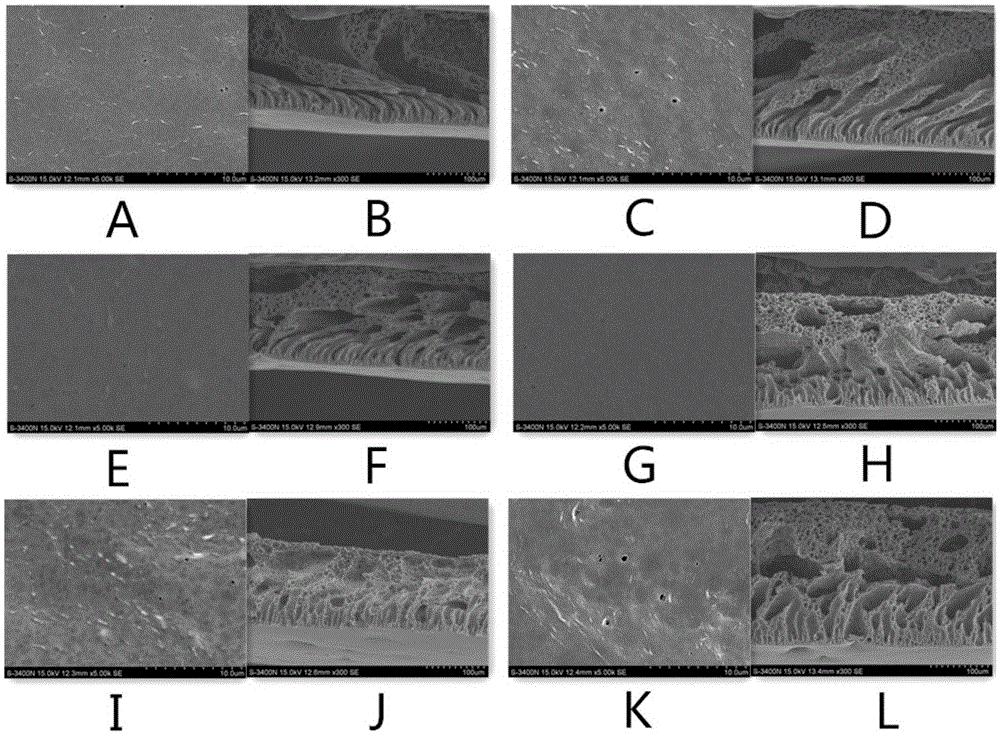

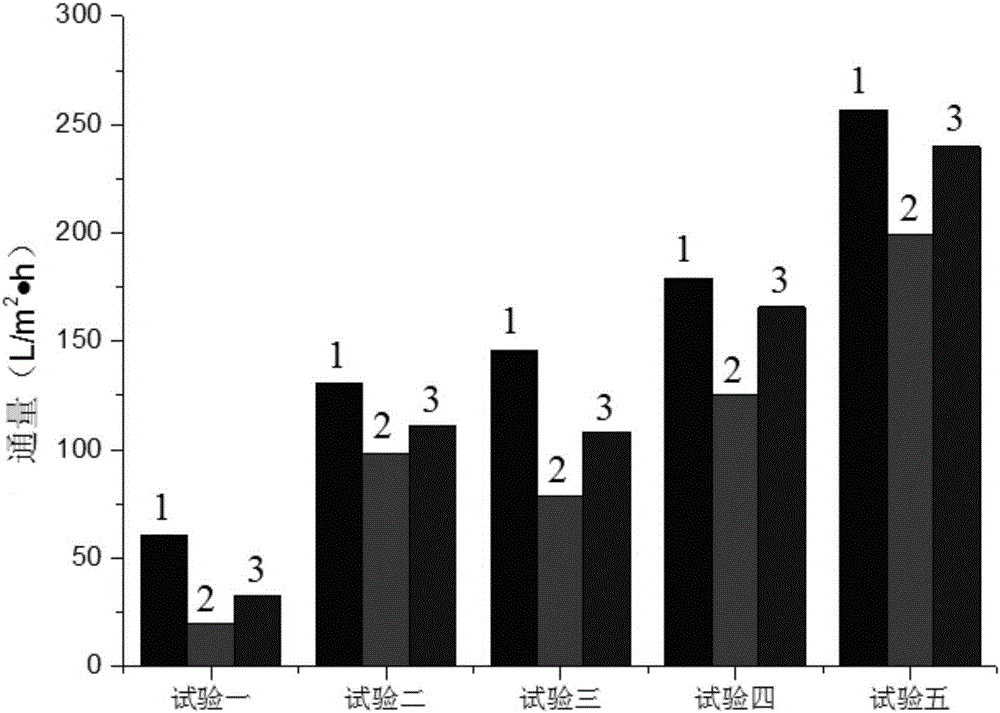

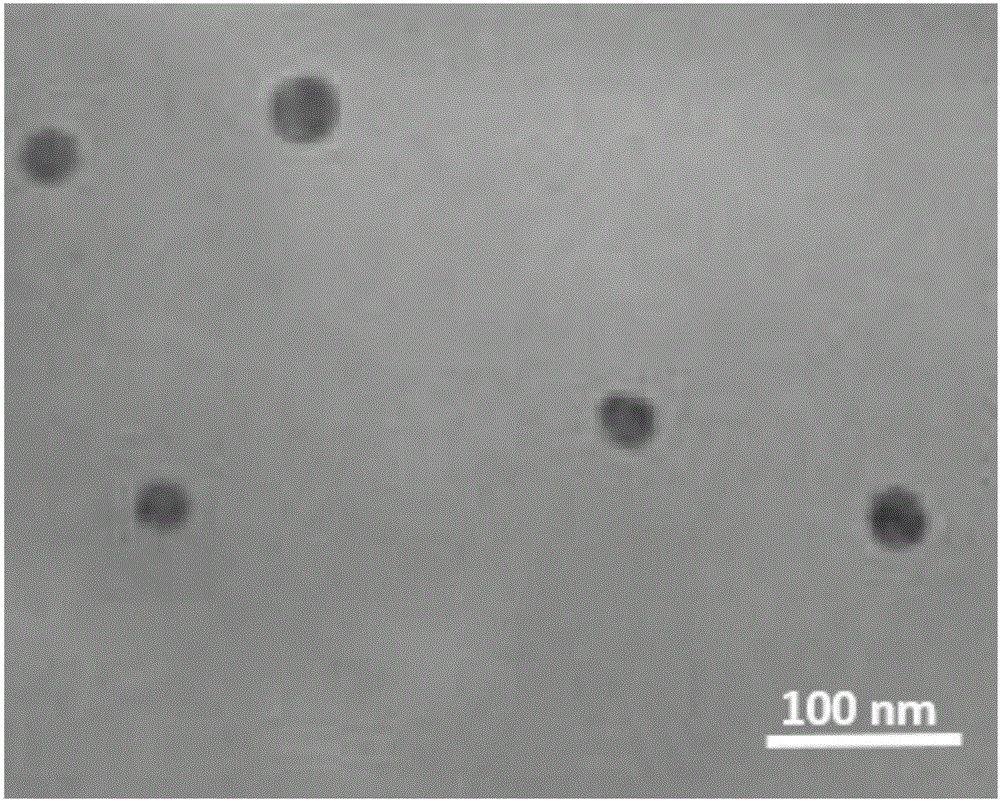

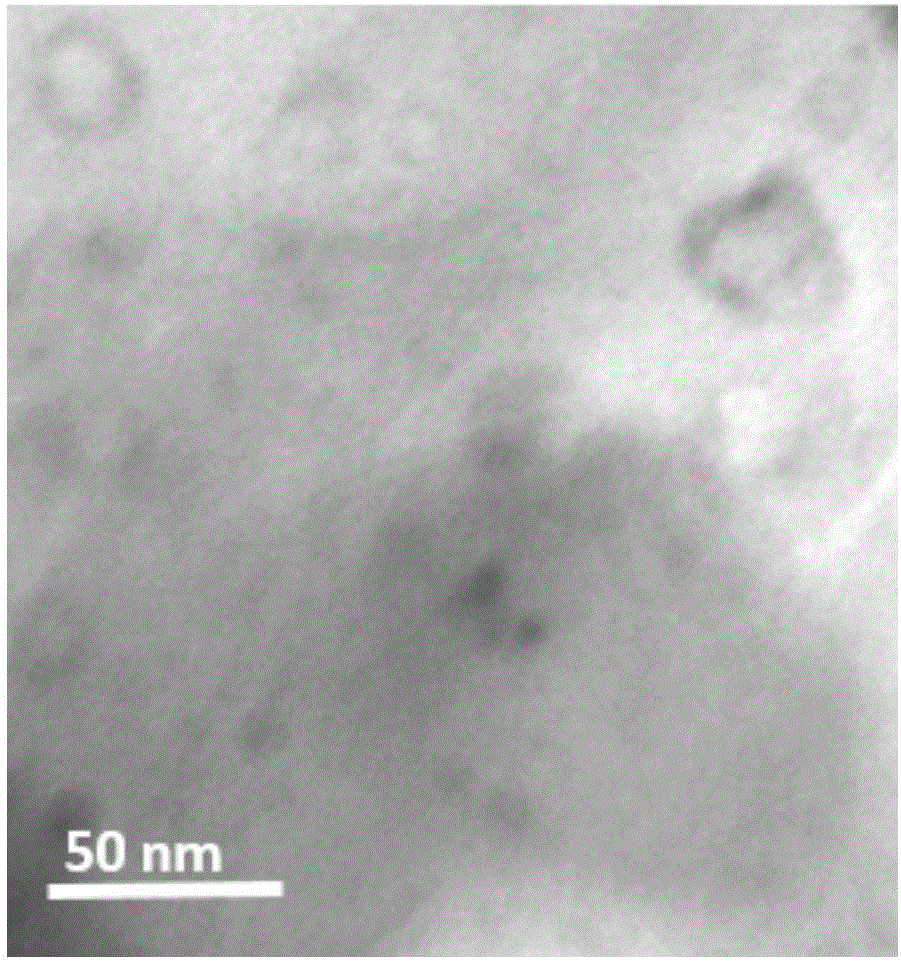

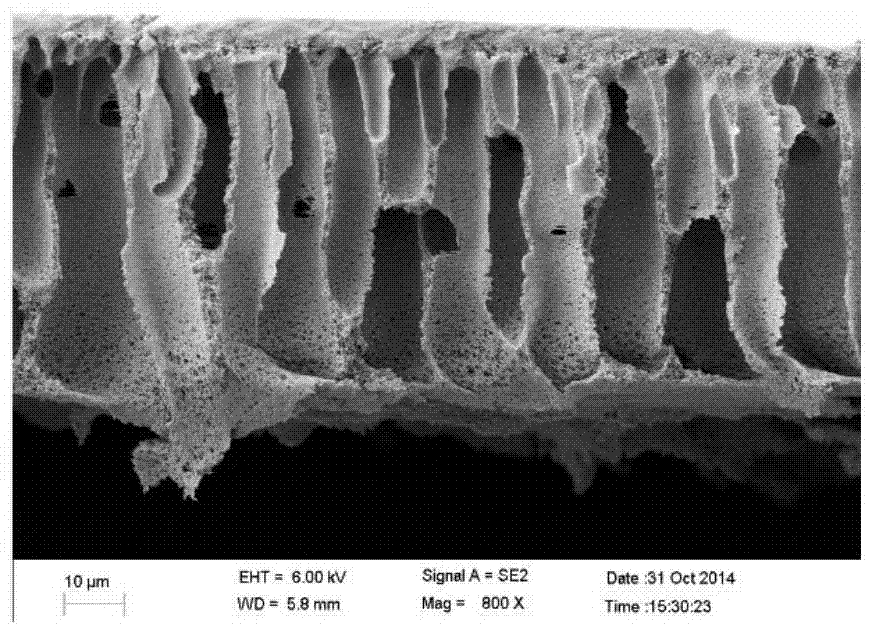

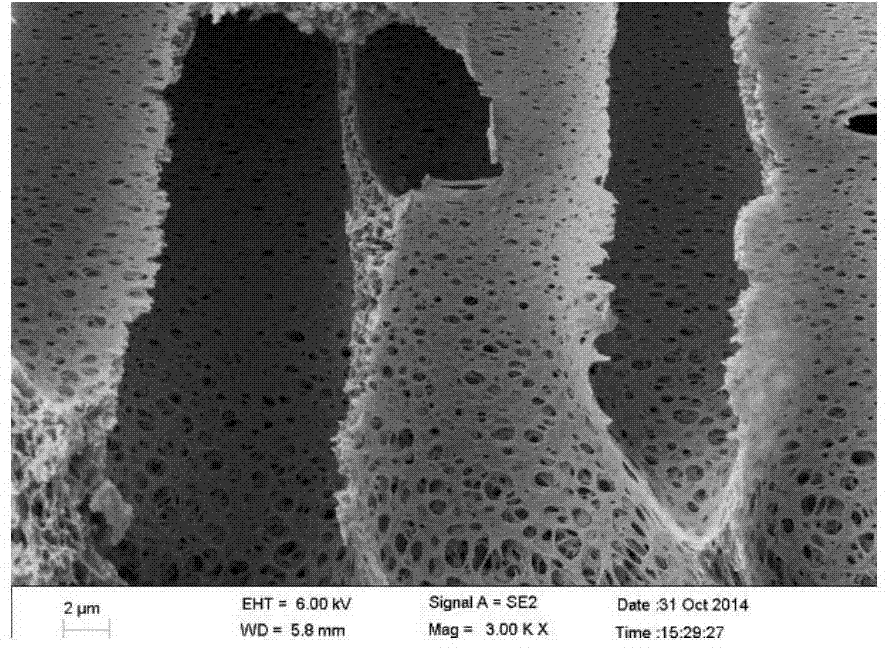

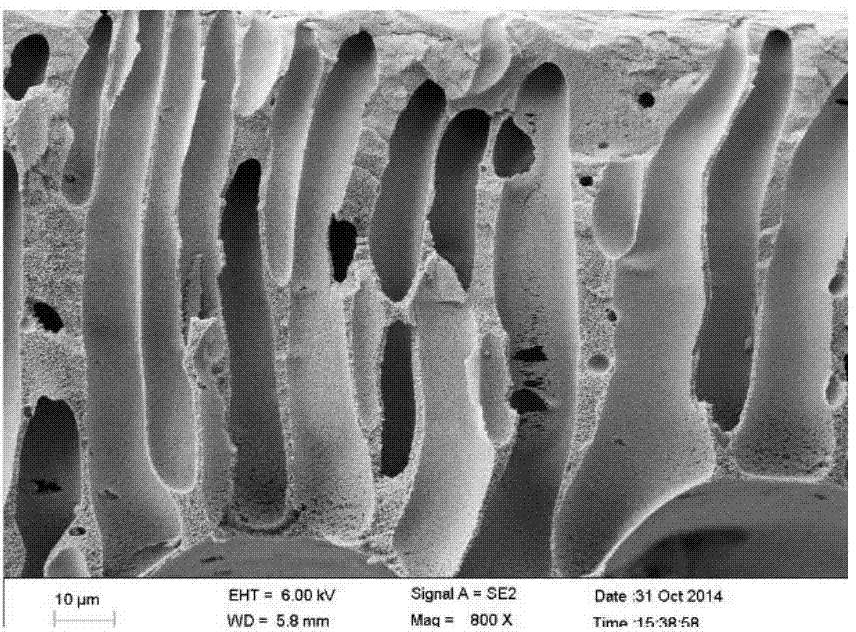

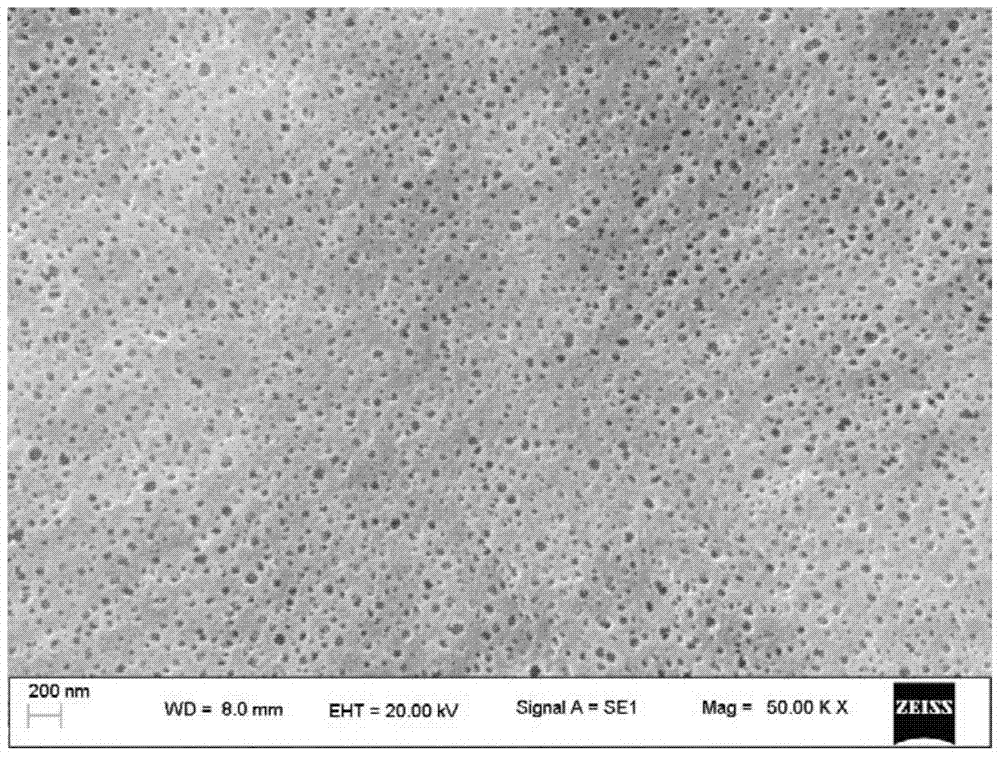

Preparation method of in-situ synthesized nano silver modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane

ActiveCN104117293AImprove hydrophilicityAvoid reunionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationPolyvinylidene difluoride

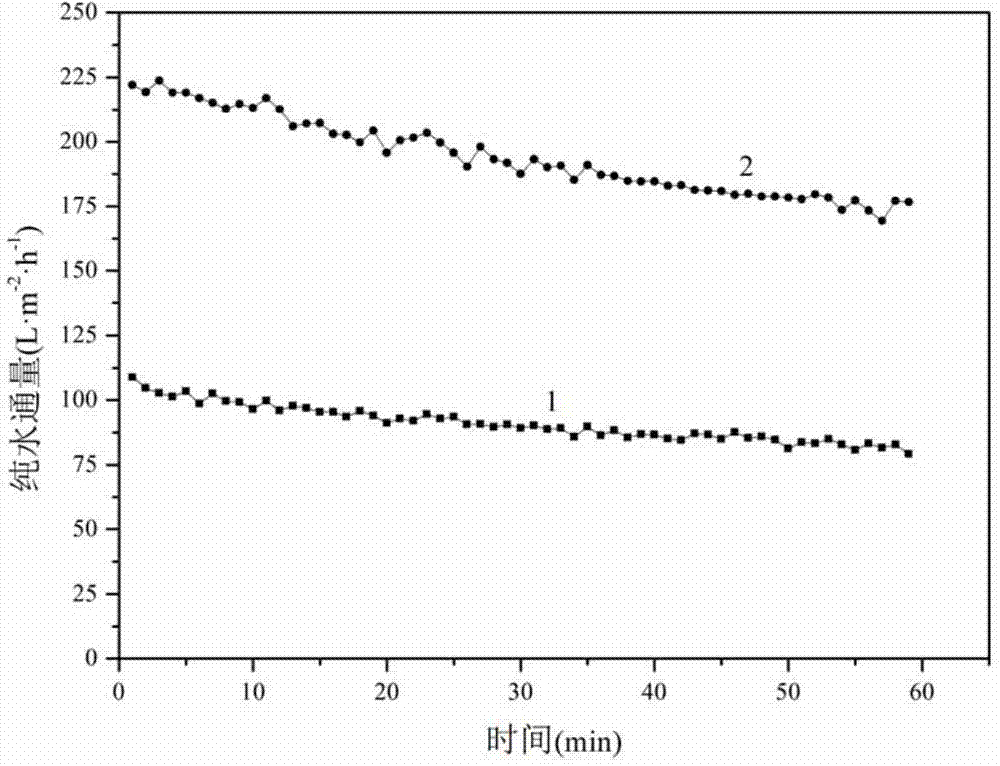

The invention discloses a preparation method of an in-situ synthesized nano silver modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane and relates to a preparation method of a modified PVDF ultrafiltration membrane. The preparation method disclosed by the invention is used for solving the problems that in the prior art, nano particles are easy to aggregate in an existing inorganic nano particle modified PVDF ultrafiltration membrane, the nano particles are diffused towards a water phase during phase separating and are enriched on the surface of the membrane and the improvement of anti-pollution performance of the PVDF ultrafiltration membrane is not obvious. The preparation method comprises the following steps: (1) preparing a PVDF solution; (2) preparing a mixed solution containing nano silver; (3) preparing a casting membrane solution; (4) casting and forming a membrane; (5) washing to obtain the in-situ synthesized nano silver modified PVDF ultrafiltration membrane. The pure water flux of the prepared in-situ synthesized nano silver modified PVDF ultrafiltration membrane is 110-180L / m<2>.h and the flux during pollution test is 70-90L / m<2>.h. According to the preparation method, the in-situ synthesized nano silver modified PVDF ultrafiltration membrane can be obtained.

Owner:HARBIN INST OF TECH

Preparation method of lasting hydrophilization modified polyvinylidene fluoride (PVDF) ultrafiltration membrane

InactiveCN103464005AImprove performanceImprove pressure resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationPollution

The invention discloses a preparation method of a lasting hydrophilization modified polyvinylidene fluoride (PVDF) ultrafiltration membrane. The preparation method of the lasting hydrophilization modified PVDF ultrafiltration membrane comprises the following steps: 1) preparing a film casting solution; 2) preparing a crosslinked blend membrane. After liquid phase blending modification is carried out on PVDF and an organic hydrophilic macromolecule PVA (polyvinyl alcohol), further anhydrous ferric chloride is added into the film casting solution, and PVA is fixed through a complexing reaction carried out on a hydroxyl on a molecular chain of the PVA and Fe<3+>, so that lasting hydrophilic modification of a membrane is realized, and water permeability stability is improved while a membrane structure is optimized; after modification, performances of the membrane are shown as follows: a contact angle is reduced by 30-40 degrees, flux is increased by 1-3 times compared with the flux before modification, and strength is increased by 1-1.5MPa; the anti-pollution capacity of the membrane is shown as follows: after filtering is carried out for 2 hours, the recovery rate of the flux of the membrane is increased by 10-20%, and the attenuation rate of the flux of the membrane is reduced by 5-10%.

Owner:四川有色环境科技有限公司

Amphiphilic fluorine-containing gradient copolymer, and preparation method and application thereof

ActiveCN104927011AEasy to prepareSimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisNon solventUltrafiltration

The invention discloses a preparation method of an amphiphilic fluorine-containing gradient copolymer, and the method is used in oil-water separation ultrafiltration membrane antifouling modification. First, with a reversible addition fragmentation chain transfer (RAFT) controlled free radical polymerization method, with a semi-continuous feeding manner, an amphiphilic fluorine-containing gradient copolymer is prepared; the prepared amphiphilic fluorine-containing gradient copolymer is adopted as a modifying agent, and is used for modifying the ultrafiltration membrane with a blending modification method, wherein the membrane is prepared with a classic non-solvent induced phase transformation method. The surface of the membrane modified with the amphiphilic fluorine-containing gradient copolymer has an amphiphilic hierarchical structure with the coexistence of hydrophilic and hydrophobic regions. The amphiphilic fluorine-containing gradient copolymer preparation method is simple; and the modified membrane preparation process has the advantages of easy operation and mild conditions. The modified membrane has good oil-water separation performance and excellent antifouling effect, and can be used in water treatment and especially the separation purification of oil-containing wastewater.

Owner:ZHEJIANG UNIV

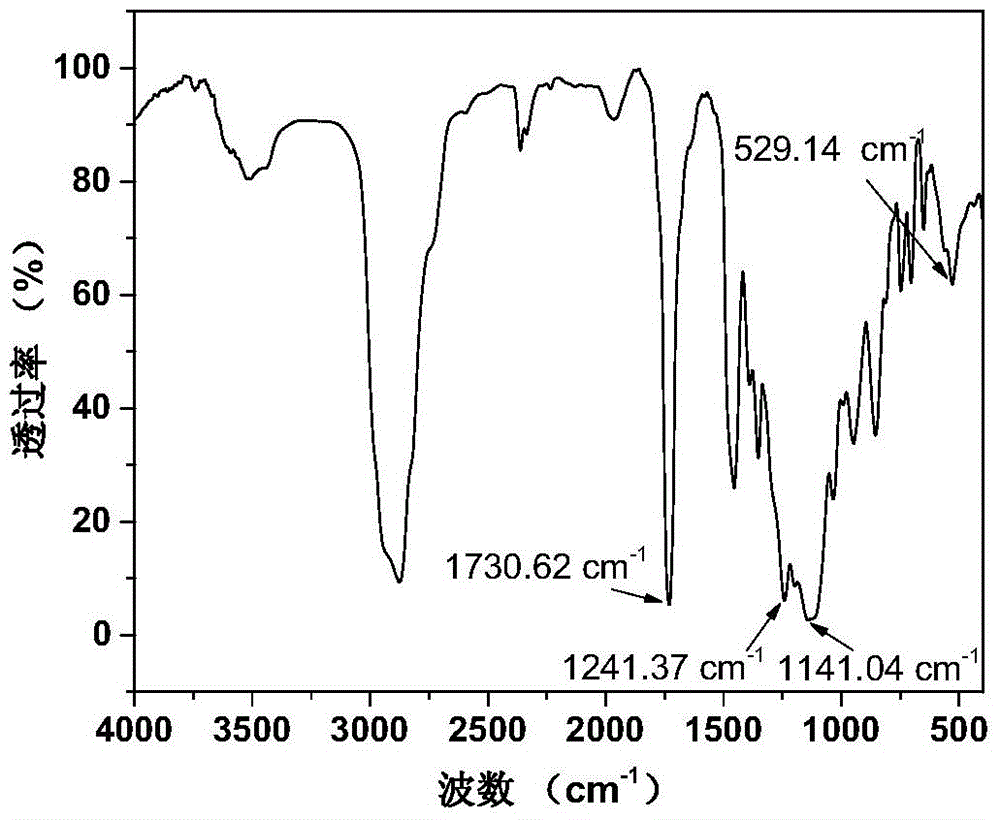

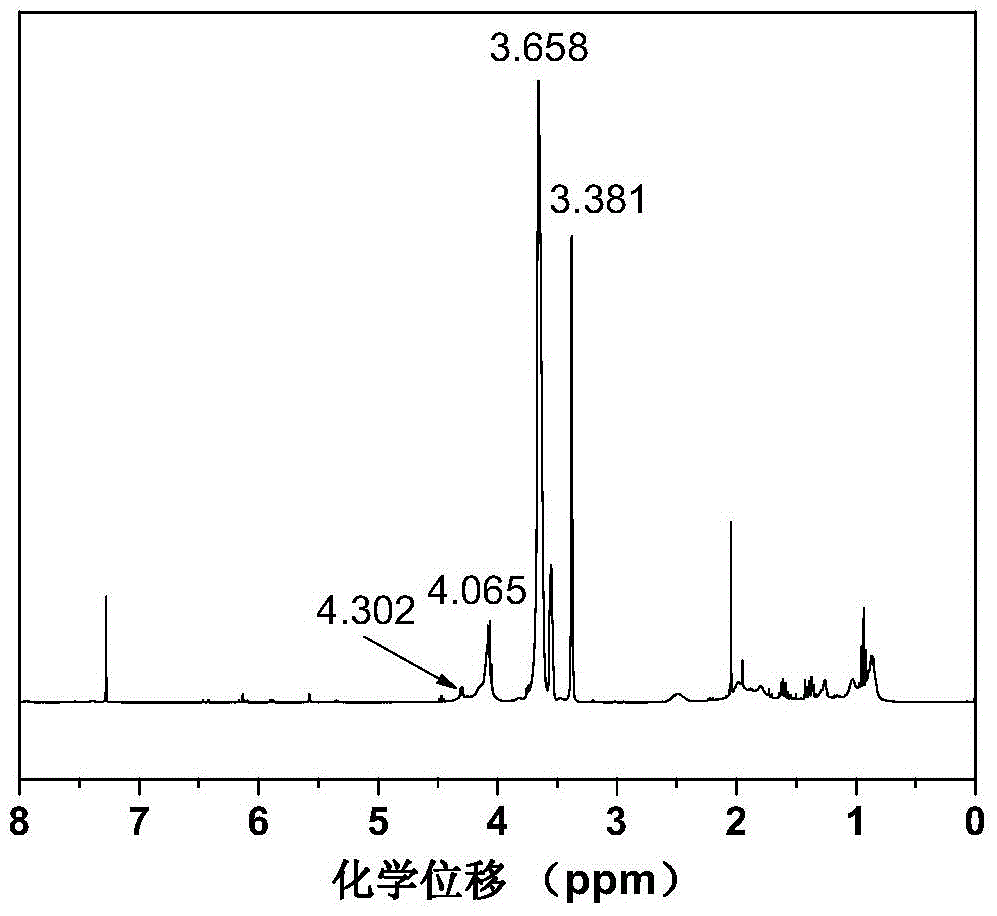

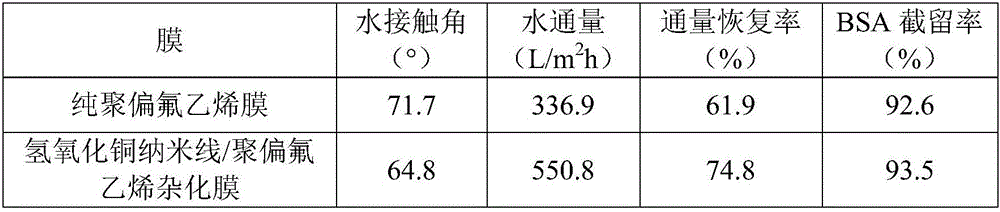

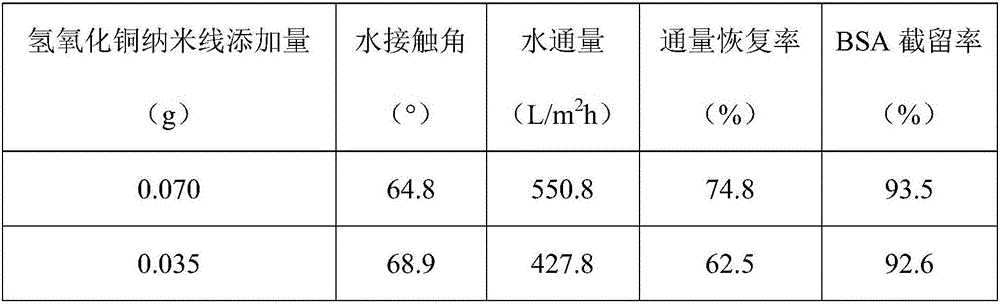

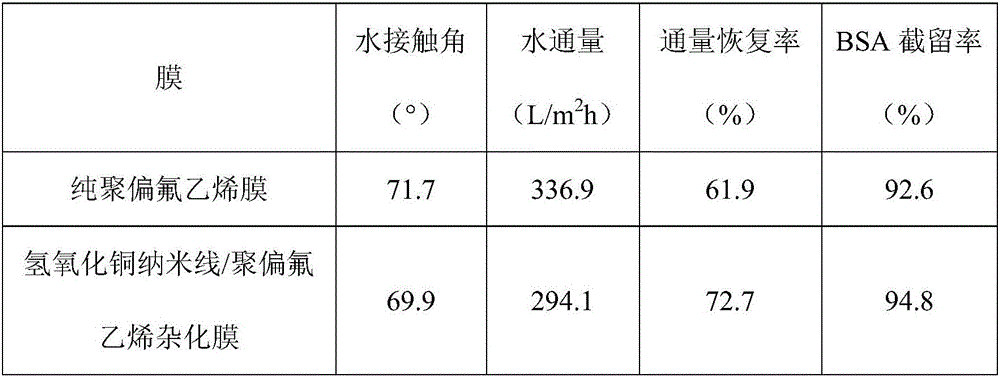

Copper hydroxide nanowire/polyvinylidene fluoride hybrid ultrafiltration membrane and preparation method thereof

InactiveCN106390777AImprove hydrophilicityIncrease water fluxMembranesUltrafiltrationNanowireUltrafiltration

The invention discloses a copper hydroxide nanowire / polyvinylidene fluoride hybrid ultrafiltration membrane and a preparation method thereof. The preparation method comprises the following steps: performing ultrasonic dispersion on a copper hydroxide nanowire in an organic solvent, adding polyvinylidene fluoride and a pore-foaming agent, stirring until the materials are uniformly mixed, standing and defoaming to obtain a membrane casting solution, and performing film scraping on a glass plate; then immersing into a coagulating bath, and preparing by an immerged phase-inversion process to obtain the copper hydroxide nanowire / polyvinylidene fluoride hybrid ultrafiltration membrane. The preparation method disclosed by the invention is simple in flow and convenient to operate; compared with a pure polyvinylidene fluoride ultrafiltration membrane, the prepared copper hydroxide nanowire / polyvinylidene fluoride ultrafiltration membrane has the advantages that the hydrophily is enhanced, and the water flux is also remarkably improved; besides, the antifouling property of the copper hydroxide nanowire / polyvinylidene fluoride hybrid ultrafiltration membrane is also greatly improved, the repeatability of the membrane is enhanced, the difficult problem that the polyvinylidene fluoride ultrafiltration membrane is difficultly popularized and used in a water treatment process due to strong hydrophobicity of the polyvinylidene fluoride ultrafiltration membrane is solved, and further industrial application is realized.

Owner:NORTHWEST UNIV(CN)

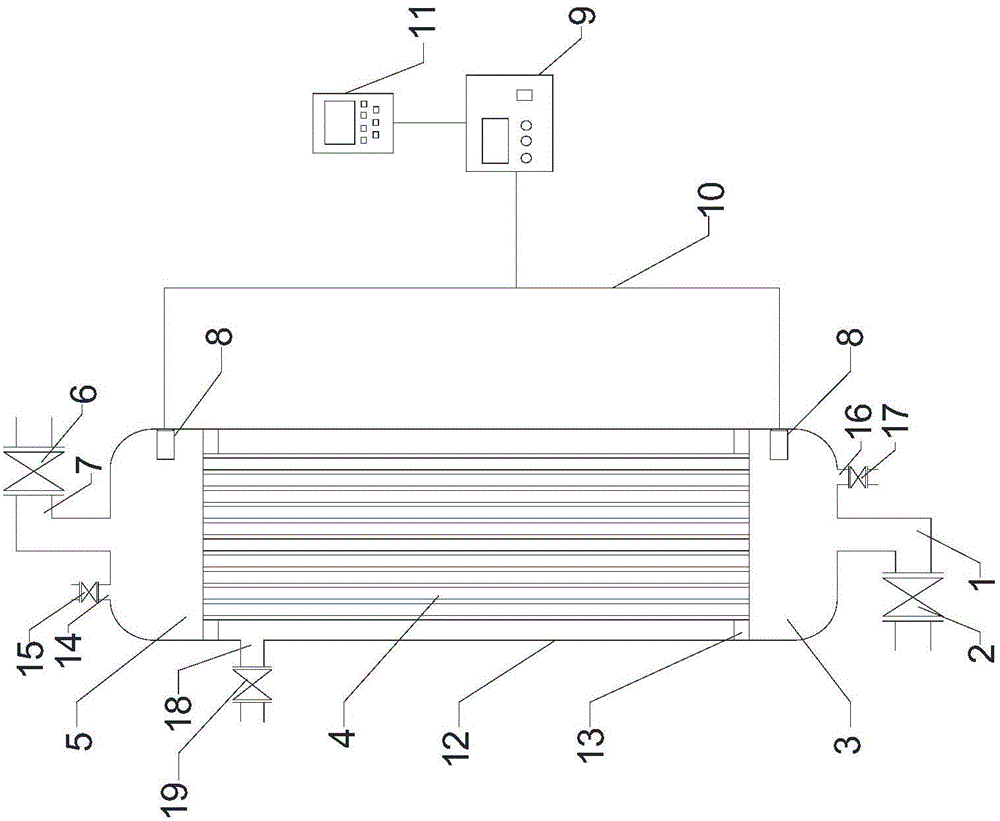

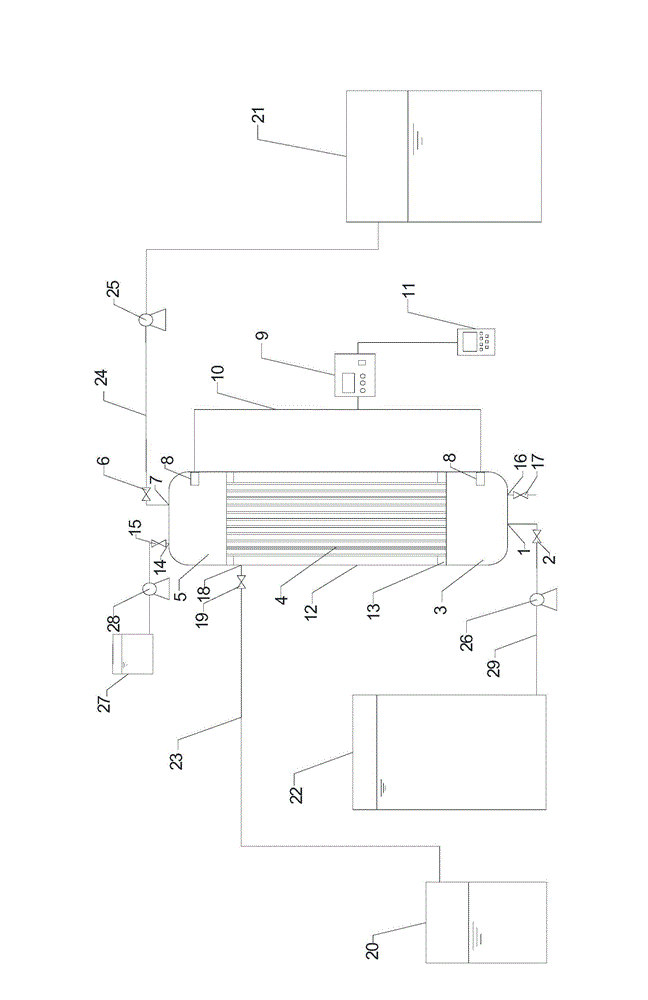

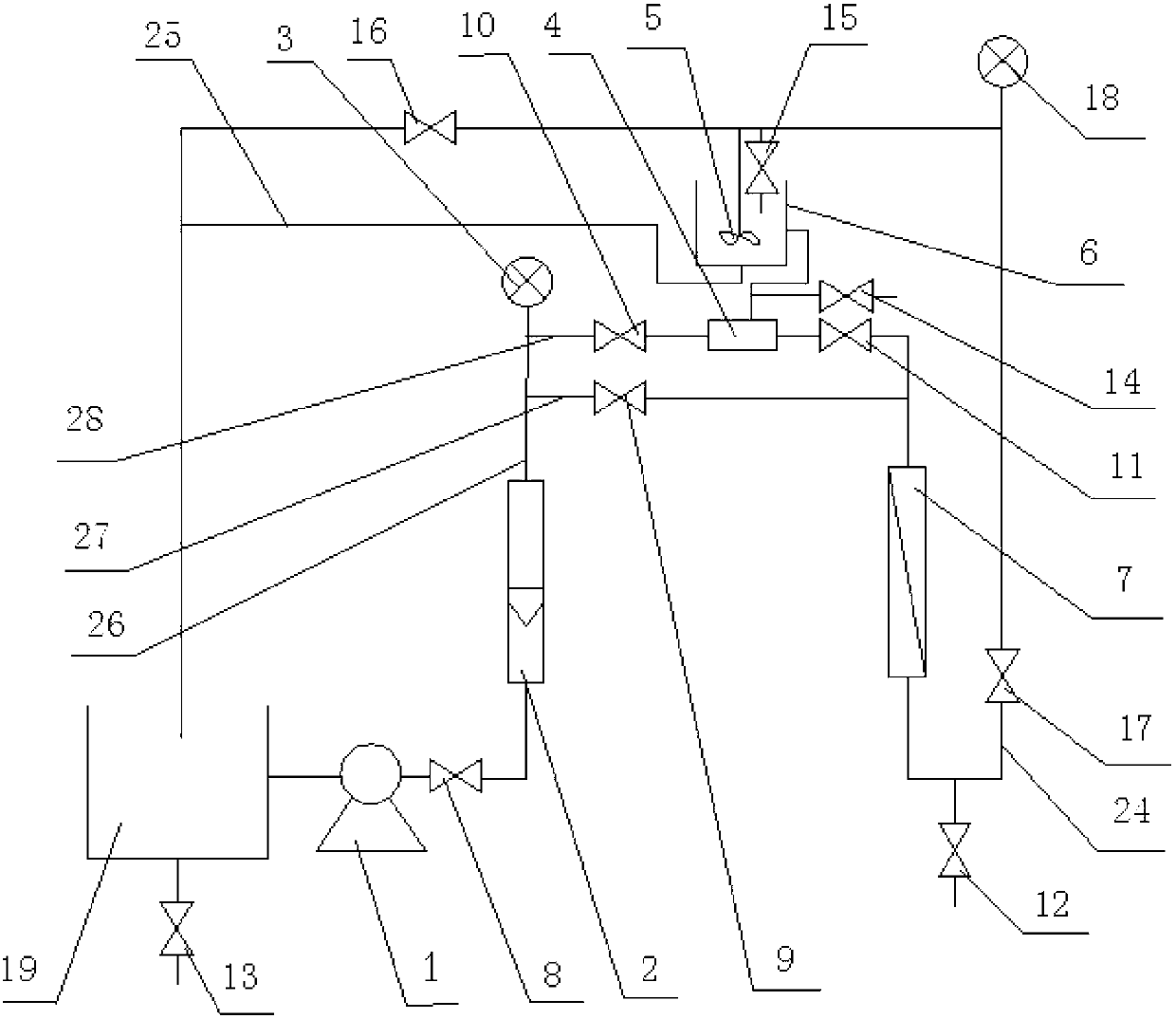

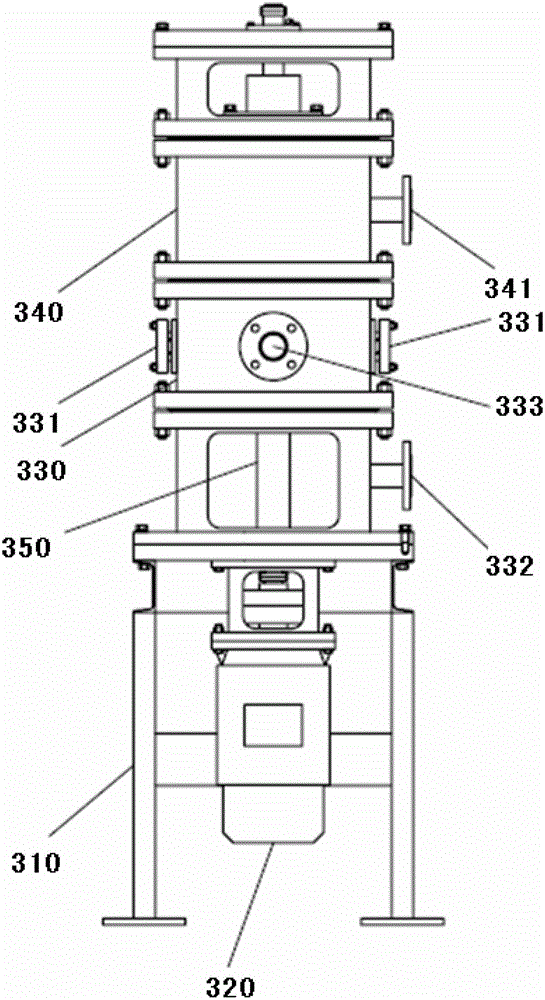

Membrane ultrasonic and synchronous incrustation removal ultrafiltration device and control method thereof

InactiveCN104528884AImprove throughputHigh flux recovery rateUltrafiltrationWater/sewage treatment bu osmosis/dialysisMicrocomputerConcentration polarization

The invention belongs to the field of water treatment technologies, and relates to a membrane ultrasonic and synchronous incrustation removal ultrafiltration device and a control method of the membrane ultrasonic and synchronous incrustation removal ultrafiltration device. A water inlet end ultrasonic contacting cavity and a water outlet end ultrasonic contacting cavity are arranged in the ultrafiltration device, an ultrasonic and synchronous incrustation removal system is installed inside the ultrafiltration device, and the ultrasonic and synchronous incrustation removal system mainly comprises an ultrasonic transducer, a connecting cable, an ultrasonic generator and a microcomputer time controller. When the ultrafiltration device works normally, ultrasonic and synchronous cleaning is controlled to be carried out on the ultrafiltration device through the time controller, the situation that incrustation crystals are attached to the surface of a membrane and grow into compact and stable incrustation can be avoided, membrane pollution is effectively controlled, and the cleaning period of the membrane is prolonged; through ultrasonic oscillation, the water flow state of on the surface of the membrane can be changed, and the phenomenon of concentration polarization on the surface of the membrane can be reduced. Meanwhile, when the ultrafiltration device is used for thorough cleaning, the ultrafiltration device can assist in mechanical cleaning, and therefore the cleaning effect is improved. By the adoption of the membrane ultrasonic and synchronous incrustation removal ultrafiltration device and the control method of the membrane ultrasonic and synchronous incrustation removal ultrafiltration device, the phenomenon of incrustation formation on the surface of the membrane can be effectively controlled, the purposes of maintaining high membrane flux, improving the working efficiency of the membrane and prolonging the service life can be achieved, and the application and popularization prospects are good.

Owner:HEBEI HAOYUAN ENVIRONMENTAL ENG

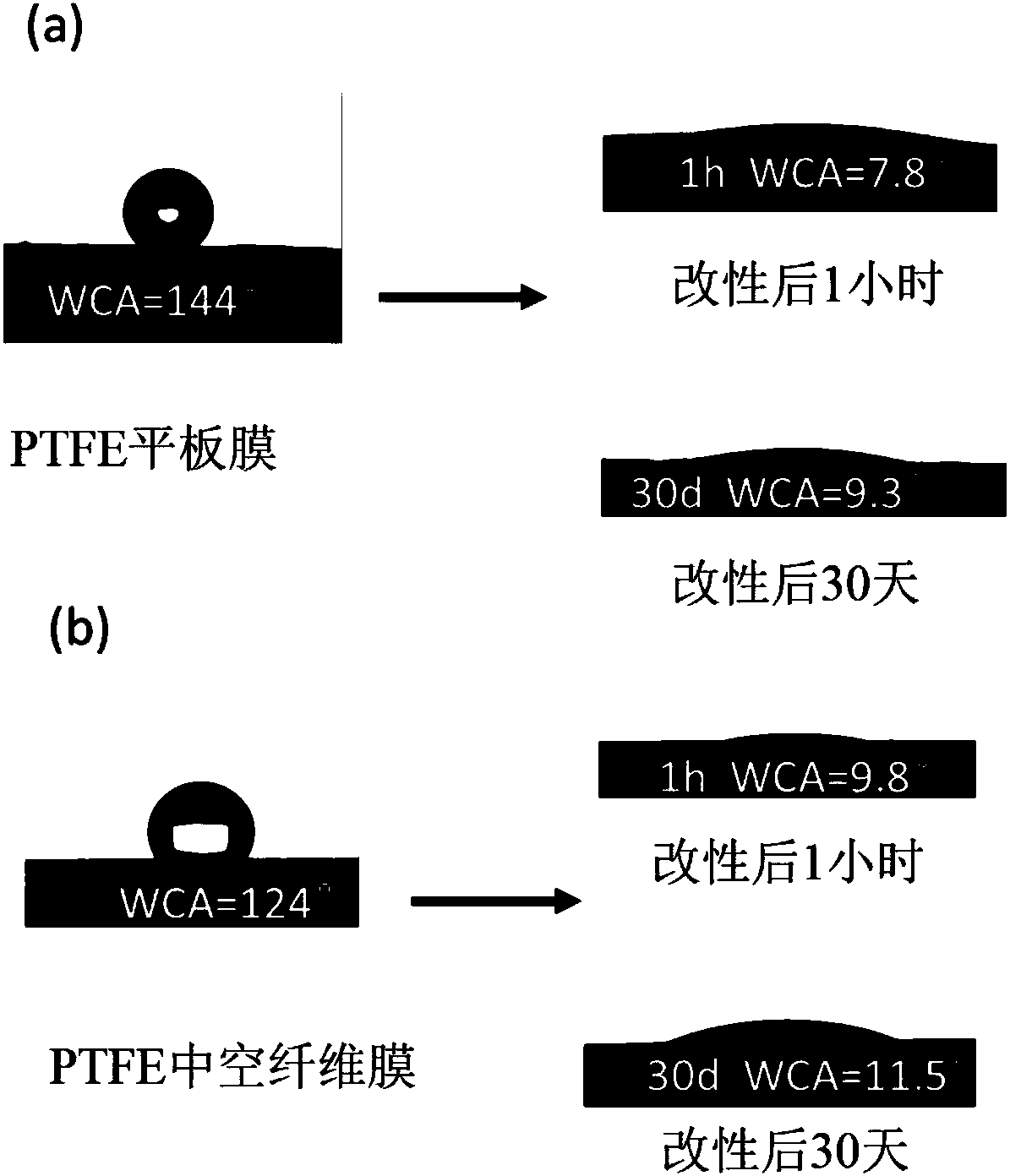

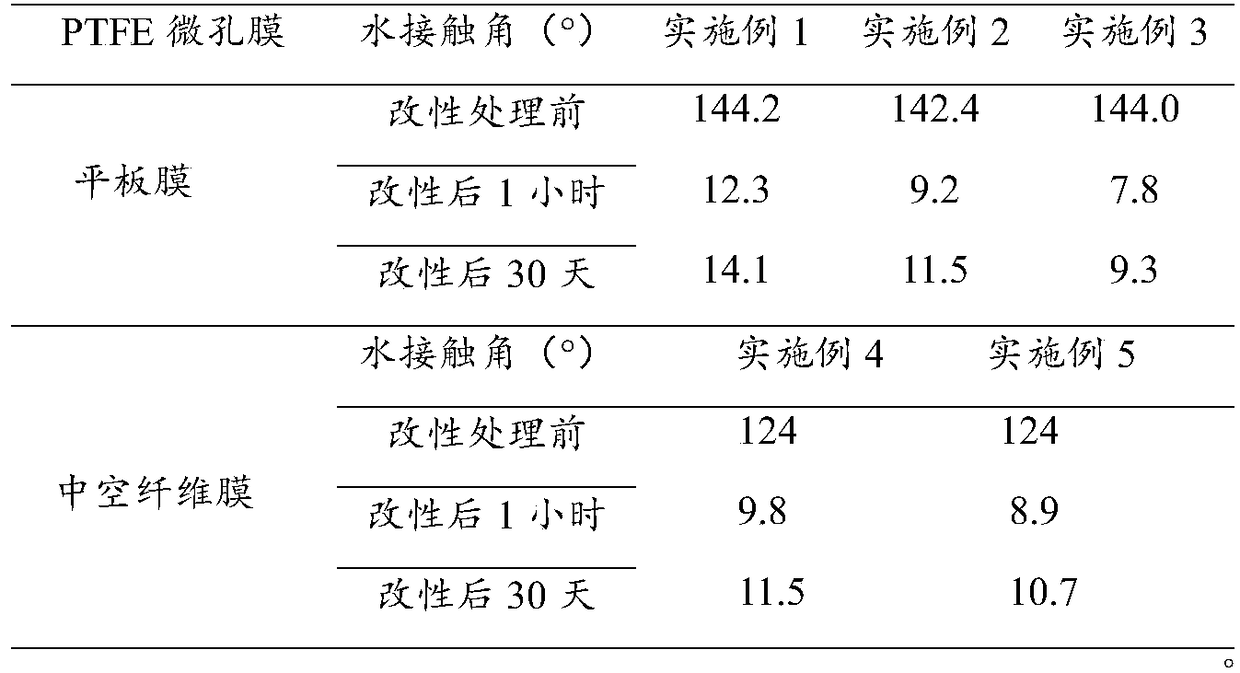

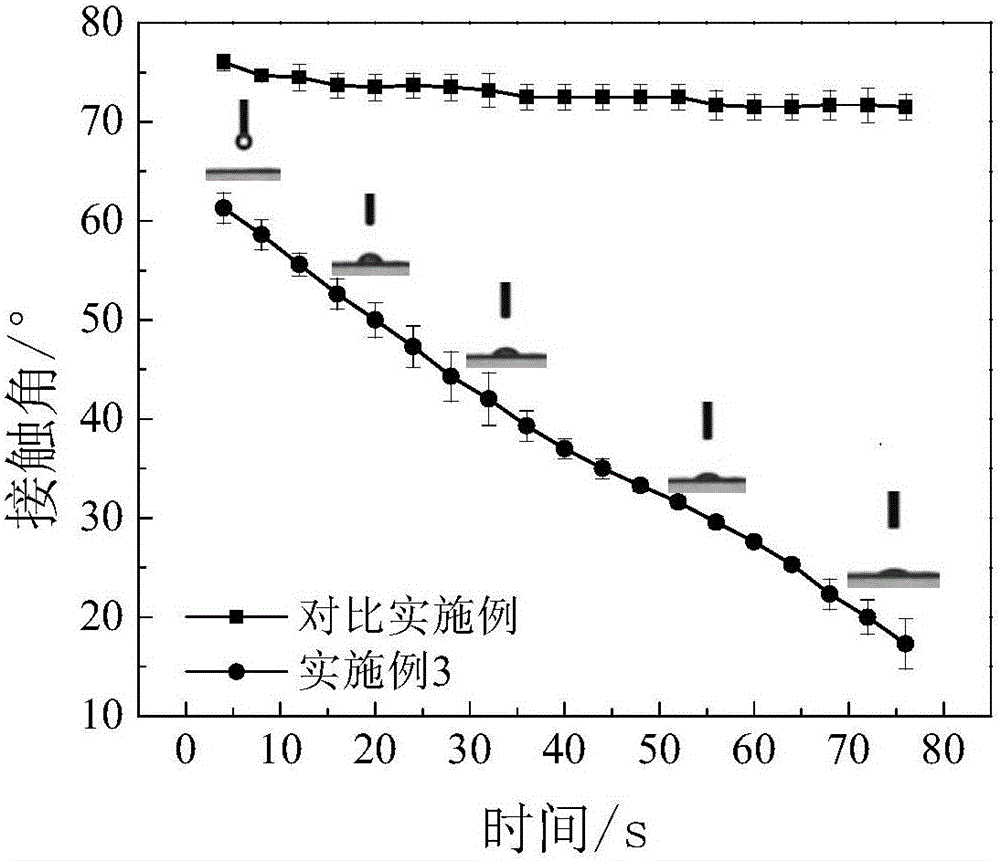

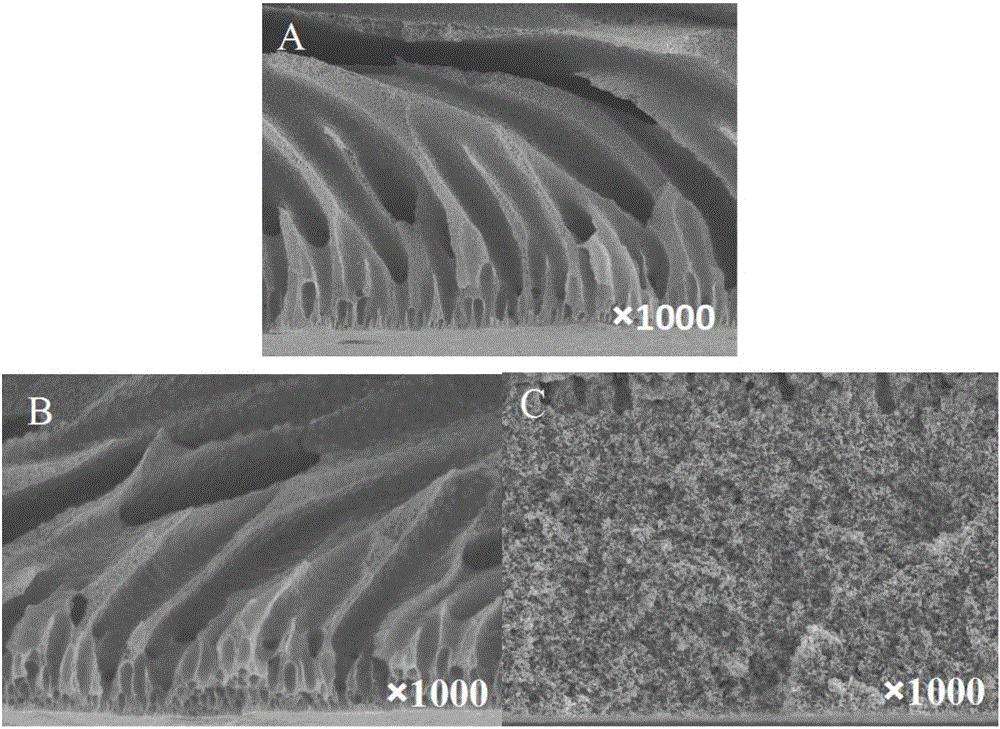

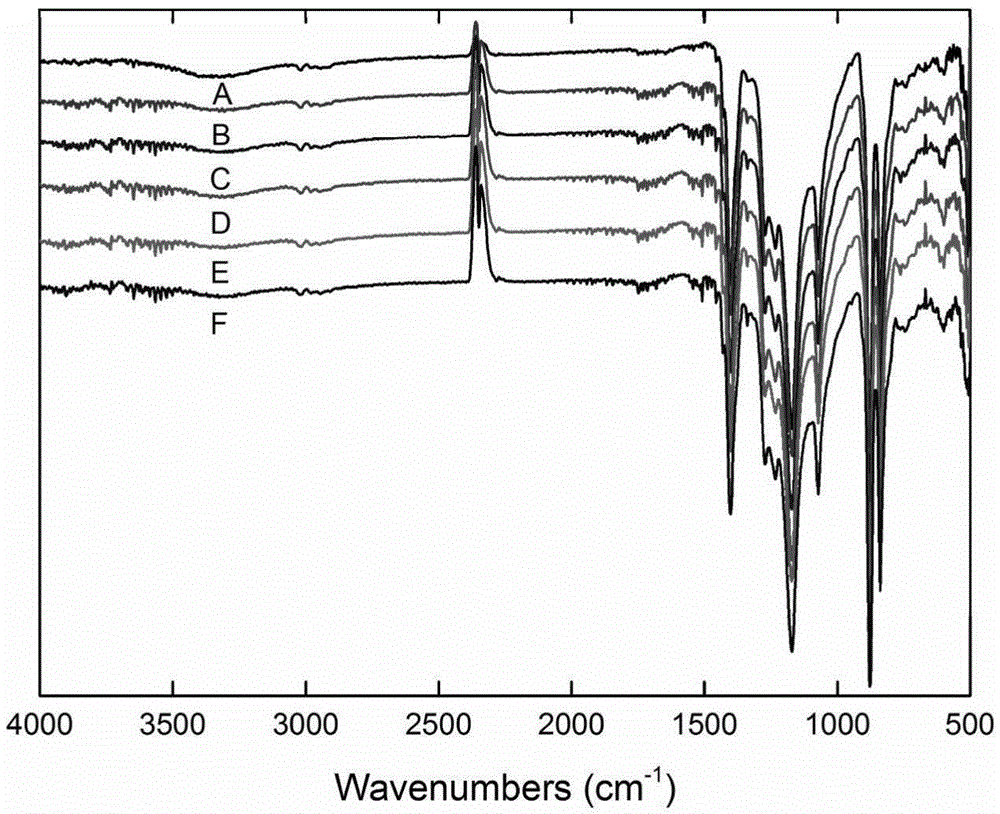

Hydrophilic modification method of polytetrafluoroethylene porous membrane

ActiveCN108211814AImprove hydrophilicitySimple processMembranesSemi-permeable membranesImpurityElectrolyte

The invention provides a hydrophilic modification method of a polytetrafluoroethylene porous membrane and belongs to the technical field of membranes. The hydrophilic modification method comprises thefollowing steps: washing the polytetrafluoroethylene porous membrane with alcohol to remove the impurities on the surface of the membrane, drying and then carrying out corona treatment to generate active groups on the surface of the membrane; putting the treated PTFE membrane in a polyelectrolyte solution containing a fluorocarbon surfactant, wherein the concentration of the fluorocarbon surfactant is 0.6-1.2wt%, and the concentration of polyelectrolyte is 0.5-3wt%; impregnating and reacting for 20-180 minutes, then taking the membrane out of the polyelectrolyte solution, washing the membranewith deionized water, and drying the membrane in vacuum to obtain a hydrophilic polytetrafluoroethylene porous membrane. The polytetrafluoroethylene porous membrane prepared by the method has excellent and lasting hydrophilcity and also has excellent anti-fouling performance; the contact angle between the polytetrafluoroethylene porous membrane and the water is less than 10 degrees.

Owner:中科瑞阳膜技术(北京)有限公司

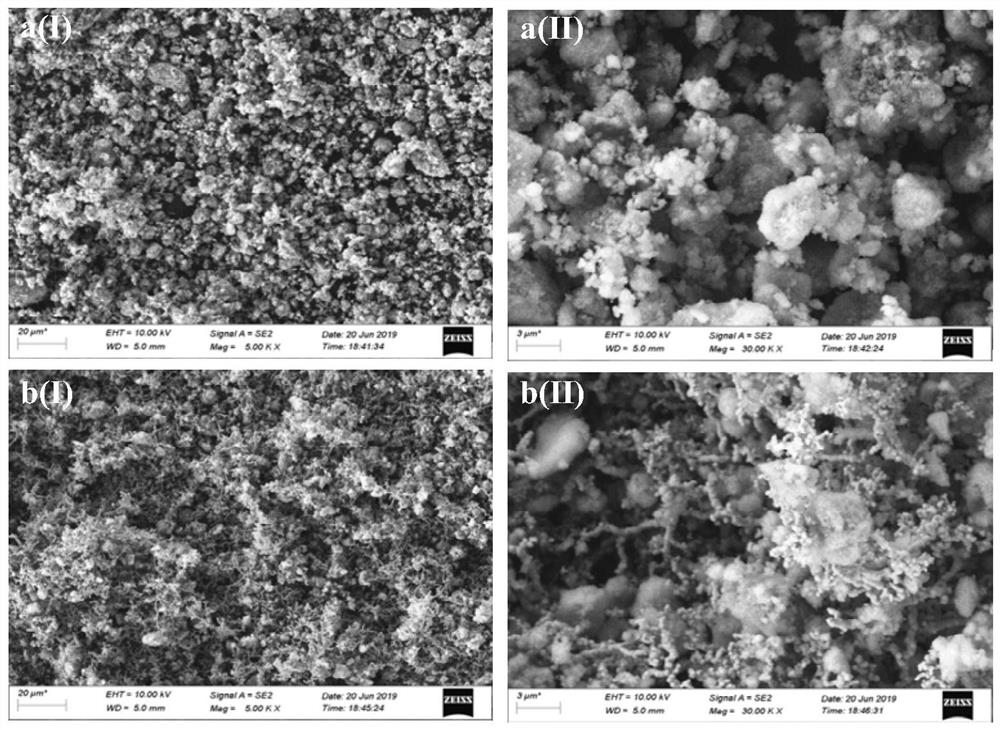

Preparation method for hydrophilic polyvinylidene fluoride (PVDF) antibacterial ultrafiltration membrane

InactiveCN105833742AHigh flux recovery rateGood antibacterial effectMembranesSemi-permeable membranesUltrafiltrationAntibacterial activity

The invention discloses a preparation method for a hydrophilic polyvinylidene fluoride (PVDF) antibacterial ultrafiltration membrane. The preparation method comprises the following steps: (1) ultrasonically mixing PVP, AgNO3 and F127 in a DMF dispersion liquid of graphene oxide, thereby acquiring a uniformly dispersed mixing casting film liquid system; (2) adding PVDF powder into the mixing casting film liquid system, magnetically stirring for 6-10h and acquiring a pre-reaction solution, wherein PVDF accounts for 15-19% of the total mass of the system; (3) carrying out vacuum degassing and sealing on the pre-reaction solution acquired in the step (2) and then putting into an oil bath at 50-80 DEG C, stirring for 6-12h, standing and de-foaming for 8-12h, thereby acquiring the casting film liquid containing antibacterial active ingredients; and (4) preparing a modified antibacterial ultrafiltration membrane according to an immersion precipitated phase inversion method. The preparation method disclosed by the invention is simple. The acquired PVDF membrane has the advantages of excellent hydrophilicity, high flux, strong anti-pollution capacity and higher antibacterial activity.

Owner:SHANGHAI INST OF TECH

Preparation method of modified polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane

InactiveCN105327624AImprove hydrophobic propertiesImprove overall performanceSemi-permeable membranesPolyvinylidene fluorideCarboxylation

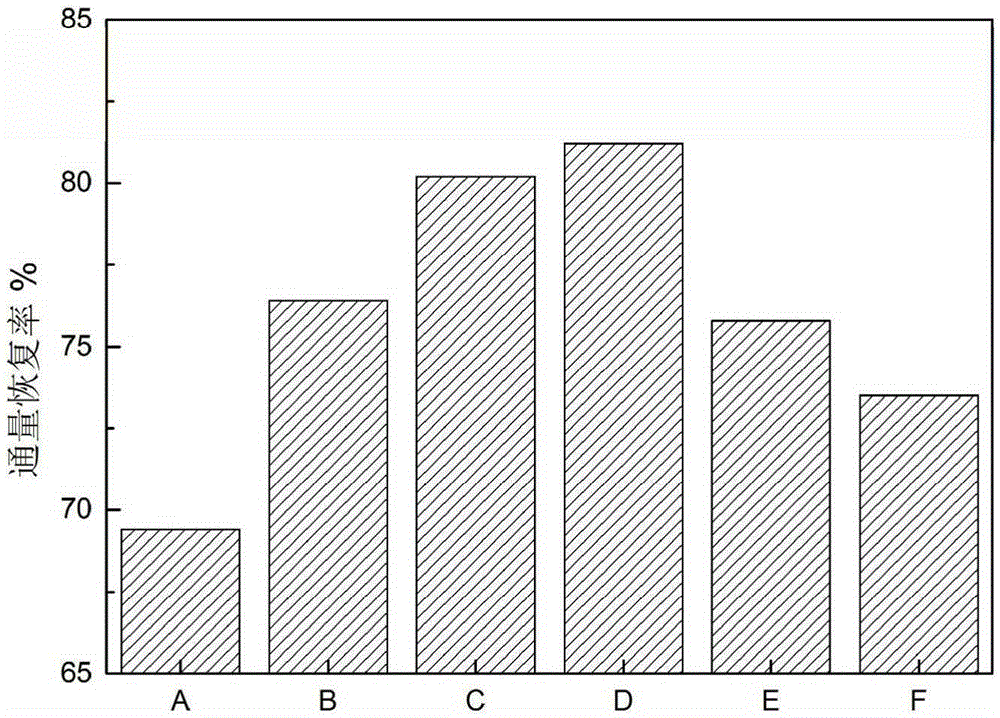

The invention relates to a preparation method of a modified polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane. The preparation method comprises the following steps of preparing membrane casting solution, wherein the membrane casting solution is prepared by polyvinylidene fluoride powder, polyvinyl alcohol powder, carboxylation multiwalled carbon nanotubes and dimethyl sulfoxide solvent; fully dispersing the carboxylation multiwalled carbon nanotube in the dimethyl sulfoxide solvent, then sequentially adding binary membrane materials prepared by the polyvinylidene fluoride powder and the polyvinyl alcohol powder, controlling the temperature to be 95 to 105 DEG C, mechanically stirring and dissolving, and obtaining uniform membrane casting solution; then after fully defoaming the obtained membrane casting solution at the temperature of 40 to 60 DEG C, scraping the membrane on a glass plate; immersing the glass plate with a membrane casting solution thin layer into coagulation bath with the temperature of 25 to 35 DEG C to split phases to form the membrane, taking out after soaking in deionized water for 5 to 7 days, naturally drying, and storing. According to the binary composite ultrafiltration membrane provided by the invention, the flux recovery rate can achieve 81.2 percent, and the binary composite ultrafiltration membrane has good hydrophilic and antifouling property.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

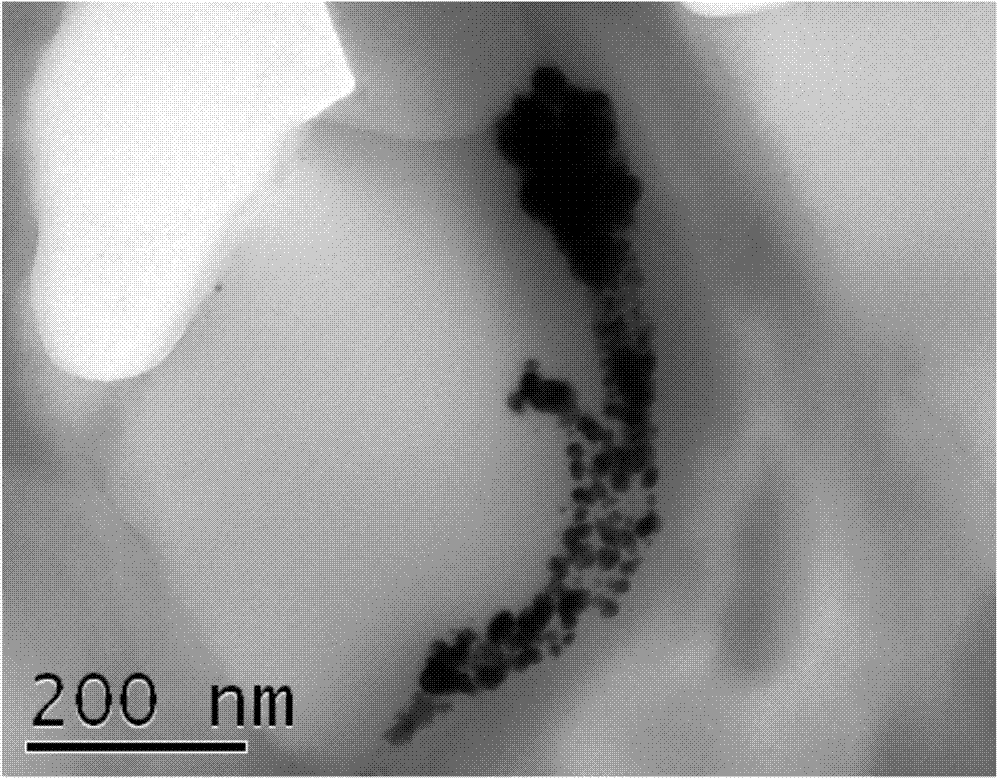

Production method of nano-silver/silica core-shell doped PVDF ultrafilter membrane

InactiveCN106582324AOvercome reunionOvercoming filterabilityMembranesUltrafiltrationFast releasePerformance-Enhancing Effects

The invention relates to a production method of a modified PVDF ultrafilter membrane, and concretely relates to a production method of a nano-silver / silica core-shell doped PVDF ultrafilter membrane. The purpose of the invention is to solve the problems of easiness in agglomeration of nano-silver the membrane, fast release rate in the membrane filtering process and unobvious anti-pollution performance enhancing effect on the PVDF ultrafilter membrane of present silver doped PVDF ultrafilter membranes. The method comprises the following steps: 1, preparing a PVDF solution; 2, preparing a nano-silver / silica core-shell particle-containing mixed solution; 3, preparing a casting solution; and 4, carrying out curtain coating to form a membrane in order to obtain the nano-silver / silica core-shell doped PVDF ultrafilter membrane. The pure water flux of the in-situ synthesized nano-silver / silica core-shell doped PVDF ultrafilter membrane produced in the invention is 120-250 L / m<2>.h. The production method of the nano-silver / silica core-shell doped PVDF ultrafilter membrane is obtained in the invention.

Owner:HARBIN INST OF TECH

Anti-fouling high-throughput polysulfone composite membrane

InactiveCN105854650AImprove hydrophilicityImprove water permeabilitySemi-permeable membranesMembranesSolventPolyvinylidene fluoride

The invention discloses an anti-fouling high-throughput polysulfone composite membrane. The anti-fouling high-throughput polysulfone composite membrane is prepared from, by weight, 50-80 parts of caprolactam-modified polysulfone, 10-20 parts of sulphonated polysulfone, 2-15 parts of polyvinylidene fluoride, 5-15 parts of polydiphenylmethylene acrylic polyurethane, 1-5 parts of polydiphenylmethylene vinyl polyurethane, 1-3 parts of perfluorinated sulfonic acid resin, 35-80 parts of a solvent, 1-4 parts of polyaniline nanofibers, 1-2 parts of nanometer zirconia, 0.1-0.5 part of nanometer lanthanum oxide, 1-2 parts of nanometer titanium dioxide, 0.2-1.5 parts of a modified boron nitride silane coupling agent, 0.3-1.5 parts of cellulose acetate, 0.5-3 parts of a polystyrene-alt-maleic anhydride copolymer and 0.5-3 parts of carboxyl betaine methacrylate. The anti-fouling high-throughput polysulfone composite membrane is good in thermal stability, excellent in weather resistance and anti-fouling performance and high in throughput.

Owner:安庆市天虹新型材料科技有限公司

Anti-pollution and high-flux ultrafiltration membrane, preparation method thereof and membrane casting solution

ActiveCN104492285AAperture controllableUniform pore size distributionSemi-permeable membranesOrganic acidHigh flux

The invention relates to a membrane casting solution for preparing an anti-pollution and high-flux ultrafiltration membrane. The membrane casting solution is prepared from the following components by weight: 16-30% of polyether sulfone, 1-6% of a mutual matching pore forming agent, 0.5-5% of an organic acid additive and 60-80% of a solvent. The invention also relates to the anti-pollution and high-flux ultrafiltration membrane and a preparation method thereof. The tubular or flat ultrafiltration membrane prepared from the membrane casting solution has the characteristics of uniform pore size distribution, high membrane flux, good stability, strong pollution resistance, high flux recovery rate after backwashing, wide range of application, good mechanical strength and chemical resistance, and is applicable to high viscosity and high solid content system. Compared with other preparation method, the preparation method has the characteristics of simple process, controllable membrane pore size, low cost and convenience for industrialized production.

Owner:JIANGSU KAIMI MEMBRANE TECH

Cleaning method and cleaning system of tubular membrane

InactiveCN103341324AHigh flux recovery rateStable fluxSemi-permeable membranesParticle flowEngineering

The invention discloses a cleaning method and a cleaning system of a tubular membrane, and provides a cleaning method and a cleaning system which can recover the membrane flux. The cleaning method comprises the following steps of: cleaning with clean water; cleaning through mixing particles, clean water and air: after mixing particles, clean water and air, and cleaning the mixture of particles, clean water and air in the tubular membrane, wherein air bubbles are broken caused by the collision of air bubbles and particles, energy is released extensively to cause partial vibration, and meanwhile, the particles and air bubbles are both rubbed with the membrane so as to lead to falling of pollutants on the surface of the membrane; and discharging the pollutants to complete the cleaning process. According to the cleaning method disclosed by the invention, the step of cleaning by mixing particles, clean water and gases is added; the air bubbles generated by the gases can be collided with the particles, and energy is released extensively so as to lead to partial vibration; turbulence is formed in a membrane component; particles flow rapidly in a system; and the air bubbles and particles are both rubbed with the surface of the membrane so as to remove surface pollutants. The cleaning effect and the cleaning efficiency can be improved greatly by combining with two aspects.

Owner:TIANJIN POLYTECHNIC UNIV

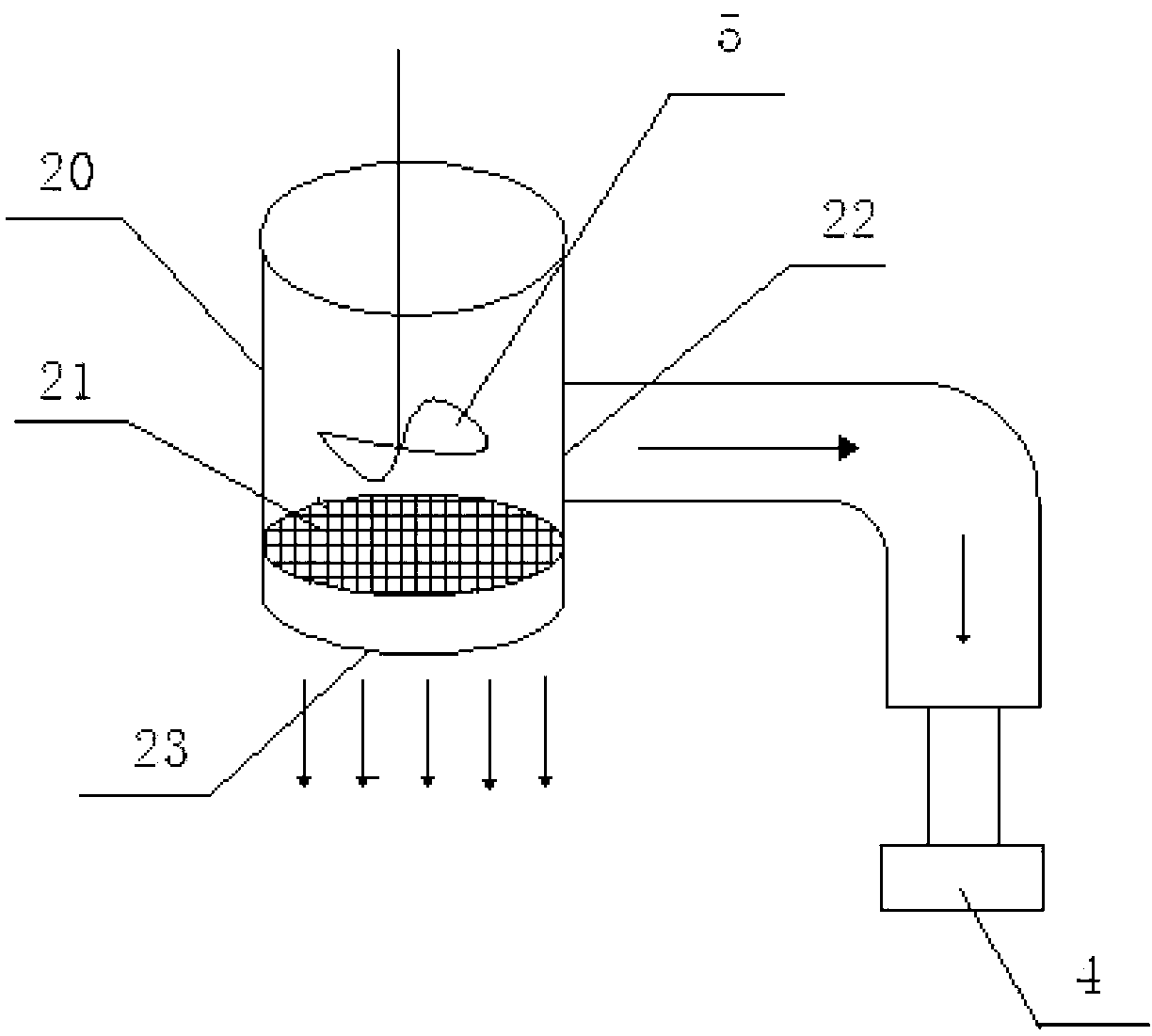

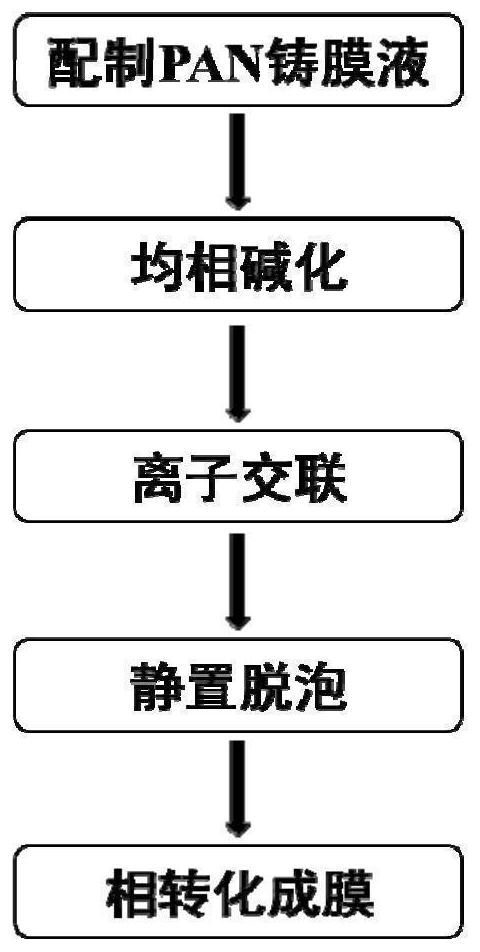

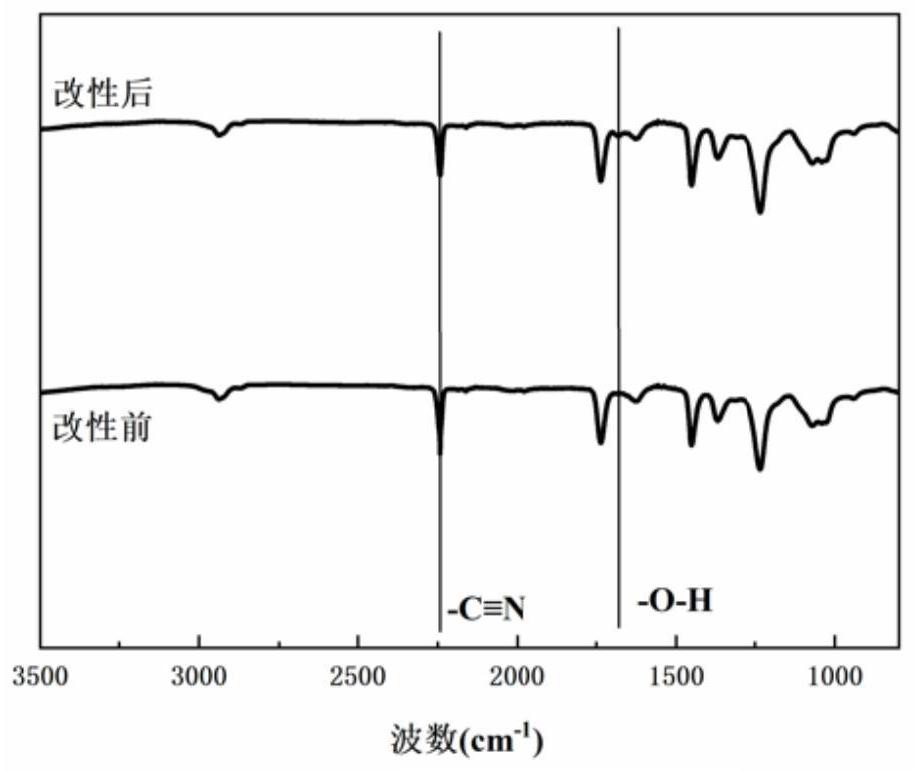

Hydrogel ultrafiltration membrane as well as preparation method and application thereof

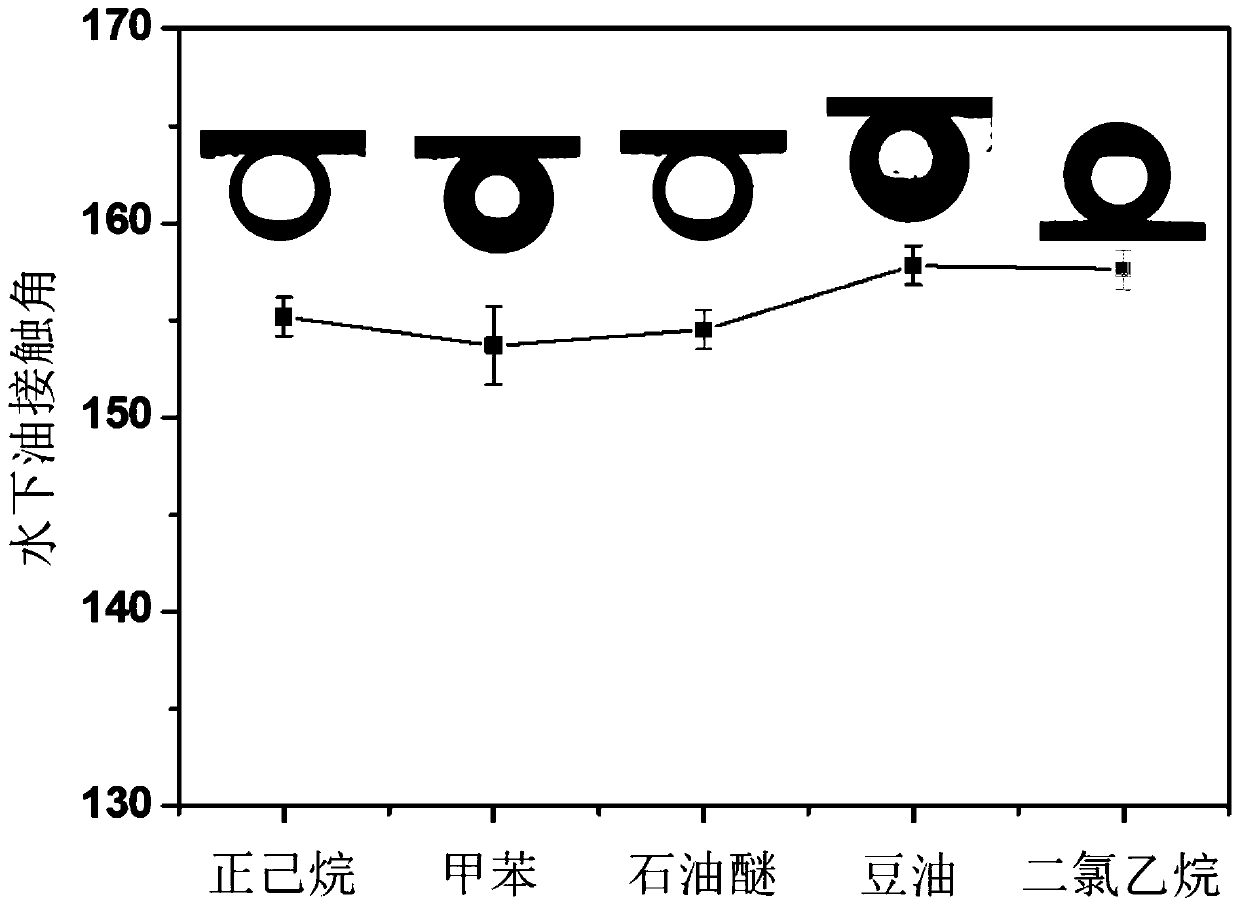

ActiveCN111701461AImprove separation efficiencyEasy to separateSemi-permeable membranesMembranesAcrylonitrileOrganic chemistry

The invention belongs to the technical field of membrane preparation, and discloses a hydrogel ultrafiltration membrane as well as a preparation method and application thereof. The preparation methodof the hydrogel ultrafiltration membrane comprises the following steps: 1) preparation of a polyacrylonitrile membrane casting solution: dissolving polyacrylonitrile in DMF to prepare the polyacrylonitrile membrane casting solution; 2) homogeneous alkalization of polyacrylonitrile: dropwise adding a NaOH aqueous solution into the polyacrylonitrile membrane casting solution under the conditions ofheating and stirring, and reacting for a period of time; 3) cross-linking to form hydrogel: dropwise adding a DMF solution containing metal ions into the membrane casting solution, continuously reacting for a period of time, and performing standing defoaming treatment under a heating condition after the reaction is finished; and 4) performing phase inversion on the membrane casting solution treated in the step 3) to prepare the hydrogel ultrafiltration membrane, The hydrogel ultrafiltration membrane disclosed by the invention not only has super-hydrophilicity-underwater super-oleophobicity andlarge water flux, but also has high separation efficiency when being used for oil-water separation; the preparation process is simple, complex equipment is not needed, and the hydrogel ultrafiltration membrane is suitable for large-scale production.

Owner:NANJING UNIV

Anti-pollution composite reverse osmosis membrane and preparation method thereof

ActiveCN112870989ASimple processStrong industrial operabilitySemi-permeable membranesGeneral water supply conservationPolyvinyl alcoholReverse osmosis

The invention provides an anti-pollution composite reverse osmosis membrane and a preparation method thereof. The composite reverse osmosis membrane comprises a polyamide reverse osmosis membrane and an antifouling layer located on the surface of the polyamide reverse osmosis membrane, and the antifouling layer comprises tannic acid and polyvinyl alcohol. The method comprises the step of making the polyamide reverse osmosis membrane contact with a coating solution, wherein the coating solution is an aqueous solution containing tannic acid and polyvinyl alcohol. The surface of the polyamide reverse osmosis membrane is coated with the coating solution through a one-step method, the process is simple, and the industrialization operability is high. The anti-pollution composite reverse osmosis membrane disclosed by the invention is high in flux, good in selectivity, strong in anti-pollution property and long in service life, has a hydrophilic smooth surface in appearance, and is beneficial to later-stage assembly rolling of the membrane.

Owner:中化(宁波)润沃膜科技有限公司

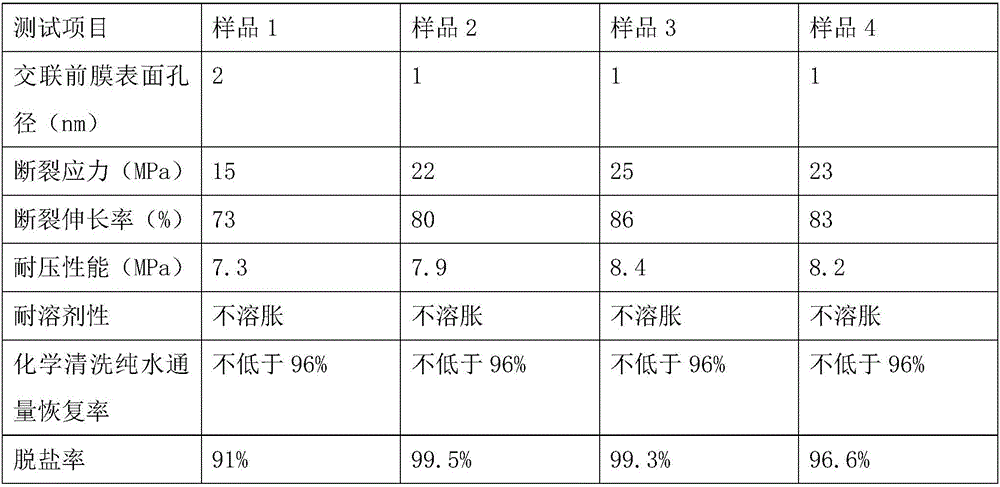

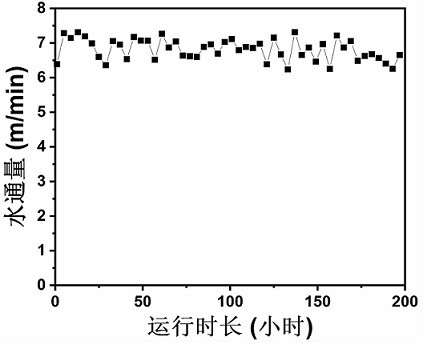

High-strength, solvent-resistant and anti-pollution hollow fiber reverse osmosis membrane and preparation method thereof

ActiveCN106512758AIncrease contentImprove acid and alkali hydrolysis resistanceMembranesSemi-permeable membranesFiberReverse osmosis

The invention discloses a high-strength, solvent-resistant and anti-pollution hollow fiber reverse osmosis membrane. The reverse osmosis membrane is prepared from components in parts by weight as follows: 65-70 parts of a hydroxyl-containing polymer, 4.9-9.9 parts of hydroxyl-containing hydrophilic inorganic nanoparticles, 0.1-0.3 parts of an antioxidant and 15-30 parts of a plasticizer. The invention further discloses a preparation method of the reverse osmosis membrane. The high-strength, solvent-resistant and anti-pollution hollow fiber reverse osmosis membrane can form an effective desalination layer, has higher hydrophilic performance, high acid and base hydrolysis resistance and solvent resistance and excellent mechanical properties and is high in chemical cleaning pure water flux recovery rate, high in desalination rate and high in pollution resistance. The problems that hollow fiber membranes prepared through traditional interfacial polymerization have non-uniform desalination layer thickness and low desalination rate. The preparation method is simple to operate, the conditions are mild and easy to control, and the cost is low.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

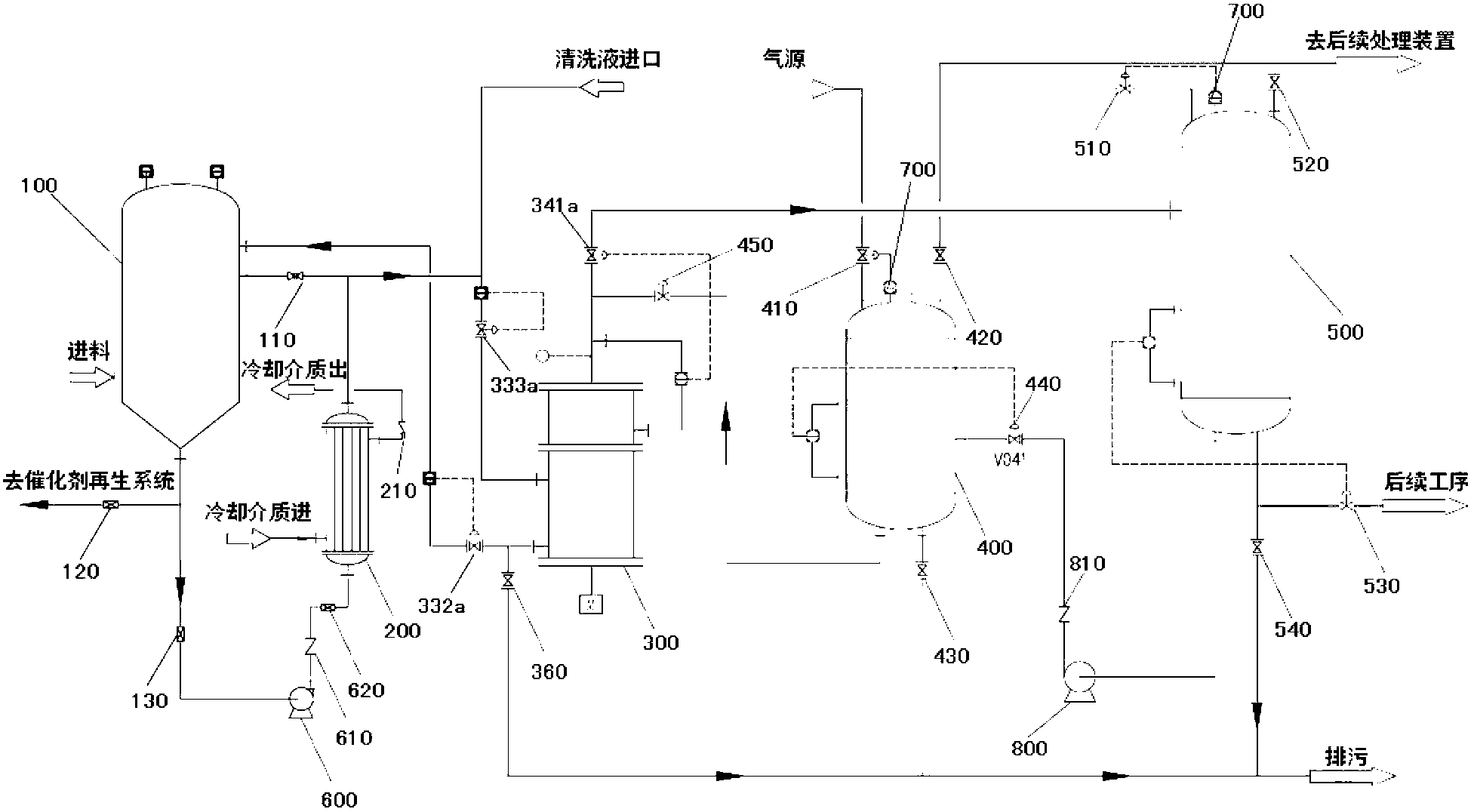

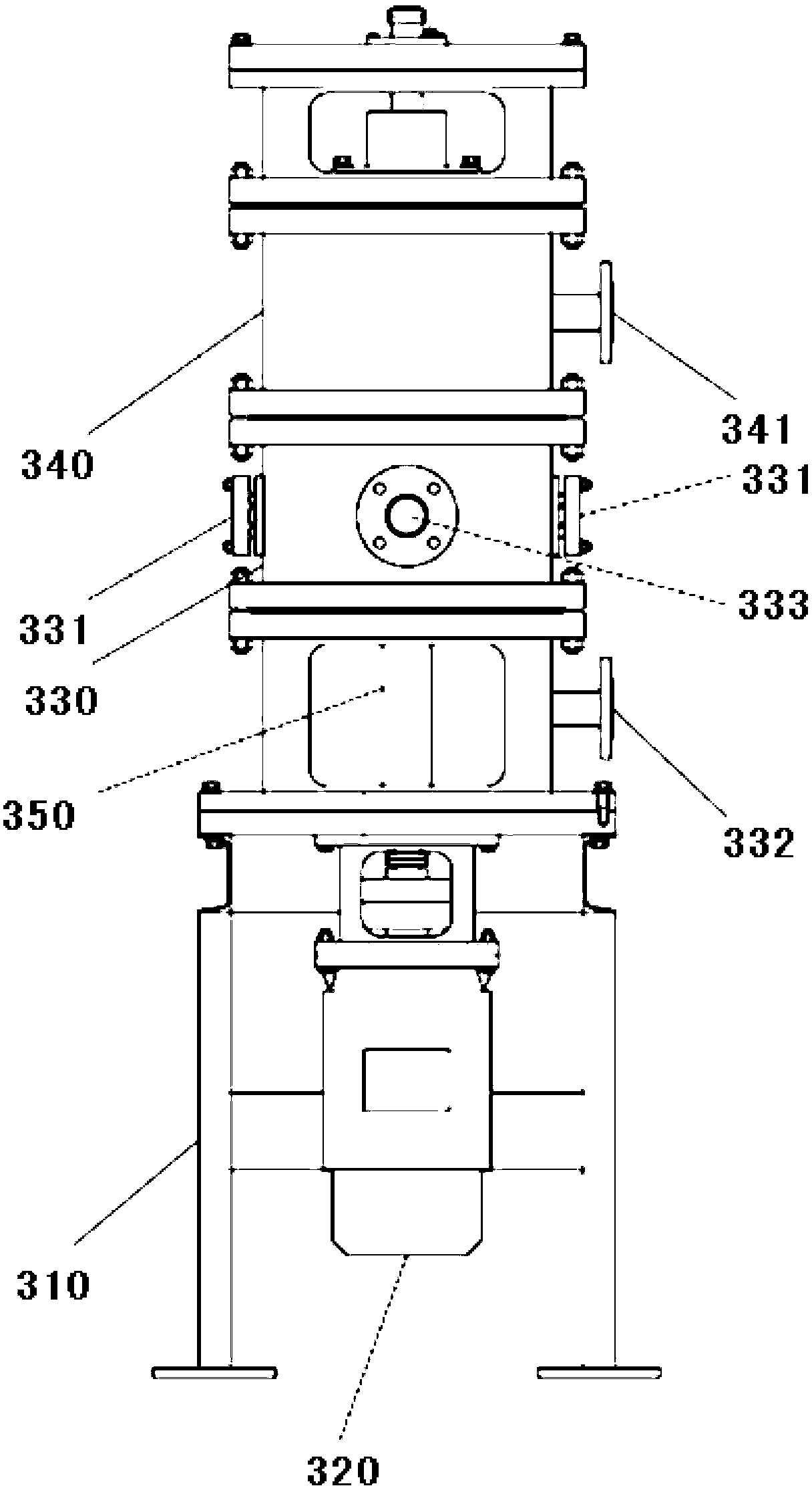

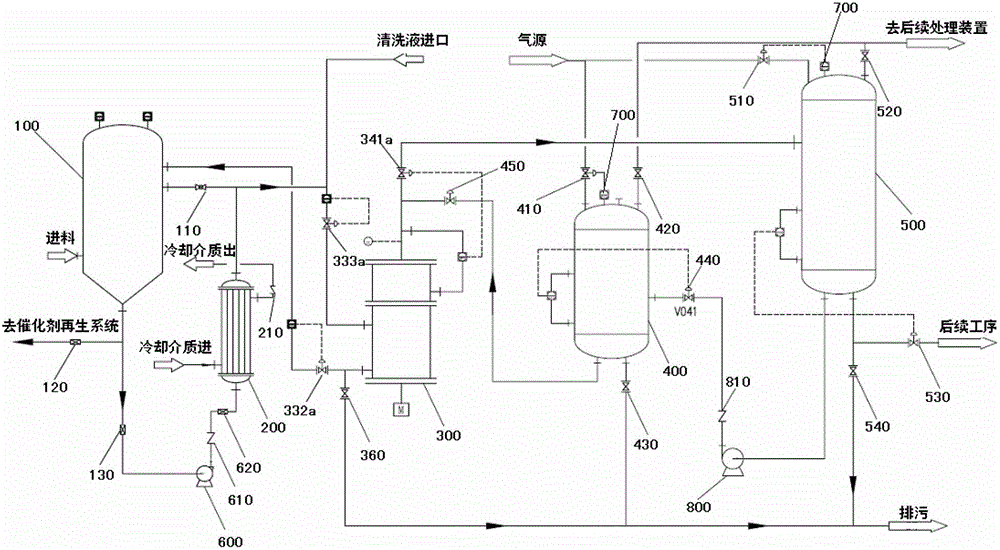

Dynamic disc membrane device applied to recycling of ultrafine solid catalyst and technology of device

The invention discloses a dynamic disc membrane device applied to recycling of an ultrafine solid catalyst and a technology of the device. The dynamic disc membrane device comprises a reaction kettle, a reaction kettle discharging heat exchanger, at least one dynamic disc seperation unit, a back washing tank and a clear liquid tank, wherein the dynamic disc seperation unit comprises a device support, a motor arranged on the device support, a membrane seperation tank arranged on the device support, a clear liquid buffer tank arranged on the membrane seperation tank and a rotating shaft connected with the motor and the membrane seperation tank; a dynamic disc membrane component is arranged in the membrane seperation tank and comprises 1 to 100 dynamic disc membranes; the dynamic disc membrane is a microfiltration or ultrafiltration ceramic disc membrane, the pore diameter of the ceramic disc membrane is 7nm-30mu m, and the diameter of the dynamic disc membrane component is 50-400mm. Microfiltration or ultrafiltration ceramic discs are adopted in the dynamic disc membrane device for cross-flow filtration and have high permeation flux so that the investment cost of the device is reduced while technological processes are shortened, a discharging effect is stale, and the retention rate of the superfine catalyst is above 99%.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

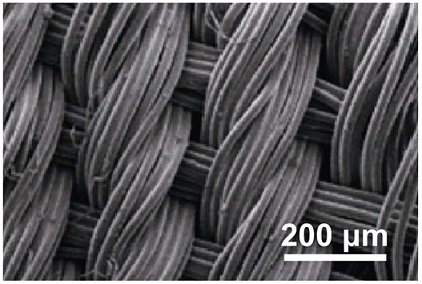

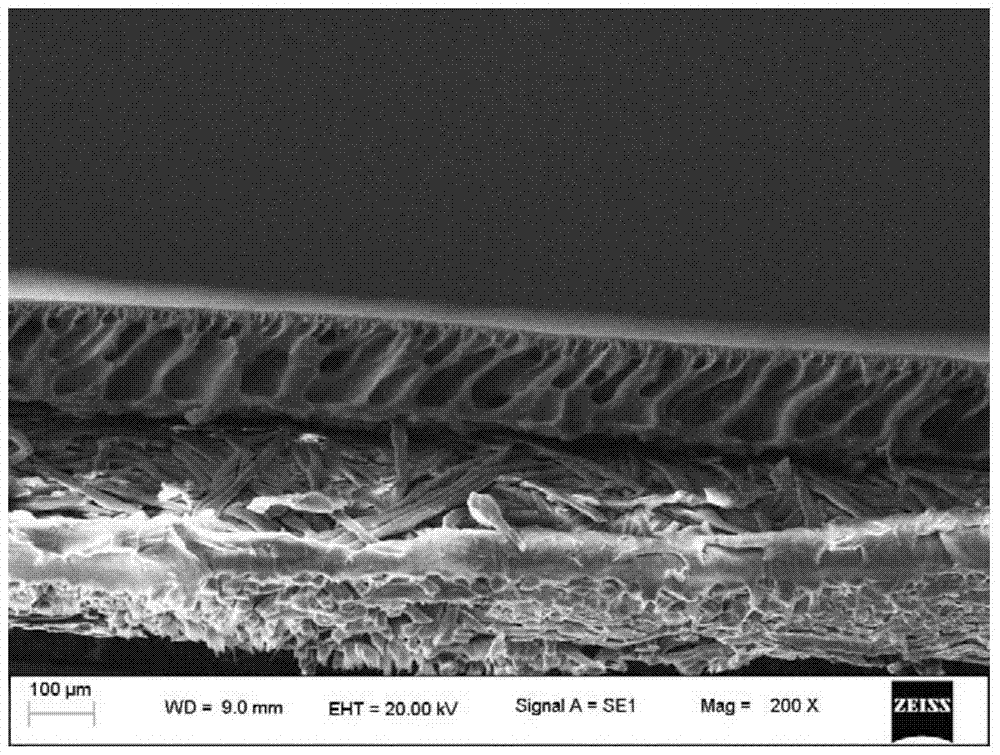

High-performance anti-scaling modified filter cloth for vacuum filter and preparation method of high-performance anti-scaling modified filter cloth

PendingCN114525674ANot easy to precipitateNot easy to stickPhysical treatmentFibre typesPolymer modifiedNanoparticle

The invention relates to high-performance anti-scaling modified filter cloth for a vacuum filter and a preparation method of the high-performance anti-scaling modified filter cloth. The preparation process comprises the following steps: (1) dispersing an amphoteric polymer modifier and nanoparticles in deionized water to prepare a modified solution; wherein the mass concentration of the amphoteric polymer modifier is 0.1-2 wt%, and the mass concentration of the nanoparticles is 0.1-5 wt%; (2) soaking the filter cloth in the modified solution prepared in the step (1) for 1-24 hours, taking out the filter cloth, and heating the filter cloth at 50-70 DEG C for 1-5 hours; (3) preparing a polyvinylidene fluoride solution with the mass concentration of 0.1-1wt% by taking chloroform as a solvent, and soaking the filter cloth treated in the step (2) into the polyvinylidene fluoride solution for 1-5 hours; and (4) performing ultraviolet irradiation on the filter cloth treated in the step (3). The modified filter cloth provided by the invention has the advantages of high water flux, long operation time, high flux recovery rate after cleaning and the like.

Owner:HEBEI IRON & STEEL GRP MINING

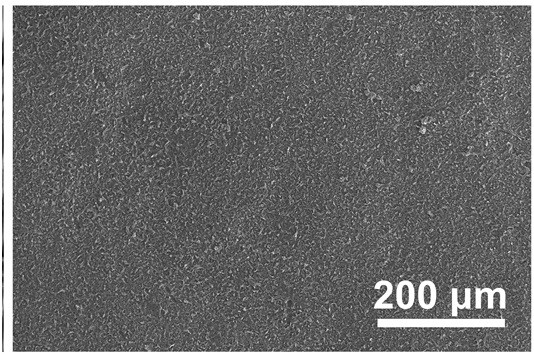

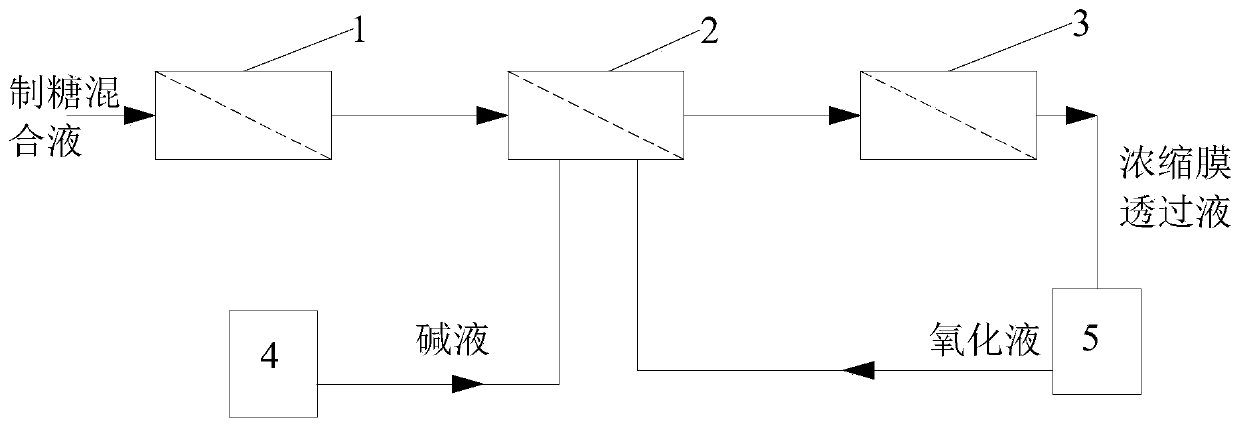

Cleaning system and method for decolorizing membrane in membrane-process sugar making system

ActiveCN111286561AReduce usageEmission reductionSemi-permeable membranesPurification by physical meansMicroorganismCatalytic oxidation

The invention provides a cleaning system and a cleaning method for a decolorizing membrane in a membrane-process sugar making system. The membrane-process sugar making system comprises a clarificationmembrane filtering unit, a decolorizing membrane filtering unit and a concentration membrane filtering unit which are connected in sequence. The cleaning system comprises an alkali cleaning unit andan enzyme catalytic oxidation unit. A liquid outlet of the alkali cleaning unit is connected with a liquid inlet of the decolorizing membrane filtering unit. A liquid inlet of the enzyme catalytic oxidation unit is connected with a permeate liquid outlet of the concentration membrane filtering unit, and a liquid outlet of the enzyme catalytic oxidation unit is connected with a liquid inlet of thedecoloration membrane filtering unit. According to the invention, the concentrated membrane permeate is catalytically oxidized into hydrogen peroxide and gluconic acid, hydrogen peroxide is added to oxidize and degrade pollutants in membrane pores and inhibit and kill microorganisms attached to the surfaces of the membrane pores, and gluconic acid can quickly shrink and recover swelling of the membrane pores after alkali cleaning, so that the stability of the membrane-process sugarcane sugar making system is improved, and the operation cost of a membrane-process sugarcane sugar making processis reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of anti-pollution ultrafiltration membrane

ActiveCN110449036BImprove performanceIncreased pure water fluxMembranesSemi-permeable membranesPurified waterCerium oxide

The invention proposes a method for preparing an anti-pollution ultrafiltration membrane. By adding modified nano-lanthanum oxide and modified nano-cerium oxide to the film-forming material, the modified nano-lanthanum oxide and modified nano-cerium oxide have a large The specific surface area can improve the performance of the ultrafiltration membrane, and both lanthanum oxide and cerium oxide are rare earth oxides. Applying them to the ultrafiltration membrane can greatly improve the pure water flux of the ultrafiltration membrane and the flux recovery rate is high. Experiments have shown that the pure water flux of the ultrafiltration membrane prepared by adding modified nano-lanthanum oxide and modified nano-cerium oxide can reach more than 170L / m2 h, and the flux recovery rate can reach more than 90%. greatly improved; the present invention adds modified nano-lanthanum oxide and modified nano-cerium oxide, there is a synergistic effect between these two oxides, compared with a single ultrafiltration membrane prepared by adding nano-lanthanum oxide or nano-cerium oxide. Water flux is greatly improved.

Owner:HEBEI ZHONGQUAN ENVIRONMENT PROTECTION TECHCO LTD

Production method of anti-pollution ultrafiltration membrane

ActiveCN110449036AImprove performanceIncreased pure water fluxMembranesSemi-permeable membranesUltrafiltrationRare earth

The invention provides a production method of an anti-pollution ultrafiltration membrane. By adding a modified nanometer lanthanum oxide and a modified nanometer cerium oxide into a film-forming material, the modified nanometer lanthanum oxide and the modified nanometer cerium oxide have large specific surface areas, thus the performance of the ultrafiltration membrane can be improved, moreover, both the lanthanum oxide and the cerium oxide are rare earth oxides, by applying the lanthanum oxide and the cerium oxide into the ultrafiltration membrane, the pure water flux of the ultrafiltration membrane can be greatly improved, moreover, the flux recovery rate is high, experiments show that the pure water flux of the ultrafiltration membrane produced by adding the modified nanometer lanthanumoxide and the modified nanometer cerium oxide can reach 170 L / m<2>.h or above, and the flux recovery rate can reach 90% or above, so that the anti-pollution capability is greatly improved. Accordingto the production method of the anti-pollution ultrafiltration membrane, by adding the modified nanometer lanthanum oxide and the modified nanometer cerium oxide, the two oxides have a synergistic effect, so that compared with an ultrafiltration membrane produced by only adding nanometer lanthanum oxide or nanometer cerium oxide, the anti-pollution ultrafiltration membrane has the advantage that the pure water flux of the anti-pollution ultrafiltration membrane is greatly improved.

Owner:HEBEI ZHONGQUAN ENVIRONMENT PROTECTION TECHCO LTD

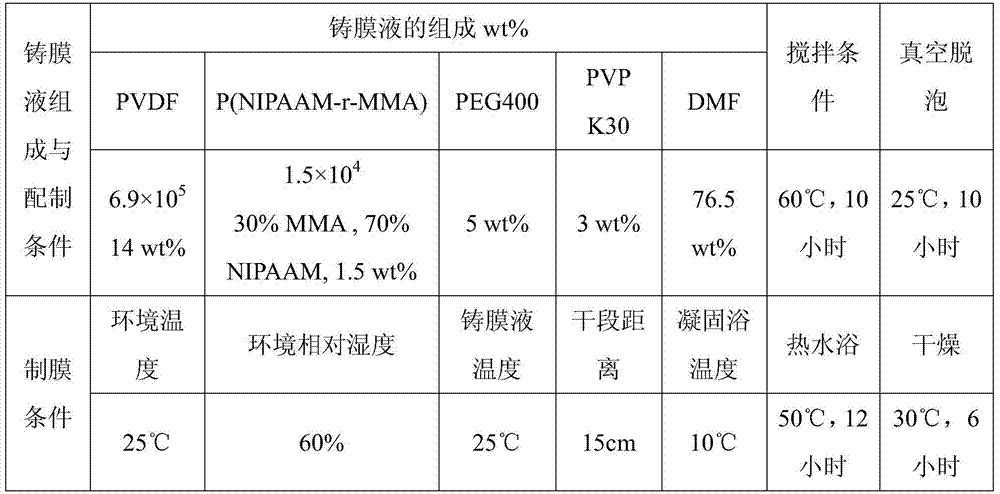

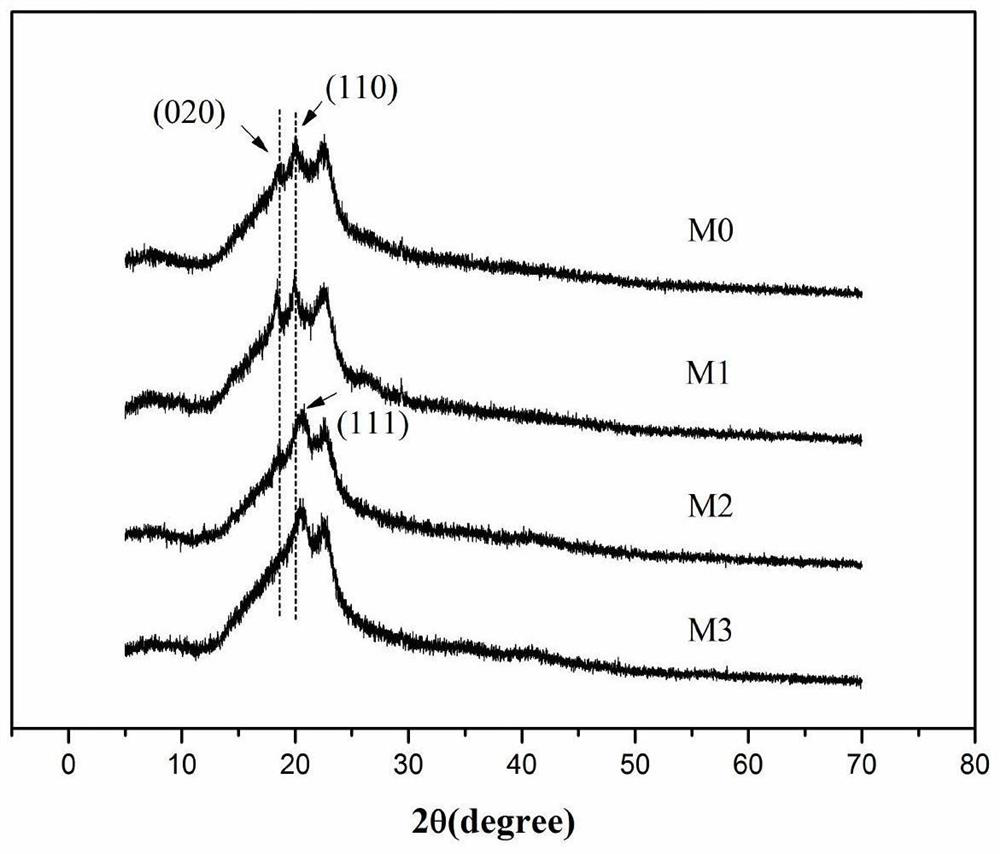

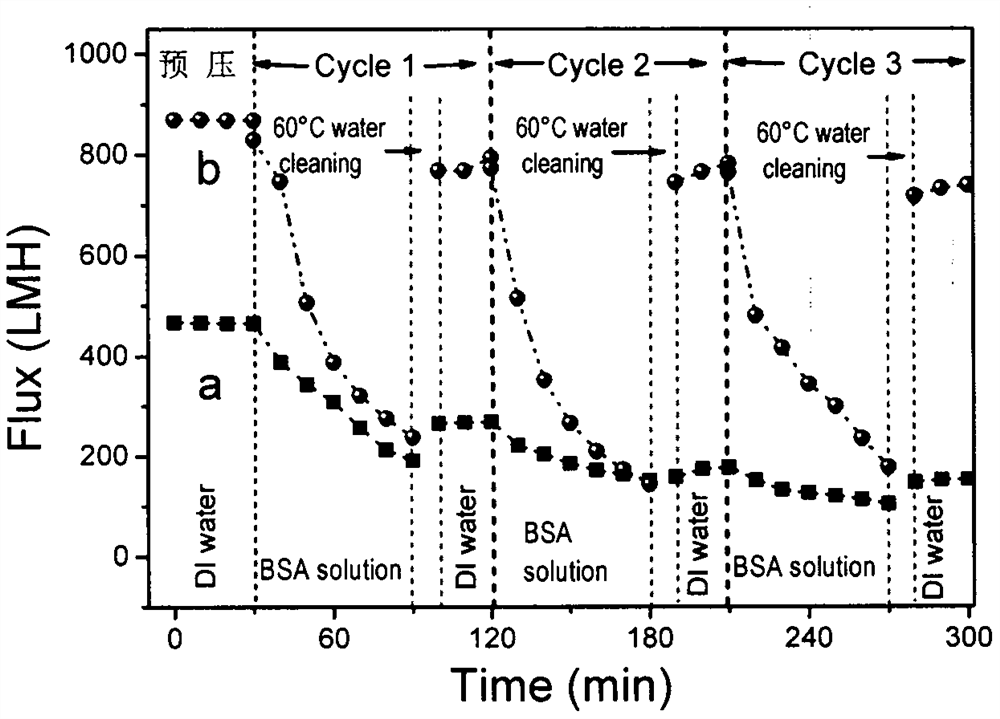

A self-cleaning polyvinylidene fluoride microporous membrane and its preparation method

InactiveCN104437124BImprove throughputHigh flux recovery rateSemi-permeable membranesFiltrationSolvent

The invention provides a self-cleaning polyvinylidene fluoride microporous membrane and a preparation method thereof, the method comprising polyvinylidene fluoride, a temperature-sensitive amphiphilic copolymer poly(N-isopropylacrylamide-methacrylic acid) Methyl ester), porogen, and solvent are stirred evenly at a temperature of 60-90°C, and the casting solution is obtained after filtration and vacuum degassing; then the casting solution is passed through a film-making mechanism, and immersed in a coagulation bath for finalization , washed in a hot water bath, and dried to obtain the self-cleaning polyvinylidene fluoride microporous membrane; wherein the mass percentages of the polyvinylidene fluoride, temperature-sensitive amphiphilic copolymer, porogen and solvent are respectively 13- 20%, 0.1-5%, 1-15% and 60-80%, and the molecular weight of the temperature-sensitive amphiphilic copolymer is 1×103˜5×104. The polyvinylidene fluoride microporous membrane prepared by the invention has the advantages of self-cleaning property, hydrophilicity, high flux, high flux recovery rate and high strength, and the preparation method is simple, and industrial production can be realized.

Owner:HUNAN OVAY TECH CO LTD

A preparation method of dopamine-assisted dispersing graphene oxide modified polyvinylidene fluoride ultrafiltration membrane

Owner:ANHUI UNIVERSITY

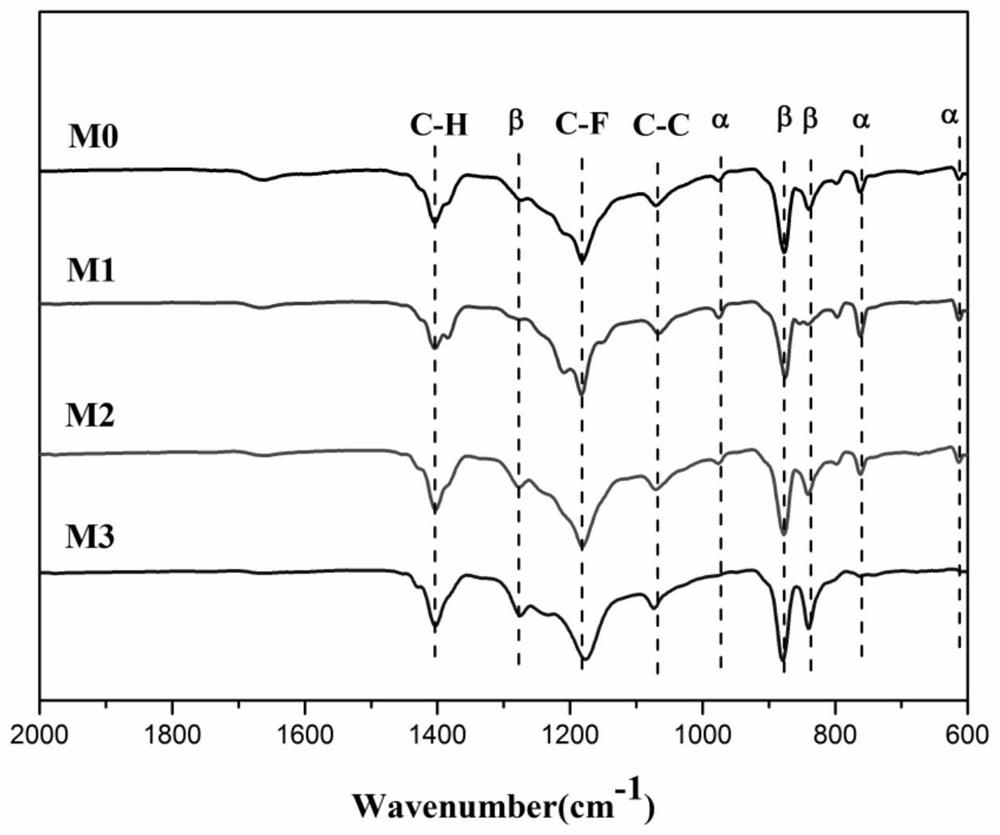

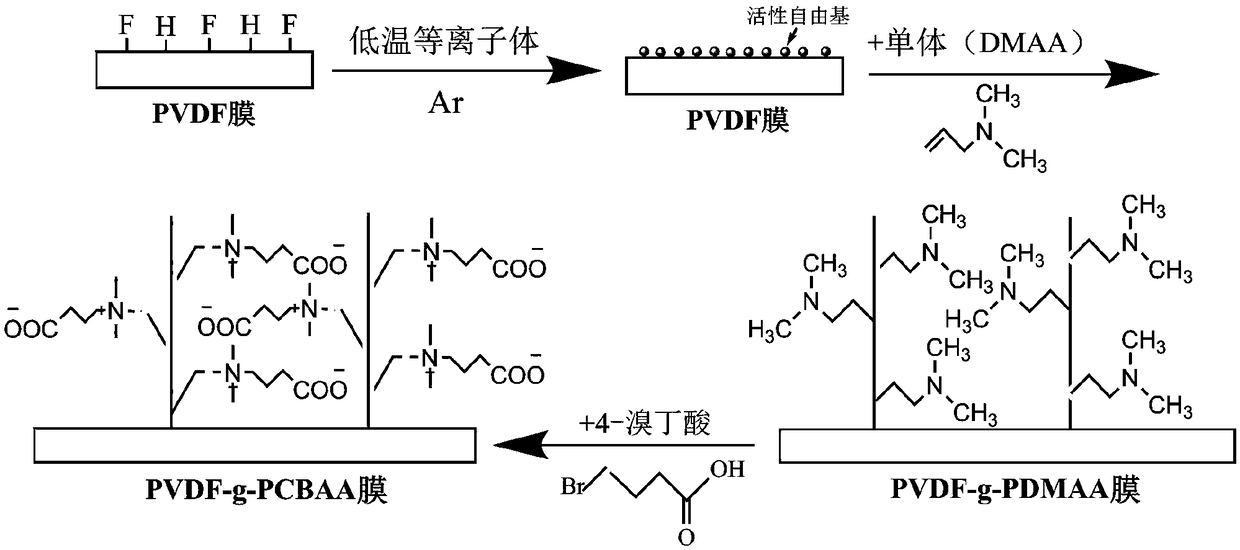

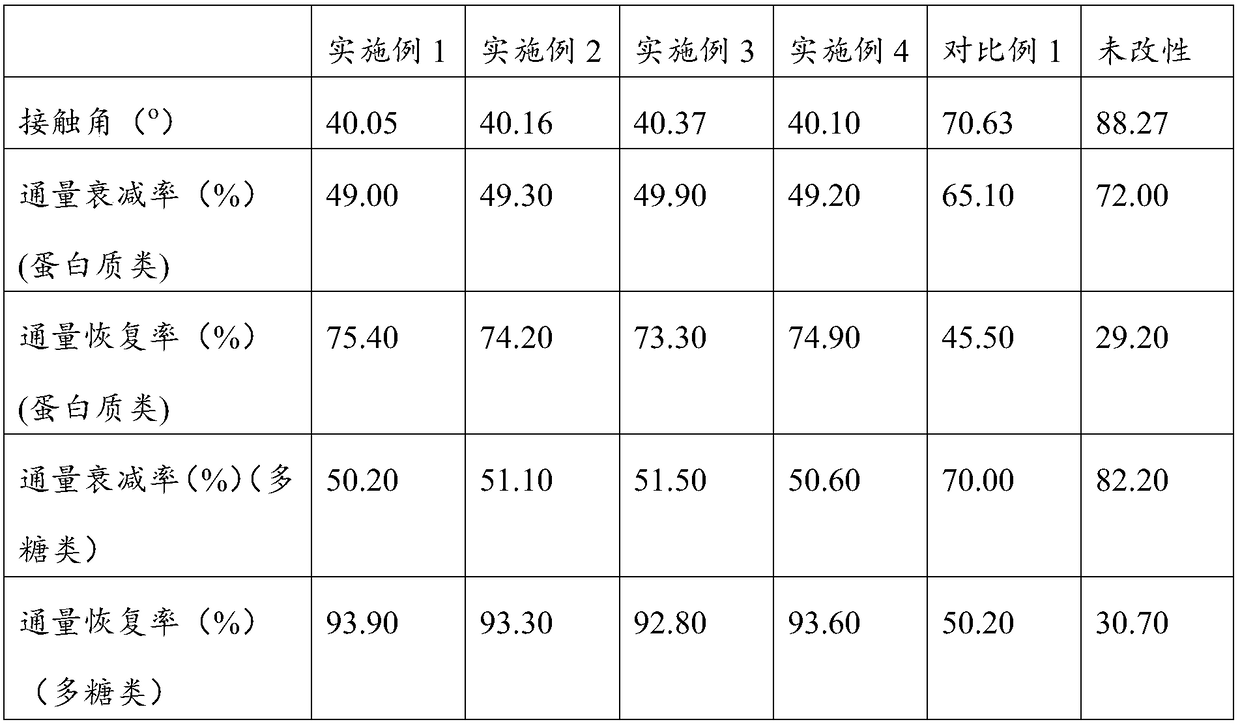

Modification method of PVDF filter membrane, the modified PVDF filter membrane, and application thereof

InactiveCN108927007AImprove hydrophilic abilitySmall flux decay rateMembranesSemi-permeable membranesGraft reactionVacuum chamber

The invention provides a modification method of a PVDF filter membrane, the modified PVDF filter membrane, and an application thereof, and belongs to the technical field of water treatment. The method, capable of solving the technical problems of poor hydrophilicity and antifouling effect of the PVDF filter membranes in the prior art, includes: processing the PVDF filter membrane in a short time under the condition of low-power plasma to activate the surface of the PVDF filter membrane; in gas state, feeding DMAA (dimethylallylamine) into a vacuum chamber, so that a grafting reaction between the gas-state DMAA and the surface of the PVDF filter membrane is initiated by plasma, thus forming plasma-modified membrane PVDF-g-PDMAA; and performing a quaterisation reaction to the grafted polymerPDMAA on the PVDF-g-PDMAA membrane and 4-bromobutyric acid to generate a zwitterionic polymer, thus obtaining zwitterionically modified PVDF filter membrane. The product is applied to the field of water pollution control.

Owner:HARBIN INST OF TECH AT WEIHAI

Dynamic disk membrane device and its technology for ultrafine solid catalyst recovery

The invention discloses a dynamic disc membrane device applied to recycling of an ultrafine solid catalyst and a technology of the device. The dynamic disc membrane device comprises a reaction kettle, a reaction kettle discharging heat exchanger, at least one dynamic disc seperation unit, a back washing tank and a clear liquid tank, wherein the dynamic disc seperation unit comprises a device support, a motor arranged on the device support, a membrane seperation tank arranged on the device support, a clear liquid buffer tank arranged on the membrane seperation tank and a rotating shaft connected with the motor and the membrane seperation tank; a dynamic disc membrane component is arranged in the membrane seperation tank and comprises 1 to 100 dynamic disc membranes; the dynamic disc membrane is a microfiltration or ultrafiltration ceramic disc membrane, the pore diameter of the ceramic disc membrane is 7nm-30mu m, and the diameter of the dynamic disc membrane component is 50-400mm. Microfiltration or ultrafiltration ceramic discs are adopted in the dynamic disc membrane device for cross-flow filtration and have high permeation flux so that the investment cost of the device is reduced while technological processes are shortened, a discharging effect is stale, and the retention rate of the superfine catalyst is above 99%.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

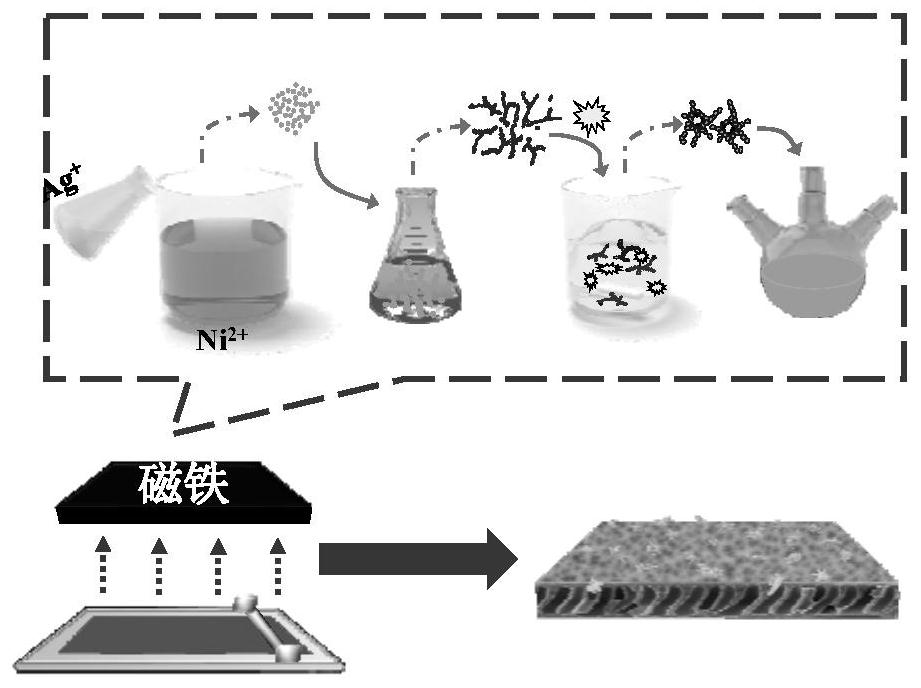

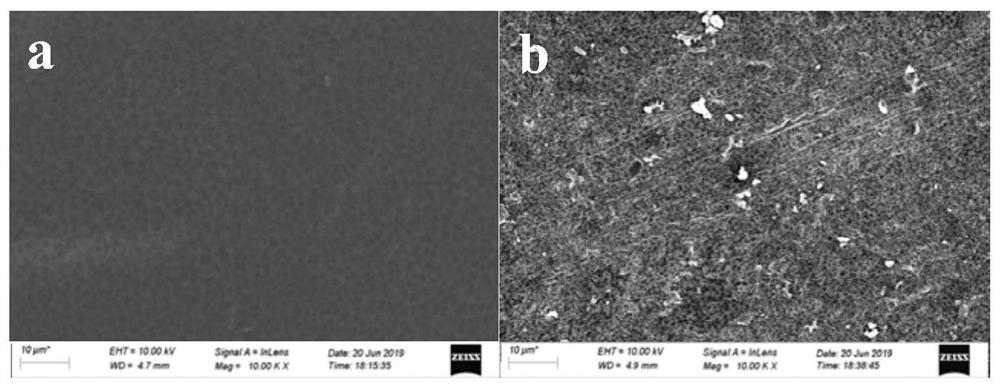

Composite separation membrane and preparation method thereof

ActiveCN110813100BHigh flux recovery rateExcellent flux restoration effectMembranesSemi-permeable membranesPhysical chemistryOxide composite

The present invention relates to the technical field of membrane separation, in particular to providing a method for preparing a composite separation membrane, comprising the following steps: putting ferromagnetic metal-zinc oxide composite particles into a polymer casting solution to obtain a blended membrane solution; The blended film solution is scraped. During the scraping process, an external magnetic field is added to attract the ferromagnetic metal-zinc oxide composite particles to the surface of the blended film solution; then phase inversion is performed. The present invention reduces the ferromagnetic metal-zinc oxide composite particles in situ on the surface of the blended membrane solution by adding an external magnetic field, greatly improving the flux recovery rate of the composite separation membrane, and the reaction process has mild conditions, no energy consumption, no reaction High efficiency and obvious promotion advantages.

Owner:ZHEJIANG NORMAL UNIVERSITY

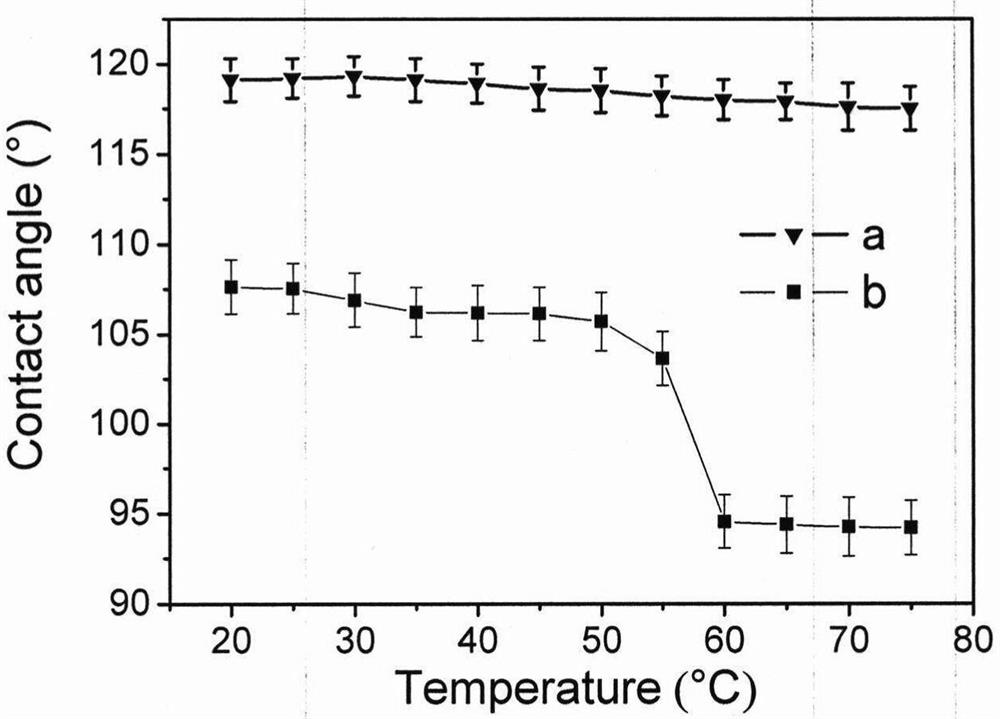

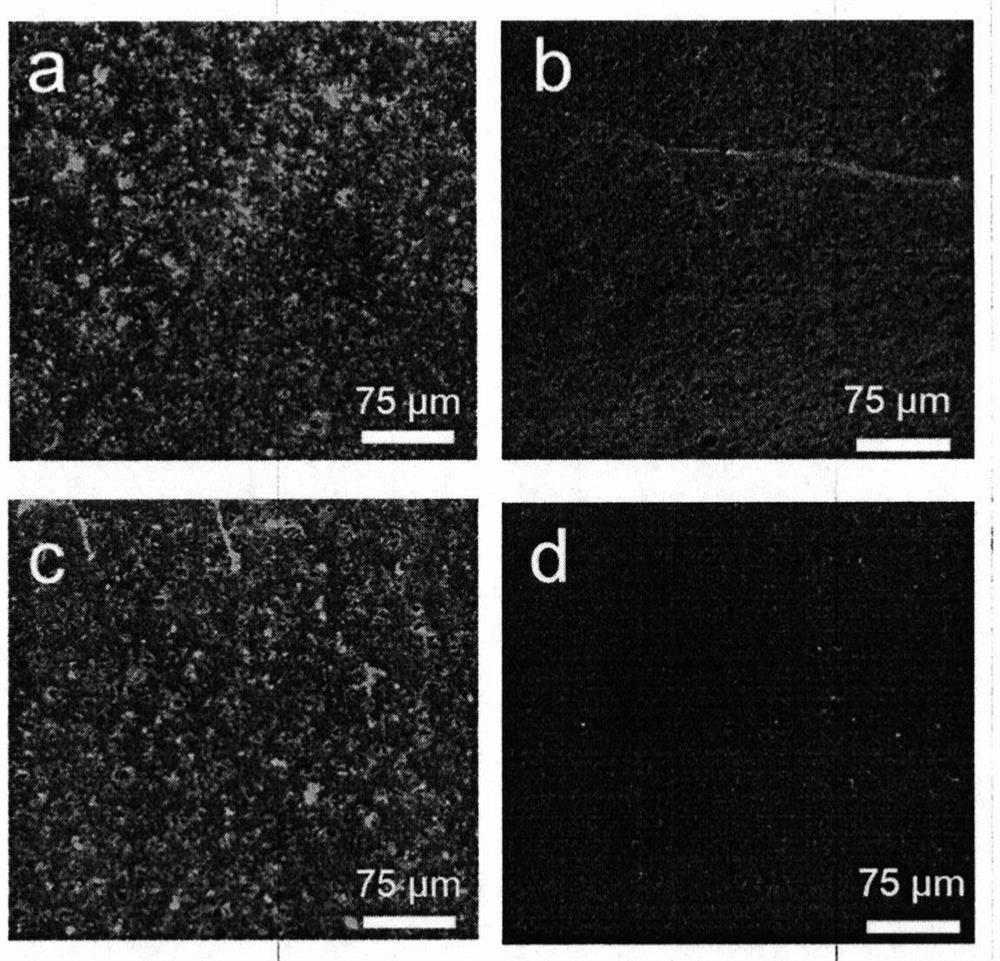

Temperature-sensitive paraffin perfusion film as well as preparation and application thereof

PendingCN114432913AEasy to prepareHigh flux recovery rateSemi-permeable membranesParaffin waxPorous membrane

The temperature-sensitive paraffin perfusion film and the preparation method thereof provided by the invention can overcome the problem that a liquid lubricant is easy to lose in the prior art, and have both the stability of a solid coating and the pollution resistance of the liquid lubricant. According to the technical scheme, the surface of the polymer porous membrane is coated with molten solid paraffin through suction filtration. The surface wettability and pollution resistance of the prepared paraffin perfusion membrane have the temperature sensitive characteristic, the stability of paraffin on the surface of the membrane is high, and efficient pollution resistance in membrane filtration can be achieved. The method can be used in the fields of wastewater treatment, food processing and biological medicine.

Owner:TIANJIN POLYTECHNIC UNIV

Anti-pollution ultrafiltration membrane and preparation method thereof

PendingCN113522062AImproved throughput and anti-pollution performanceHigh membrane flux recovery rateMembranesUltrafiltrationChemistryPerylene derivatives

The invention provides an anti-pollution ultrafiltration membrane and a preparation method thereof. The anti-pollution ultrafiltration membrane is mainly prepared from, by mass, 15-25 parts of PVDF membrane raw materials, 50-70 parts of DMAC solvent and a modifier, and the modifier comprises one or two of cyclodextrin and polyrotaxane; wherein the addition mass of the cyclodextrin is 1-5wt% of the PVDF membrane raw material, and the addition mass of the polyrotaxane is 1-6wt% of the DMAC solvent. According to the anti-pollution ultrafiltration membrane disclosed by the invention, one or two of cyclodextrin (CD) and derivative polyrotaxane (PR) thereof are introduced into the membrane raw materials, so that the flux and the anti-pollution performance of the membrane are improved, the flux recovery rate of the membrane is improved, the flux attenuation rate is reduced, the irreversible pollution index is obviously reduced, and the anti-pollution performance of the ultrafiltration membrane is further obviously improved.

Owner:XINJIANG DELAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com