Preparation method of in-situ synthesized nano silver modified PVDF (Polyvinylidene Fluoride) ultrafiltration membrane

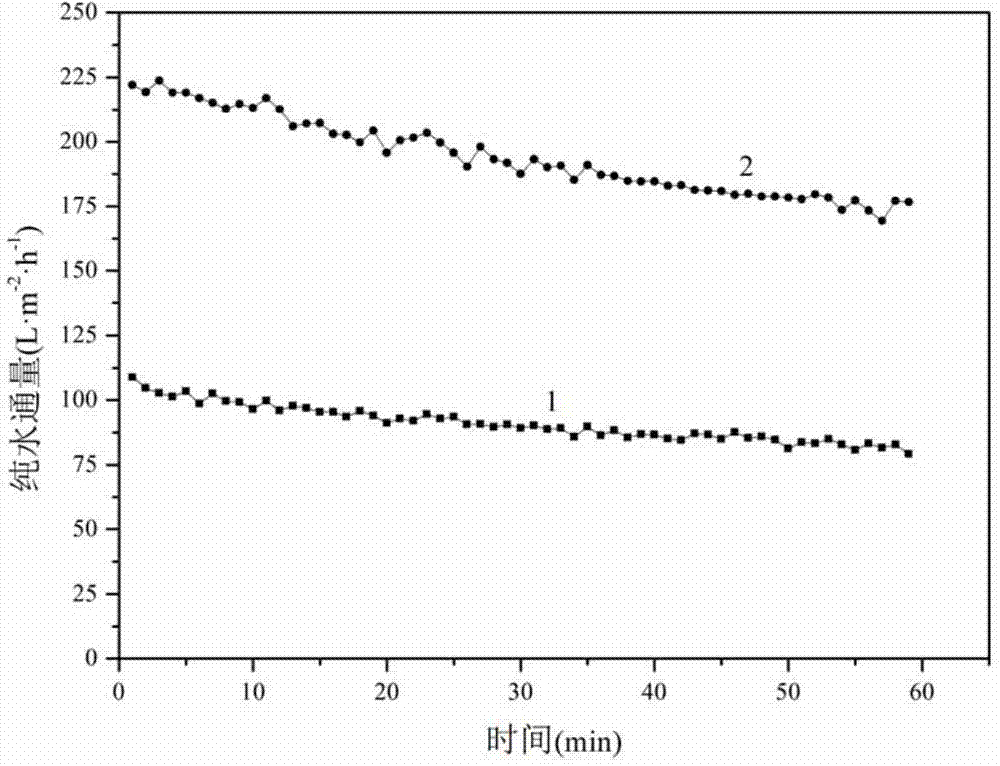

An in-situ synthesis, nano-silver technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy aggregation of nanoparticles and ineffective improvement of anti-pollution performance of PVDF ultrafiltration membranes, etc. Achieve the effects of enhancing hydrophilicity and antibacterial properties, increasing water flux, and increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: this embodiment is a kind of preparation method of in-situ synthesis nano-silver modified PVDF ultrafiltration membrane, specifically completes according to the following steps:

[0028] 1. Preparation of PVDF solution: Mix PVDF powder with dispersing solvent Ⅰ, stir at a stirring speed of 400r / min-600r / min and a temperature of 50°C-60°C for 4h-6h to obtain a PVDF solution;

[0029] The mass ratio of PVDF powder and dispersion solvent I described in step 1 is 16:(70~100);

[0030] 2. Preparation of mixed solution containing nano-silver: AgNO 3 Dissolve in dispersing solvent II, then add porogen, and then ultrasonically disperse at a power of 50W-550W for 60min-120min to obtain a mixed solution containing nano-silver;

[0031] AgNO as described in step 2 3 The mass of dispersing solvent II is 1:(10~50);

[0032] AgNO as described in step 2 3 The mass ratio to porogen is 1:(0.5~3);

[0033] 3. Preparation of casting solution: at a stirring sp...

specific Embodiment approach 2

[0045] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the dispersing solvent I described in step 1 is N,N-dimethylformamide, 1-methyl-2-pyrrolidone, 1-vinyl -2-pyrrolidone or N,N-dimethylacetamide. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the dispersion solvent II described in step 2 is N,N-dimethylformamide, 1-methyl-2-pyrrolidone, 1-vinyl-2-pyrrolidone or N,N-dimethylacetamide. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com