Composite separation membrane and preparation method thereof

A technology for separating membranes and composite particles, applied in the field of membrane separation, can solve the problems of hindering the photocatalytic function of composite membranes, reducing the antifouling effect, etc., and achieve the effects of excellent flux recovery effect, environmental friendliness and high reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

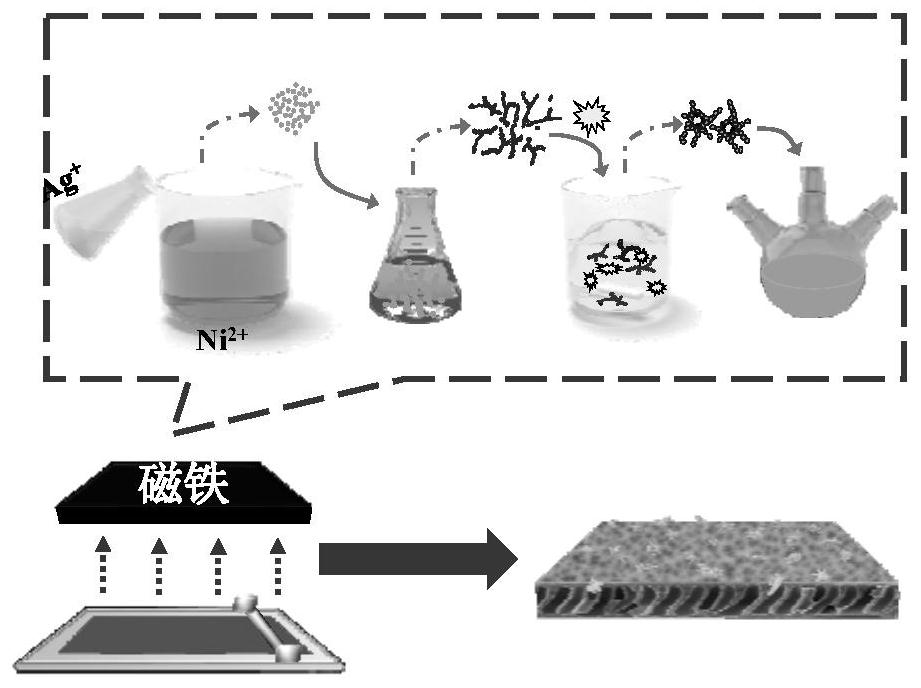

[0033] 25g nickel sulfate hexahydrate, 50g sodium pyrophosphate decahydrate, 45 milliliters of ammonia (28%) and 1.5g dimethylaminoborane are poured into 1 liter of deionized water, then, 5 milliliters of silver nitrate (1.597 g / liter) into the dissolving solution, and after fully reacting at 25°C for 20 minutes, a solid precipitate-nickel was obtained, and the precipitated material was taken out, dried and fully ground.

[0034] The above-prepared nickel particles were immersed in a 2 g / L dopamine solution at a controlled temperature of 35° C., placed in a shaking incubator for 24 hours, and sucked out with a magnet to obtain dopamine-coated nickel particles. The role of dopamine is to adhere to zinc oxide (abbreviation: ZnO) particles next. The dopamine-coated nickel particles prepared above were immersed in 200 ml of deionized water containing 3 g of zinc oxide, and stirred at room temperature for 12 hours to obtain nickel particles adhered with zinc oxide. Put the prepar...

Embodiment 2

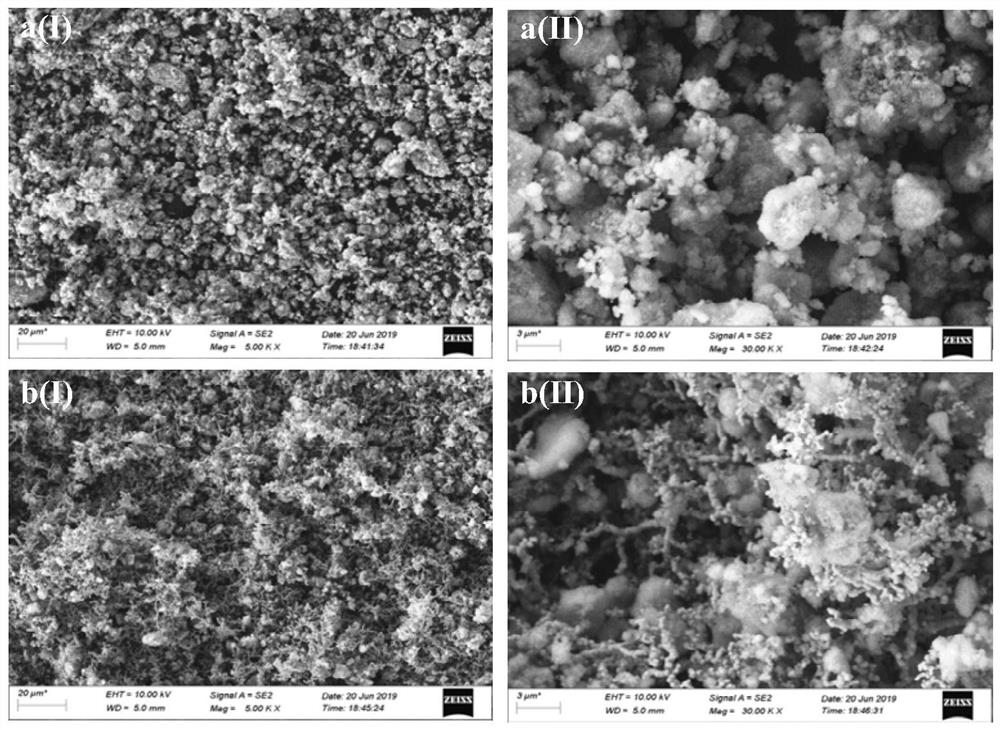

[0036] In order to investigate the morphology change of the particle surface before and after compounding, this embodiment carried out SEM test on the film, as shown in figure 2 Shown, a (I) and a (II) are the SEM images of the particles before compounding under different magnifications, b (I) and b (II) are the SEM images of the Ni-ZnO composite particles under different magnifications, wherein, The magnifications of a(I) and b(I) are the same, and the magnifications of a(II) and b(II) are the same. It is found that the surface of Ni-ZnO composite particles has a huge difference in morphology compared with the original particles. Nickel and ZnO A network structure was formed, demonstrating the successful recombination of Ni with ZnO.

Embodiment 3

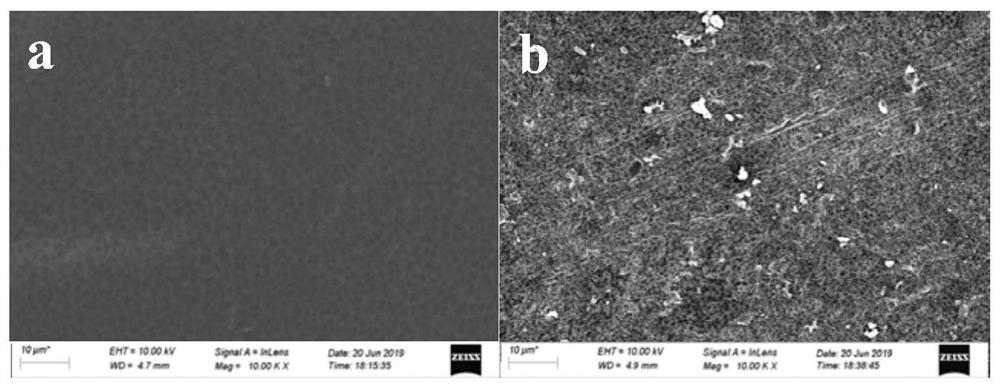

[0038] In order to investigate the morphology change of the film surface before and after compounding, this embodiment carried out SEM test on the film, as image 3 Figure a shows the SEM image of the PVDF membrane before compounding, and Figure b shows the SEM image of the PVDF-Ni-ZnO composite separation membrane. It was found that a protruding particle structure appeared on the surface of the PVDF-Ni-ZnO composite separation membrane, which proved that Ni was successfully compounded on the surface of the PVDF membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com